Vacuum pumping pipeline device for spacecraft environmental simulation test equipment

An environmental simulation test, vacuum pumping tube technology, applied in the simulation device of space navigation conditions, space navigation equipment, pump device, etc. To solve the problem, to solve the long cooling time, solve the oil backflow pollution of the rough vacuum pump, and shorten the cooling time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention intends to optimize the design on the basis of the liquid nitrogen cold trap pipeline of the rough vacuum pipeline of the existing space environment simulator.

[0017] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

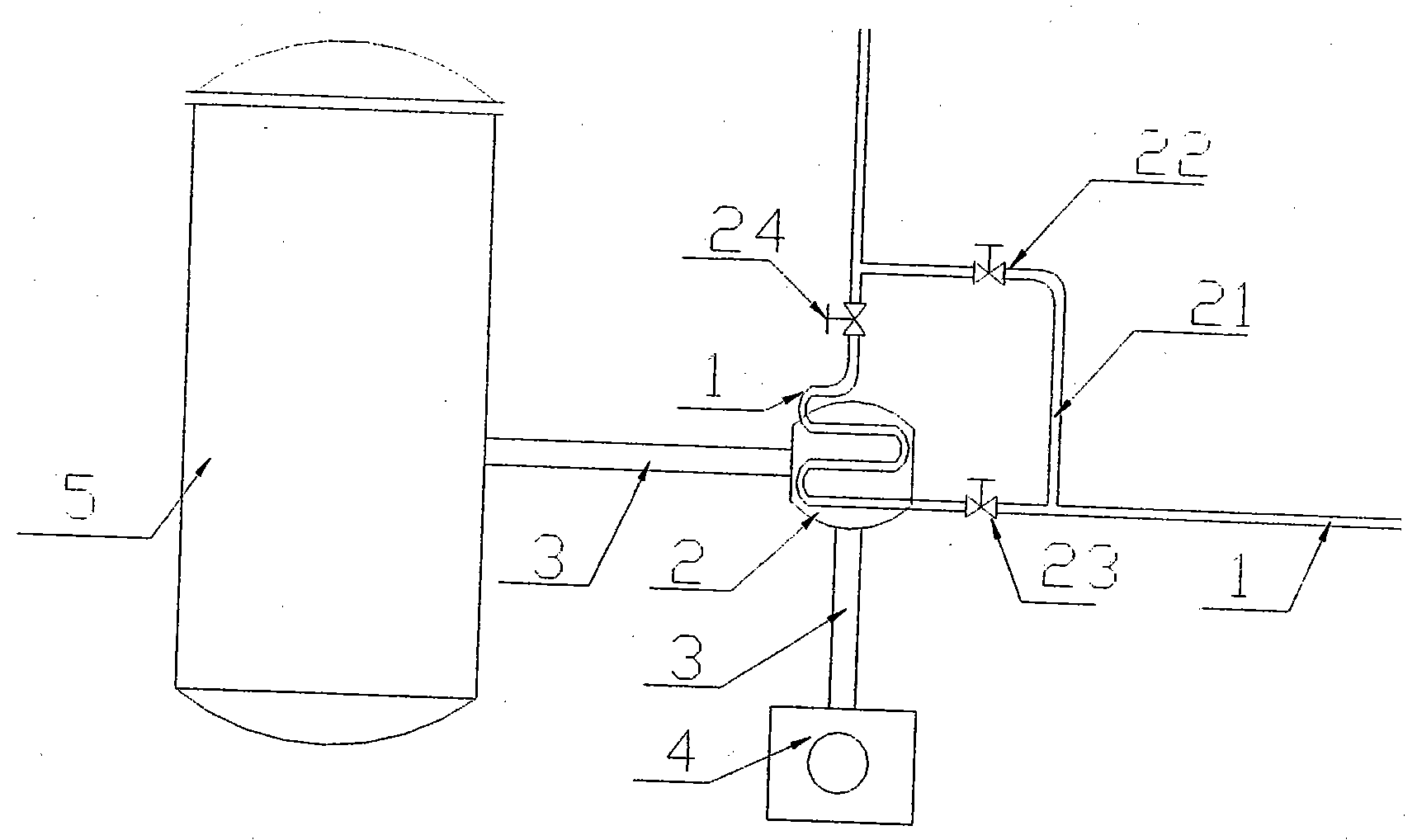

[0018] Accompanying drawing is the structural schematic diagram that the present invention is applied to space environment simulation test equipment, as shown in the embodiment of accompanying drawing, the rough vacuuming pipeline of existing equipment comprises:

[0019] The spacecraft space environment simulator 5 is connected with the oily vacuum roughing unit 4 through the vacuum roughing pipeline 3; in the vacuum roughing pipeline 3, a liquid nitrogen oil blocking cold trap 2 is connected in series; the liquid nitrogen blocking oil cooling trap In the well 2, there is a liquid nitrogen pipeline 1, which is connected with the liquid nitrogen filling system.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com