A Novel Sputtering Ion Pump for Anode Barrel Array

An anode cylinder and ion pump technology, applied in the field of sputtering ion pump, can solve problems such as low pumping speed, and achieve the effects of simple structure, long service life and wide working pressure range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be noted that all directional indications (such as up, down, left, right, front, back...) in the embodiments of the present invention are only used to explain the relationship between the components in a certain posture (as shown in the accompanying drawings). Relative positional relationship, movement conditions, etc., if the specific posture changes, the directional indication will also change accordingly.

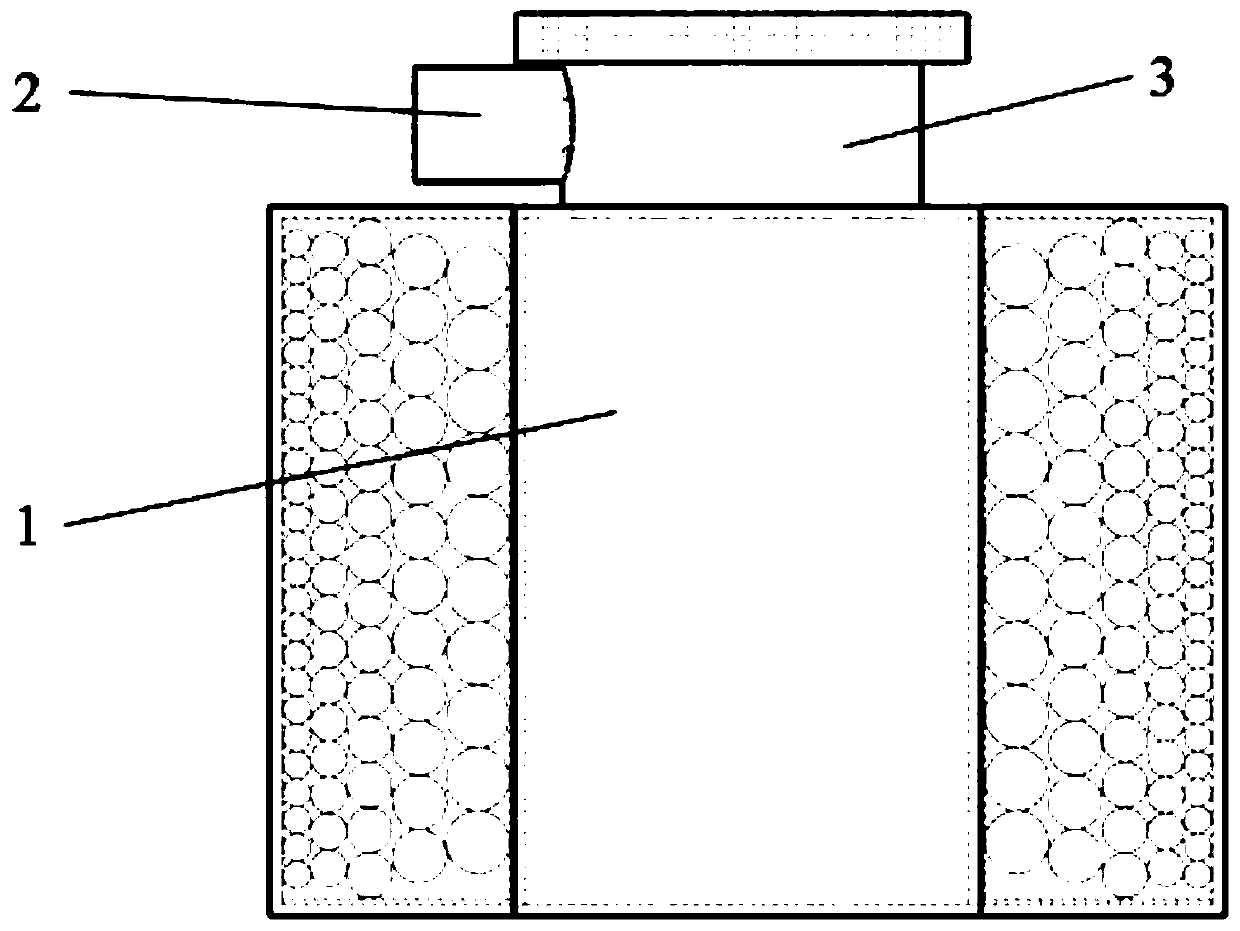

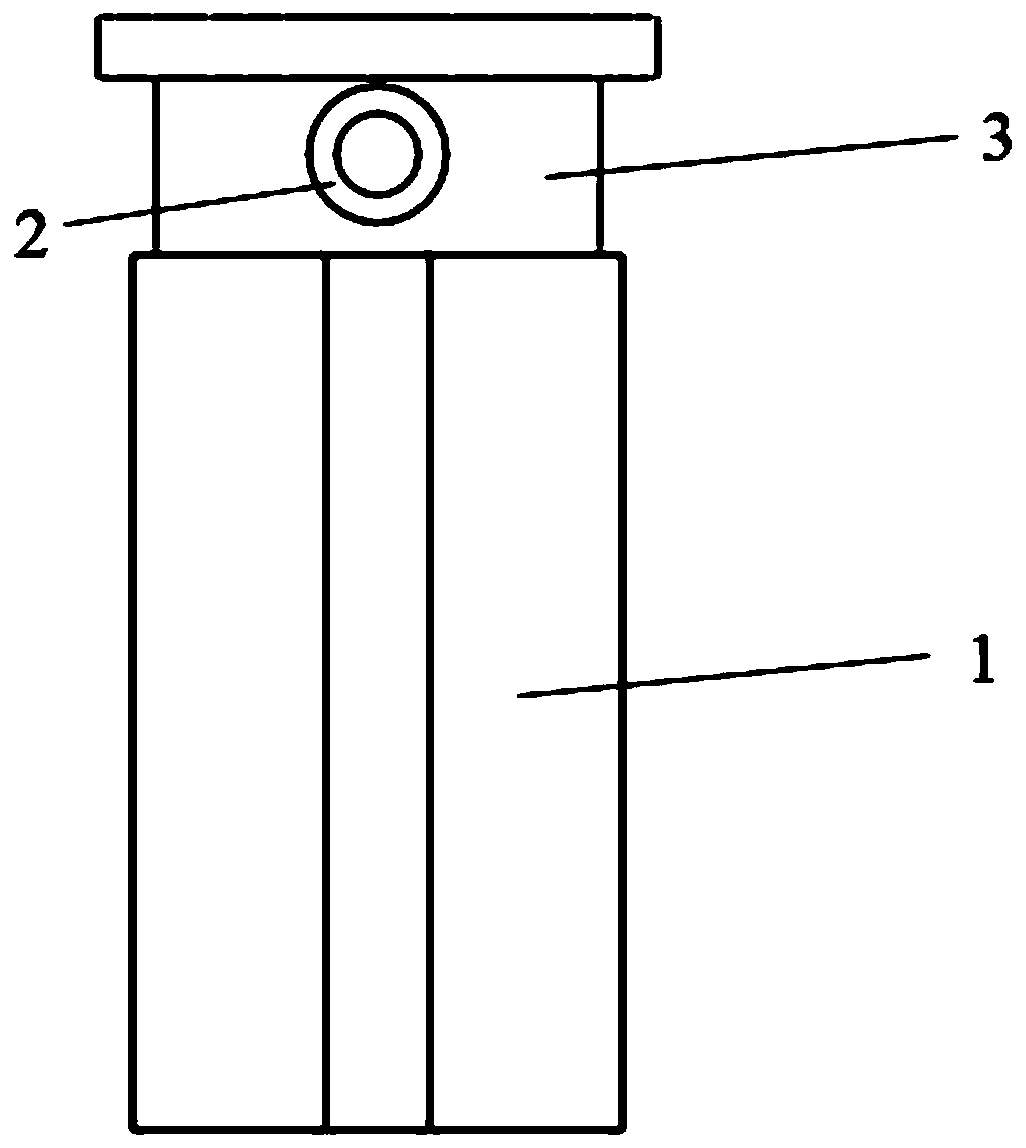

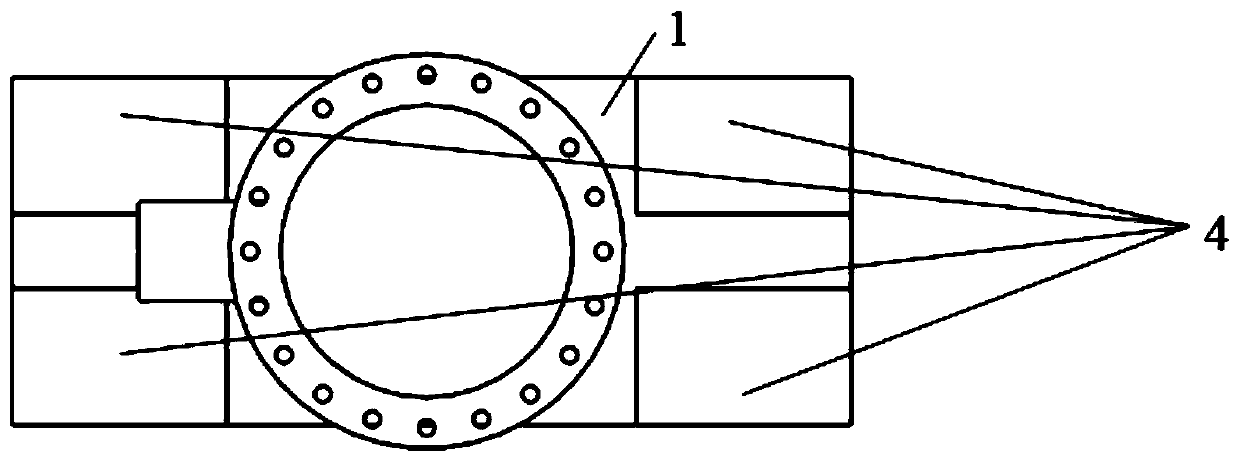

[0023] Such as Figure 1 to Figure 6 As shown, the present invention provides a sputtering ion pump with a novel anode cylinder array, which includes a casing 1 , a high voltage electrode 2 , a cathode plate 5 and an anode cylinder array 6 .

[0024] The shell 1 is a rectangular column structure, and its material is mainly 316 stainless steel. The top of the shell 1 is provided with an air inlet 3. The air inlet 3 is processed by stamping. It is a cylindrical pipe structure, and its material is mainly 316 stainless steel. Stainless steel, the gas flows ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com