Gas amount measurement device

一种测量装置、气体量的技术,应用在分析材料、仪器等方向,能够解决不能测量等问题,达到准确性质的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

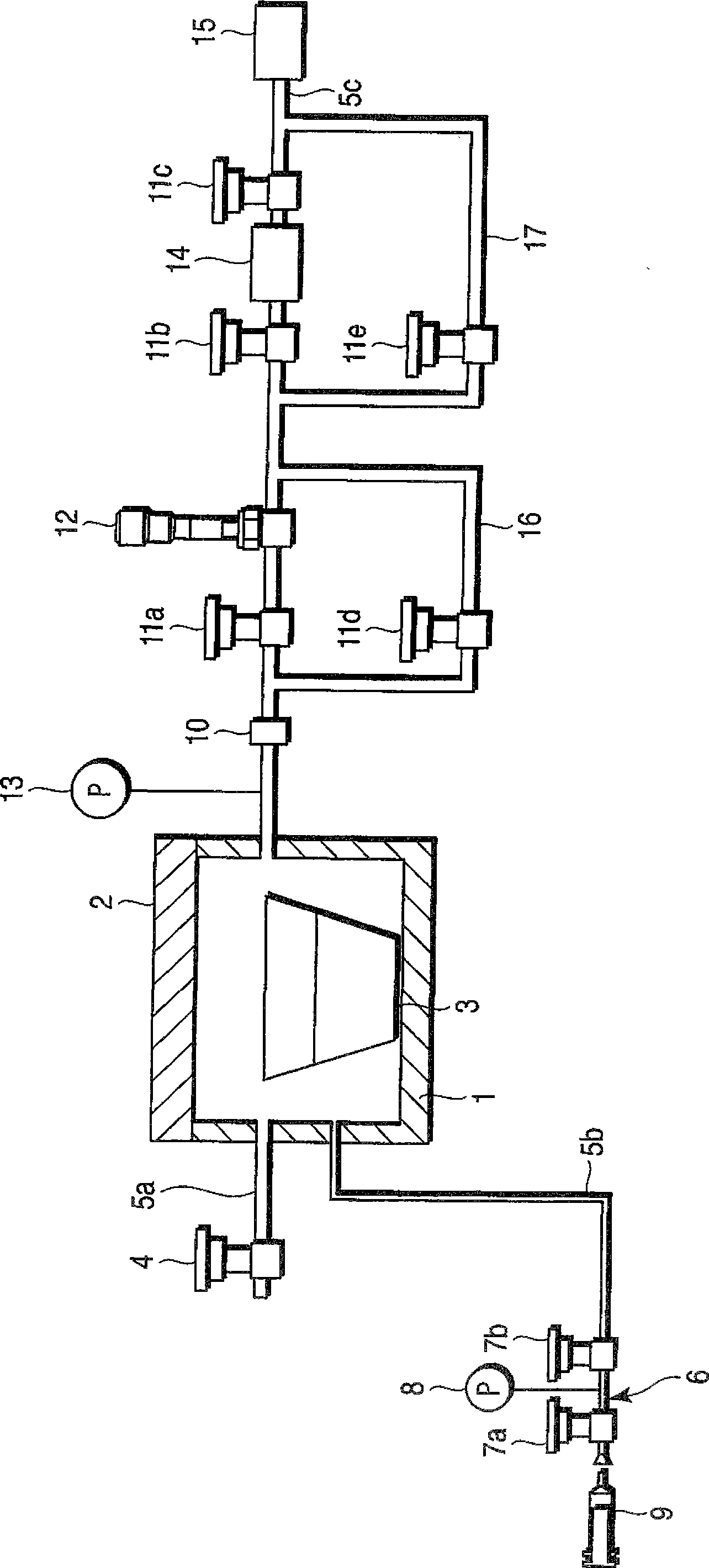

[0022] refer to figure 1 , reference numeral 1 denotes a vacuum container having a lid 2 that is freely openable / closeable. A sampling measuring cup 3 containing molten metal (not shown) serving as a sample is placed in the vacuum container 1 . The first pipe 5 a to which the purge valve 4 is connected is connected to the upstream side of the vacuum container 1 . The second pipe 5b to which the calibration gas generator 6 is connected is connected to the upstream side of the vacuum container. The calibration gas generator 6 is provided to include calibration valves 7a and 7b, a pressure gauge 8 connected to a pipe 5b between the valves 7a and 7b, and an air cylinder 9. When the calibration gas flows in, the internal pressure of the pipe 5b (pipe portion) between the valves 7a and 7b of the calibration gas generator 6 is adjusted to 1 atm.

[0023] The third pipe 5c is connected to the downstream side of the vacuum container 1 . From the side of the vacuum container 1, a va...

no. 2 approach

[0036] refer to Figure 4 , the gas amount measuring device according to the second embodiment will be described. Figure 4 neutralize figure 1 The same components as shown in are denoted by the same reference numerals and will not be described here again. and figure 1 Compared to the first embodiment shown, the second embodiment is characterized in that a heater 21 is provided around the sampling cup 3 .

[0037] According to the second embodiment, the drop in temperature of the molten metal contained in the sampling measuring cup 3 can be suppressed due to the presence of the heater 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com