Gas pipeline system of reaction chamber and control method of gas pipeline system

A technology of gas pipelines and reaction chambers, which is applied in the direction of discharge tubes, electrical components, circuits, etc., can solve the problems of impure cooling gas and easy contamination of wafers, etc., and achieve the effect of reducing the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

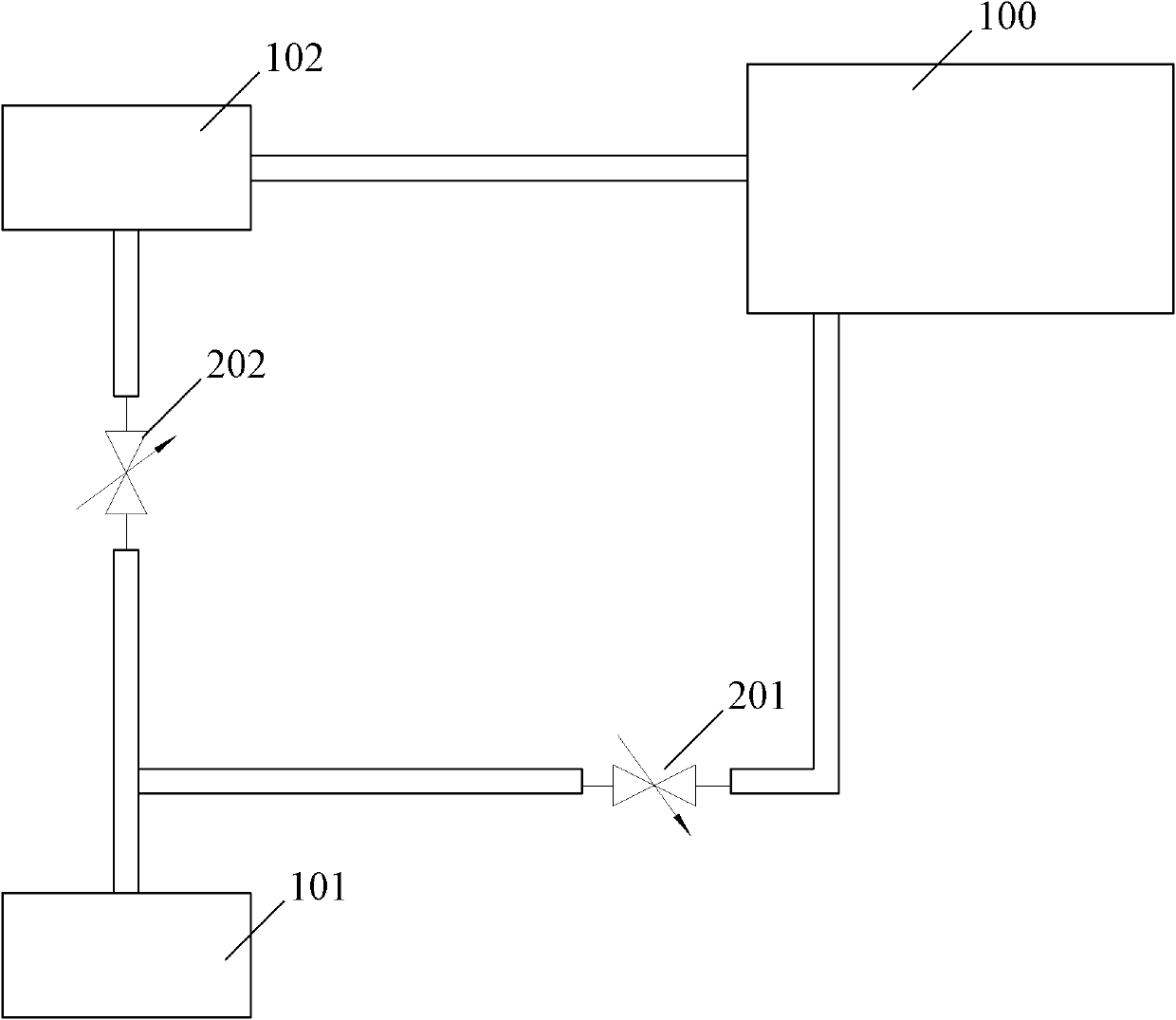

[0027] The existing reaction chamber gas pipeline system uses a rough pump to pump air from the reaction chamber and discharge the cooling gas from the turbo vent pump. When the valve is switched, due to the pressure difference between the reaction chamber and the turbo vent pump air cooling unit, it is easy to appear The cooling gas backfills into the reaction chamber and contaminates the wafer. The present invention solves the above problems by reducing the air pressure of the air cooling unit, monitoring the air pressure difference between the reaction chamber and the air cooling unit of the turbo vent pump, and controlling the opening and closing of the butterfly valve.

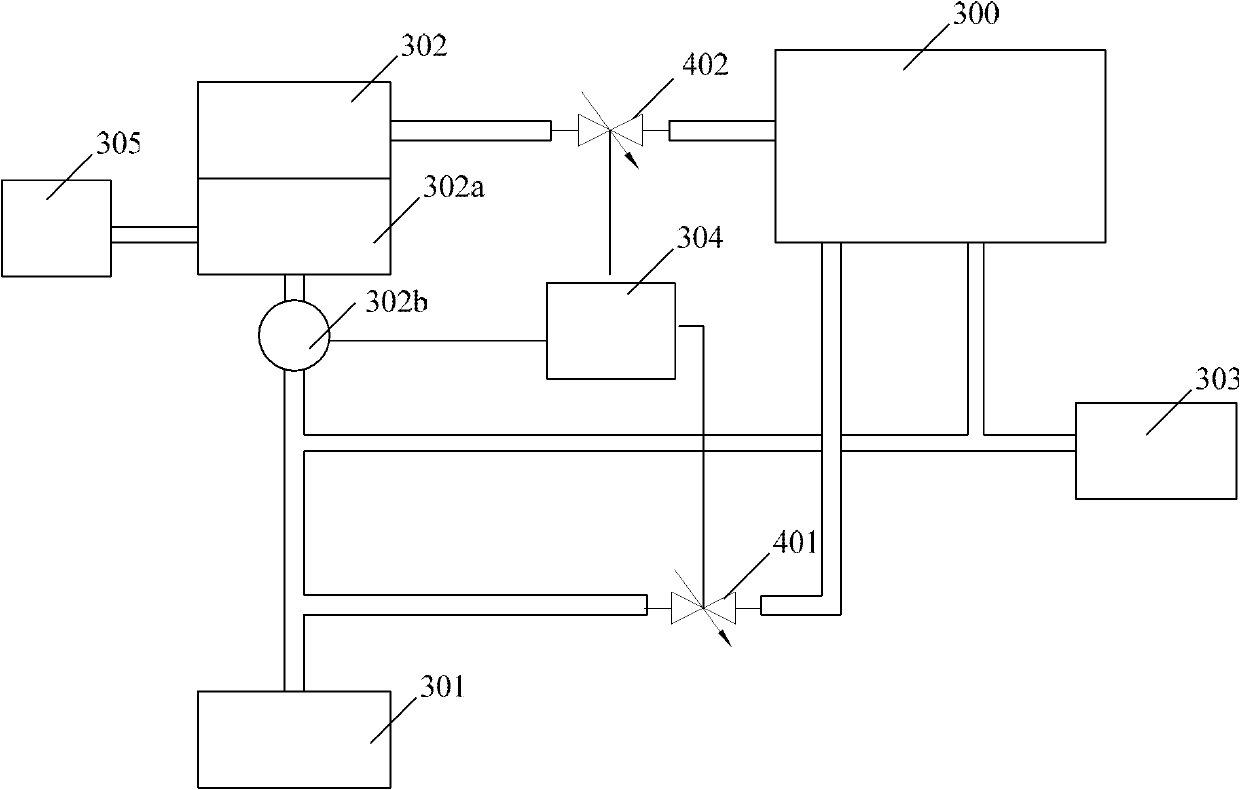

[0028] Such as figure 2 As shown, the basic structure of the gas transmission pipeline system of the present invention includes: a rough pump 301, connected to the reaction chamber 300 via a butterfly valve 401, and used to pump air to the reaction chamber 300; a turbine ventilation pump 302, the turbine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com