Fluorine pump system and control method thereof

A technology of fluorine pump and refrigeration cycle, applied in the field of fluorine pump system and its control, to achieve the effect of solving the problem of oil return, strong applicability, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below with reference to the accompanying drawings.

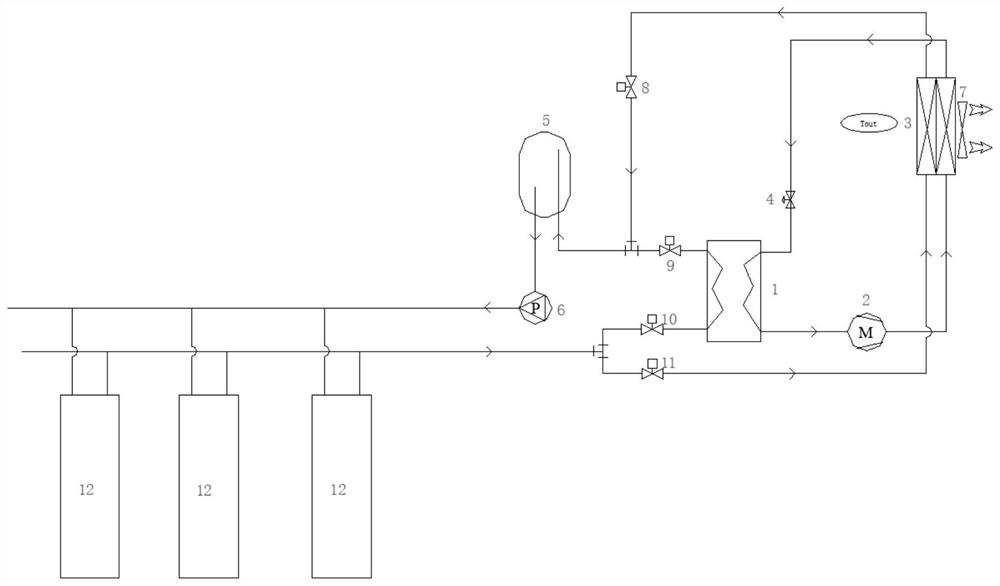

[0022] Such as figure 1 As shown in A-fluoro-pump system, comprising indoor and outdoor fluoro pump host terminal 12, the outdoor-fluoro intermediate heat exchanger includes a main pump 1, a compressor 2, 3, electronic expansion valve condenser 4, liquid tank 5, the refrigerant a pump 6, an electric flow control valve I8, electric flow control valve II9, the electric motor and the flow regulating valve III10 IV11 flow regulating valve, wherein the condenser 3 is the Double-tube heat exchanger, including a condenser coil and a condenser coil A B. A compressor 2, a condenser coil A, the electronic expansion valve 4 and the intermediate heat exchanger constituting the first refrigeration cycle 1, the end chamber 12, an electric flow control valve III10, an intermediate heat exchanger, an electric flow control valve II9, the accumulator 5 and tank 6 constitutes a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com