Patents

Literature

35results about How to "Flexible system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

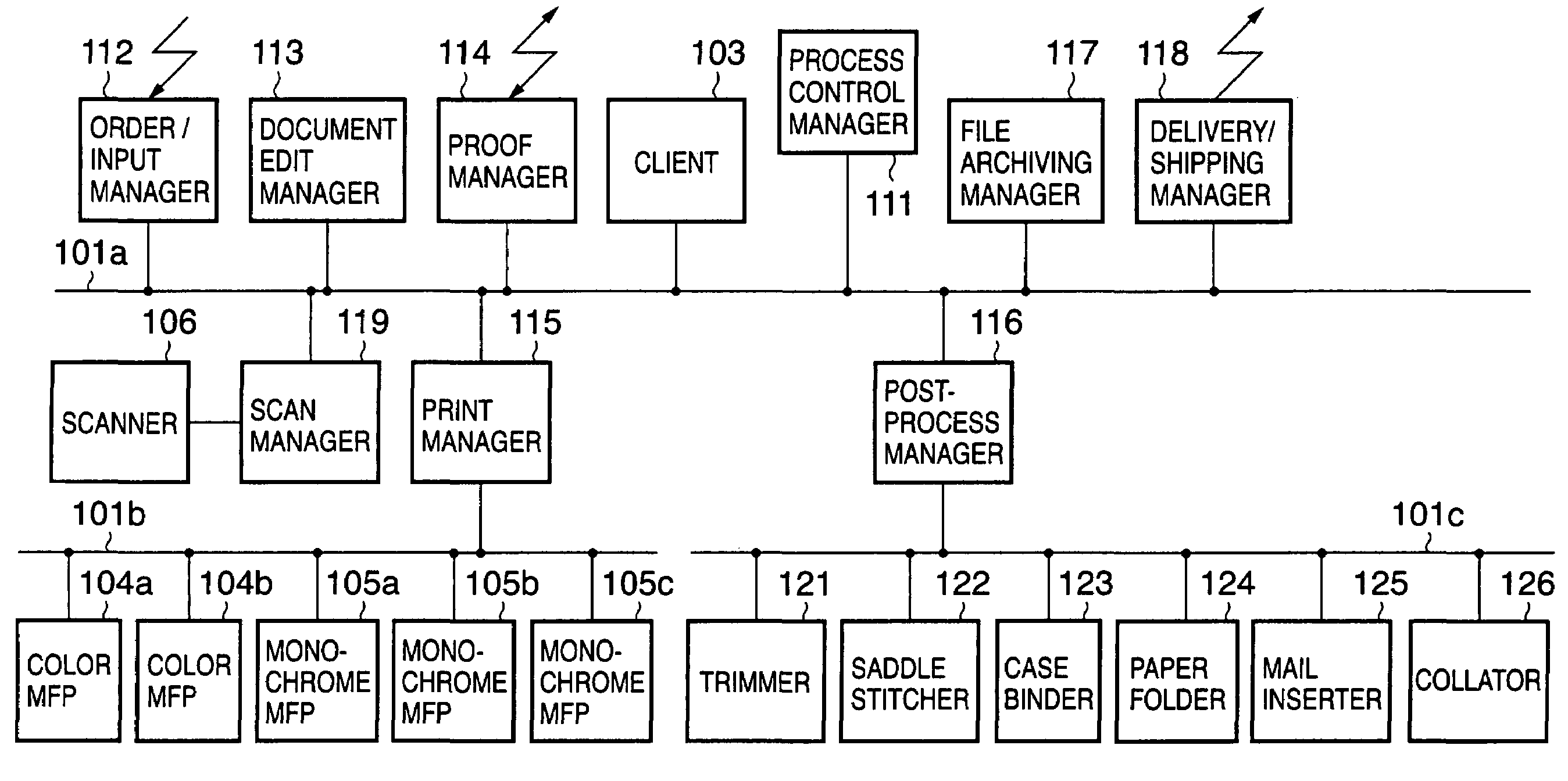

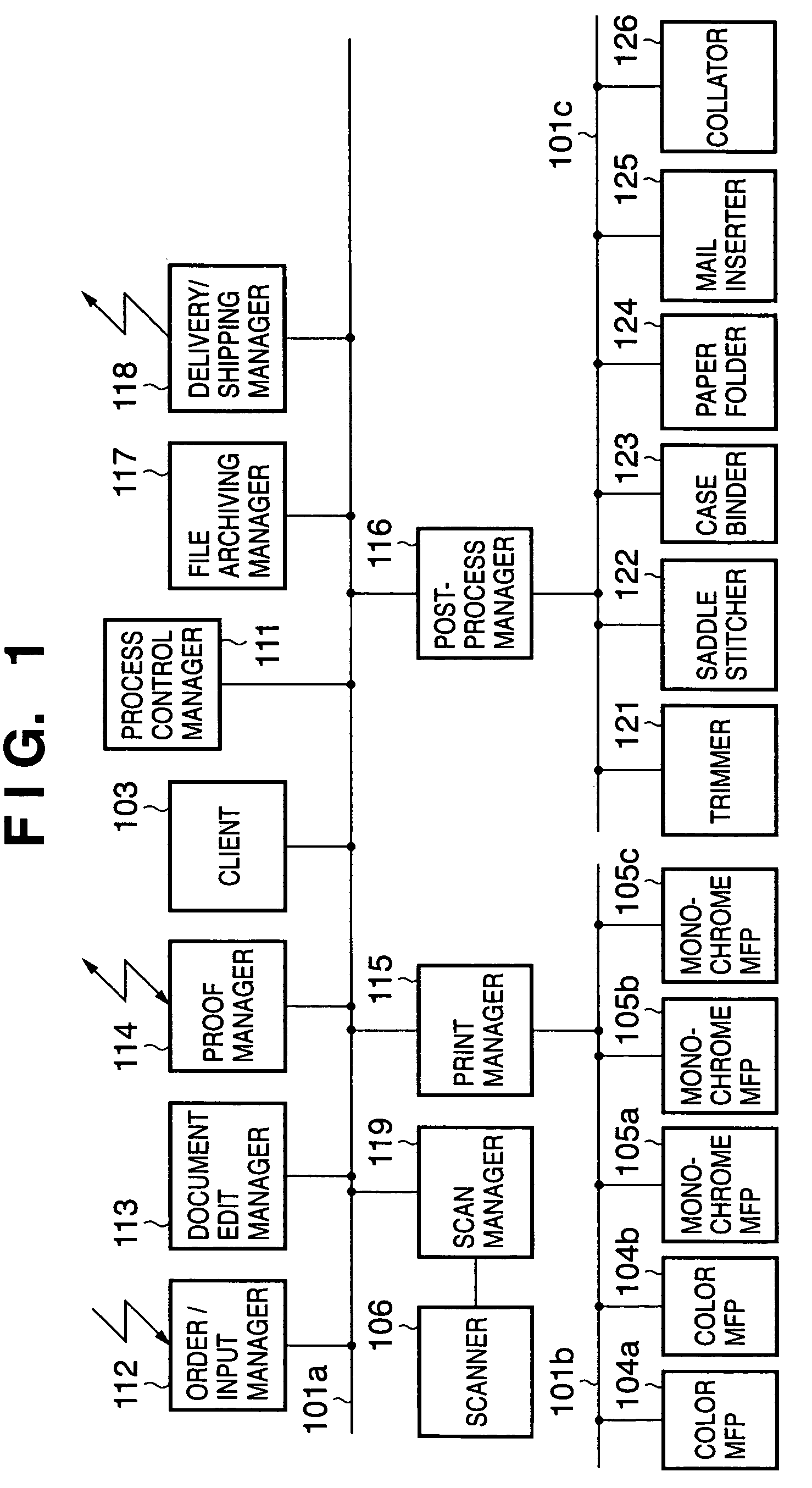

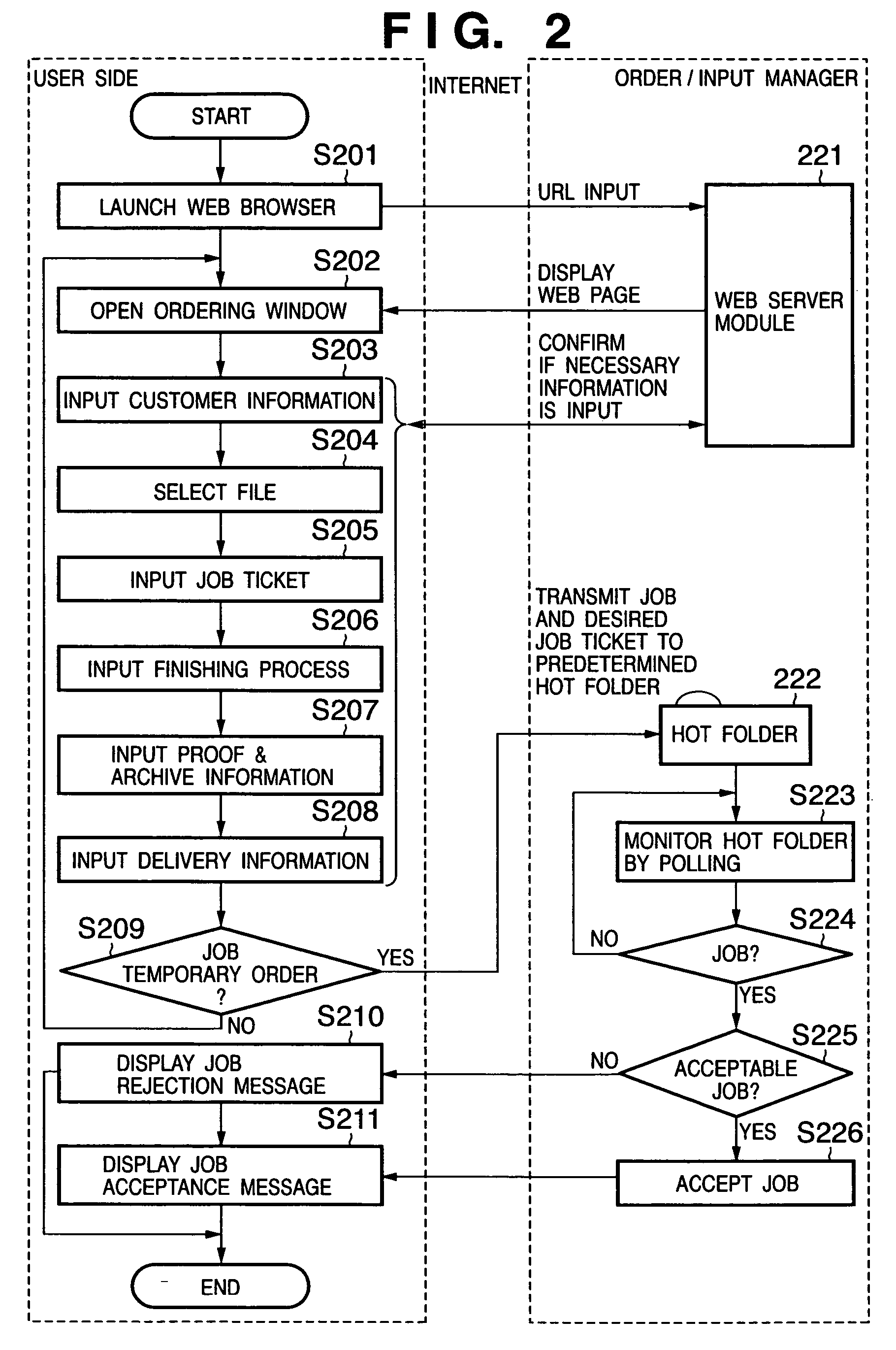

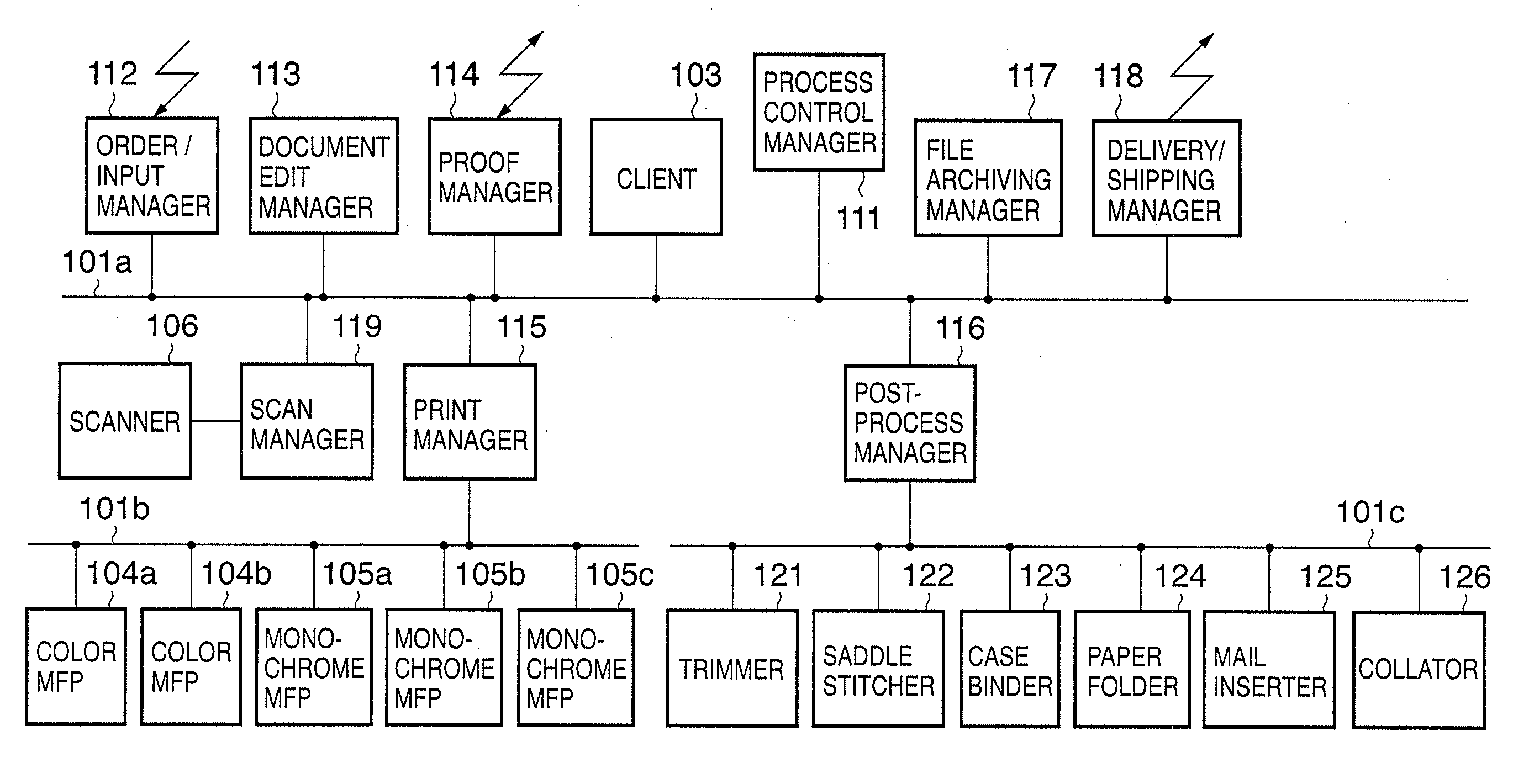

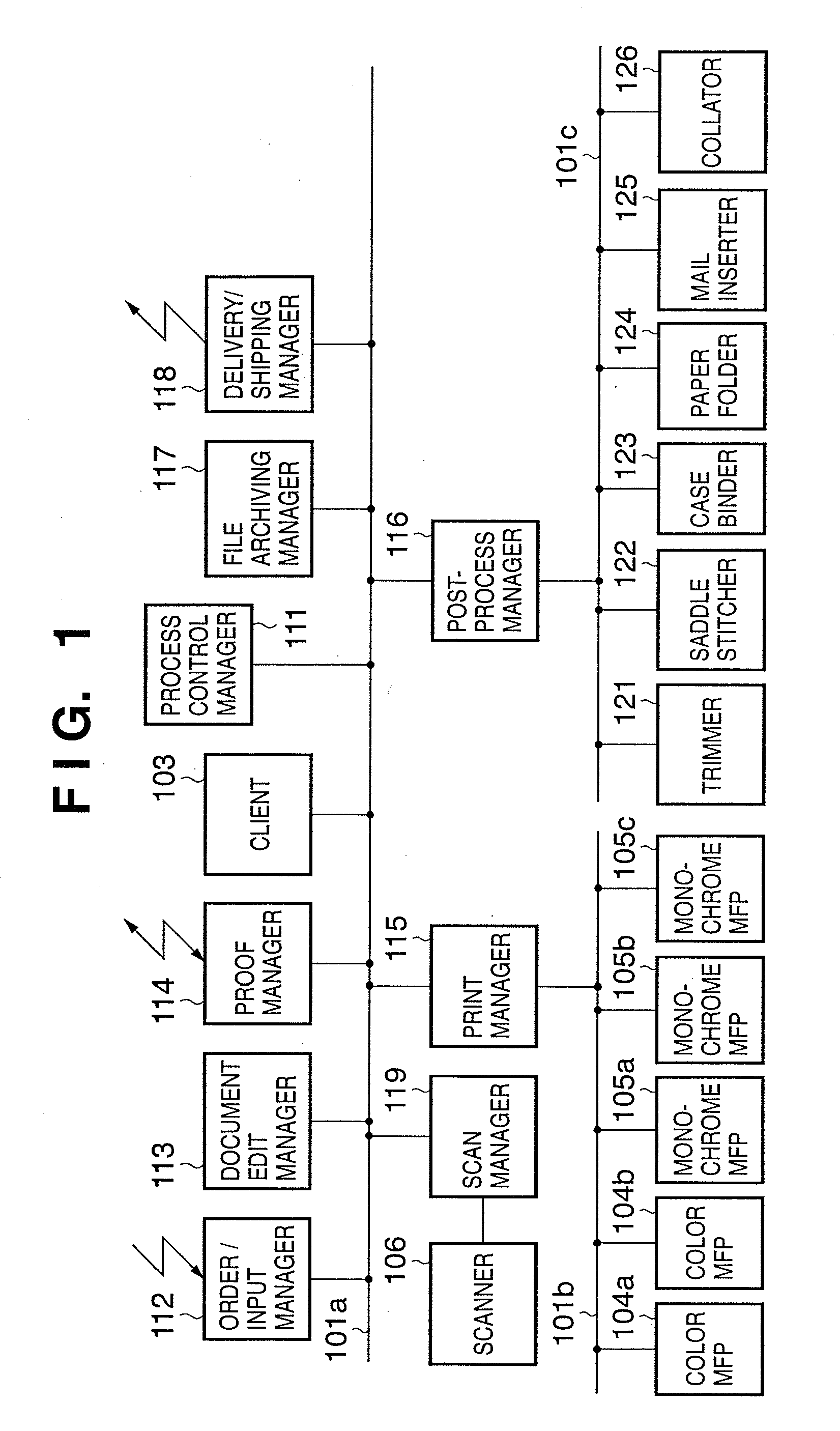

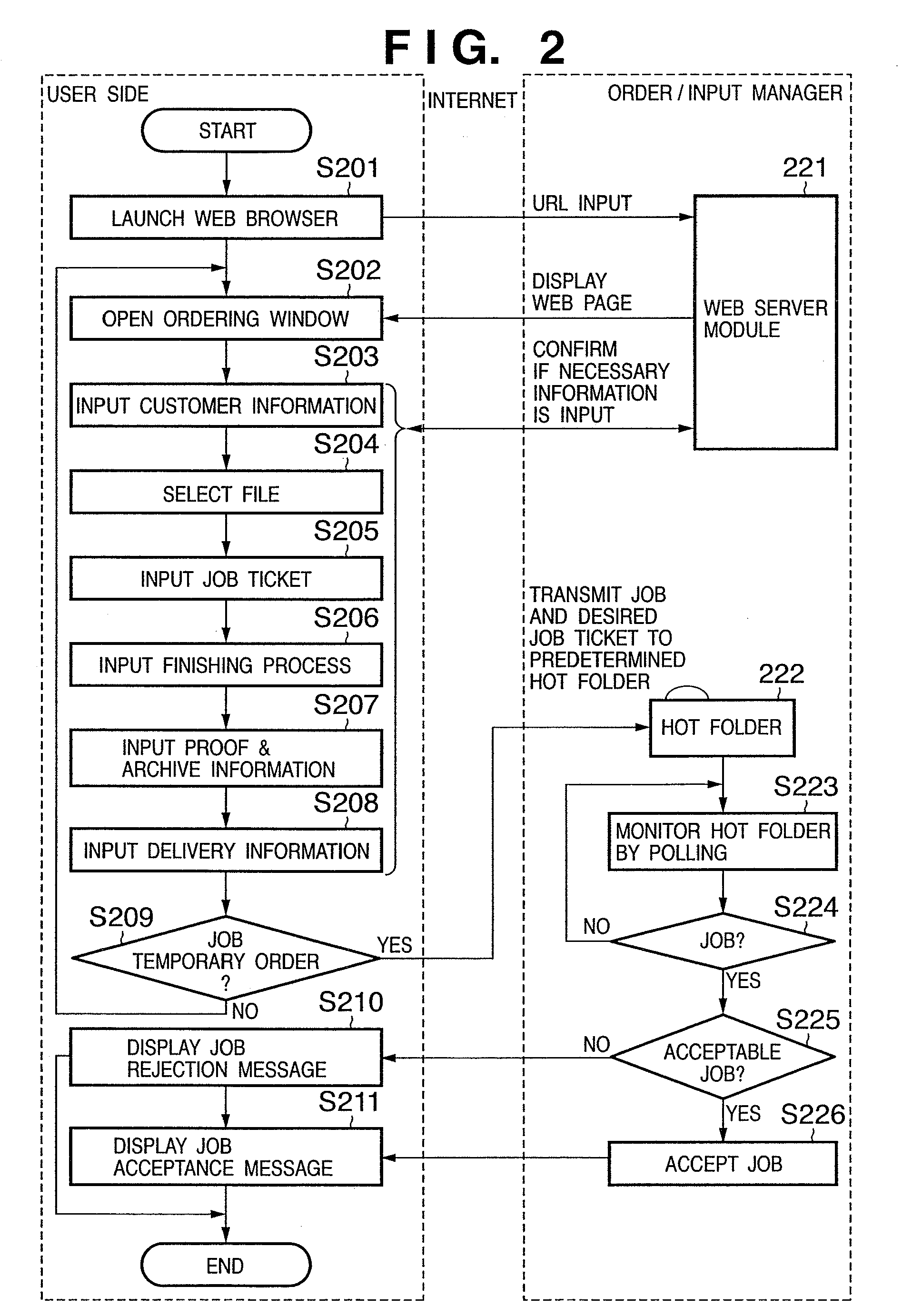

Image forming system, method and program of controlling image forming system, and storage medium

InactiveUS7567360B2Flexible systemEfficient managementDigital computer detailsSpecial data processing applicationsImage formationWork flow

In order to implement and manage an optimal system in the printing business and POD market, in an image forming system which comprises a plurality of devices including at least one of an image forming device which can print data in a storage unit that can store data of a plurality of jobs including data of a first job and data of a second job which is input after the data of the first job, and a sheet processing device which can execute a sheet process for a sheet printed by the image forming device, a schedule associated with a plurality of work flows including a first work flow that includes a plurality of process steps using a plurality of devices of the image forming system required to complete the first job, and a second work flow that includes a plurality of process steps using a plurality of devices of the image forming system required to complete the second job can be set.

Owner:CANON KK

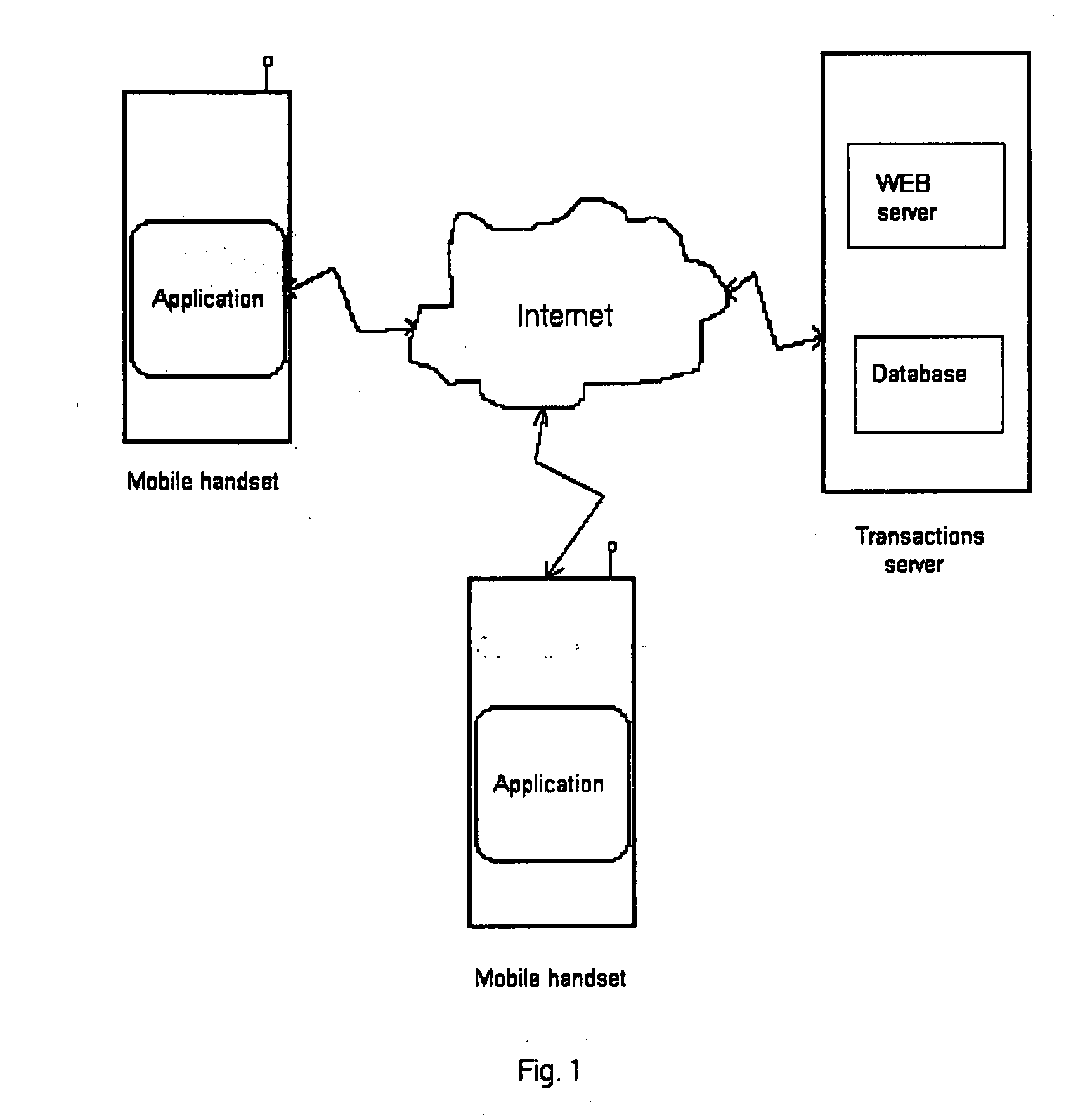

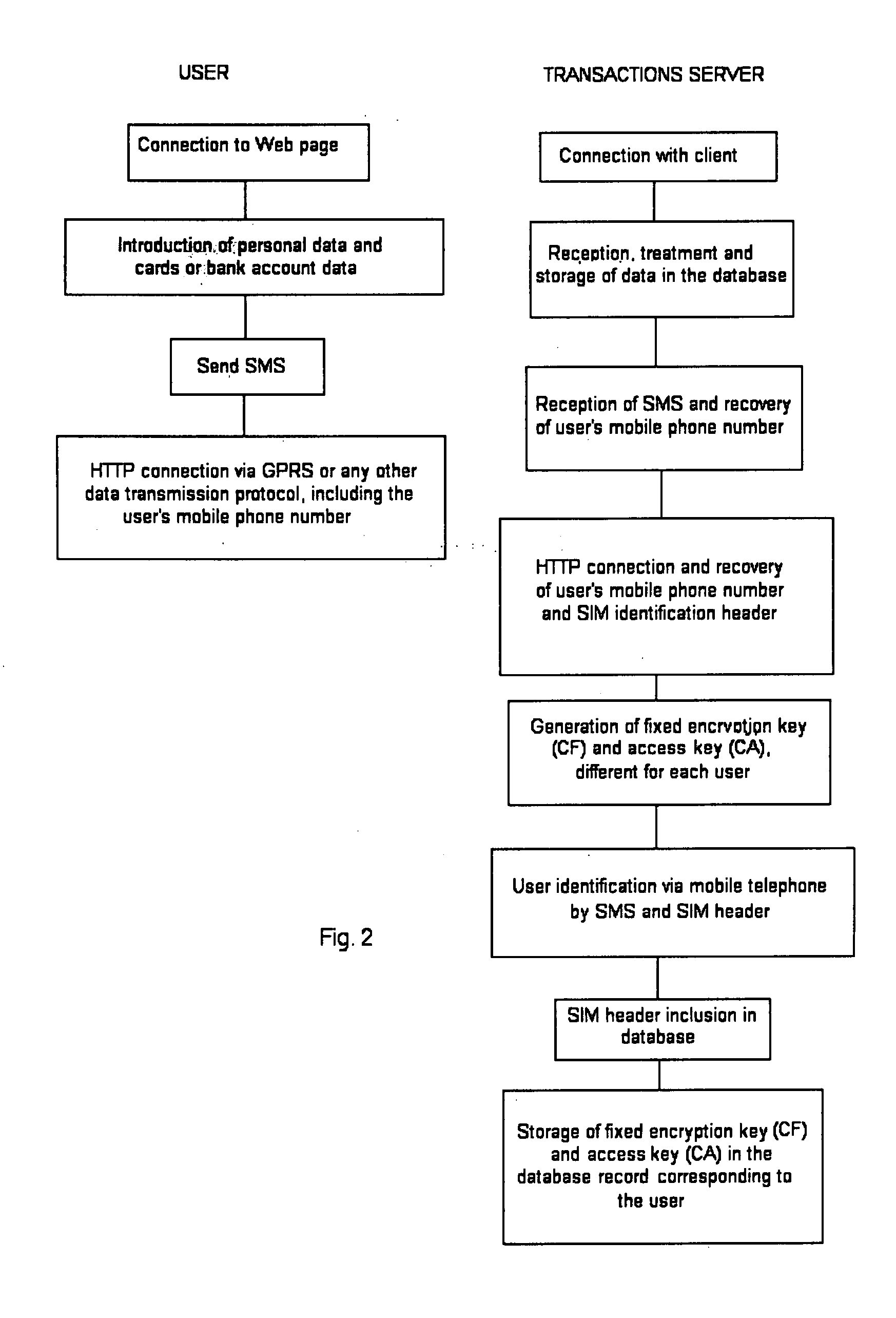

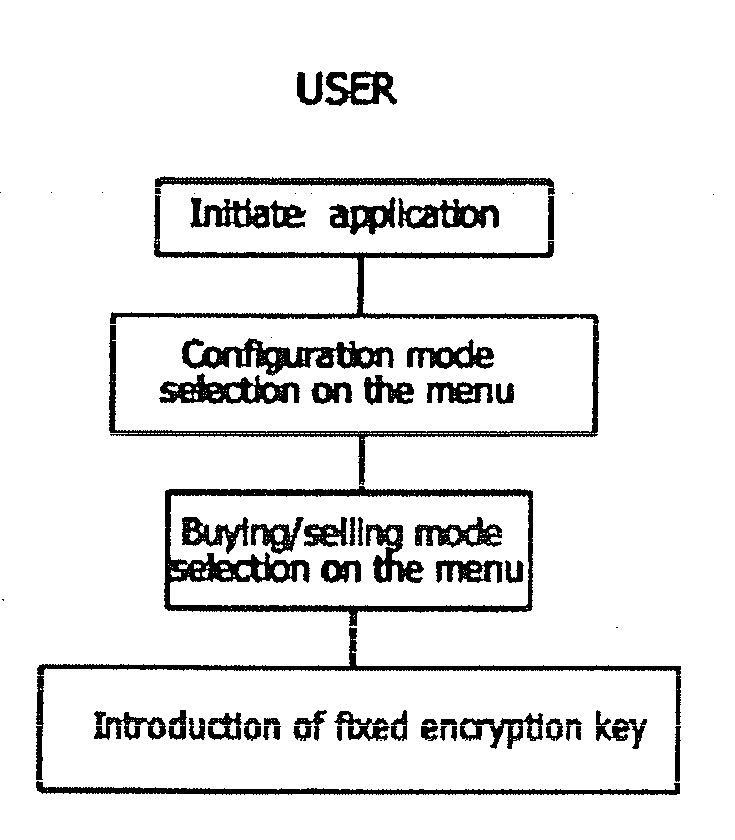

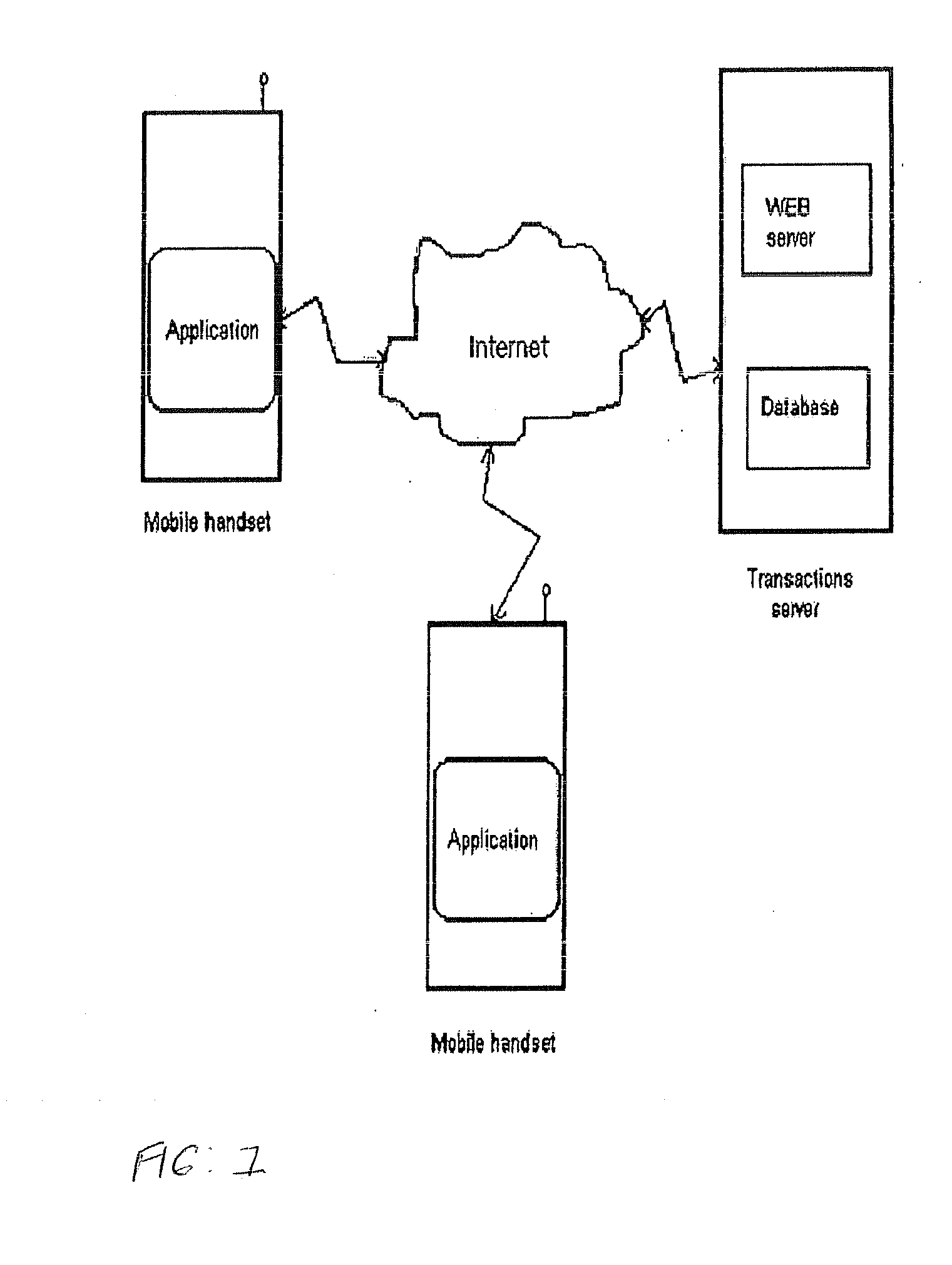

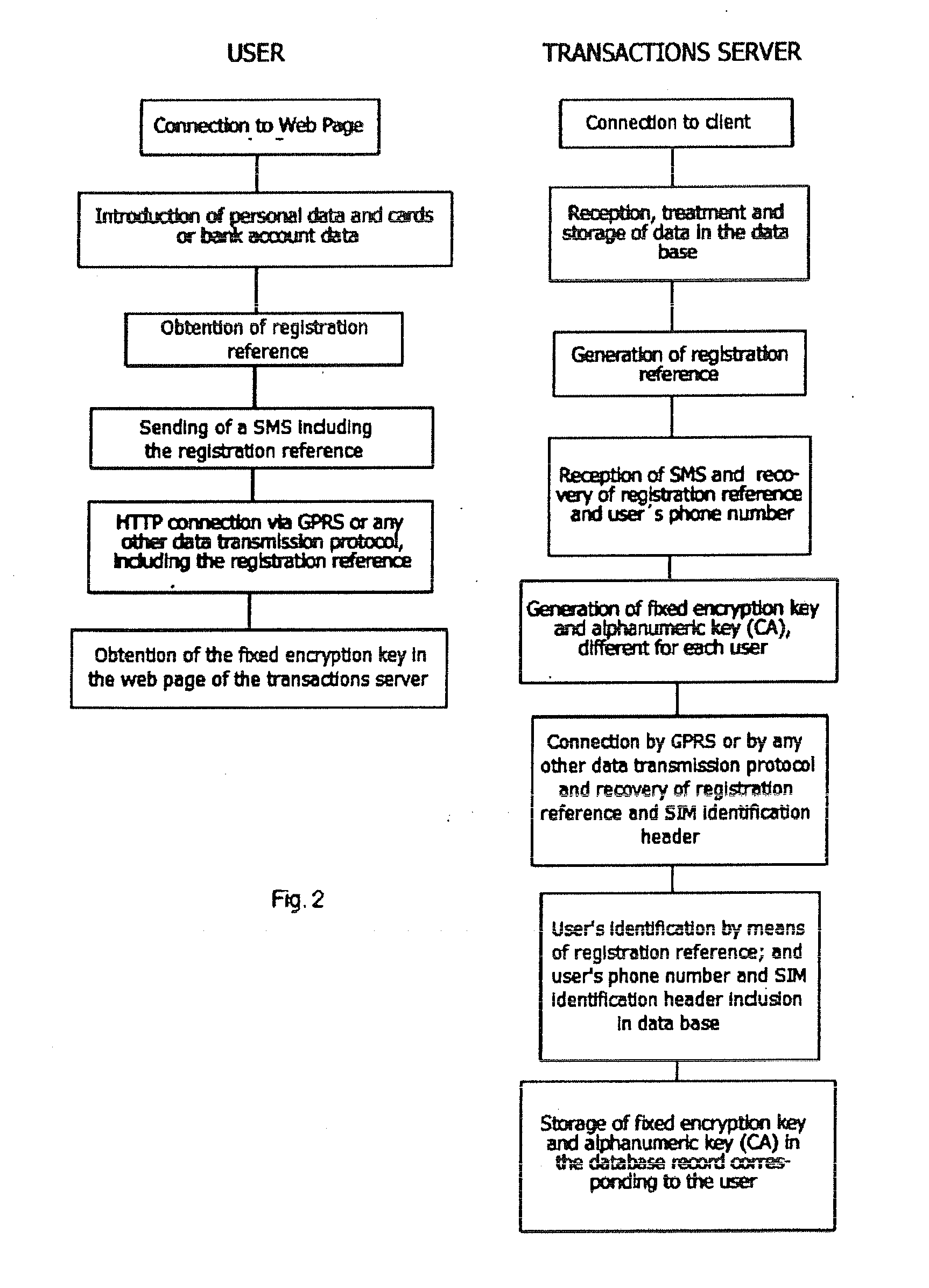

Method To Make Payment Or Charge Safe Transactions Using Programmable Mobile Telephones

InactiveUS20080091614A1Flexible systemRobustness and safetyComplete banking machinesAcutation objectsPaymentTransaction service

This is a method to carry out safe transactions using programmable mobile telephones. The use of programmable handsets—for example with Java technology—, to which an application is downloaded (e.g. Java application) allows people to carry out safe transactions. The application allows the buyer / seller to carry out the transaction, including the verification, with just one connection. The data that was sent is then encrypted and transmitted via GPRS or any other data transmission protocol, to a transactions server, where the transactions are verified and authorised. The security of the process is provided mainly by the use of up to five non related identification elements, including an access key unique for each user, stored in the mobile handset.

Owner:ETRANS L C

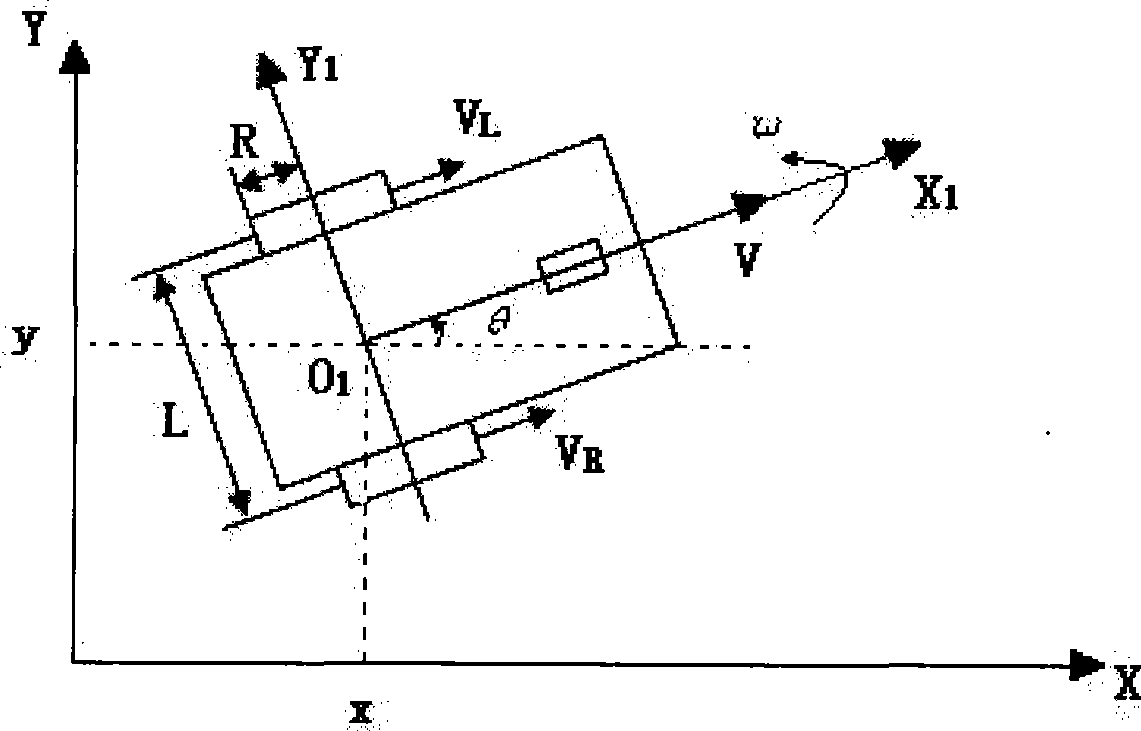

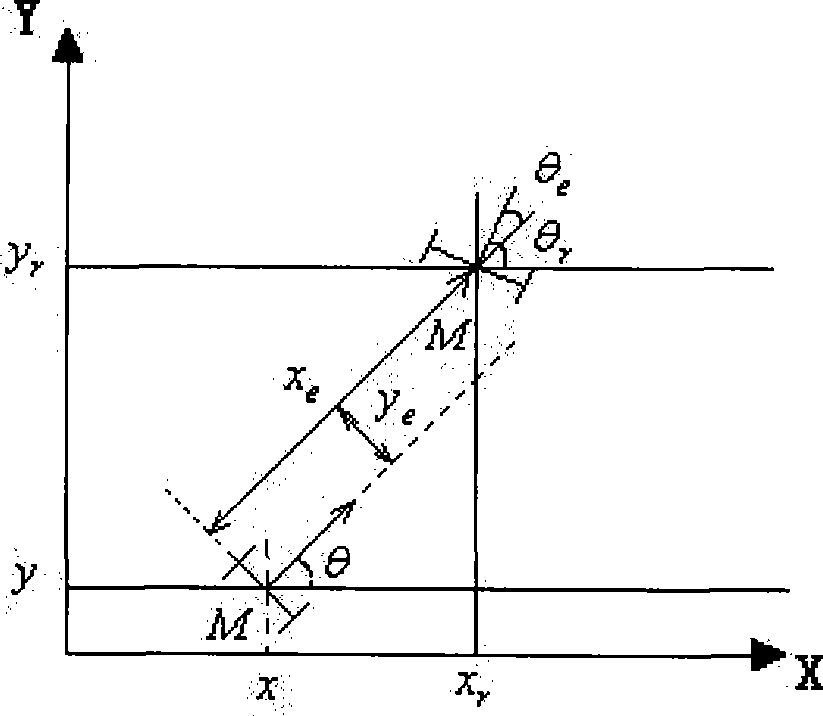

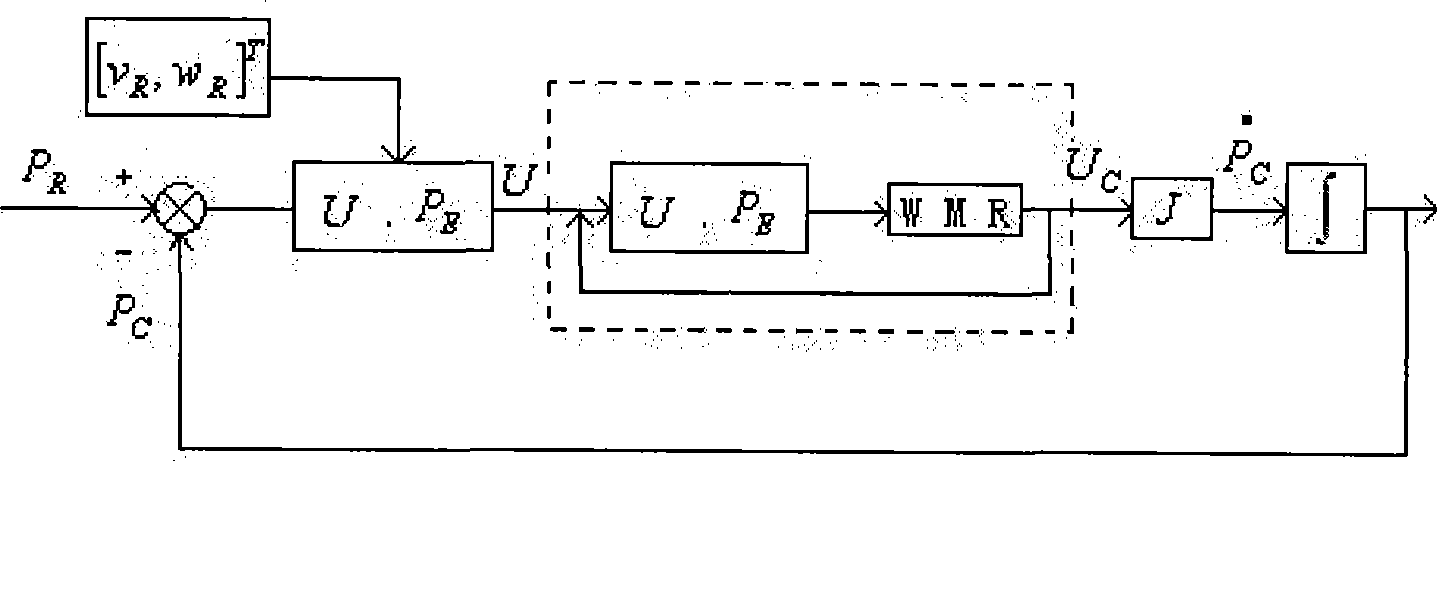

Wheeled mobile robot trace tracking method based on quantum behavior particle cluster algorithm

InactiveCN101436073ASimplify the design processFlexible systemAdaptive controlPosition/course control in two dimensionsMotion rangeParameter design

The invention discloses a method for tracing the track of a wheeled mobile robot based on a quantum-behaved particle swarm algorithm. The method sets a coordinate system within a motion range first, establishes a kinematic model of the wheeled robot, utilizes an inversion design method to decompose the kinematic model, obtains an error propagation equation of a reference pose and an actual pose through the track generated by path planning, takes the equation as a target function, utilizes the quantum-behaved particle swarm optimization algorithm to obtain parameters of a controller with quick speed and strong global solving capacity, designs the controller through the group of parameters, and further guarantees that the robot can be stably and quickly converged on the target track, namely the target function value is close to or less than an allowable value within a limited time period. The method solves the problems of high nonlinearity and non-integrity of track tracing of the wheeled mobile robot, and can quickly realize track tacing of the wheeled mobile robot and improve the tracing control effect of the mobile robot.

Owner:JIANGNAN UNIV

Image forming system, method and program of controlling image forming system, and storage medium

ActiveUS20090244620A1Flexible systemEfficient managementDigital computer detailsSpecial data processing applicationsImage formationWork flow

In order to implement and manage an optimal system in the printing business and POD market, in an image forming system which comprises a plurality of devices including at least one of an image forming device which can print data in a storage unit that can store data of a plurality of jobs including data of a first job and data of a second job which is input after the data of the first job, and a sheet processing device which can execute a sheet process for a sheet printed by the image forming device, a schedule associated with a plurality of work flows including a first work flow that includes a plurality of process steps using a plurality of devices of the image forming system required to complete the first job, and a second work flow that includes a plurality of process steps using a plurality of devices of the image forming system required to complete the second job can be set.

Owner:CANON KK

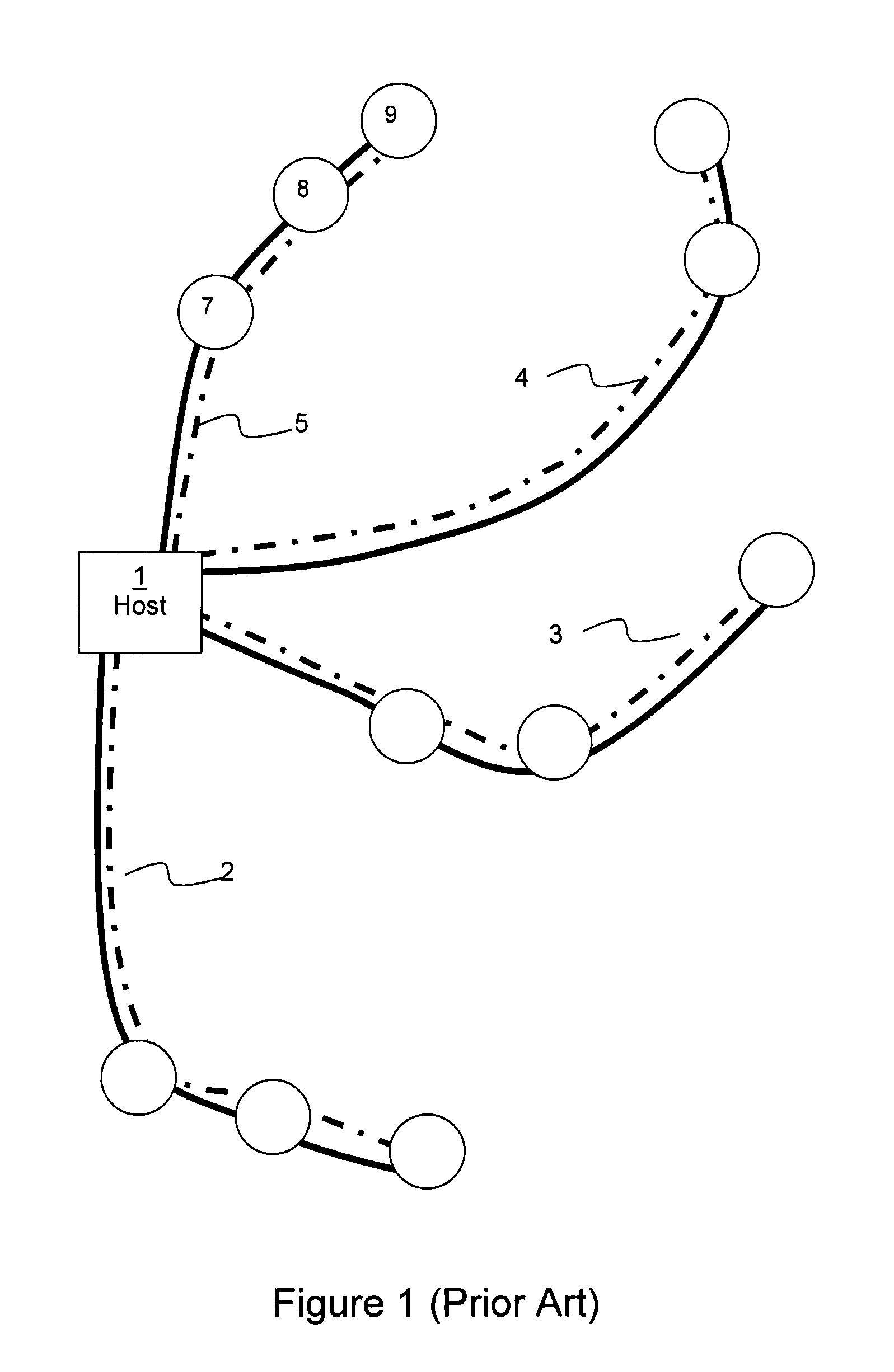

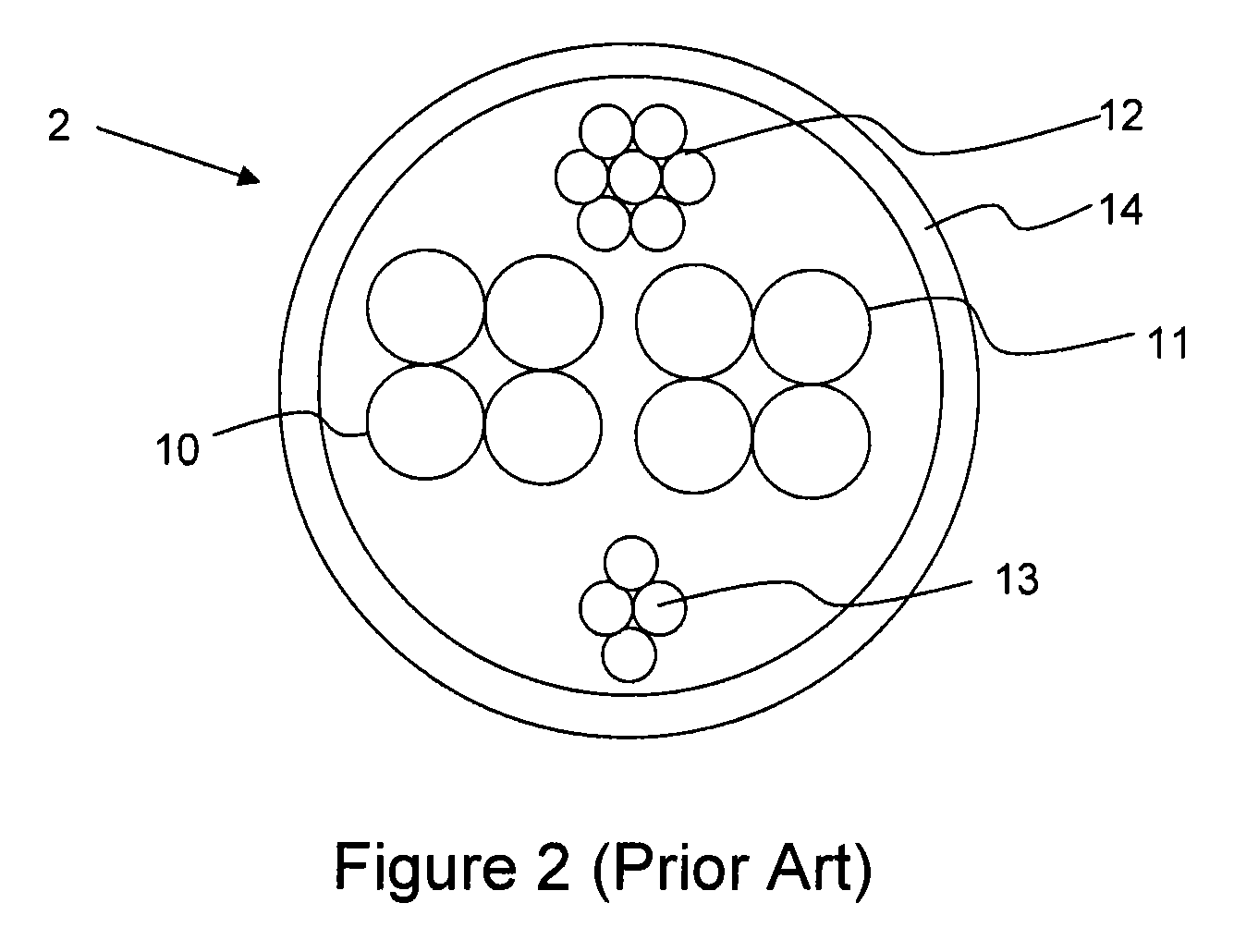

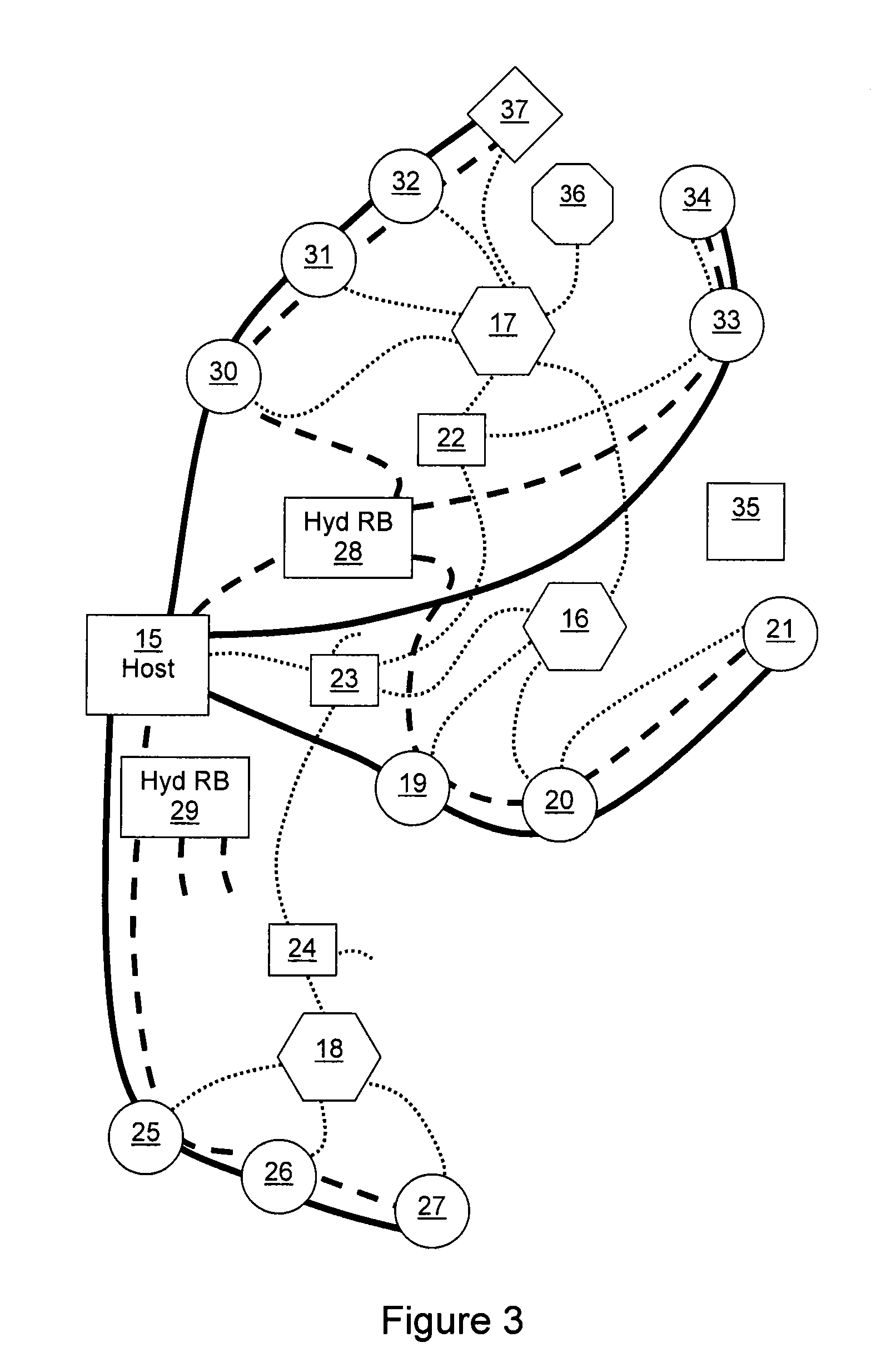

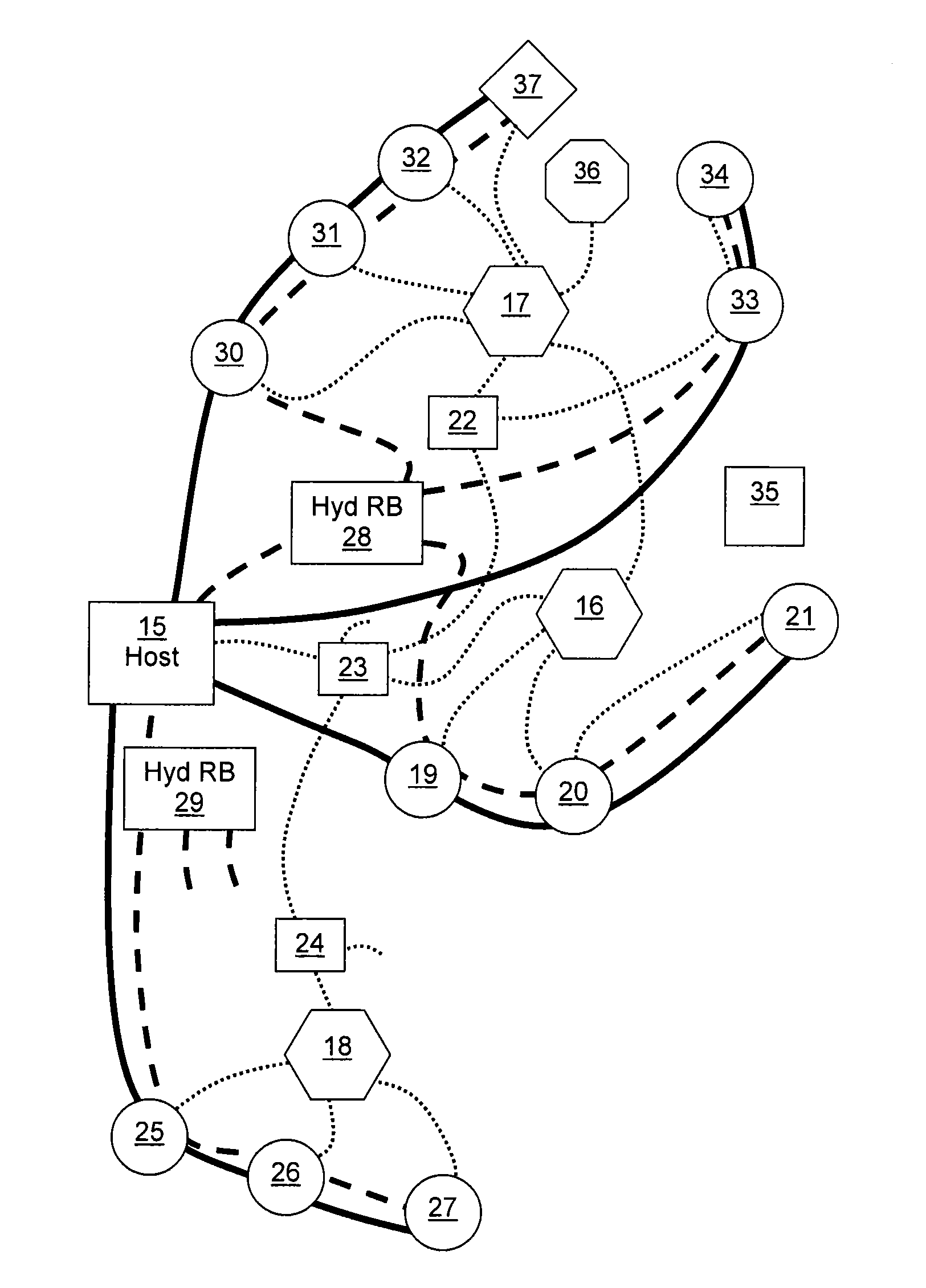

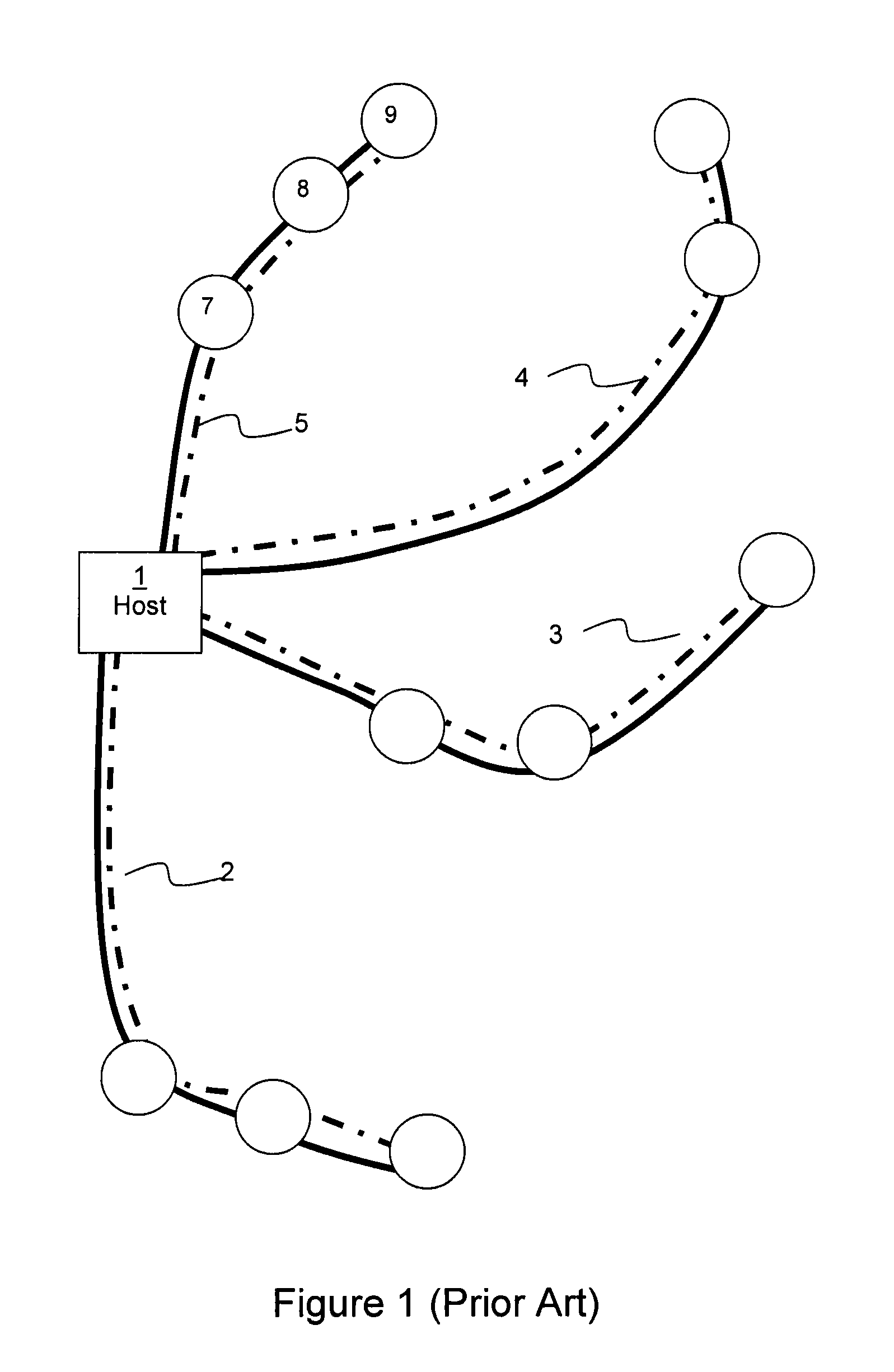

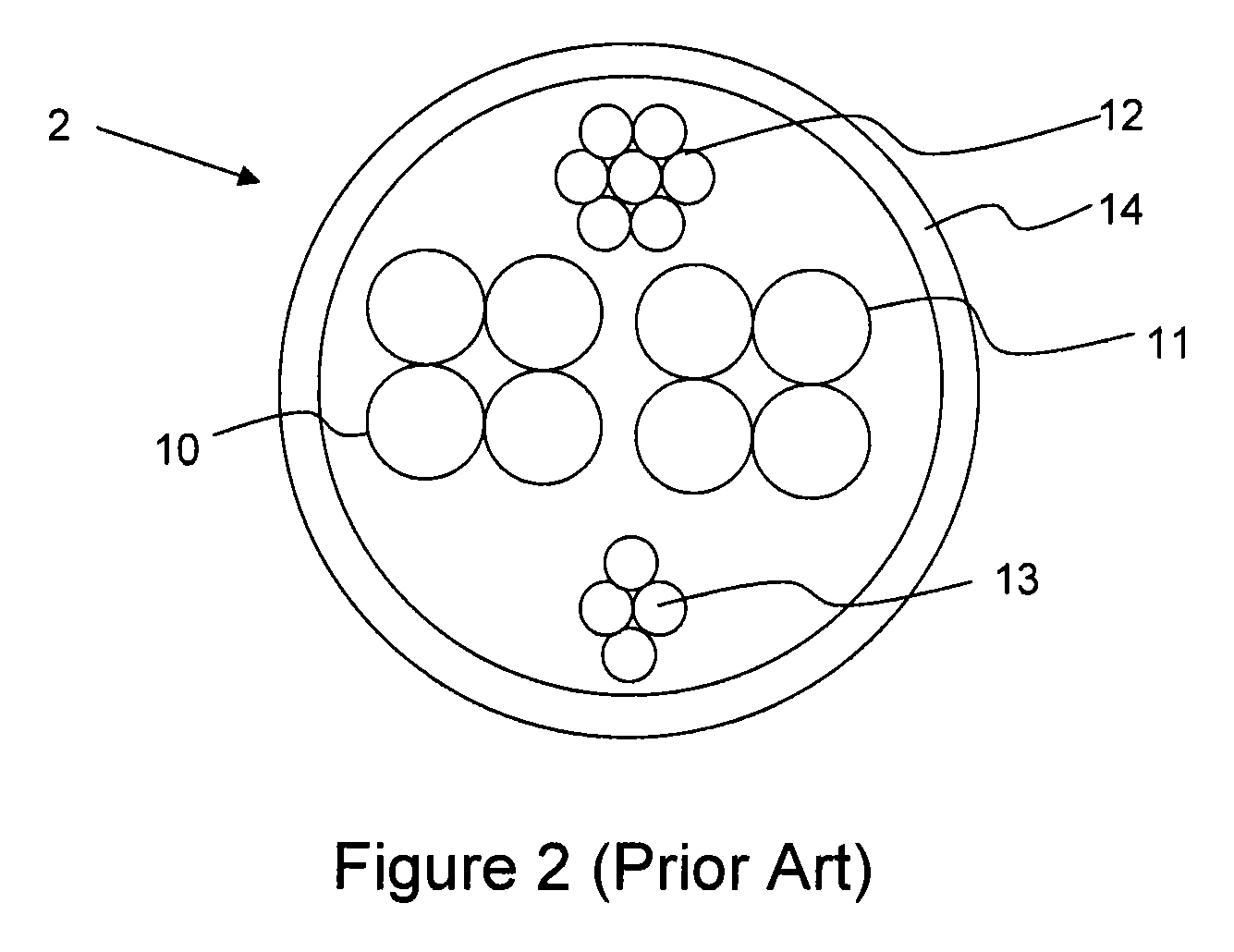

Subsea hydrocarbon production system

ActiveUS20110290497A1Provides redundancyFlexible systemSurveyDrilling rodsPower overData transmission

A subsea oil and / or gas production system comprises a host production facility and a plurality of subsea wells. A fluid conveying network is provided that connects each subsea well to the host production facility. A separate electrical power and data network is provided for conveying direct current electrical power and data, operatively connected to each subsea well for providing each subsea well with data transfer and electrical power services. The use of direct current ensures that the electrical power and data network can provide power over much greater distances than currently available, and the use of separate networks for conveying fluids and for providing electrical power and data transfer allows for a much more flexible system.

Owner:DEN NORSKE STATS OLJESELSKAP AS

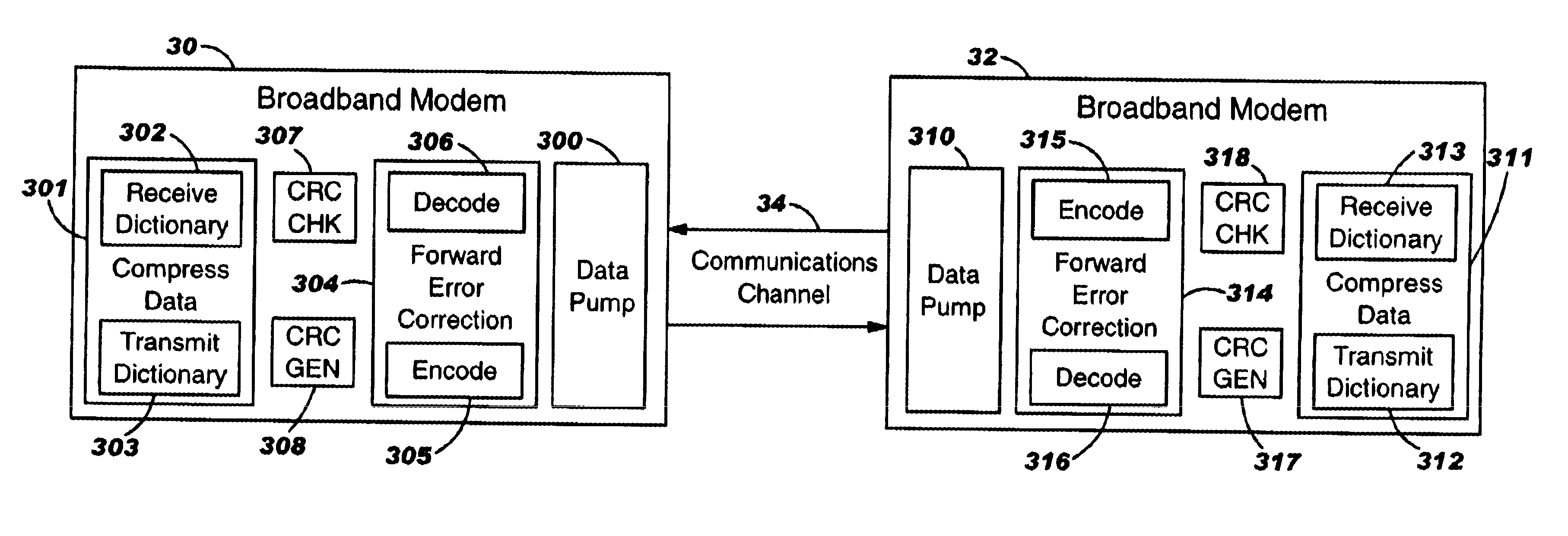

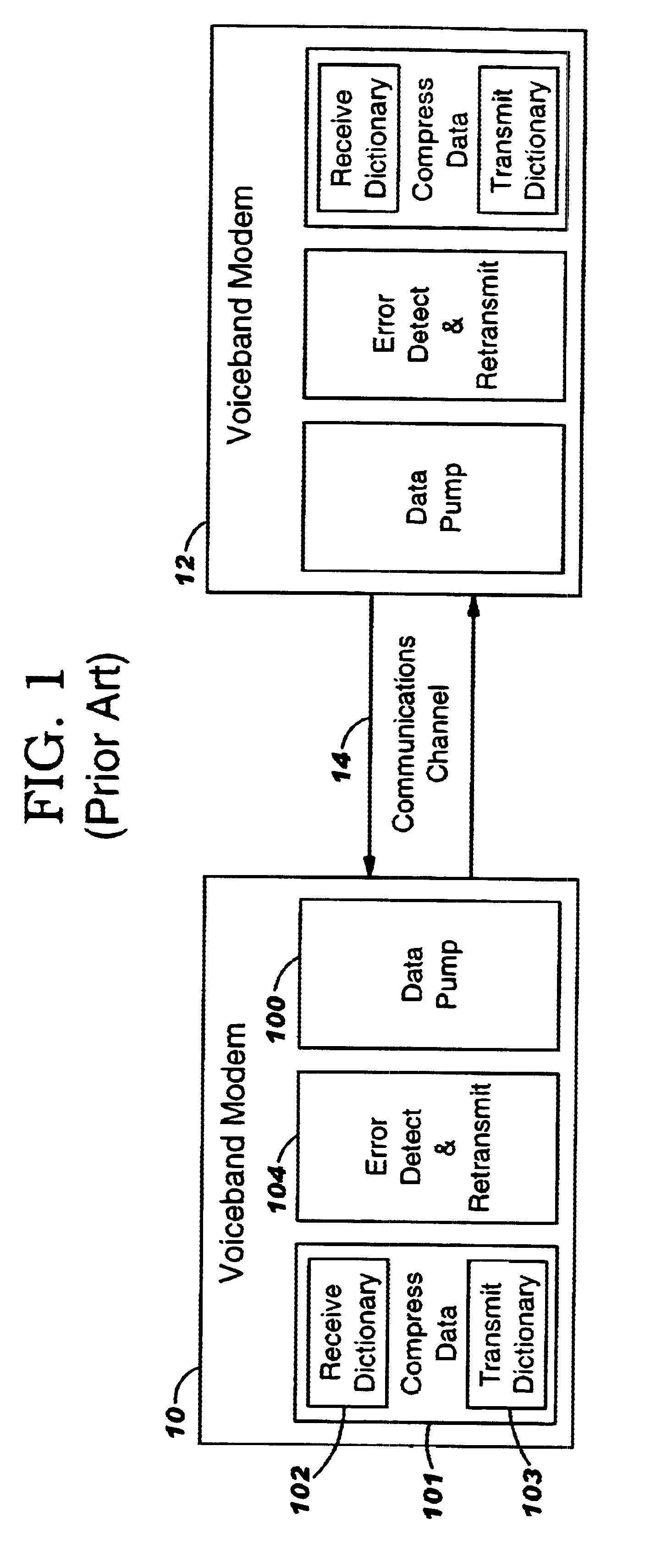

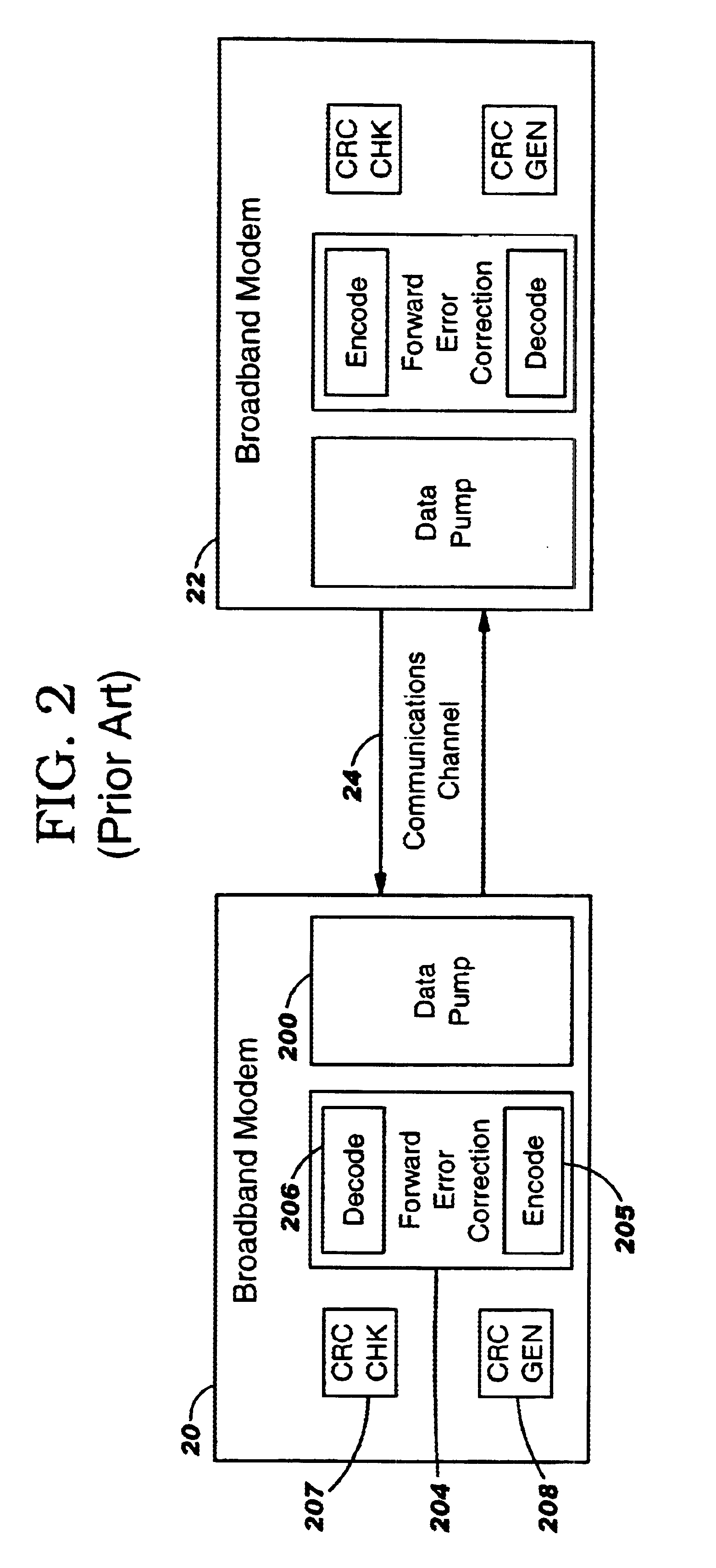

Data compression over communications links which are exposed to occasional errors

InactiveUS6643815B1Flexible systemAvoid timeoutError preventionError detection/correctionData compressionTransceiver

Re-synchronization of sets of transmit and receive state variables in a communication system is achieved when an error is detected, without disrupting the connection. Each of first and second transceivers, connected by a communications channel, have a common set of transmit and receive state variables supporting a data encoding algorithm function. The transmitter of one of the first and second transceivers fist encodes data to be transmitted and updates the transmit state variables according to the data encoding algorithm and the receiver of the receiving transceiver validates whether or not each data block has been received correctly. During the process of decoding the data, the receive state variables are updated according to the same algorithm used to update the transmit state variables, thereby keeping the two sets of state variables in synchronism with each other. When an error is detected, re-synchronization occurs by switching to transparent mode in the direction of communication in which the error occurred and resetting the corresponding transmit and receive sets of state variables.

Owner:IBM CORP

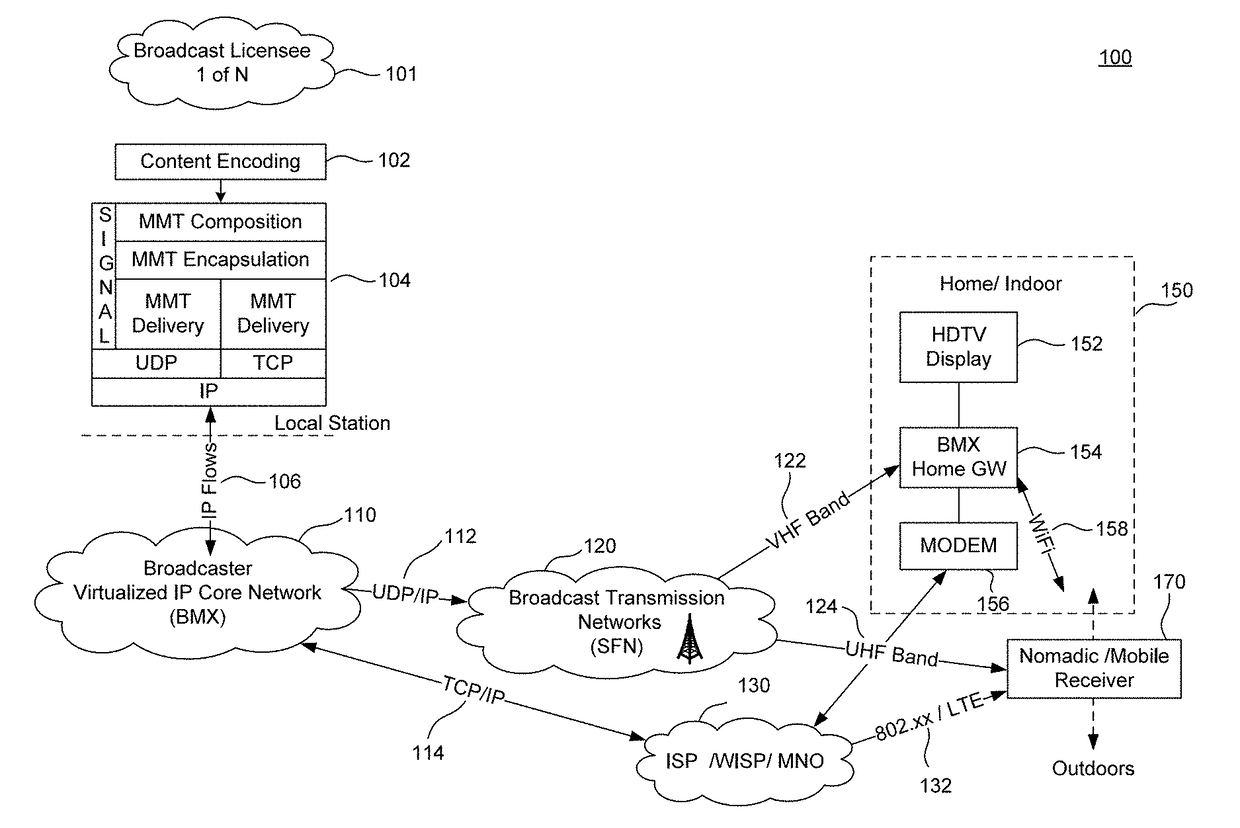

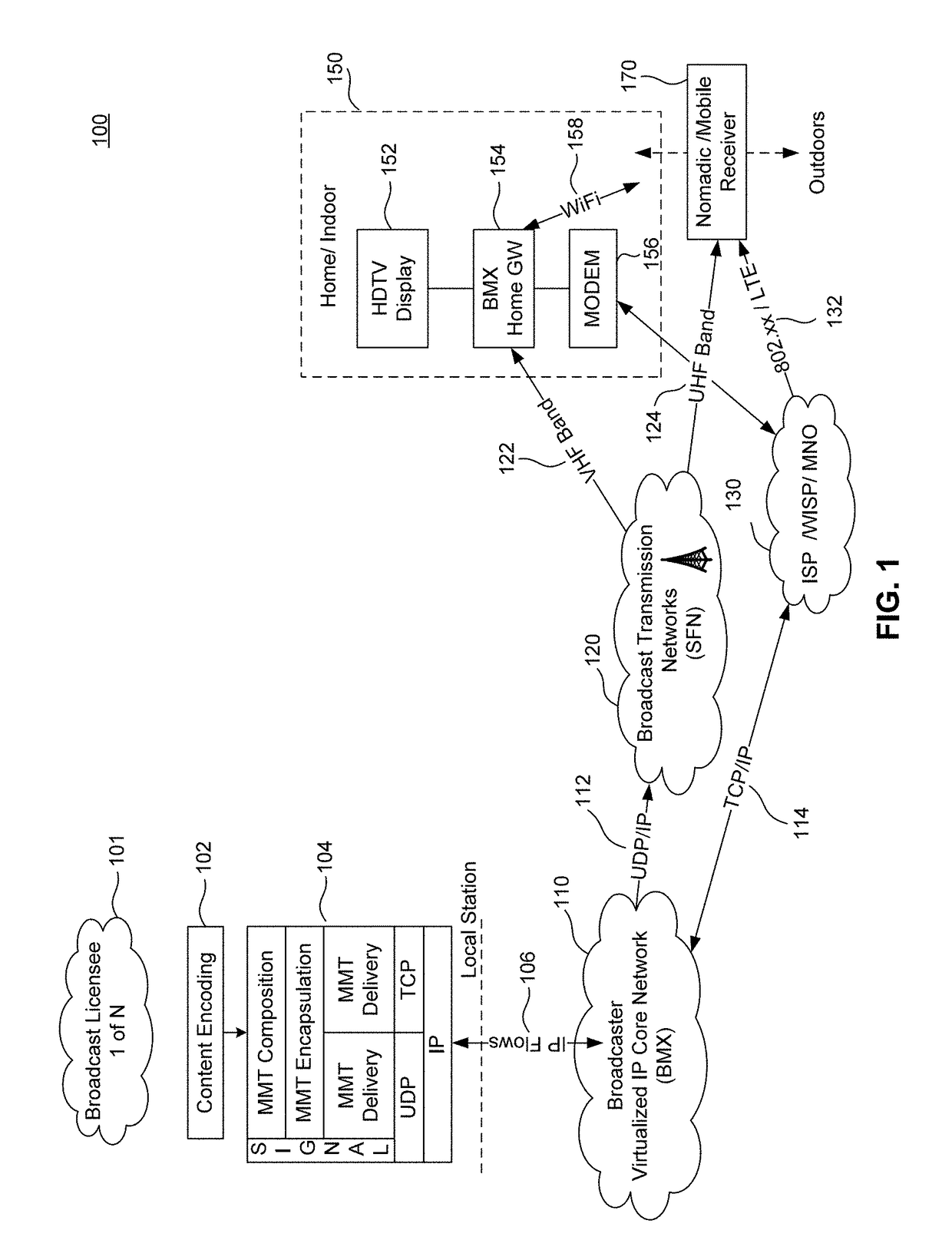

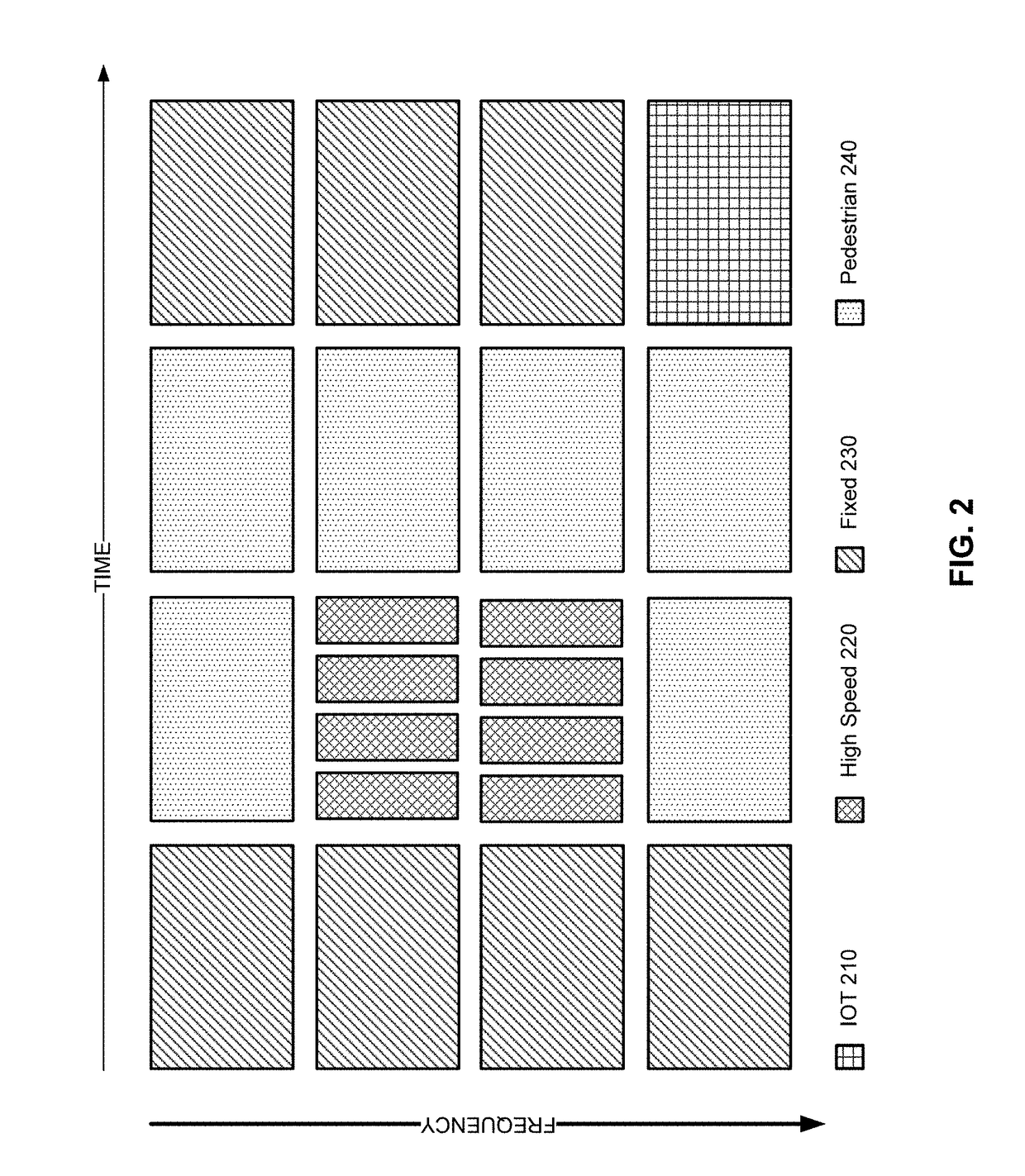

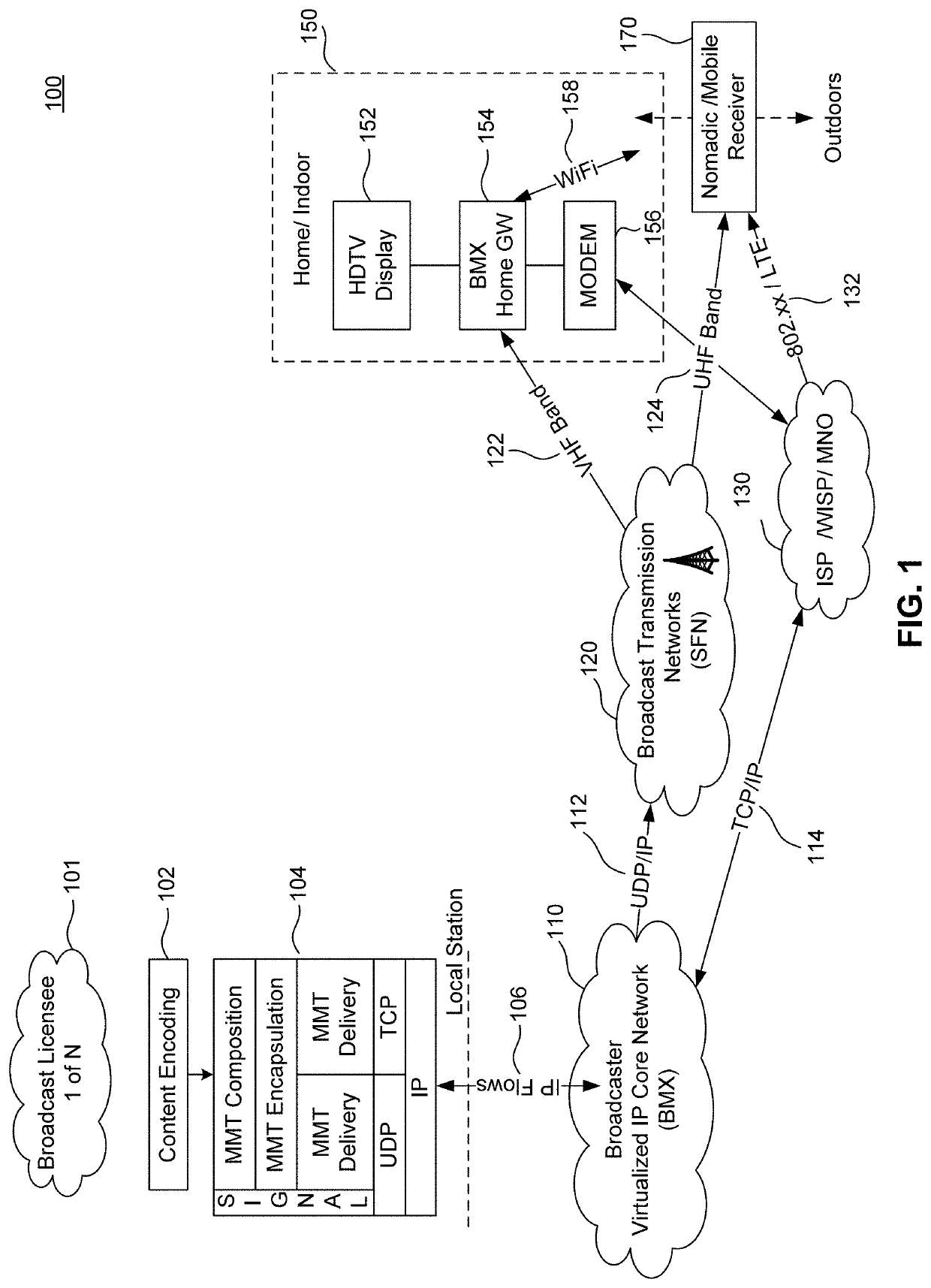

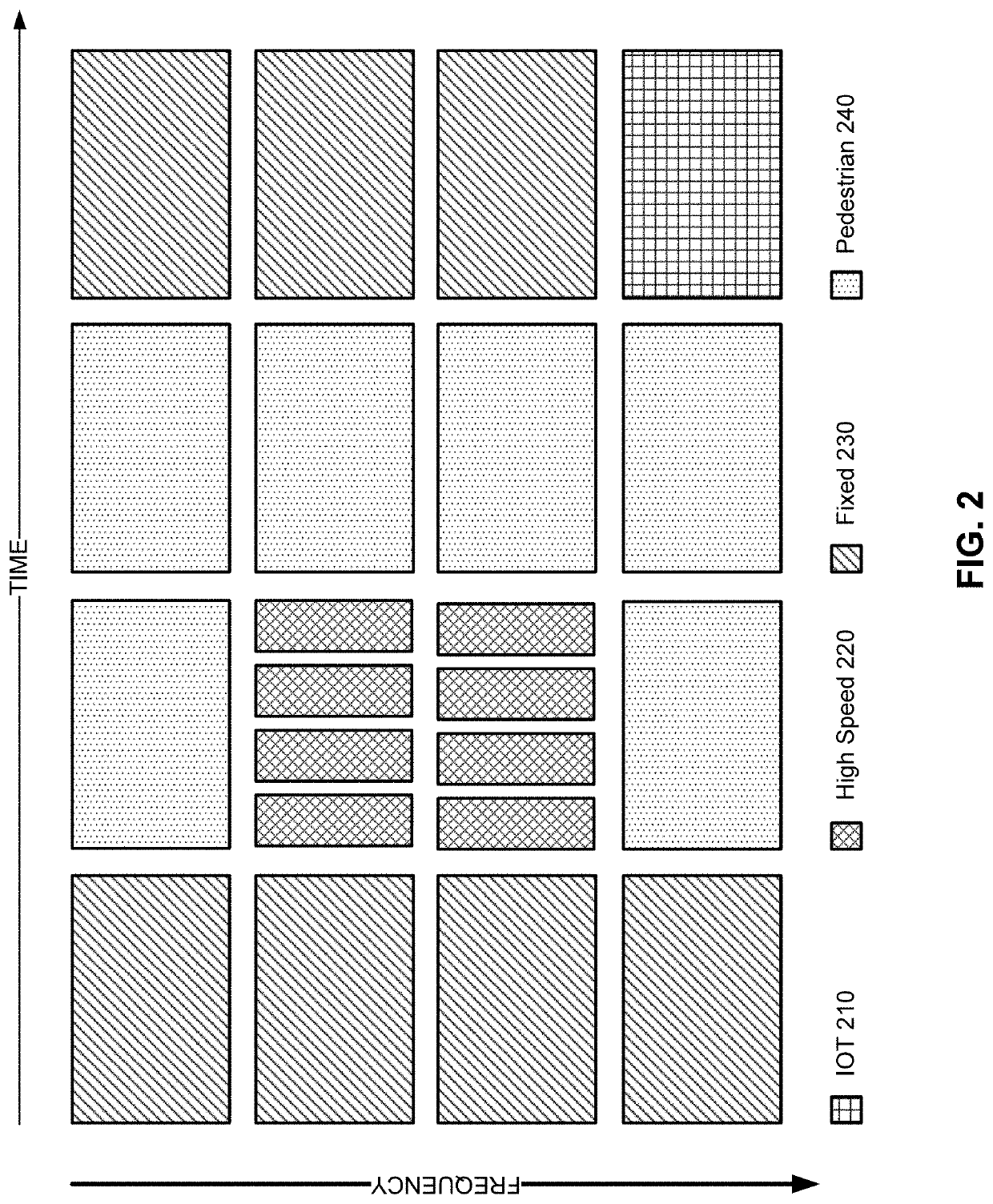

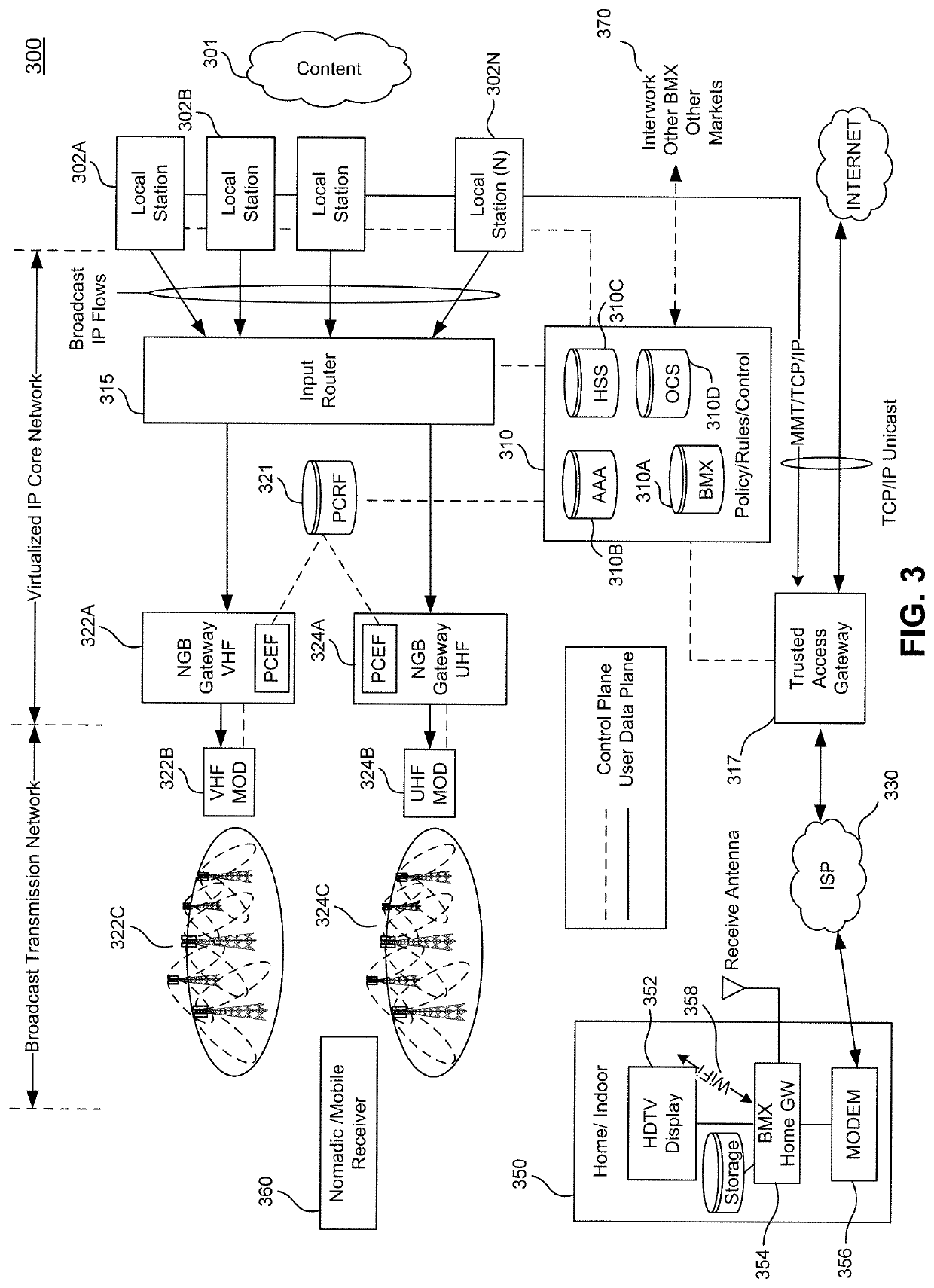

Next generation terrestrial broadcasting platform aligned internet and towards emerging 5g network architectures

ActiveUS20170295409A1FlexibleFlexible systemNetwork traffic/resource managementStore-and-forward switching systemsService-level agreementTTEthernet

A Next Generation Broadcast Platform (NGBP) is disclosed that utilizes 5G software-defined networking (SDN) and network function virtualization (NFV) technologies. The NGBP is designed to enable a new paradigm for broadcasters, wherein the model of fixed wireless spectrum access granted only to the licensees of the spectrum is replaced by a flexible model in which licensed spectrum is pooled together and allocated dynamically to broadcast licensees as well as outside tenants. The NGBP is implemented using SDN / NFV technology, and includes a broadcast market exchange (BMX) entity that allocates the spectrum between tenants based on service level agreements (SLAs) with those users. The NGBP also includes an internet protocol (IP) core and a broadcast centralized radio access network (BC-RAN) which apply the major network functions to broadcaster content in accordance with the determinations of the BMX. The SDN / NFV implementation offers several distinct advantages over NGBP implemented with dedicated network hardware.

Owner:SINCLAIR BROADCAST GRP

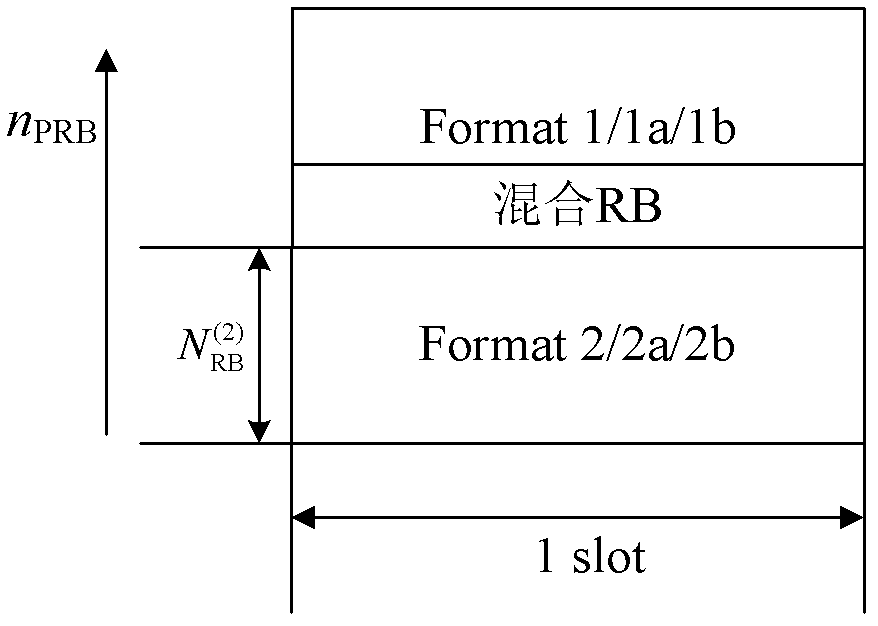

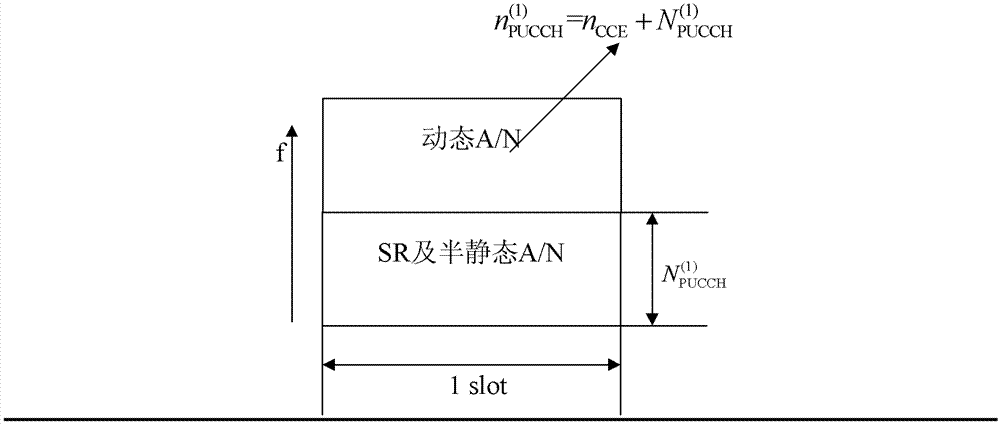

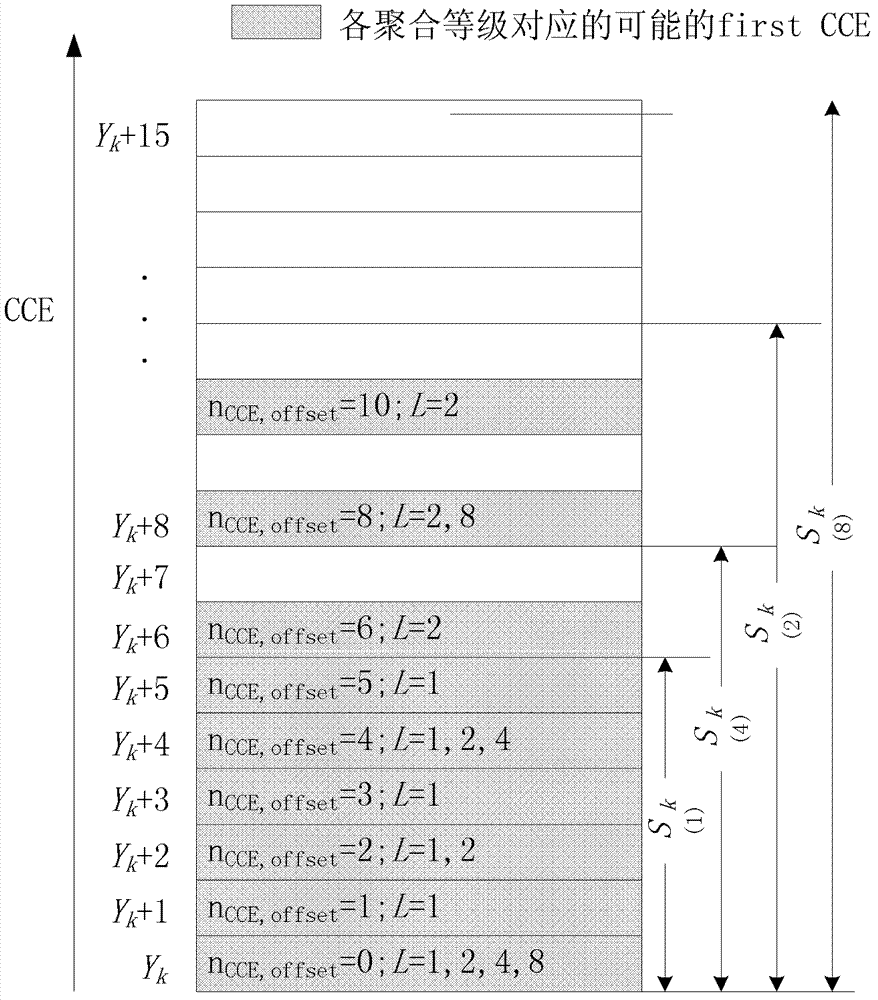

Physical uplink control channel resource allocation method and system

ActiveCN103249147AEasy dynamic configurationFlexible approachWireless communicationControl channelComputer science

The invention relates to a physical uplink control channel resource allocation method and system. The method comprises the following steps: a base issues parameters or newly added bits aiming at a user device and used for determining the physical uplink control channel resource allocation to the user device; and the user device receives the parameters or the newly added bits and determines the physical uplink control channel resource allocation according to the parameters or the newly added bits. By adopting the method and the system, provided by the invention, a physical uplink control channel can flexibly and easily realize the resource allocation of the physical uplink control channel.

Owner:ZTE CORP

Method to Make Payment or Charge Safe Transactions Using Programmable Mobile Telephones

ActiveUS20110231319A1Flexible systemRobustness and safetyCryptography processingPayment architecturePaymentTransaction data

A system, method and mobile application for conducting financial transactions wherein a mobile device operated by a user is operably coupled to a server over a mobile communication network. Both the server and the user's mobile device store a user encryption key (UEK) and a user access key (UAK). A software application stored on the user's mobile device and the server are configured to conduct a transaction wherein a session key (SK) specific to the transaction is exchanged in an encrypted form based upon the UEK. The software application is further configured to i) generate transaction data, ii) access the UAK stored on the mobile device, iii) encrypt the UAK and transaction data into an encrypted form based upon the SK, and iv) send the UAK and transaction data in encrypted form from the mobile device to the server over the mobile communication network in order to conduct the transaction.

Owner:ETRANS L C

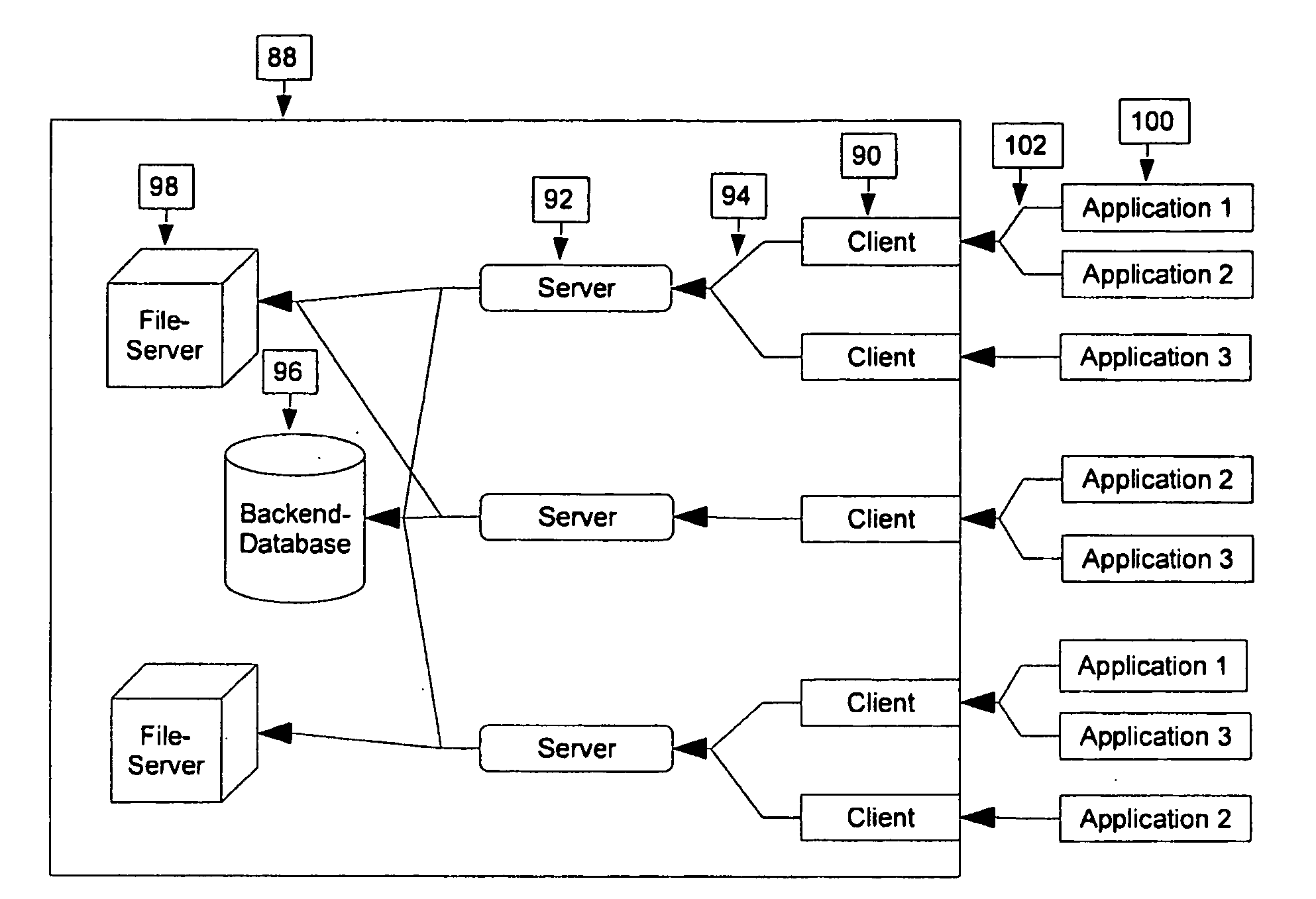

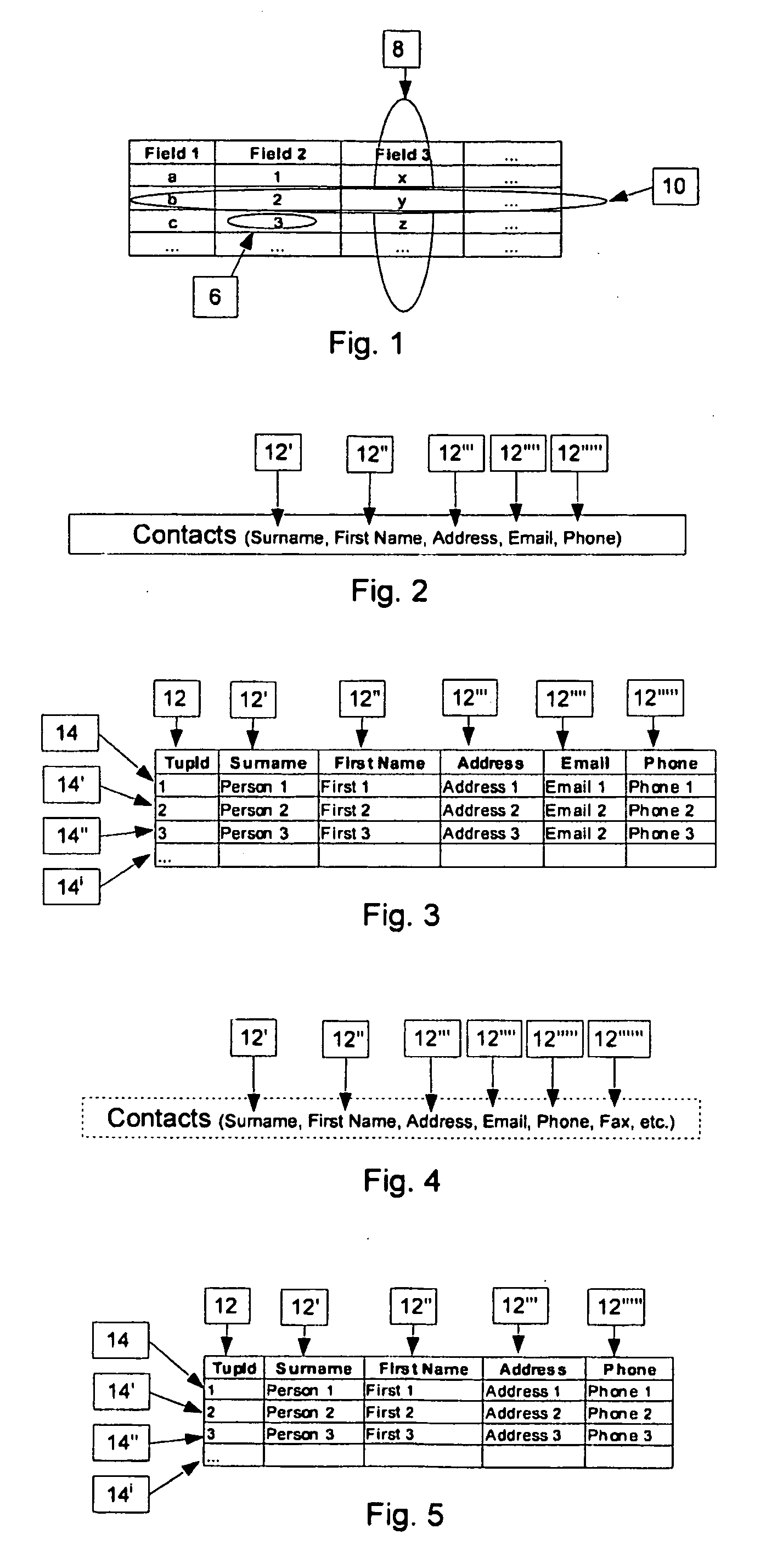

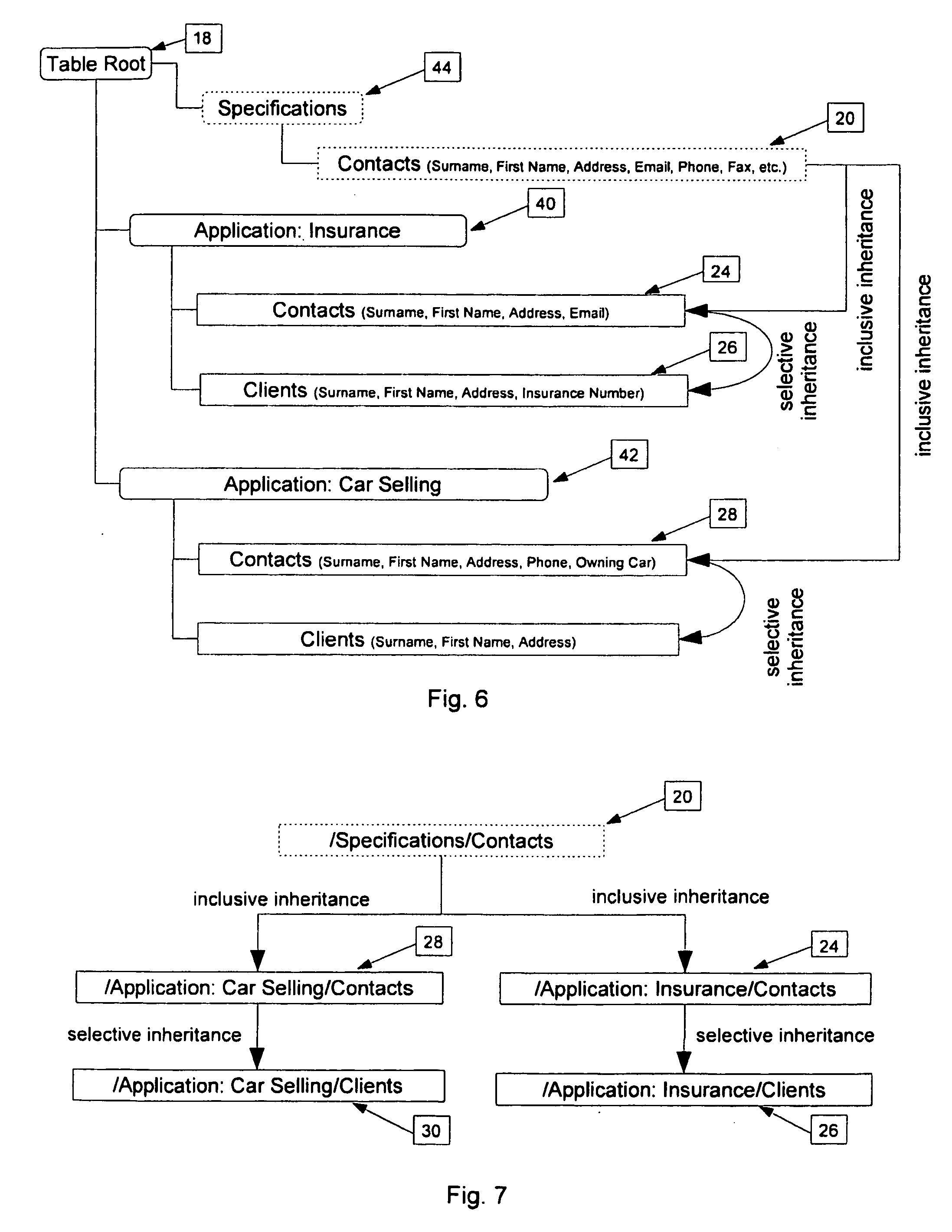

Method for providing or operating a framework for the realization of independently developed programs

ActiveUS20100287212A1Flexible processDifficult to manageSoftware engineeringDigital data processing detailsApplication softwareApplication specific

A method for providing a framework to provide a basis for the realization of independently developed programs. The framework comprises at least one database table specification, each said database table specification being centrally provided and comprising a list of table fields, any selection of which can be selected by a program developer to derive an application specific database table including selected table fields taken from said database table specification and optionally one or more further application specific table fields. The framework automatically creates a basic database table and a program developer only concerns himself with said application specific database table and not with said basic database table. The method involves the use of inclusive and selective inheritance of database tables resulting in great flexibility and substantial benefits in practice.

Owner:BECKER STEFAN

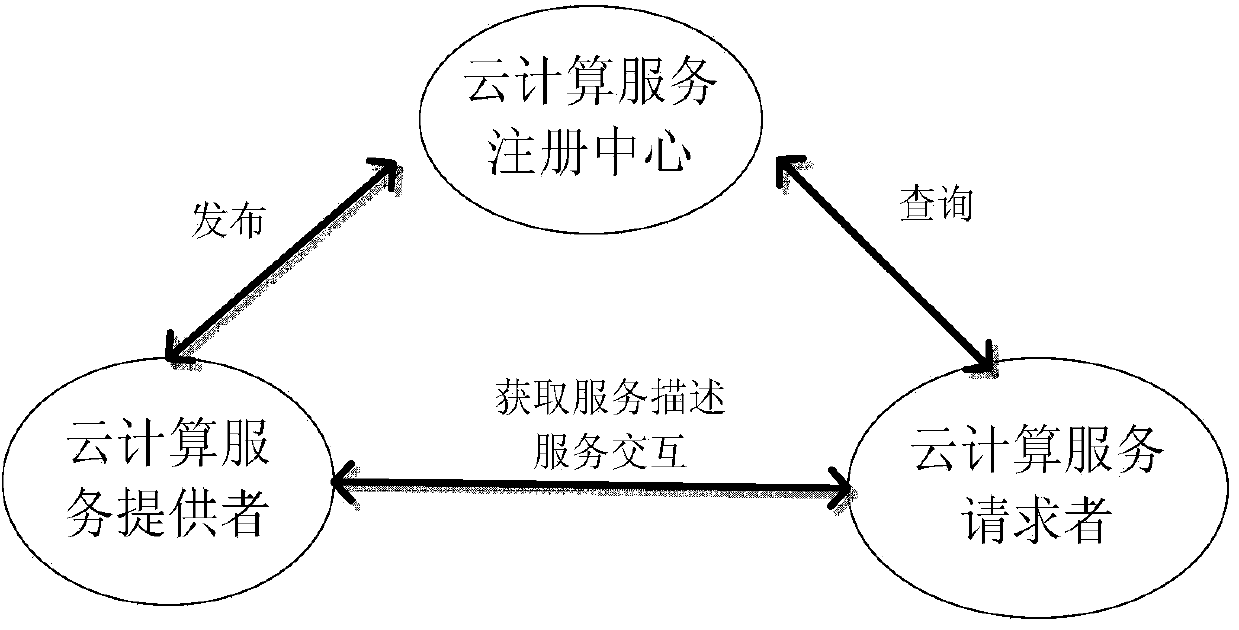

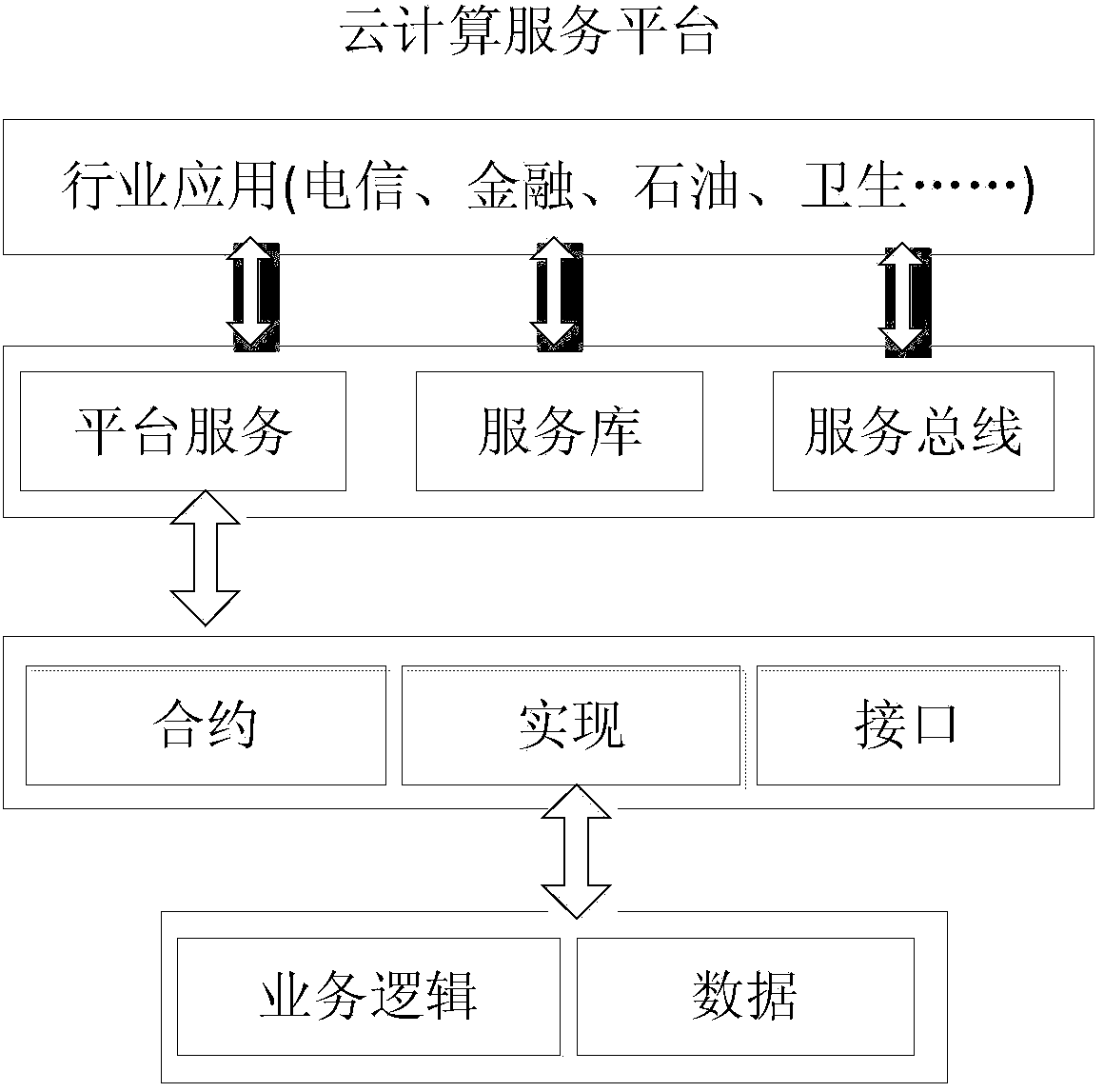

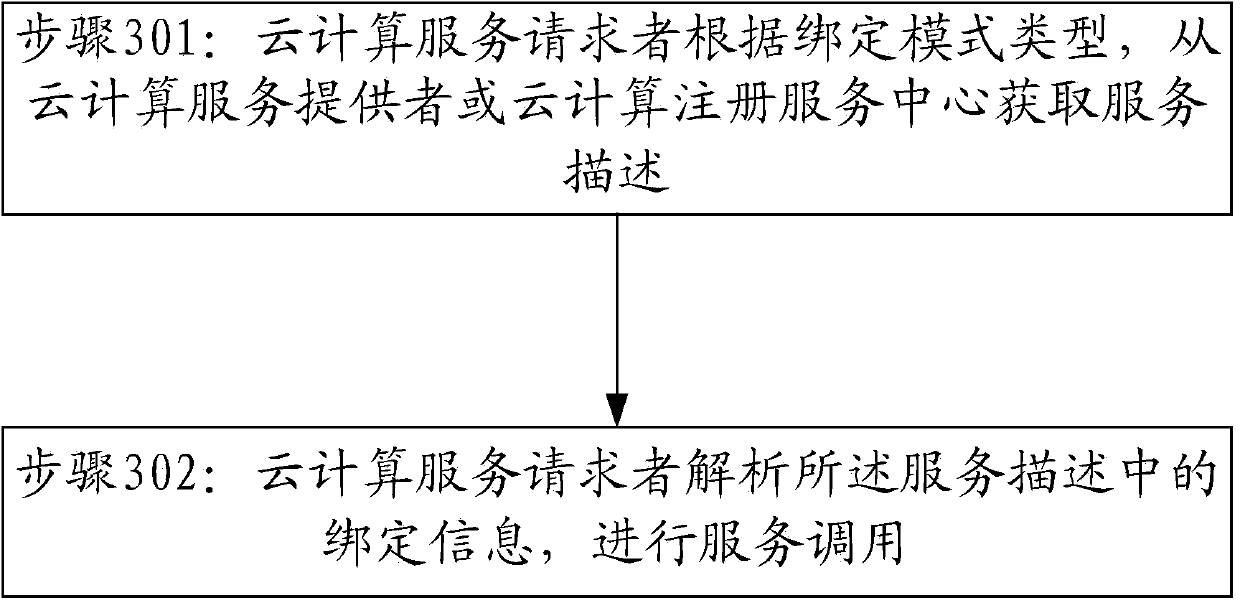

Construction method and system of cloud computing service platform

InactiveCN103701935AImprove scalabilityMeet build requirementsTransmissionLoose couplingLayered Service Provider

The invention provides a construction method and system of a cloud computing service platform, which is applied to the technical field of computer applications. The method comprises the following steps: a cloud computing service requester obtains service description from a cloud computing service provider or a cloud computing registration service center according to the type of binding mode, and analyzes binding information in the service description to perform service calling. According to the method provided by the invention, existing IT (information technology) infrastructures of an enterprise are protected with the help of an SOA (service-oriented architecture) and the loose coupling property thereof in the cloud computing service platform; by using a cloud computing service architecture of the SOA mode, the enterprise can add new services or update the existing services according to a modularization way to solve new business requirements, provide choices to provide the services through different channels, take the existing applications of the enterprise as the services and further protect existing IT infrastructure investment.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

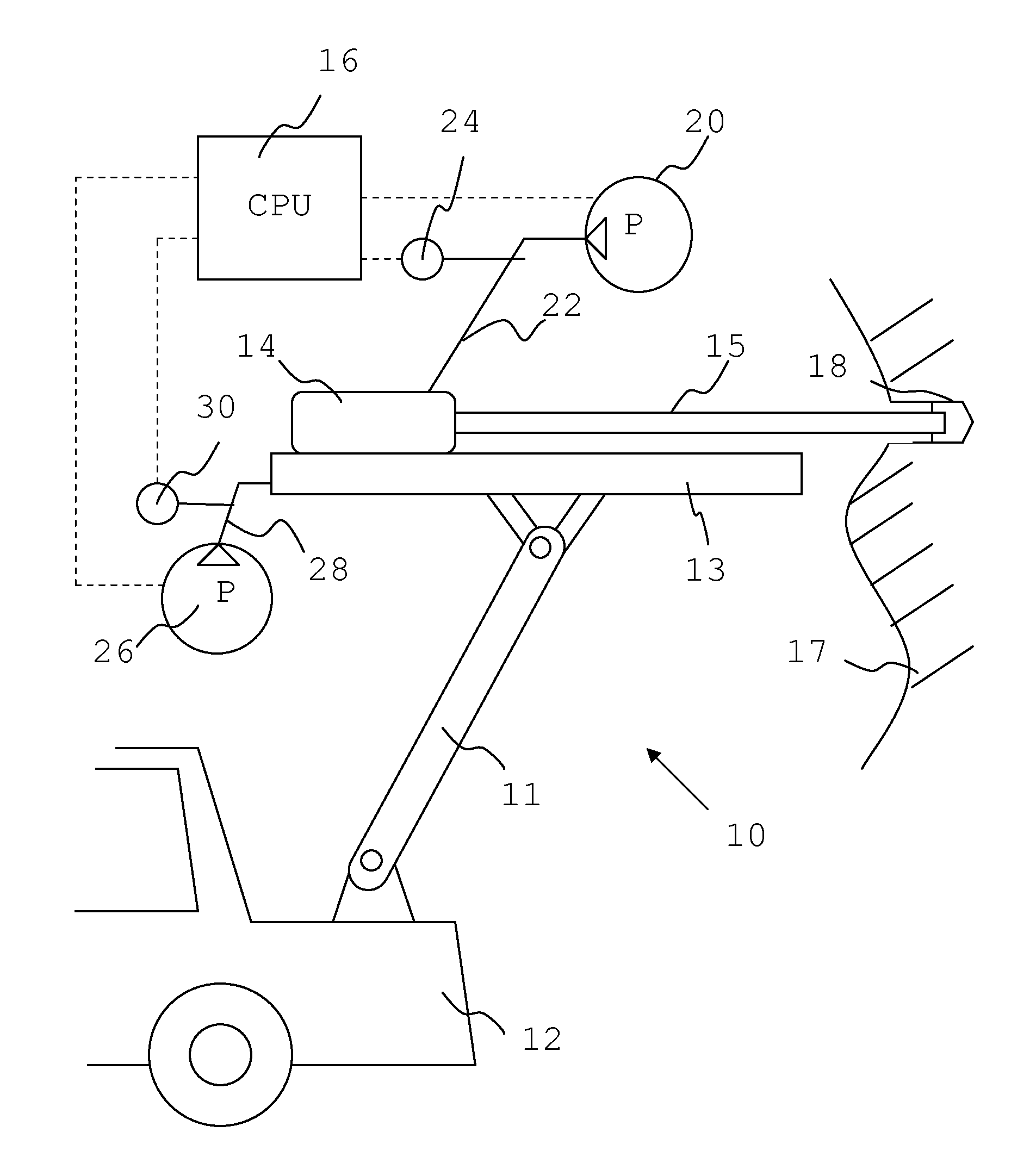

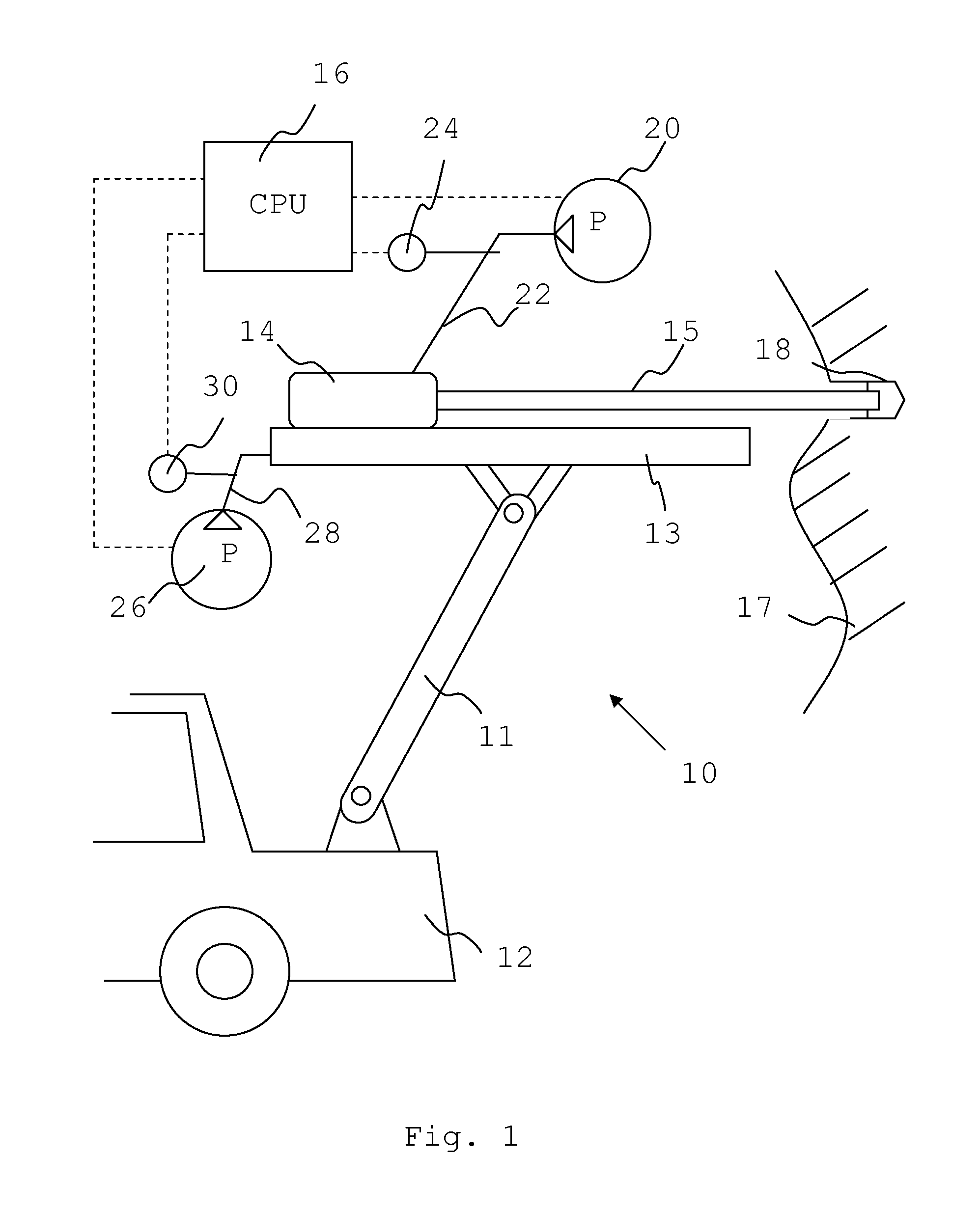

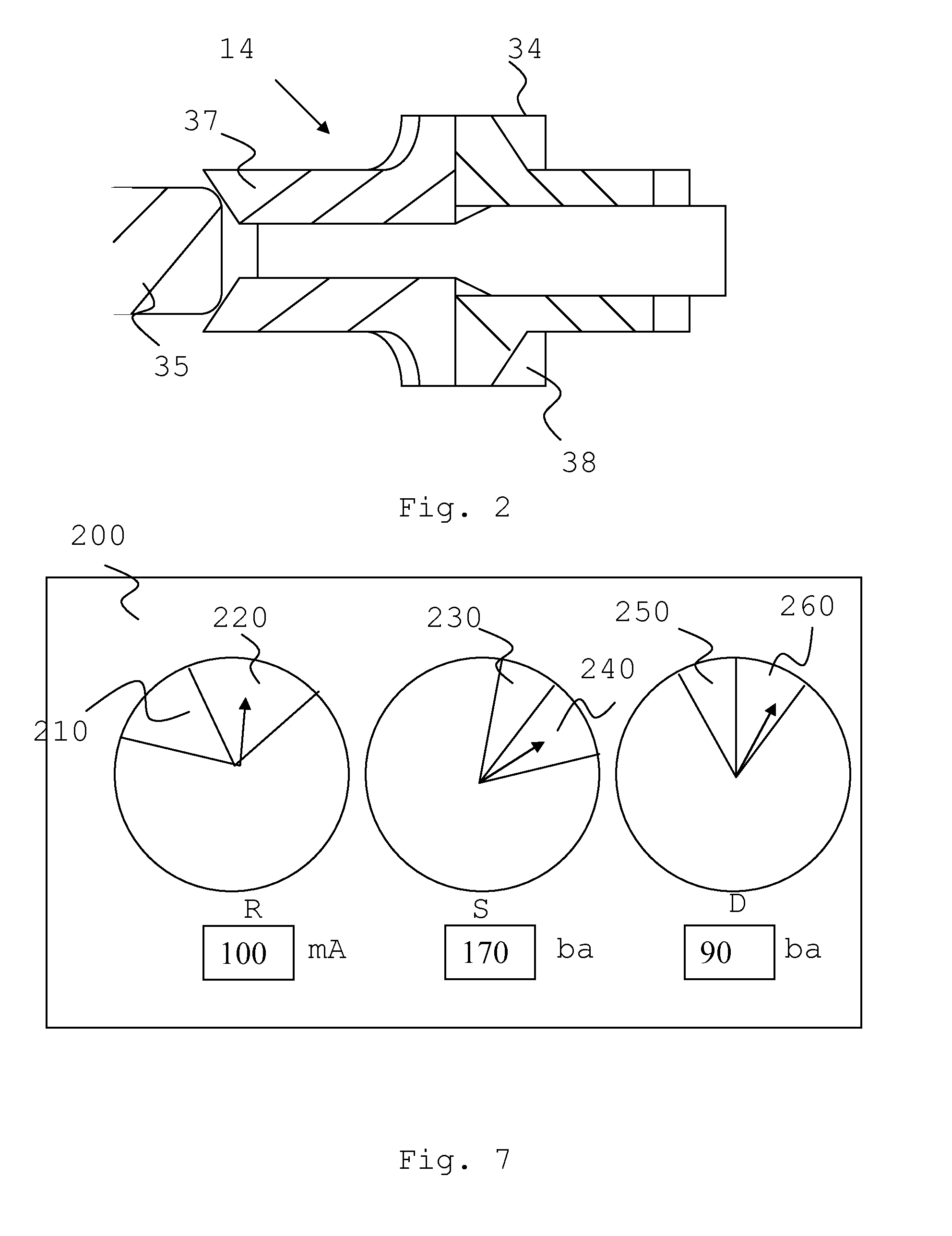

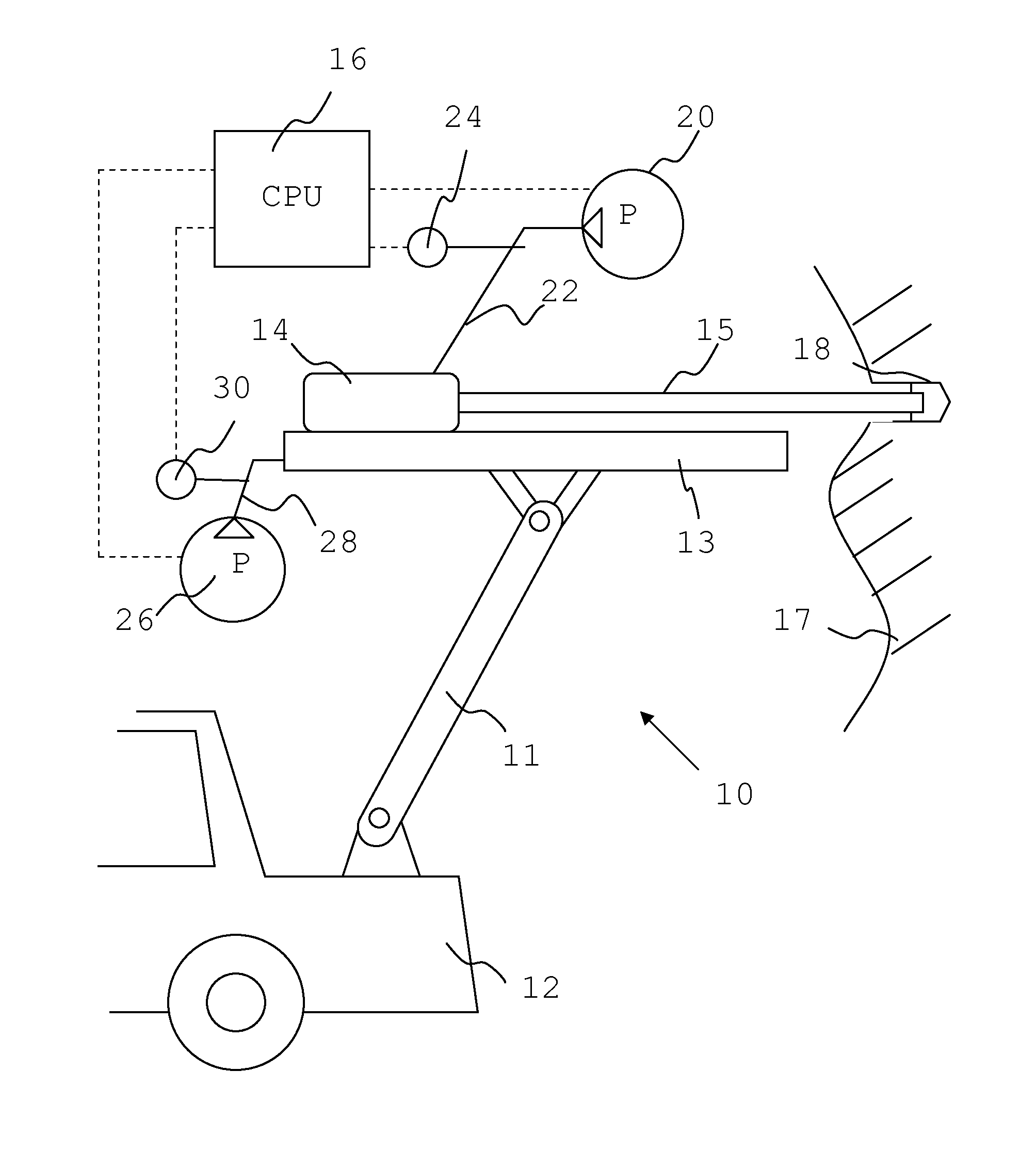

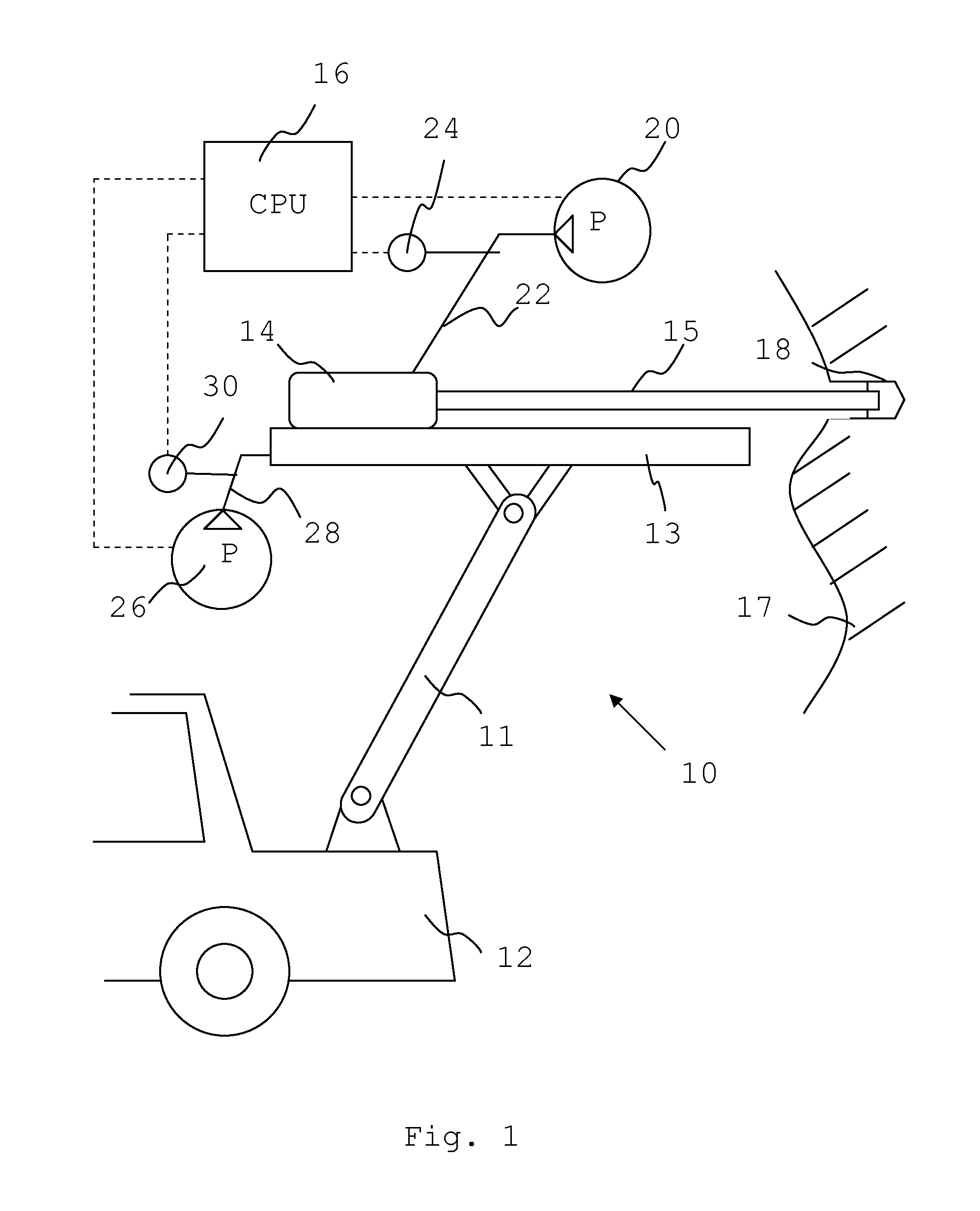

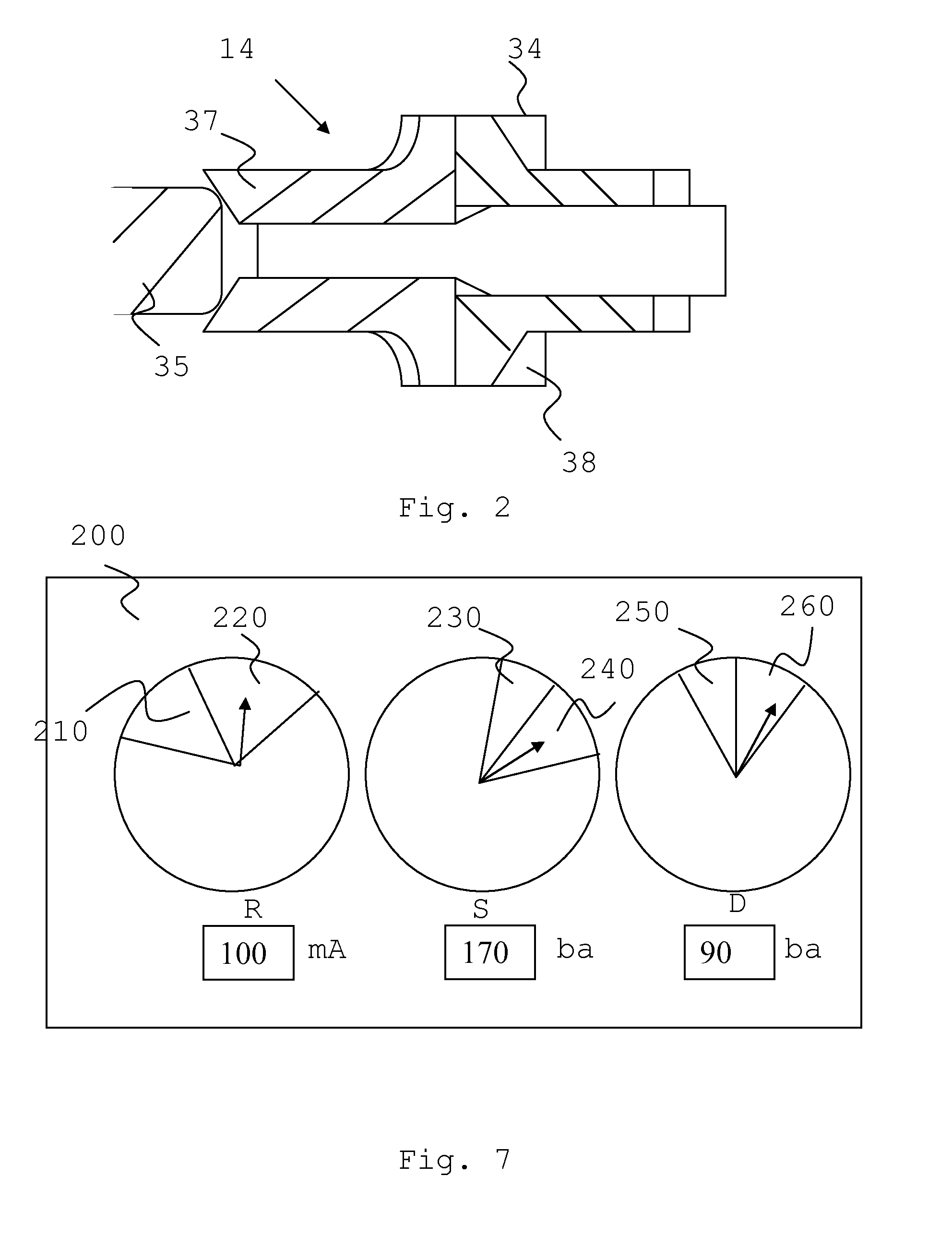

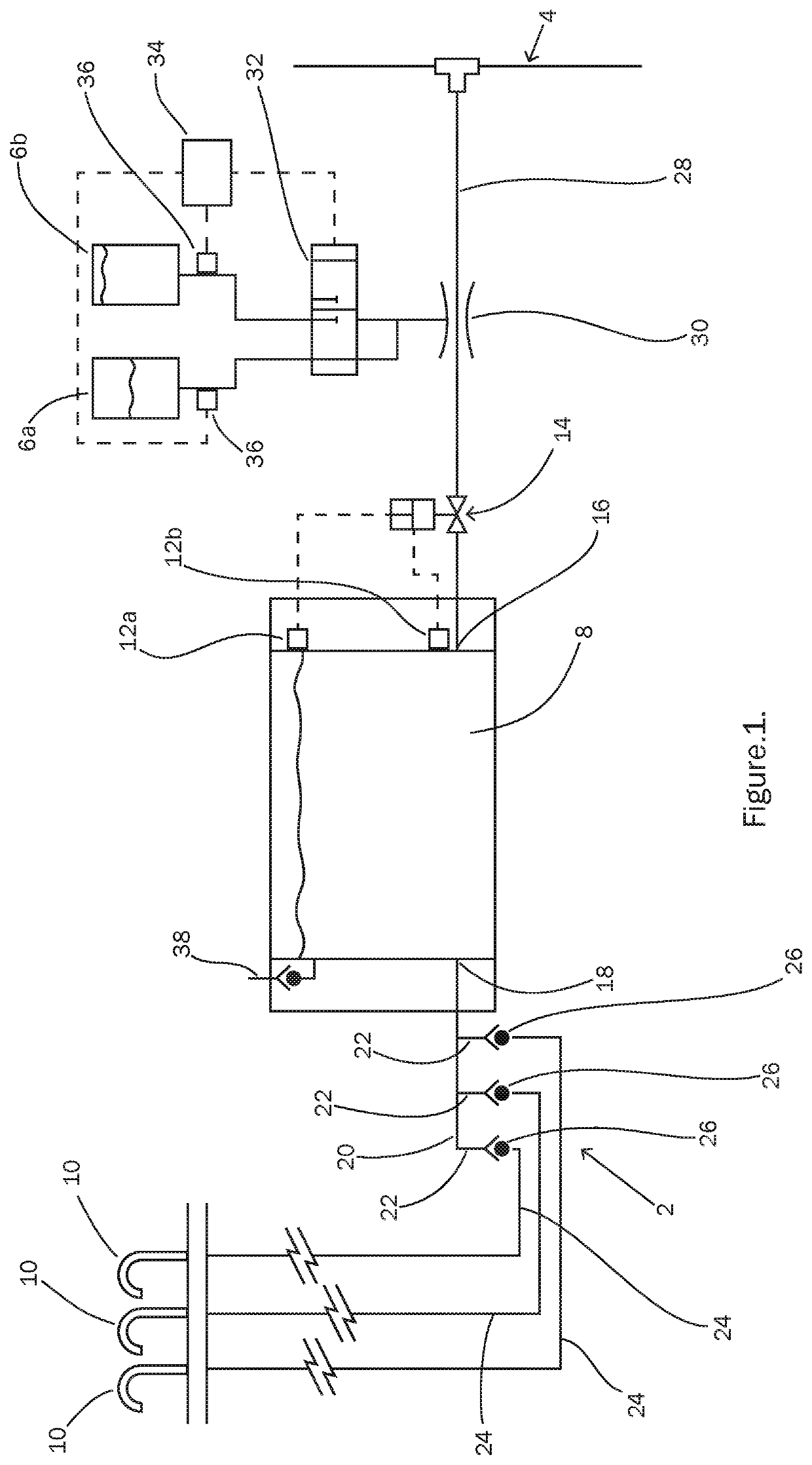

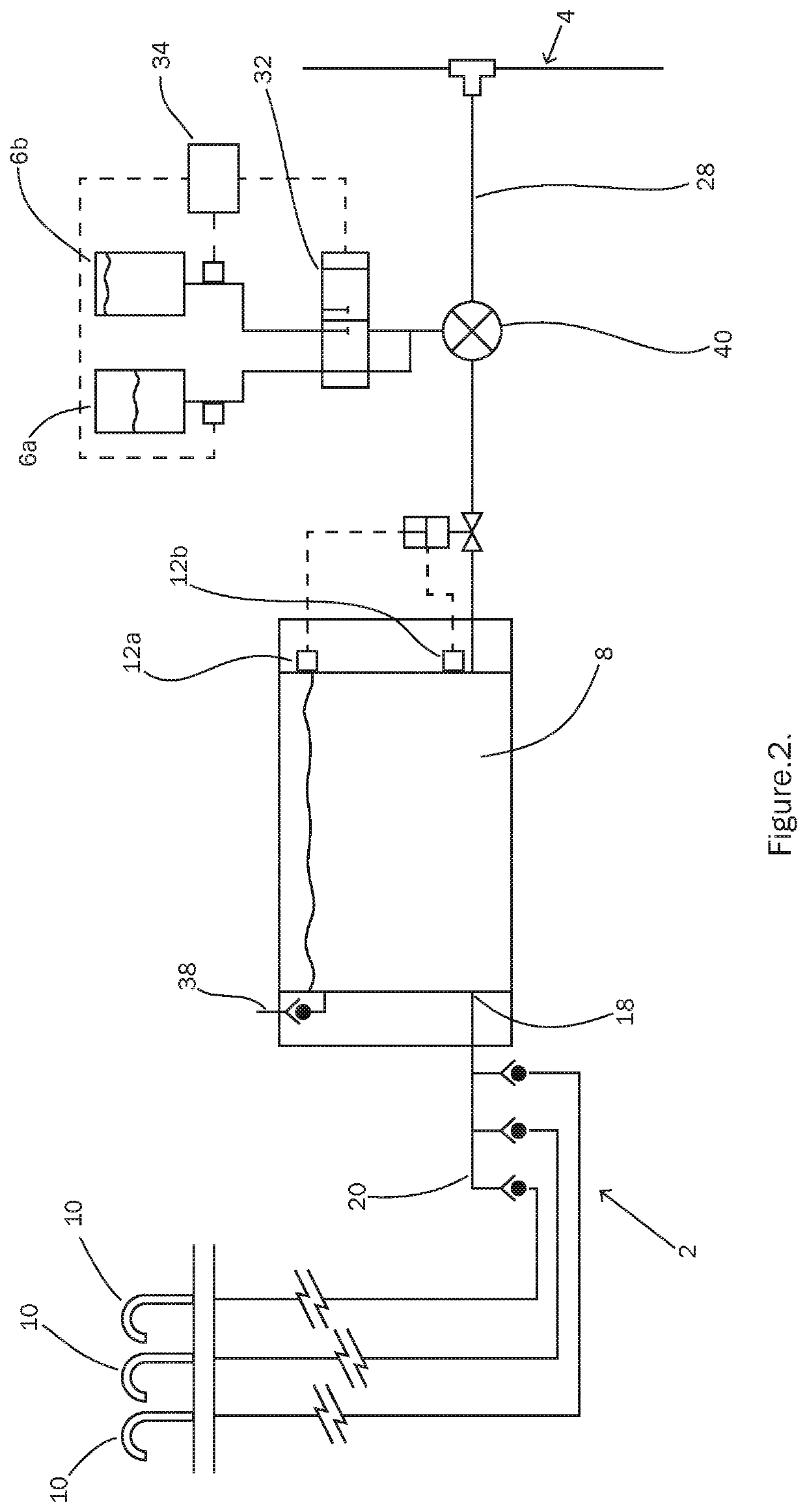

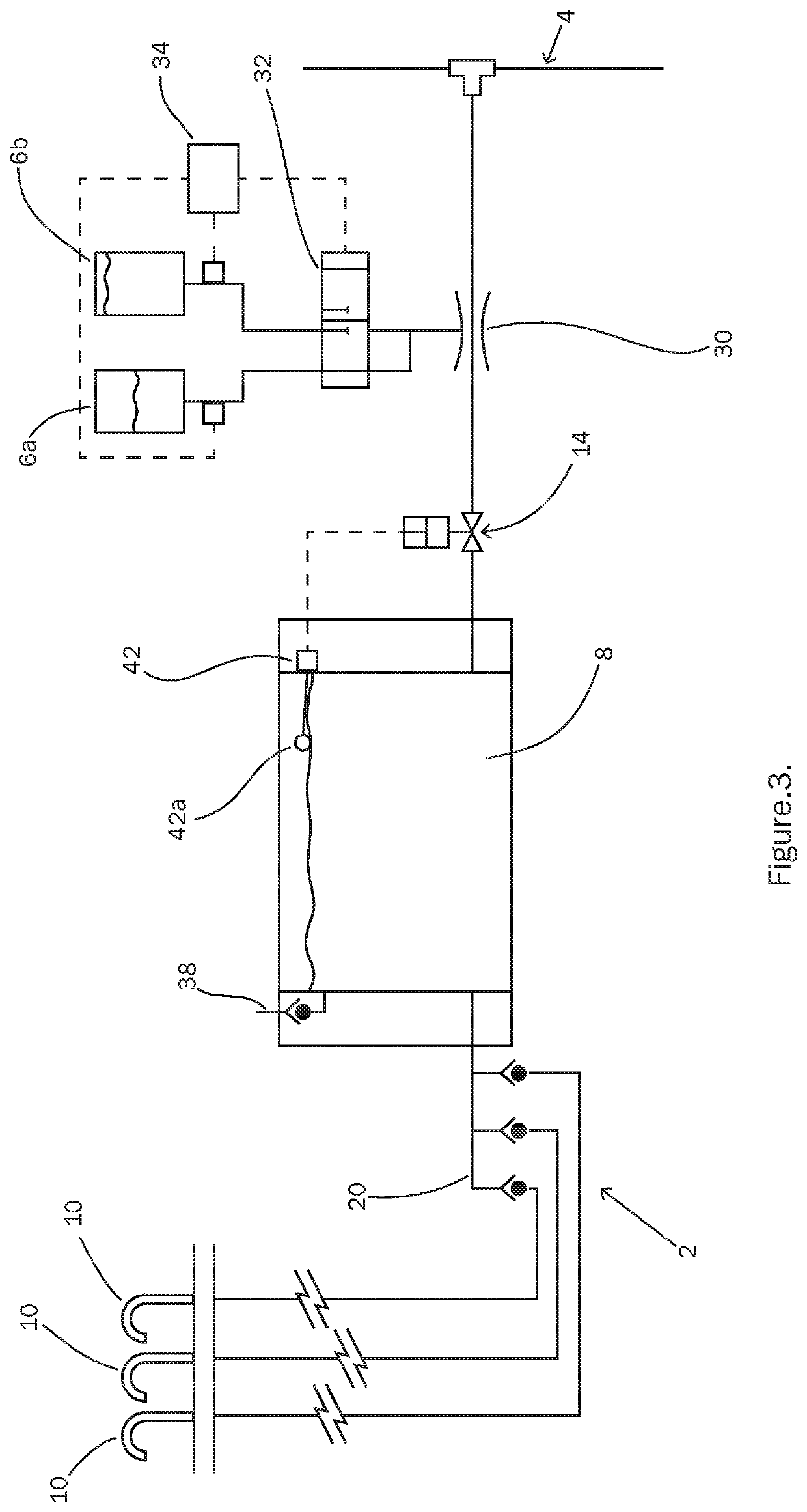

Method and an arrangement for controlling a rock drill

ActiveUS20110147084A1Small fluctuationAvoid damageSampled-variable control systemsDrill bitsShock waveControl system

An arrangement and a method for controlling at least one drill parameter when drilling in rock with a rock drill, comprising an impulse-generating device arranged to induce shock waves in a tool acting against the rock with a percussive force generated via a shock wave-generating pressure. The arrangement also comprises a rotation-generating device arranged to supply a torque to the impact device with a rotation generated via a rotation pressure, and a pressurisable damping chamber arranged to at least partially regulate the rock drill's contact with the rock via the prevailing pressure in the damping chamber, in which connection the shock wave-generating pressure is regulated depending on the rotation pressure. The arrangement comprises a control system arranged to: determine a first parameter value representing the damping pressure or feed pressure, determine a second parameter value representing the drill bit's rotation pressure, determine a deviation between the above second parameter value and a rotation pressure reference value, determine a parameter reference value depending on the above deviation and regulate the percussion pressure based on a function of the above deviation and the above parameter reference value.

Owner:EPIROC ROCK DRILLS AB

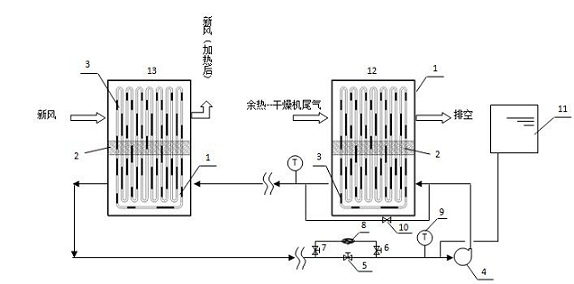

Long-distance waste heat recovery system of drying tail gas

ActiveCN101865622AFlexible systemSmall footprintIndirect heat exchangersDrying solid materialsHeat carrierProcess engineering

The invention relates to a long-distance waste heat recovery system of drying tail gas, which can effectively recover the waste heat of drier tail gas and transmit heat to a required node to preheat fresh air with lower energy consumption, and the preheated fresh air returns to a drying system to dry the material, therefore, the waste heat recycle is realized. The long-distance waste heat recovery system comprises a drying equipment tail gas heat source, wherein the heat source is connected with at least one first-level oscillatory flow heat pipe, the oscillatory flow heat pipe heats a heat carrier in a long-distance conveyer device, a plurality of second-level oscillatory flow heat pipes for acquiring heat energy are arranged on the long-distance conveyer device, and a control device is arranged on the long-distance conveyer device.

Owner:SHAN DONG TIAN LI DRYING EQUIP

Subsea hydrocarbon production system

A subsea oil and / or gas production system comprises a host production facility and a plurality of subsea wells. A fluid conveying network is provided that connects each subsea well to the host production facility. A separate electrical power and data network is provided for conveying direct current electrical power and data, operatively connected to each subsea well for providing each subsea well with data transfer and electrical power services. The use of direct current ensures that the electrical power and data network can provide power over much greater distances than currently available, and the use of separate networks for conveying fluids and for providing electrical power and data transfer allows for a much more flexible system.

Owner:DEN NORSKE STATS OLJESELSKAP AS

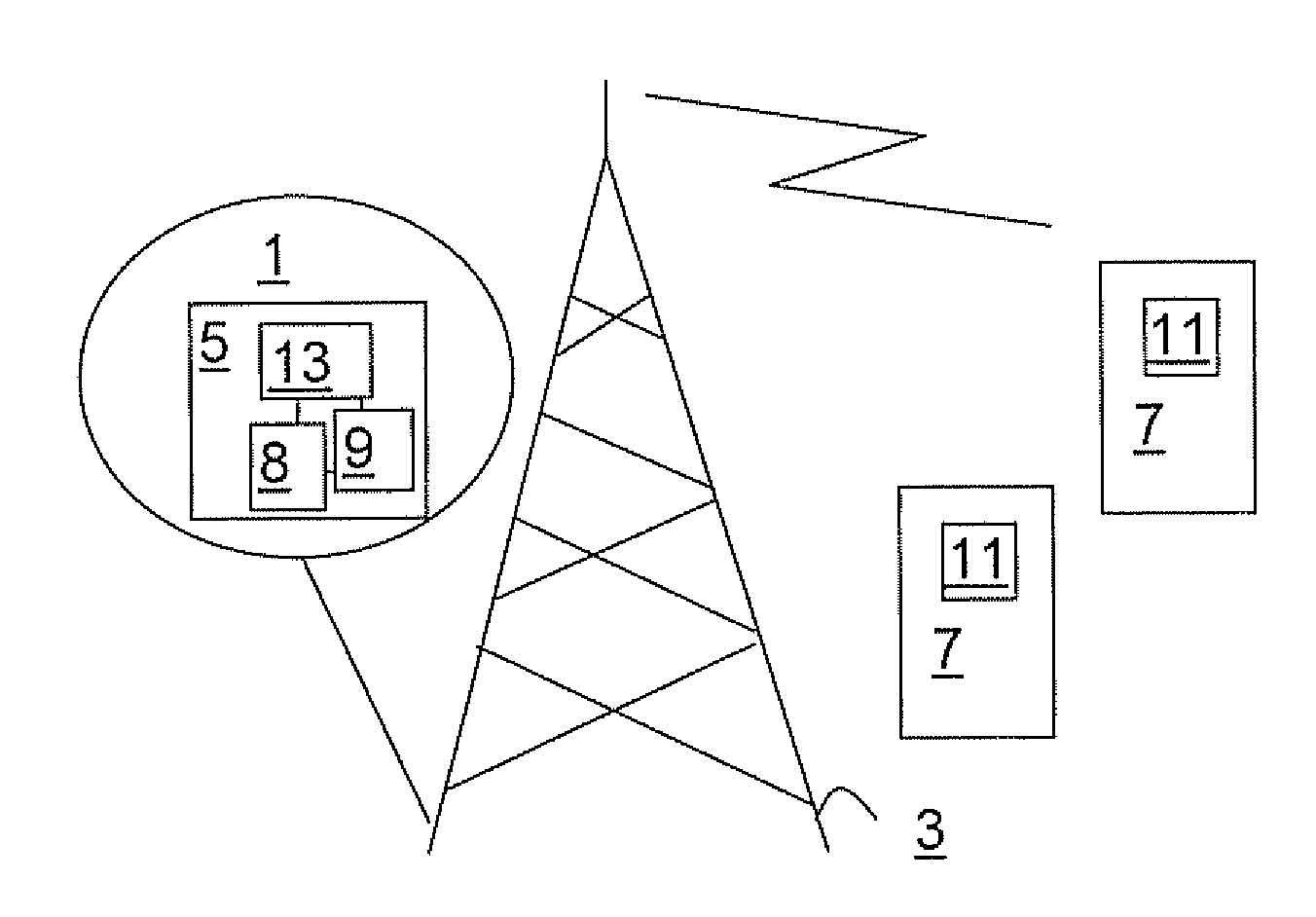

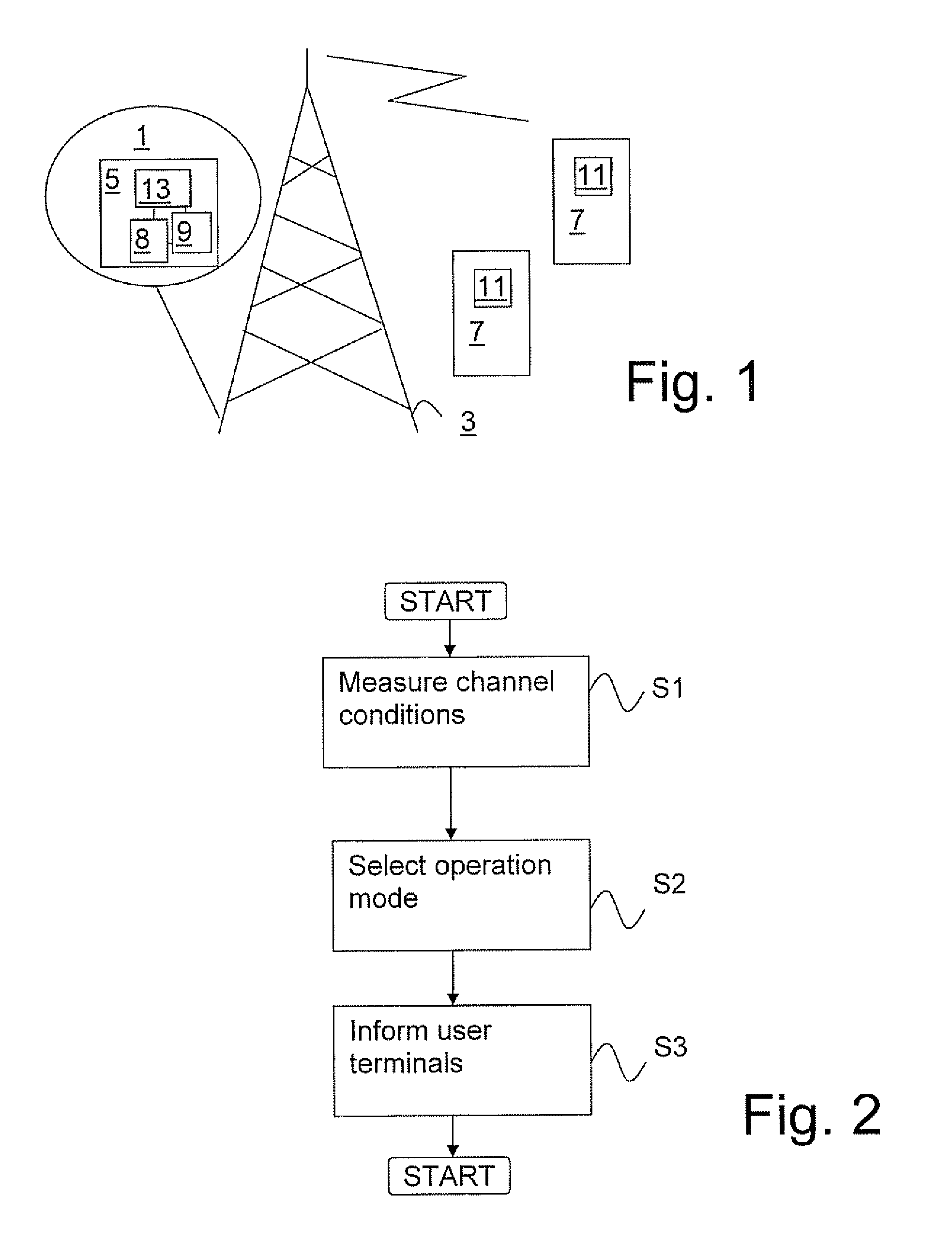

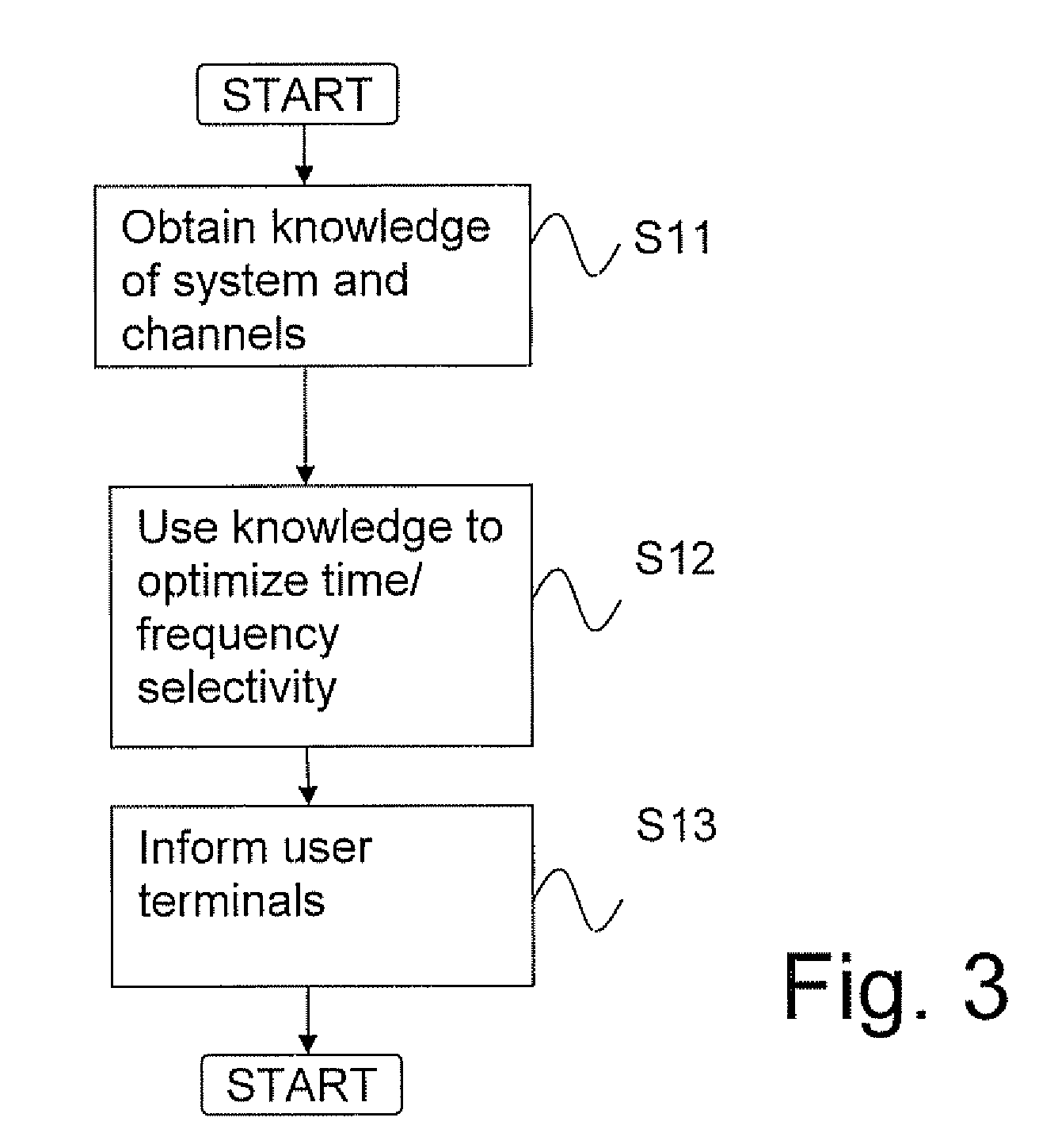

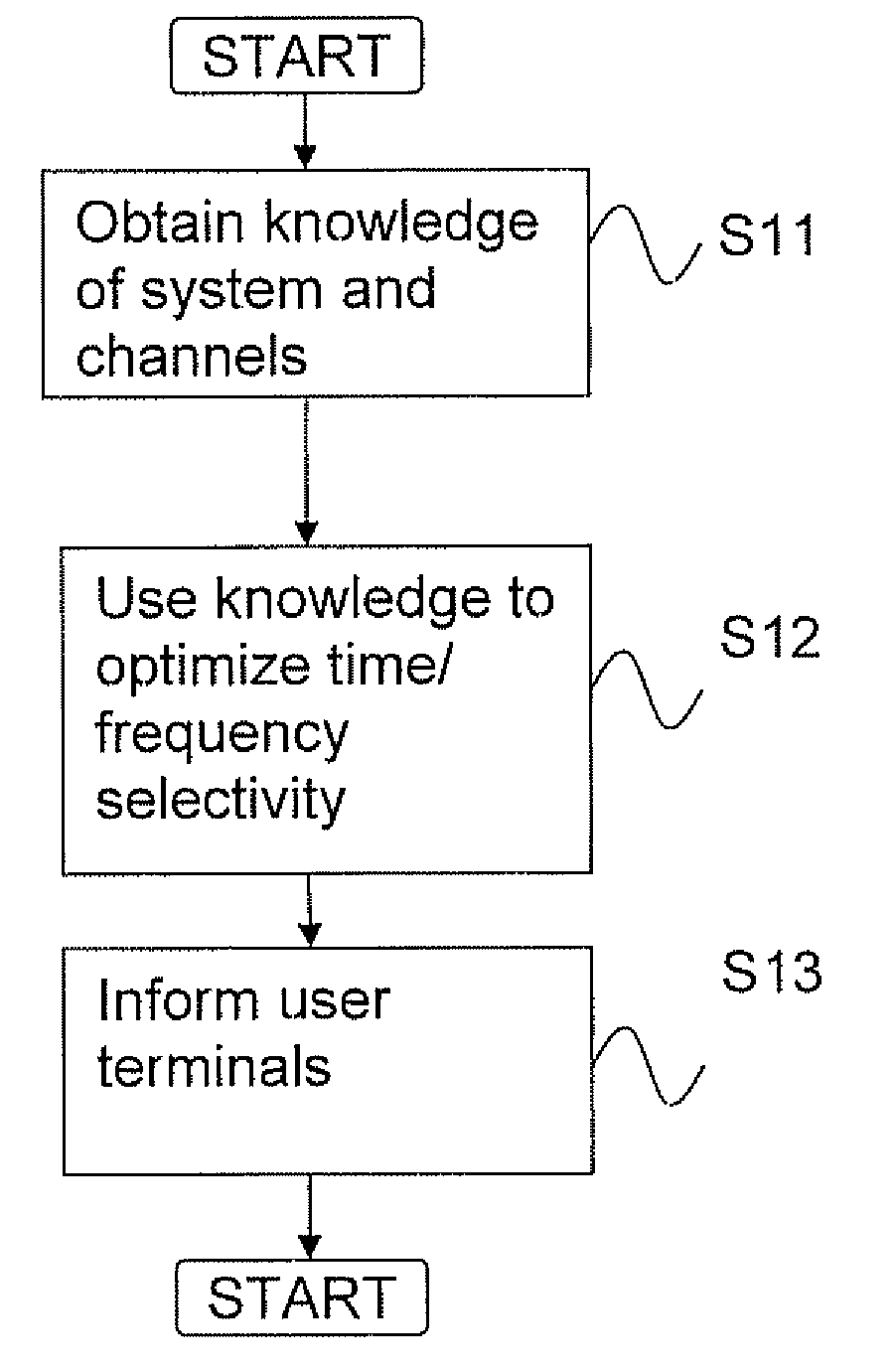

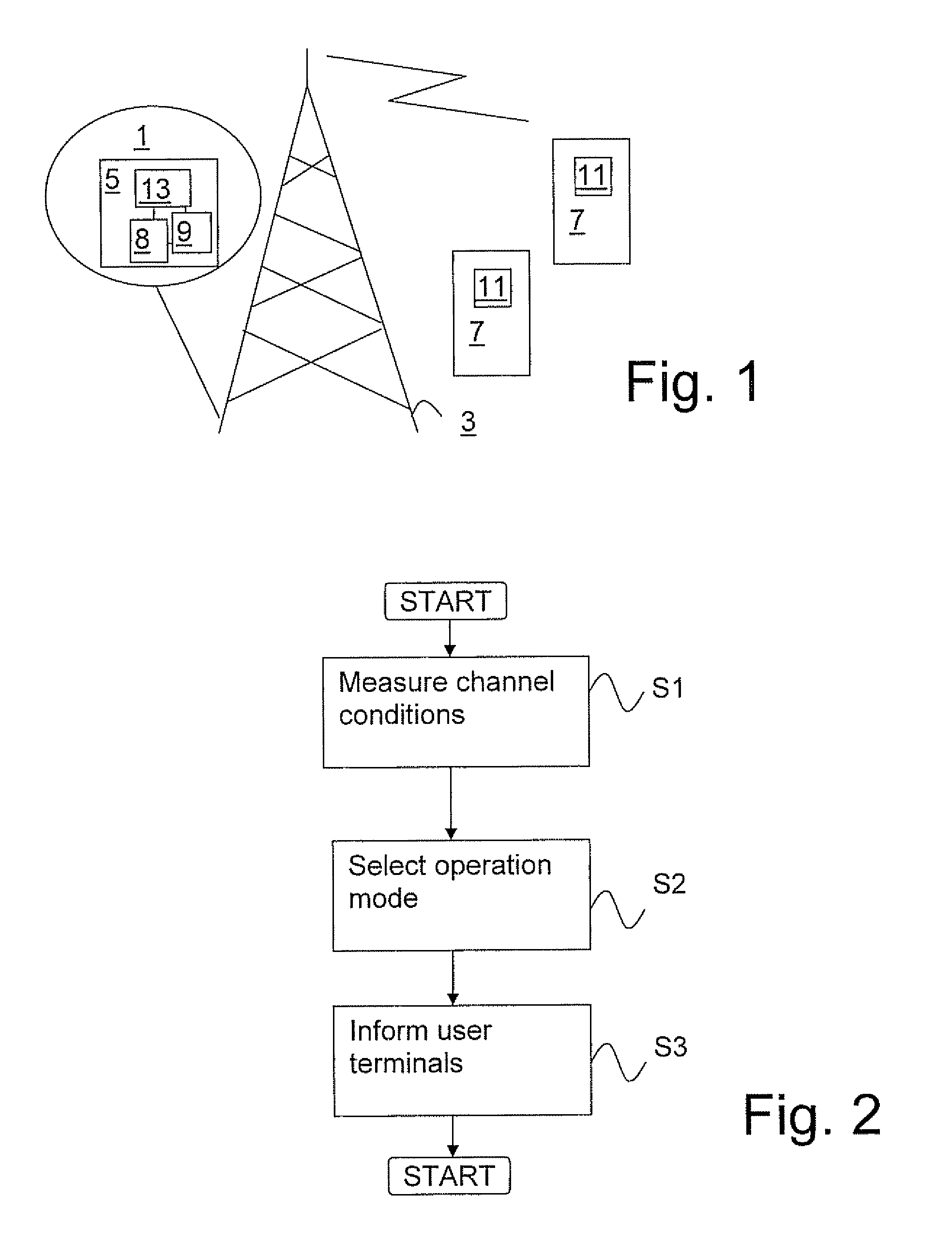

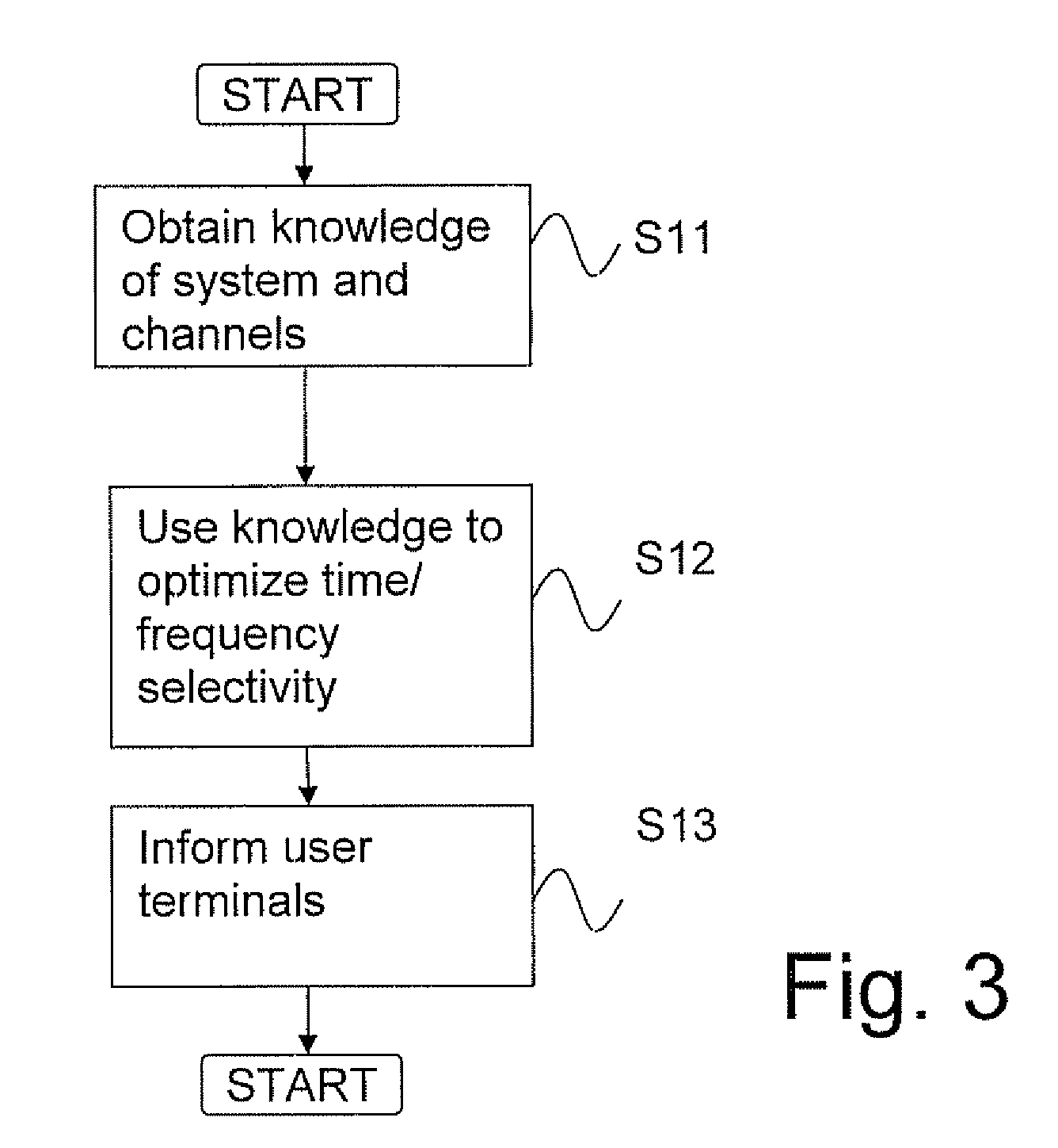

Method and apparatus for improved single cell adaption due to change in environment

ActiveUS20100046382A1Improve abilitiesReduce overheadReceivers monitoringSpatial transmit diversityTelecommunicationsFrequency selection

A communication method for use in a wireless communications network is proposed, said method comprising the steps of—monitoring at least one property representative of the channel variability in time and / or frequency, for each of at least two channels in the cell, used to communicate with said at least two user terminals;—using the result of the monitoring to control, by a control node in the network or in one of the user terminals, the communication in the cell. The control of the communication may include artificially inducing time selectivity and / or frequency selectivity or selecting an operating mode for the cell.

Owner:TELEFON AB LM ERICSSON (PUBL)

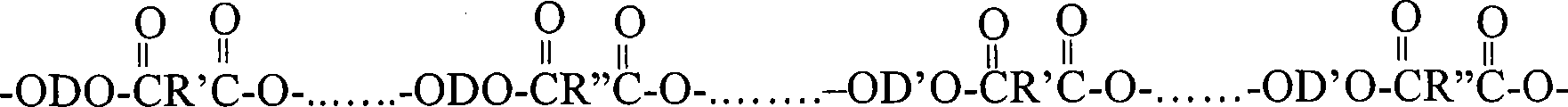

Process for making polybutylene terephthalate (PBT) from polyethylene terephthalate (PET)

InactiveCN101415746AFlexible general systemFlexible systemPlastic recyclingPolytetramethylene terephthalatePolyethylene terephthalate glycol

The invention relates to a process for making modified polybutylene terepththalate random copolymers from a polyethylene terephthalate component. In one embodiment, the invention relates to a two step process in which a 1,4-butane diol component reacts with a polyethylene terephthalate component under conditions that depolymerize the polyethylene terephthalate component into a molten mixture and the molten mixture is placed under subatmospheric conditions that produce the modified polybutylene terepththalate random copolymers. In another embodiment, the invention relates to a three step process in which a diol component selected from the group consisting of ethylene glycol, propylene glycol, and combinations thereof reacts with a polyethylene terephthalate component under conditions sufficient to depolymerize the polyethylene terephthalate component into a first molten mixture; and where the first molten mixture is combined with 1,4-butane diol under conditions that create a second molten mixture that is subsequently placed under subatmospheric conditions that produce the modified polybutylene terepththalate random copolymers. The invention also relates to compositions made from processes of the invention.

Owner:SABIC INNOVATIVE PLASTICS IP BV

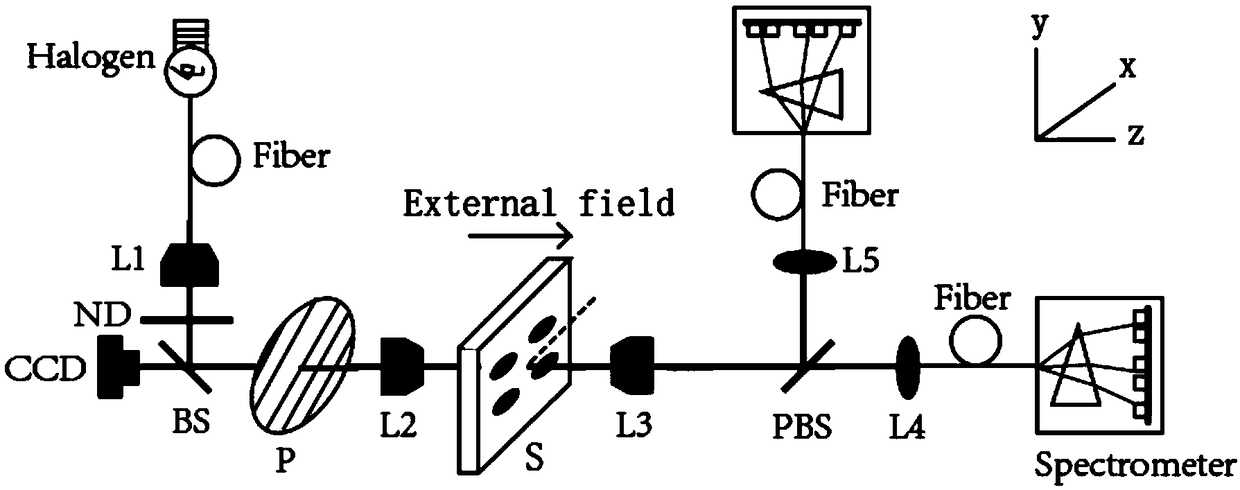

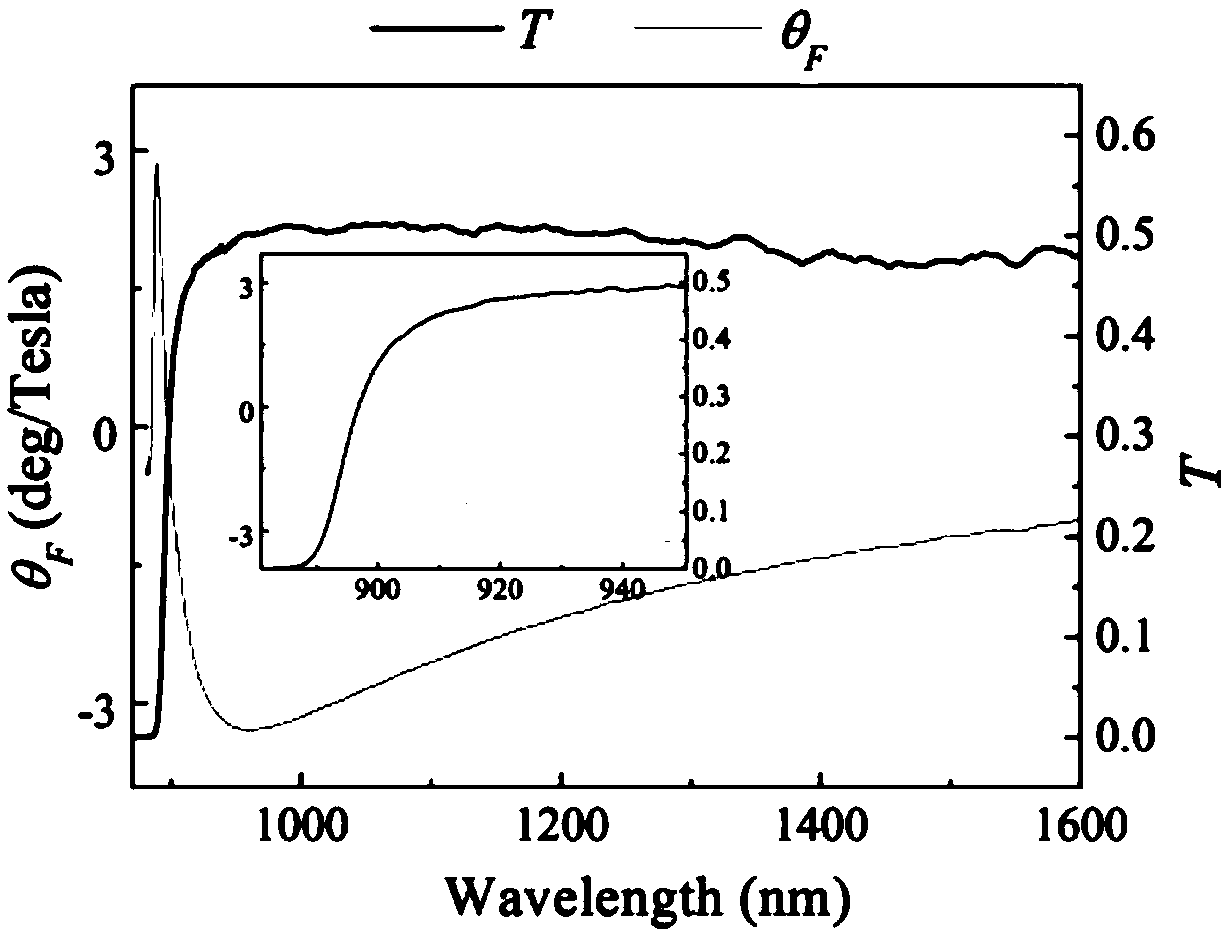

Microscopic polarization spectral analysis system and method

InactiveCN109405971ASuppression of common mode noiseImprove signal-to-noise ratioPolarisation spectroscopySpectrographPolarization beam splitter

The present invention provides a microscopic polarization spectral analysis system. The system comprises a white light source, a polarization system, a polarization analysis system and a microscopic imaging system. A sample is arranged between the polarization system and the polarization analysis system; the polarization system comprises an optical polarizer rotated around a center shaft; the polarization analysis system comprises a polarization beam splitter, a first spectrograph and a second spectrograph, and the polarization beam splitter is connected with the first spectrograph and the second spectrograph through optical fibers; and the microscopic imaging system comprises an objective lens arranged at the front of the sample and an imaging lens arranged at the front of a camera. The system is suitable for the whole spectral region from ultraviolet to infrared, simple to construct and can measure the magneto-optic features of the whole spectrum.

Owner:南京昆腾科技有限公司

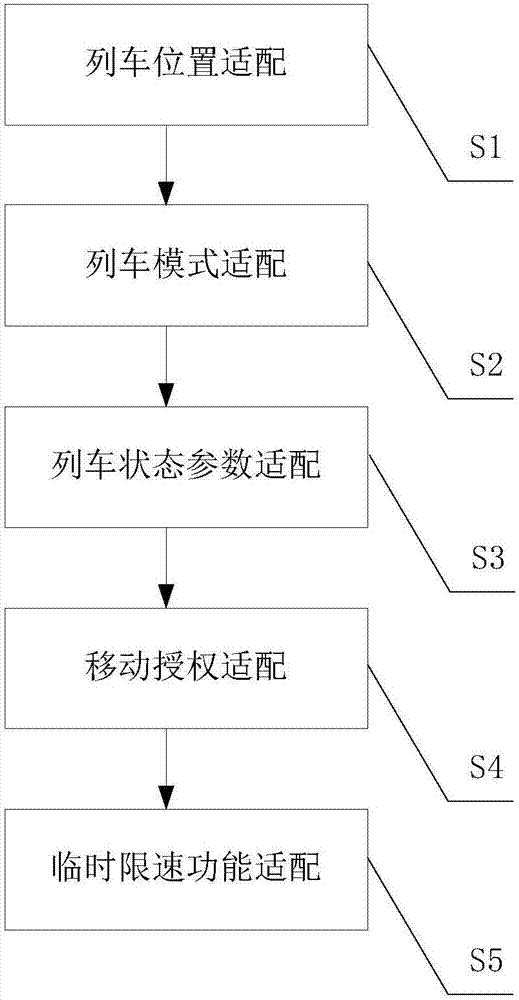

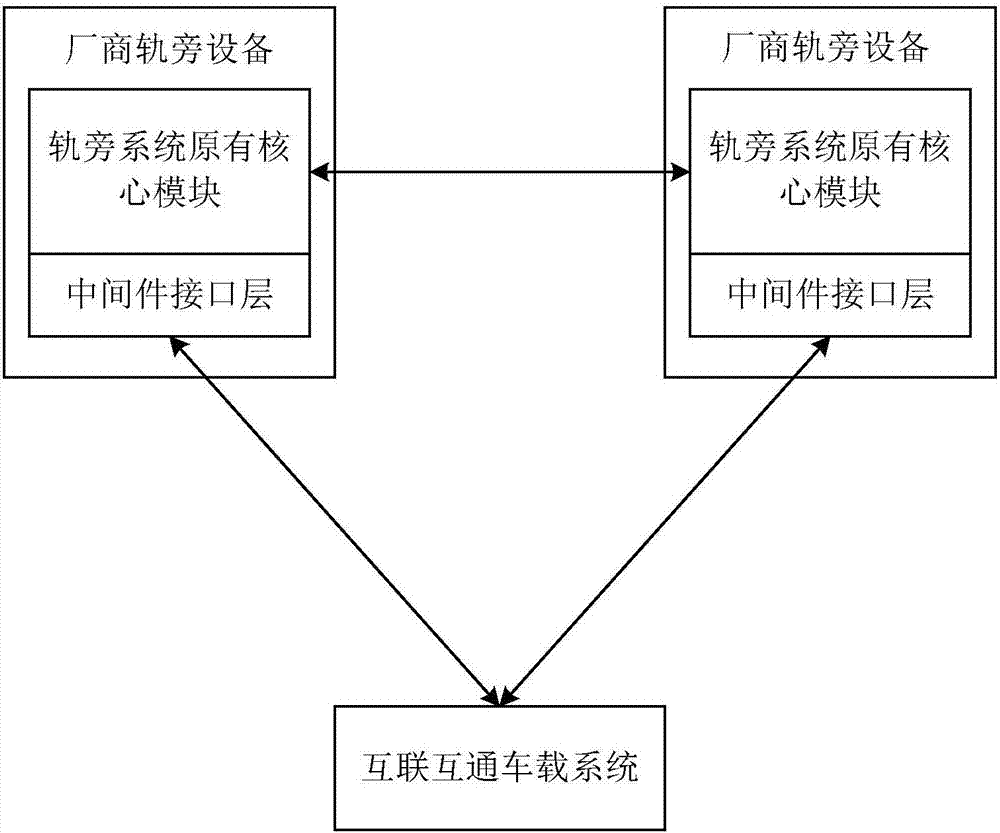

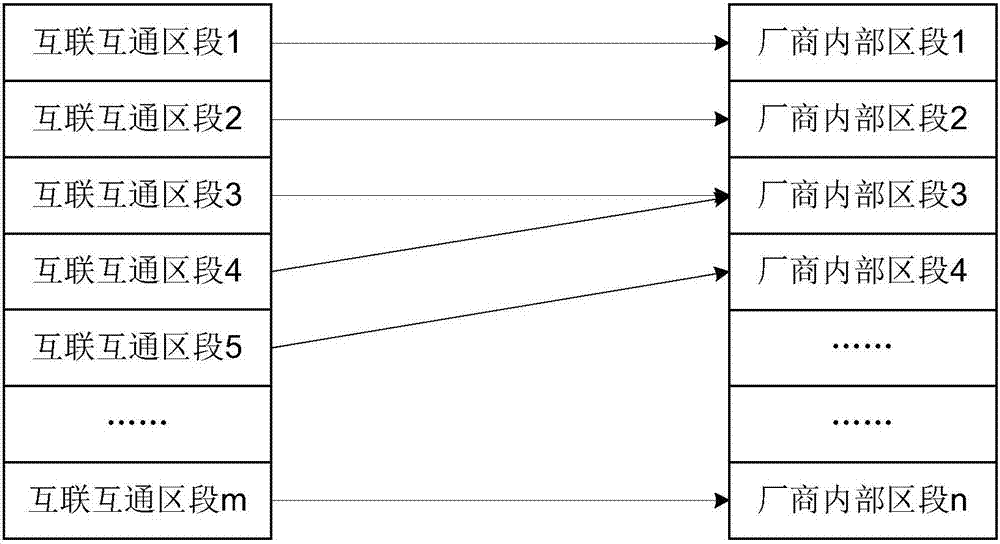

Middleware adapting method used for allowing trackside system to be compatible with train-mounted systems of different manufacturers

ActiveCN107215362AAvoid design costs and system risksFlexible systemGeometric CADRailway traffic control systemsSystem structureAuthorization

The invention discloses a middleware adapting method used for allowing a trackside system to be compatible with train-mounted systems of different manufacturers. The method based on a middleware system interface layer arranged in the trackside system includes: train mode adapting; train state parameter adapting; movement authorization adapting and temporary speed limitation function adapting. The method has the advantages that the information of the train-mounted systems of different manufacturers is converted into information which can be identified by trackside equipment through the universal interface layer, then the information is treated, and the treatment results are converted into information which can be identified by the train-mounted systems of different manufacturers; seamless, intercommunicated, safe and reliable operation of trains equipped with train-mounted equipment of different signal manufacturers on one track transit line equipped with trackside equipment of different signal manufacturers or multiple track transit lines equipped with trackside equipment of different signal manufacturers can be achieved, and design cost and system risks caused by large-scale modification of an existing system structure.

Owner:SHANGHAI ELECTRIC THALES TRANSPORTATION AUTOMATION SYST CO LTD

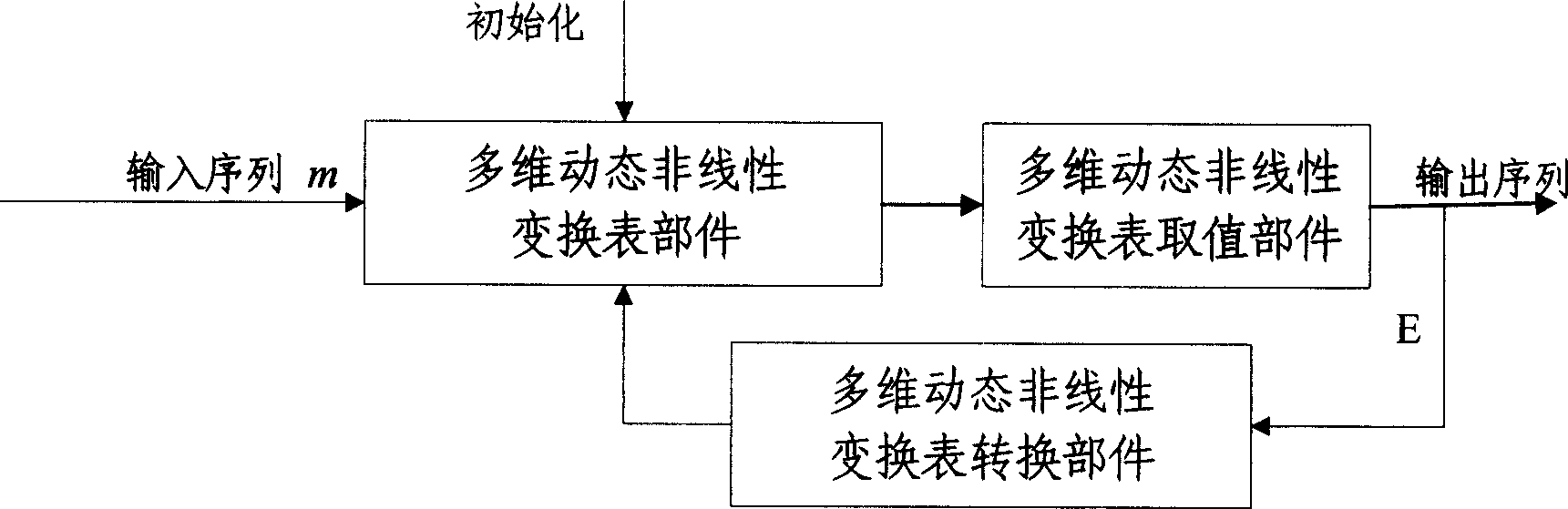

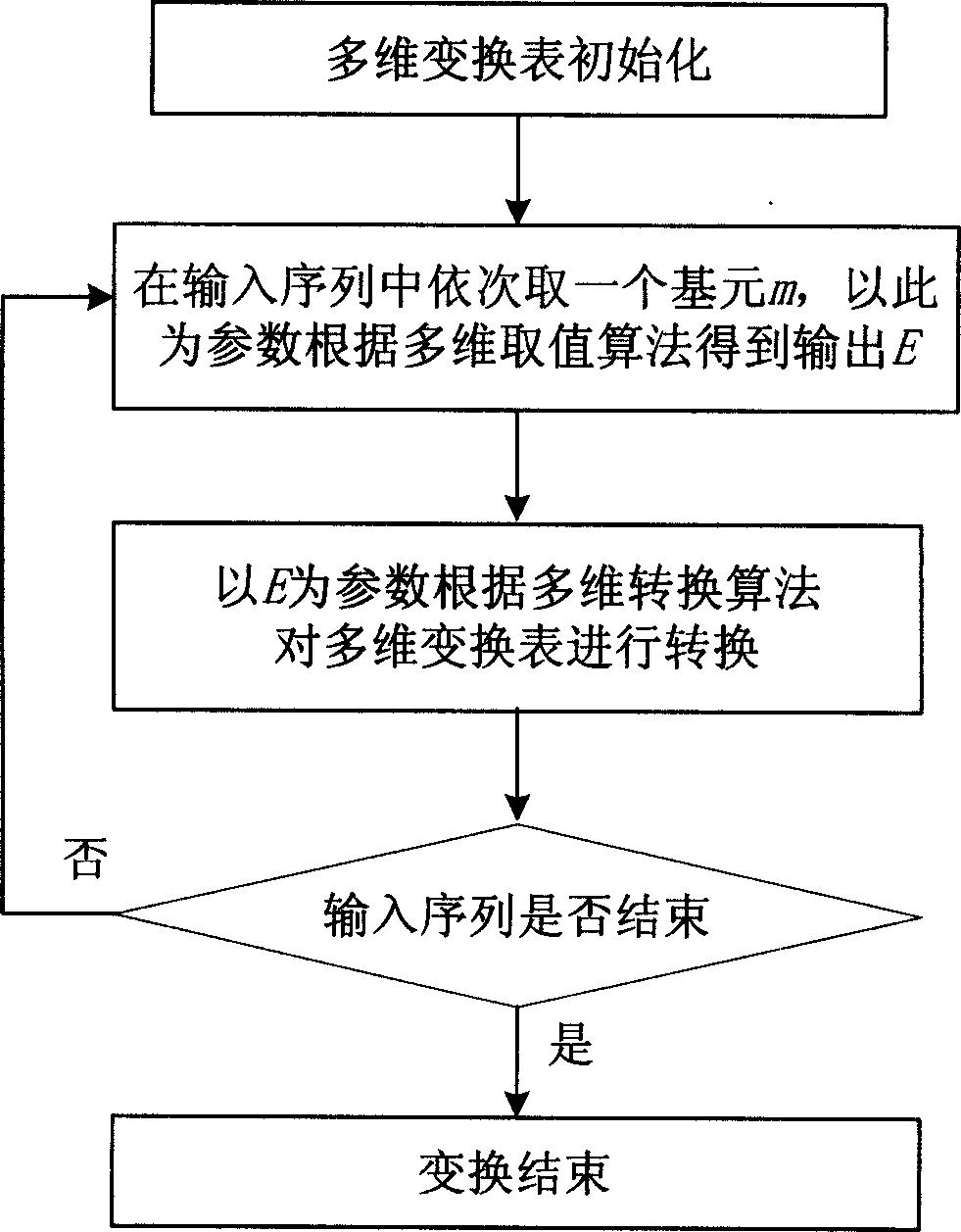

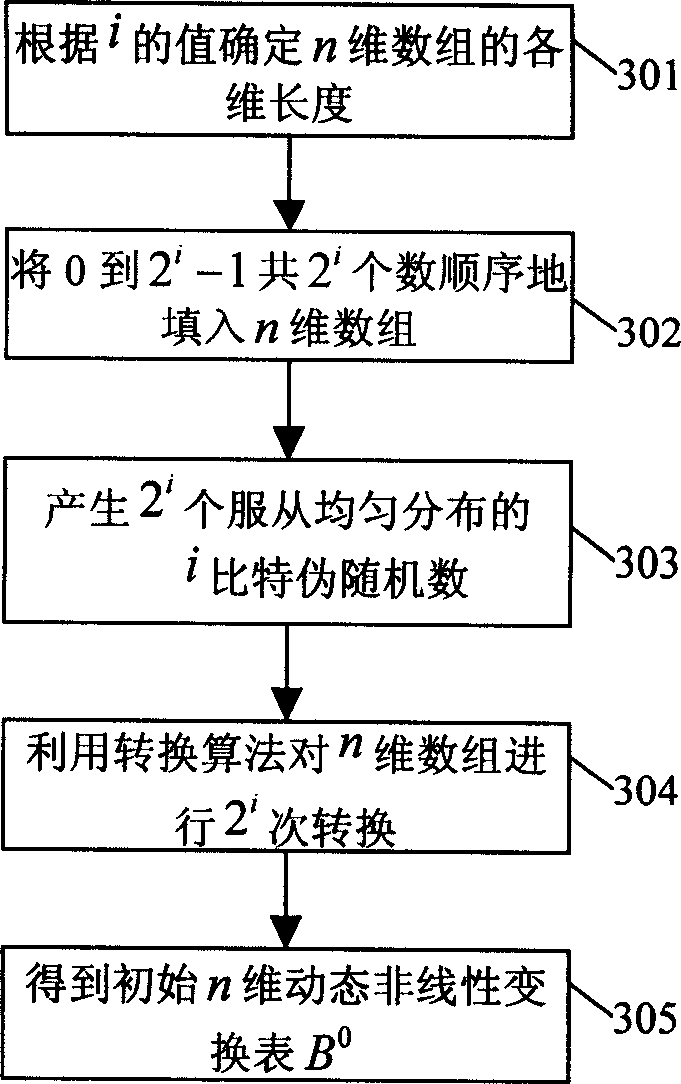

System and methof of carrying out multiple dimentional dynamic non-linear transform for input sequence

InactiveCN1916837ALong cycleReduce correlationRandom number generatorsTransformation algorithmLinear transform

A method for carrying out multidimensional dynamic nonlinear transform MDNT on input sequence includes finalizing initialization of MDNT table (MDNTT), obtaining input value from input sequence and using said input value as parameter to obtain output value according to value-taking algorithm of MDNTT, using said output value as parameter to carry out conversion on MDNTT according to conversion algorithm of MDNTT, naming converted MDNTT to be B1 and using obtained B1 as Bo of next circulation, judging whether input sequence is ended or not, ending transform if it is or otherwise obtaining input value to make transform continuously.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Pretreatment method of liquid hazardous waste

InactiveCN110194549AFlexible systemReduce manufacturing costWater/sewage treatment by irradiationWater contaminantsChemistryHigh concentration

The invention discloses a pretreatment method of liquid hazardous waste, the method comprises the following steps: A1, receiving: classifying is performed according to organic matter concentrations inwaste liquids, a waste liquid with the organic matter concentration more than 2000 mg / L is a high-concentration organic waste liquid, and a waste liquid with the organic matter concentration not morethan 2000 mg / L is a low-concentration organic waste liquid; A2, impurity removal; A3, storage: a liquid storage tank is completely sealed and immersed into groundwater to avoid direct sunlight; A4, disposal in a furnace, the high-concentration organic waste liquid in the A 1 has certain danger, after being collected on site, the high-concentration organic waste liquid is stored for no more than 12 hours, after oxidation treatment, the high-concentration organic waste liquid is directly mixed with pulverized coal and sent to a boiler burner for disposal; the low-concentration organic waste liquid in the liquid storage tank in the A2 is mixed with pulverized coal after atomization treatment, and then sent to the boiler burner for disposal. The pretreatment method is one of various treatmentmethods for treating the hazardous waste and municipal solid waste, has high cost performance, can realize reduction, hazard-free treatment and recycling.

Owner:WUHAN YONGQING ENVIRONMENTAL PROTECTION TECH ENG

Method and apparatus for improved single cell adaption due to change in environment

ActiveUS8009622B2Reduce overheadFlexible systemSpatial transmit diversityReceivers monitoringTelecommunicationsOperation mode

A communication method for use in a wireless communications network is proposed, said method comprising the steps of—monitoring at least one property representative of the channel variability in time and / or frequency, for each of at least two channels in the cell, used to communicate with said at least two user terminals; —using the result of the monitoring to control, by a control node in the network or in one of the user terminals, the communication in the cell. The control of the communication may include artificially inducing time selectivity and / or frequency selectivity or selecting an operating mode for the cell.

Owner:TELEFON AB LM ERICSSON (PUBL)

Next generation terrestrial broadcasting platform aligned internet and towards emerging 5G network architectures

ActiveUS10652624B2Flexible systemNetwork traffic/resource managementMultiple digital computer combinationsService-level agreementVirtualization

Owner:SINCLAIR BROADCAST GRP

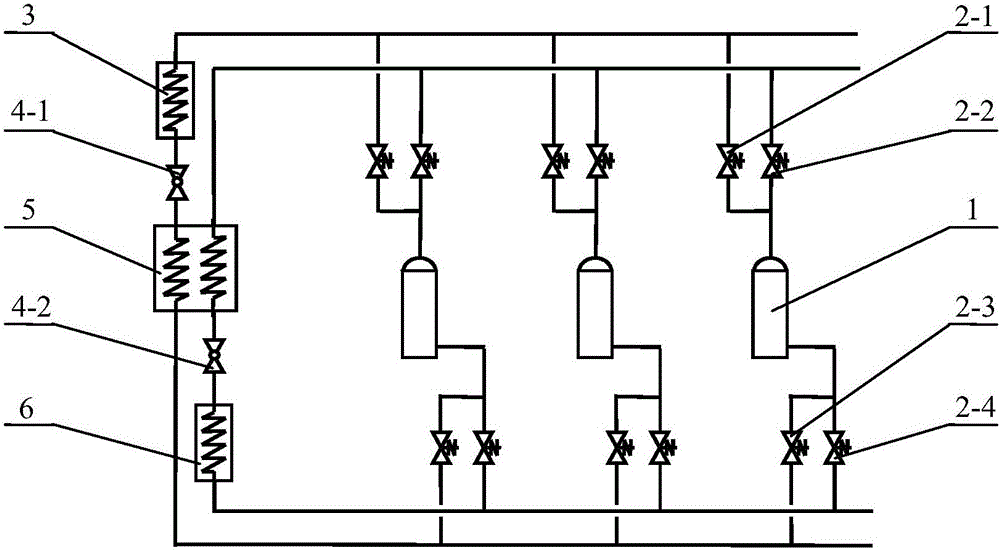

Variable-flow single-working medium cascade refrigeration system with common condenser and common evaporator

ActiveCN105758047AFlexible systemFacilitate energy regulation between stagesMechanical apparatusCompression machines with cascade operationEvaporatorEngineering

The invention discloses a variable-flow single-working medium cascade refrigeration system with a common condenser and a common evaporator. According to the invention, each refrigeration compressor unit is composed of a refrigeration compressor and four electromagnetic valves, wherein an exhaust end of the refrigeration compressor is connected with the corresponding first electromagnetic valve and the corresponding second electromagnetic valve; a suction end of each refrigeration compressor is connected with the corresponding third electromagnetic valve and the corresponding fourth electromagnetic valve; the first electromagnetic valves connected to the refrigeration compressors are connected in parallel and then are connected with an inlet in the condenser; the second electromagnetic valves connected to the refrigeration compressors are connected in parallel and then are connected with a condensation side inlet in a condensation evaporator; the third electromagnetic valves connected to the refrigeration compressors are connected in parallel and then are connected with an evaporation side outlet in the condensation evaporator; the fourth electromagnetic valves connected to the refrigeration compressors are connected in parallel and then are connected with an outlet in the evaporator; an outlet in the condenser is connected with an evaporation side inlet in the condensation evaporator through a high temperature level throttle valve; a condensation side outlet in the condensation evaporator is connected with an inlet in the evaporator through a low temperature level throttle valve. The cascade refrigeration system of the invention is formed by single working medium, and does not contain an expansion container and other devices, so that the structure is simple.

Owner:TIANJIN UNIV OF COMMERCE

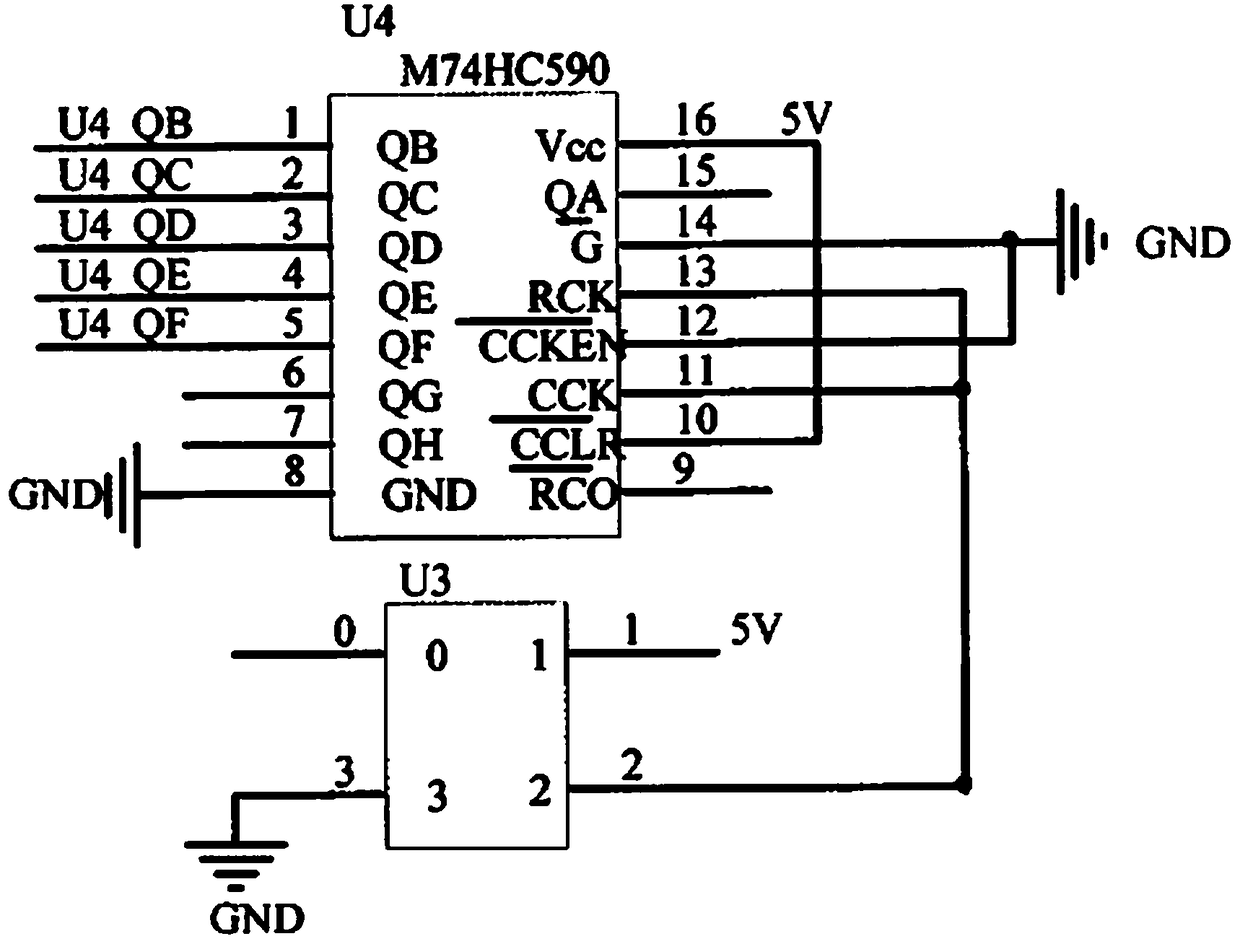

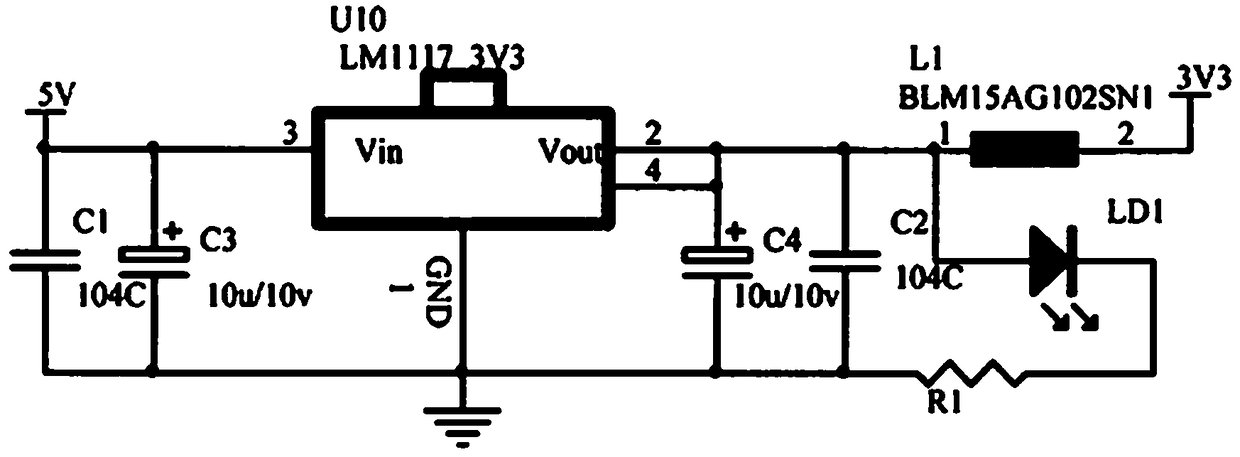

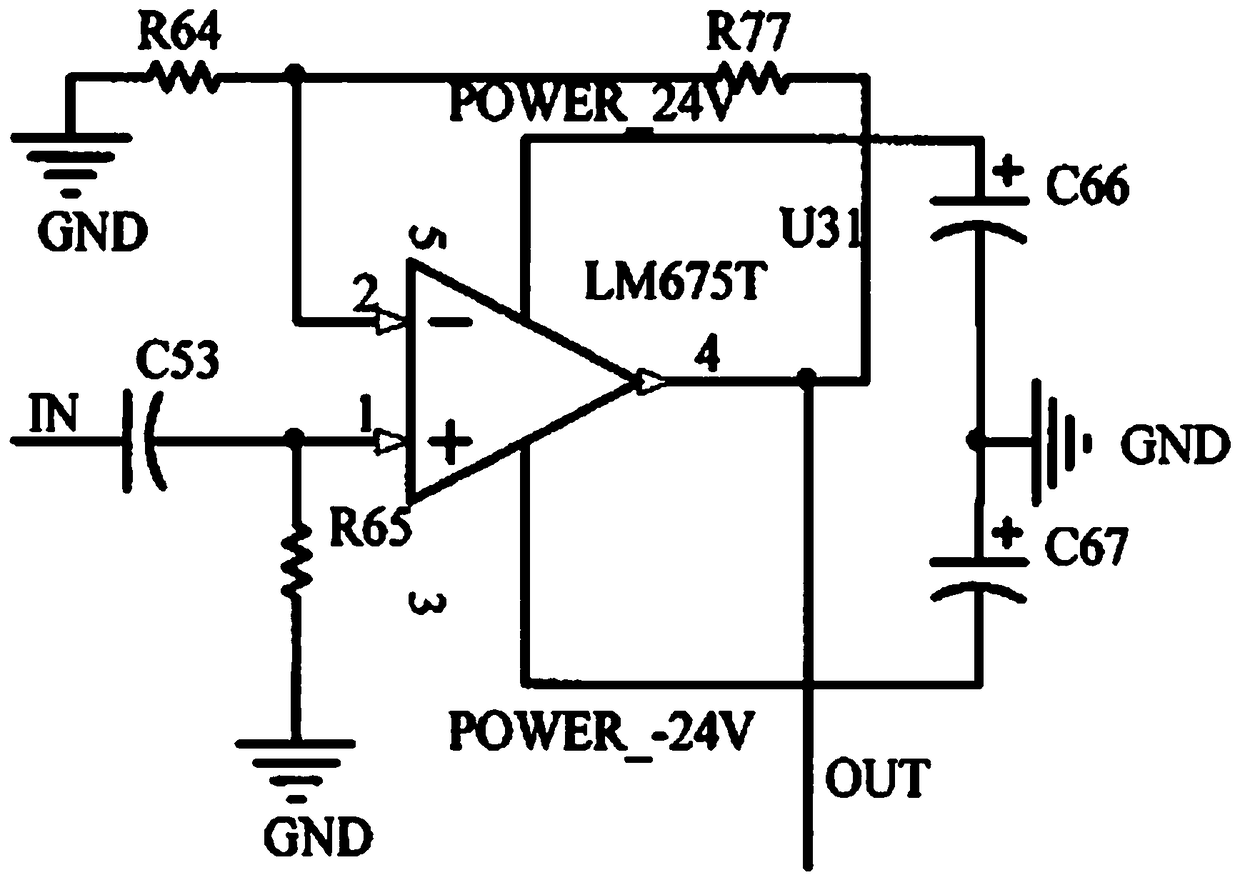

Continuous ink jet type code spraying machine control system with double ARM architectures

InactiveCN108081770AGood real-time performanceFlexible systemOther printing apparatusSine waveARM architecture

A continuous ink jet type code spraying machine control system with double ARM architectures is suitable for the code spraying field. The control system is composed of a power circuit, a clock circuit, a digital-analog interface circuit, a sine wave generating circuit and a power amplifying circuit. According to the system, the optimal phase is obtained through a quantitative processing technologyand a statistic method, and thus the work reliability and stability of the control system are improved, the circuits have good real-time performance, stability and reliability, and the system is moreflexible, higher in performance and good in anti-interference performance.

Owner:周晓萍

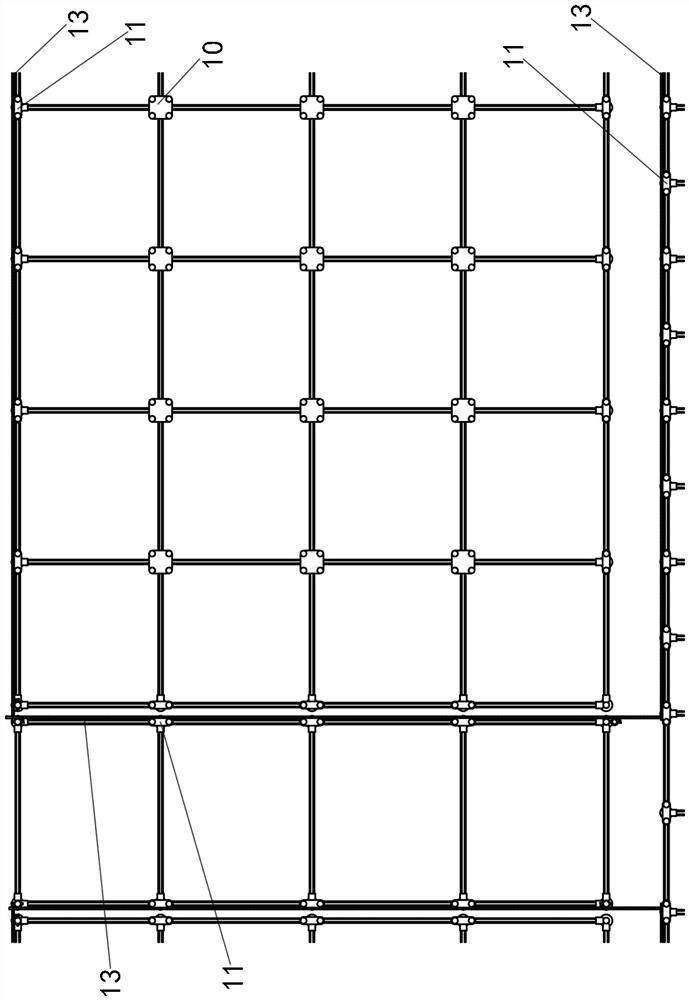

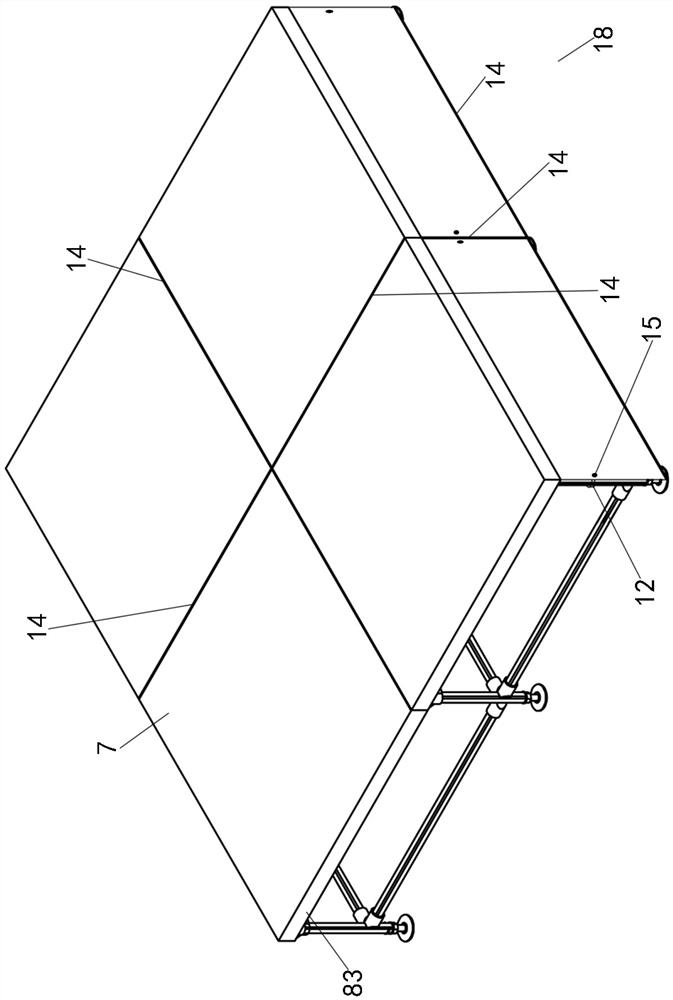

Elevated floor capable of being doubled as plenum chamber and construction method thereof

ActiveCN111764590AImprove site adaptabilityLess investmentCovering/liningsLighting and heating apparatusClassical mechanicsSteel frame

Provided are an elevated floor capable of being doubled as a plenum chamber and a construction method thereof. The elevated floor comprises an elevated floor body and the plenum chamber. The elevatedfloor body comprises a frame which stands on the ground and is arranged around a center building and surface plates laid on the whole frame body. The frame comprises a set of adjustable bases, a set of vertical rods, a set of brackets and a set of cross rods. The adjustable bases and the bottom ends of the vertical rods are vertically adjustable and are in threaded connection. Each bracket comprises a supporting plate, a stand rod sleeve and a bracket convex head, each surface plate comprises a set of unit surface plates, and each unit surface plate comprises a plate body, a steel frame and abracket bearing groove. According to the elevated floor, an elevated platform is provided, and the problem of elevating leveling is solved; meanwhile, an air supply area is tightly blocked, and the lower space of the elevated platform is fully utilized for ground static-pressure air supply; the frame body has enough rigidity, and therefore the platform can meet the normal people stream load needs;and the air supply plenum chamber on the lower portion of the elevated floor is even in air supply, the elevated floor and the plenum chamber can be used in commo through the whole system, mounting and demounting are fast, and the elevated floor and the plenum chamber can be cyclically used.

Owner:CHINA CONSTR FIRST DIV GROUP CONSTR & DEV

Method and an arrangement for controlling a rock drill

ActiveUS8708058B2Avoid damageService lifeSampled-variable control systemsDrill bitsShock waveControl system

Owner:EPIROC ROCK DRILLS AB

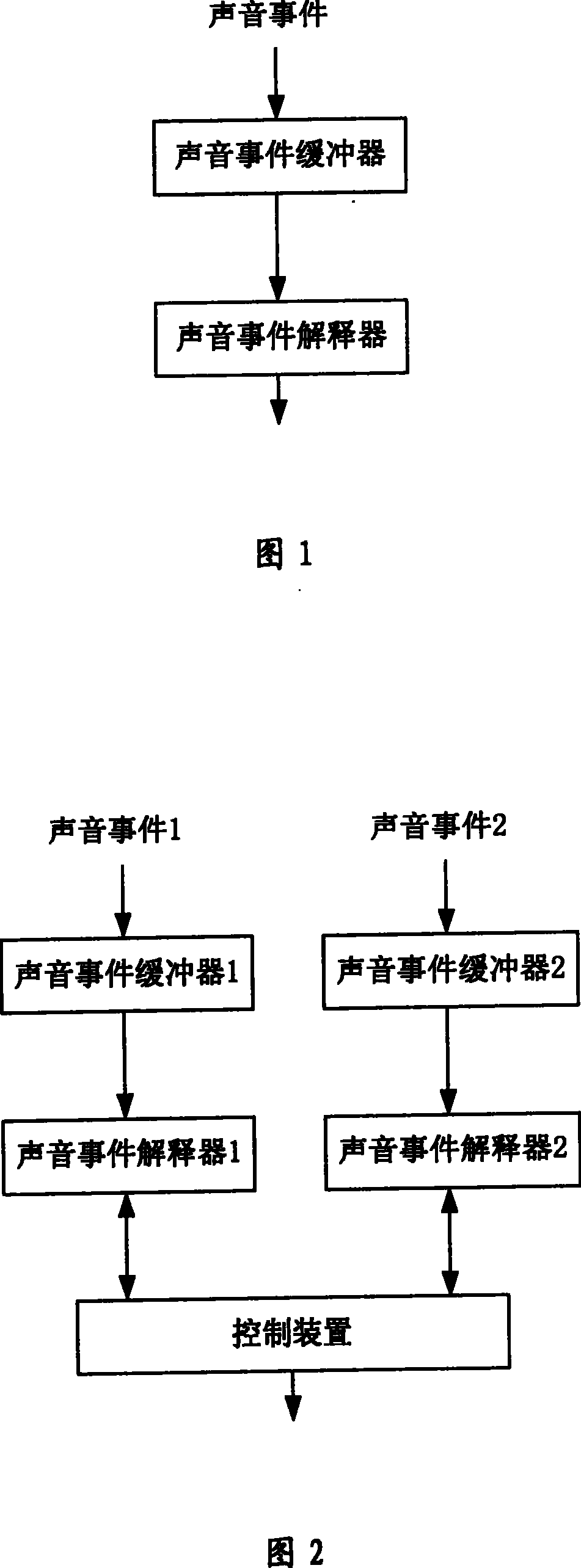

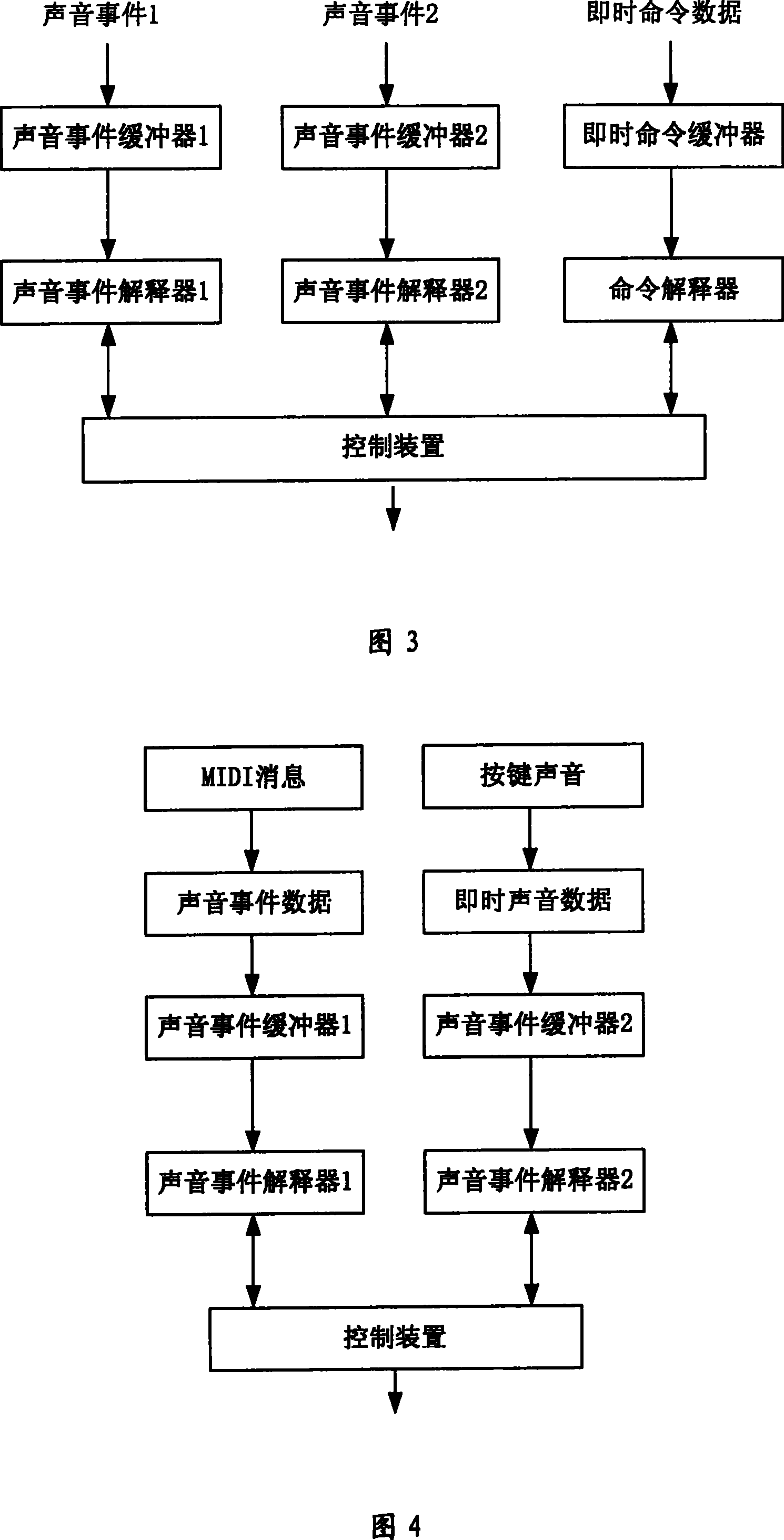

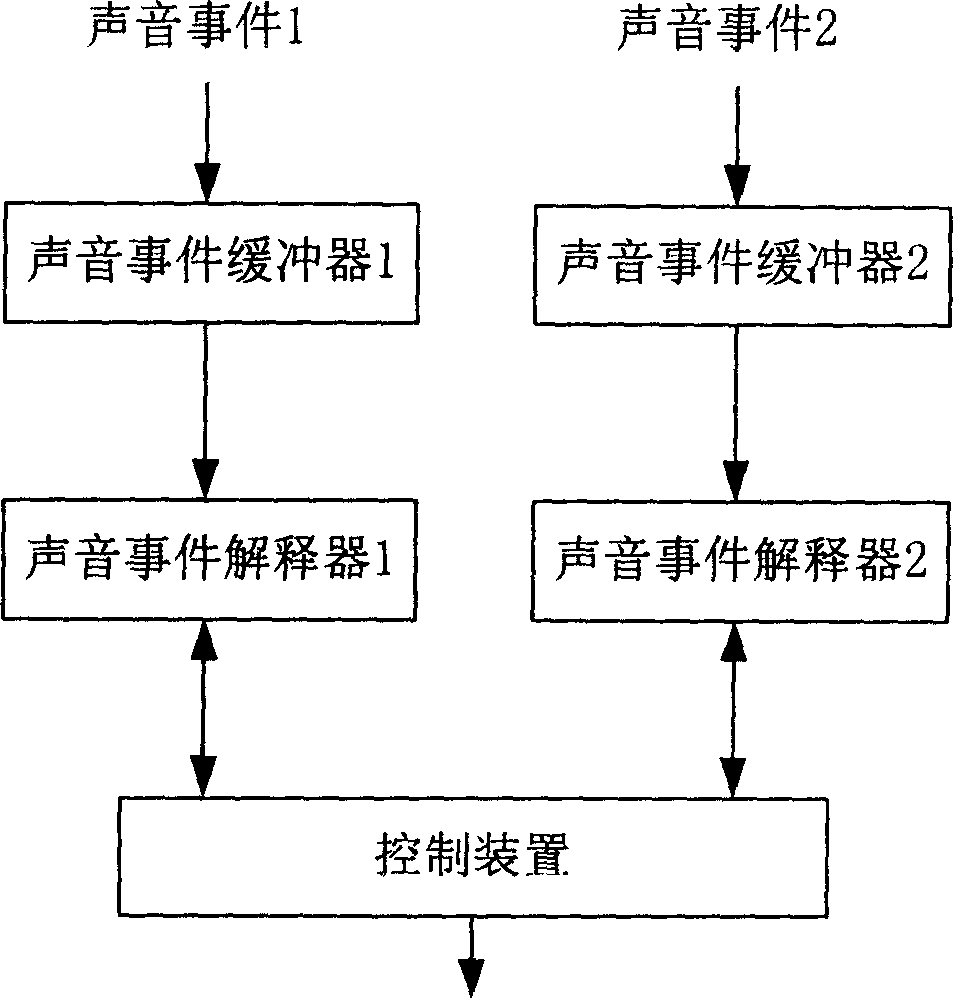

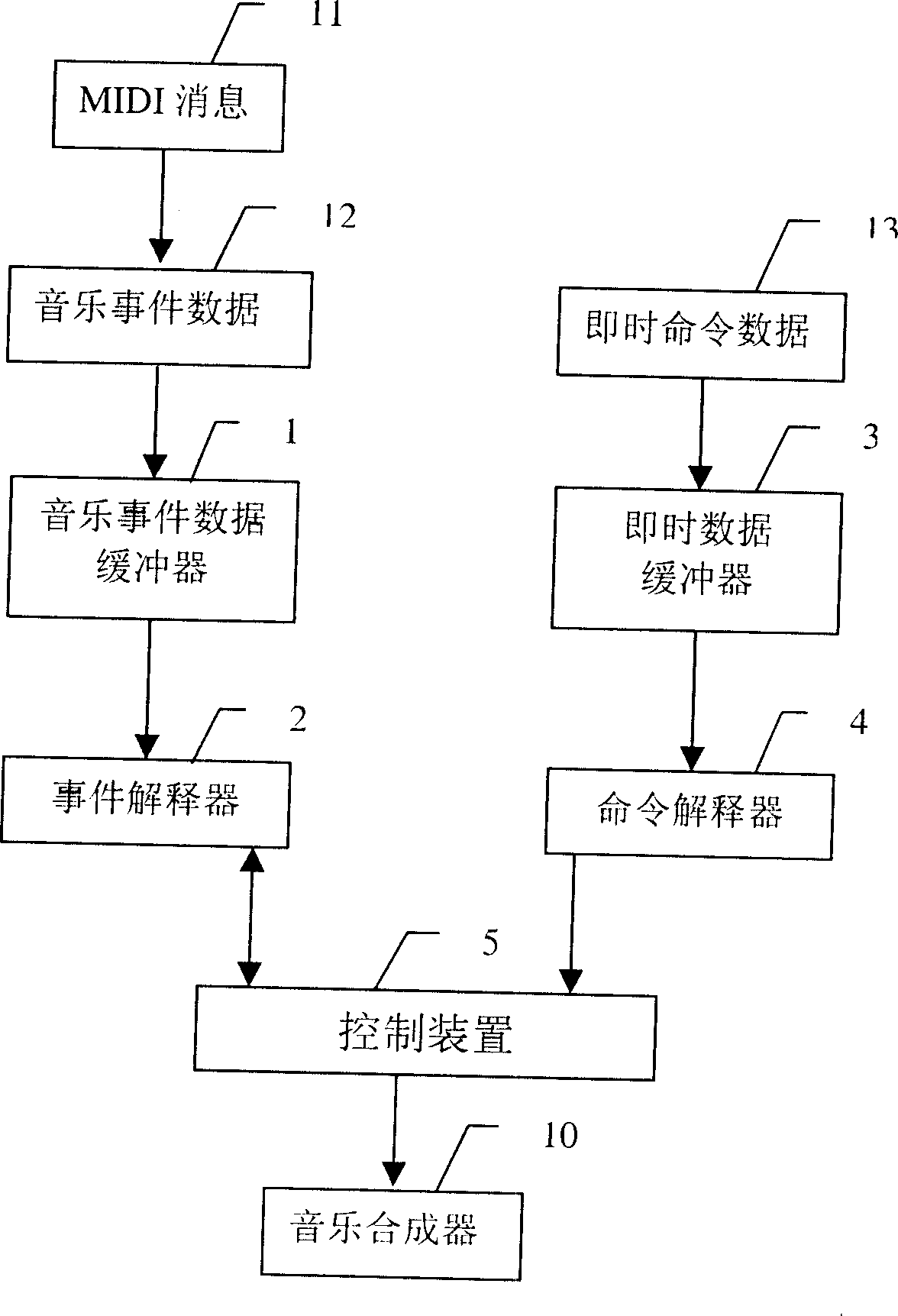

Audio frequency sequence device and sound document treatment method

InactiveCN1719513BSupport simultaneous playbackInstant changeElectrophonic musical instrumentsSpeech synthesisSound fileAudio frequency

Owner:VIMICRO CORP

Liquid supply system

PendingUS20220257068A1Flexible systemReduce the possibilityDomestic plumbingHolders and dispensersWater sourceMechanical engineering

A liquid supply system for supplying liquid to one or more liquid dispensers is provided. The system comprises a water source for supply of water to the system; a concentrate reservoir for supply of concentrate to the system; and a liquid reservoir coupled to the water source and the concentrate reservoir, and configured to be coupled to one or more liquid dispensers. In use, the liquid reservoir is configured to supply liquid to the or each dispenser and is replenished via the water source and concentrate reservoir.

Owner:DEB IP

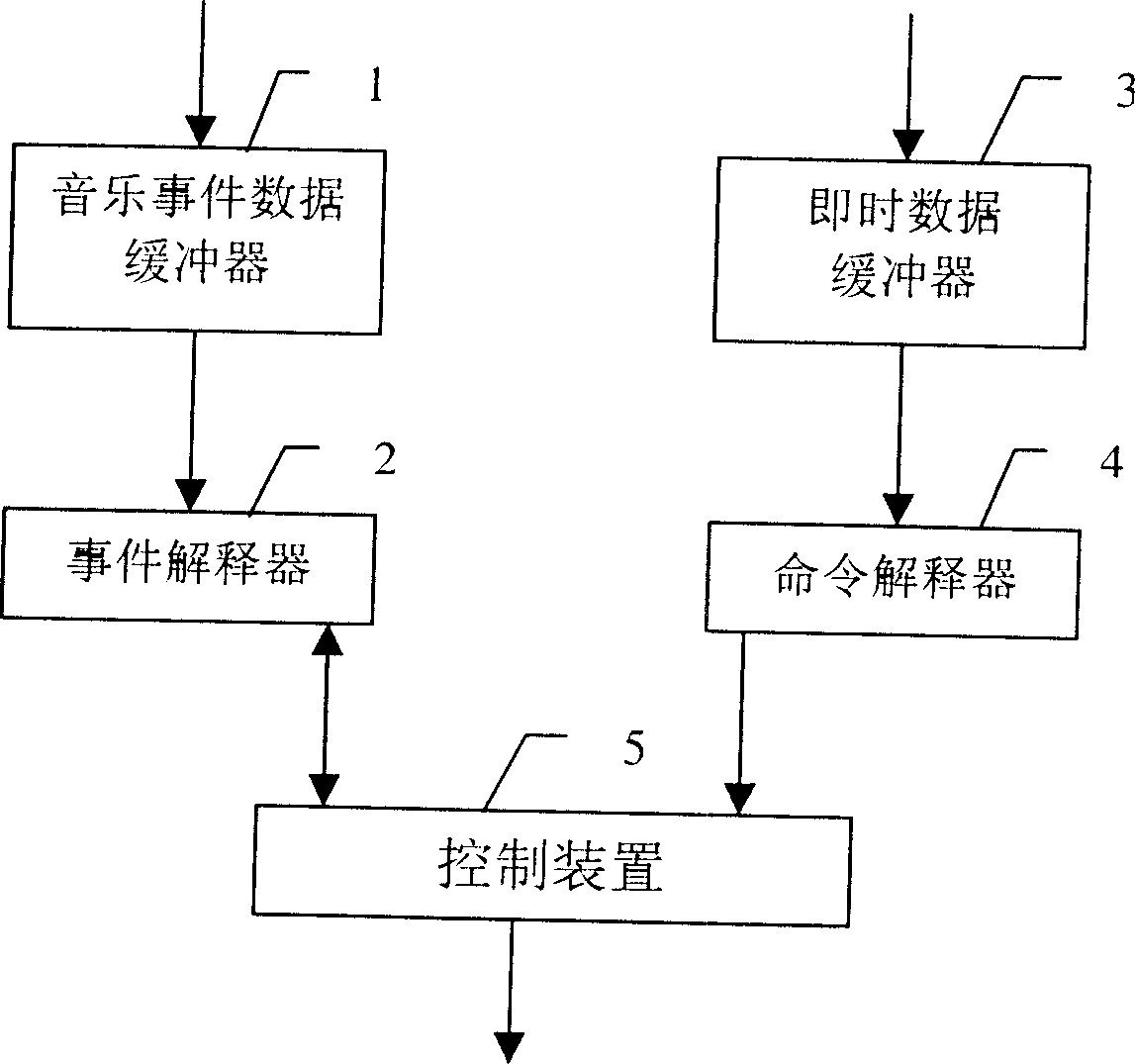

An audio frequency sequence device

InactiveCN1234108CInstant changeFlexible installationElectrophonic musical instrumentsSpeech synthesisReal-time dataAudio synthesis

The invention relates to the field of audio synthesis, and specifically discloses an audio sequencer. The audio sequencer of the present invention includes: a music event data buffer, an event interpreter, an instant data buffer, a command interpreter, and a control device. The control device issues a control command so that the processing priority of the immediate data buffer is higher than that of the music event data buffer. According to the present invention, the user can instantly change the music being played.

Owner:VIMICRO CORP

Method to make payment or charge safe transactions using programmable mobile telephones

ActiveUS9342664B2Flexible systemRobustness and safetyCryptography processingPayment protocolsPaymentTransaction data

A system, method and mobile application for conducting financial transactions wherein a mobile device operated by a user is operably coupled to a server over a mobile communication network. Both the server and the user's mobile device store a user encryption key (UEK) and a user access key (UAK). A software application stored on the user's mobile device and the server are configured to conduct a transaction wherein a session key (SK) specific to the transaction is exchanged in an encrypted form based upon the UEK. The software application is further configured to i) generate transaction data, ii) access the UAK stored on the mobile device, iii) encrypt the UAK and transaction data into an encrypted form based upon the SK, and iv) send the UAK and transaction data in encrypted form from the mobile device to the server over the mobile communication network in order to conduct the transaction.

Owner:MOBILCASH LC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com