Patents

Literature

35results about How to "Meet build requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

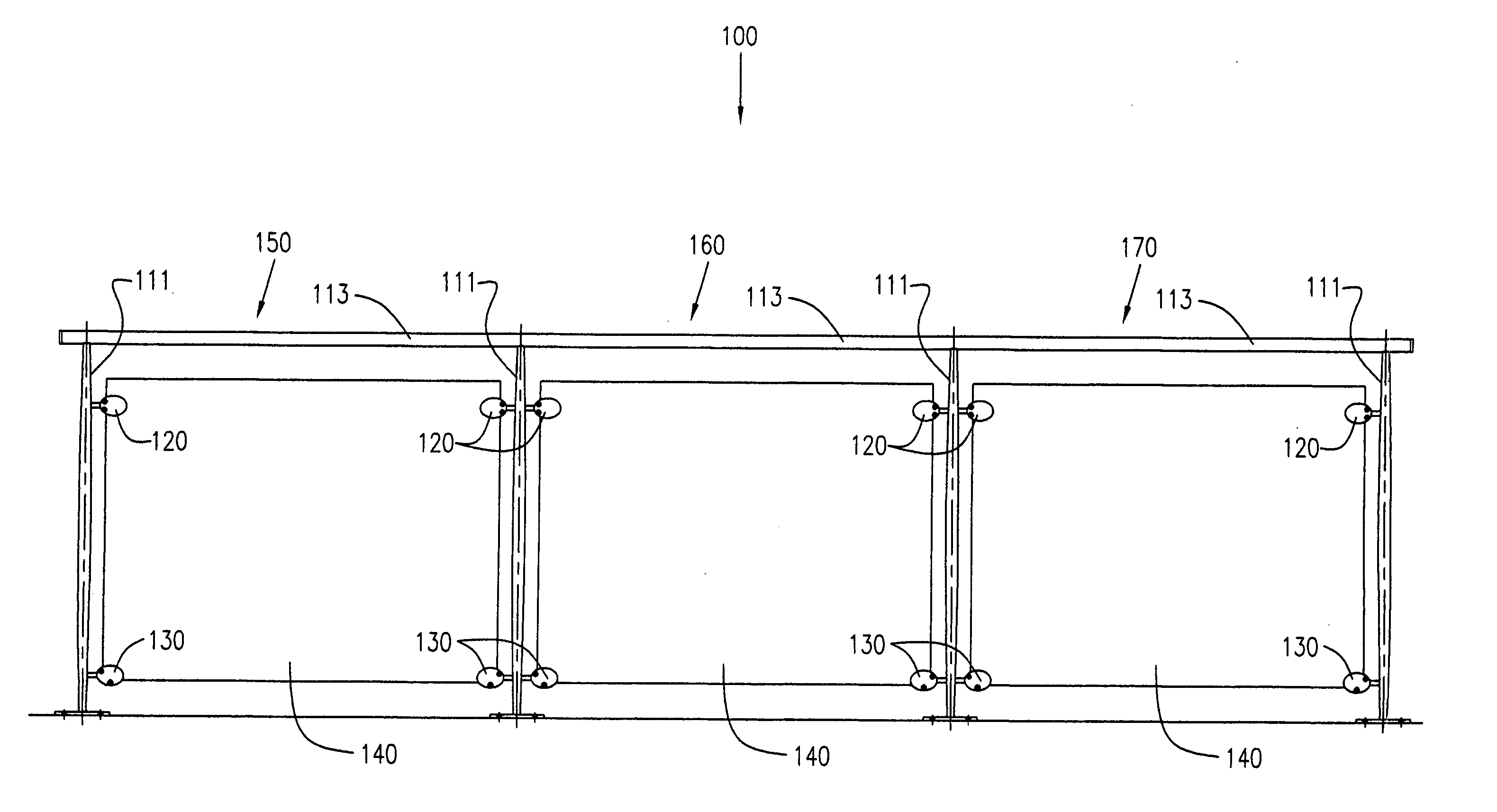

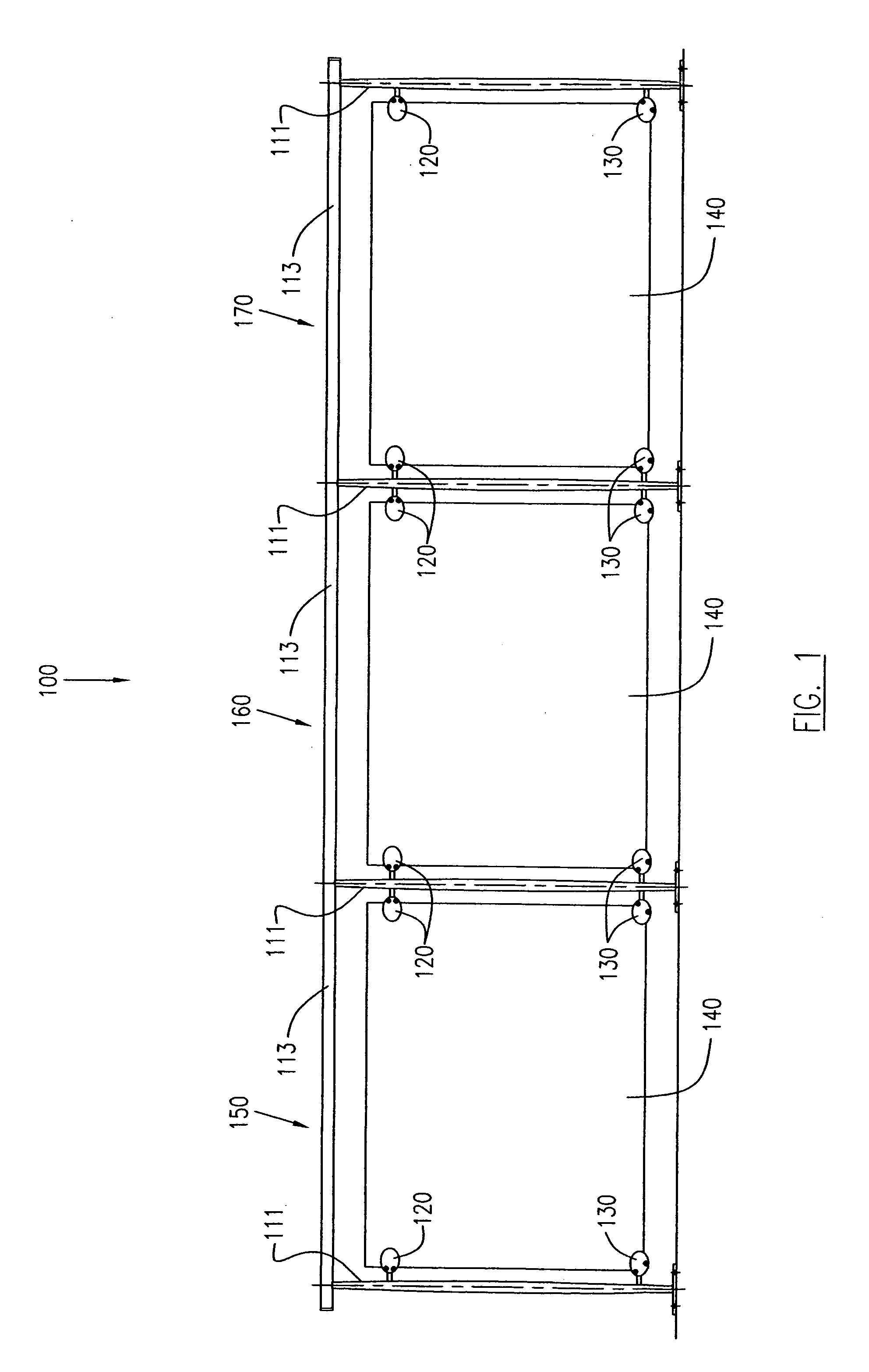

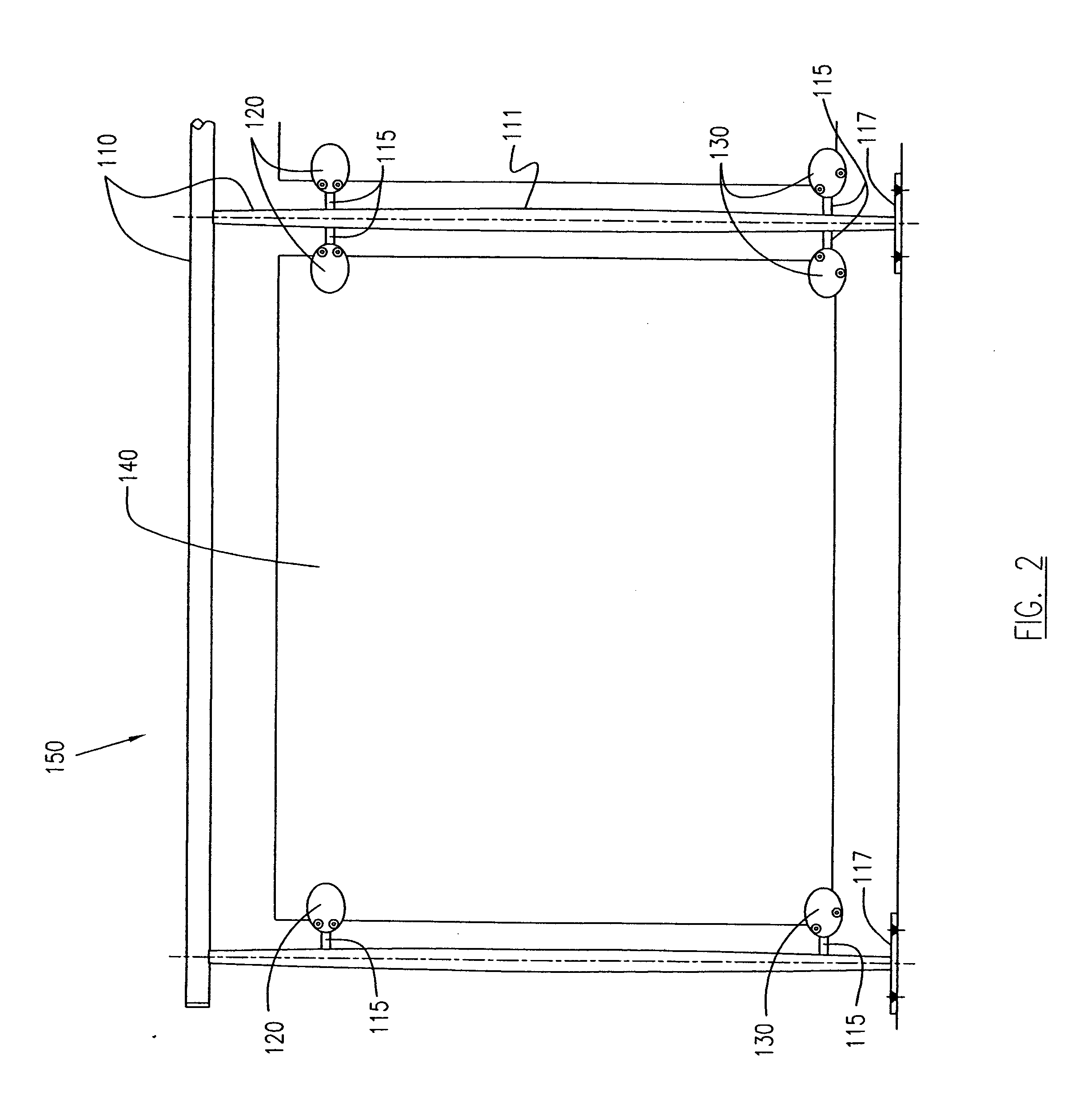

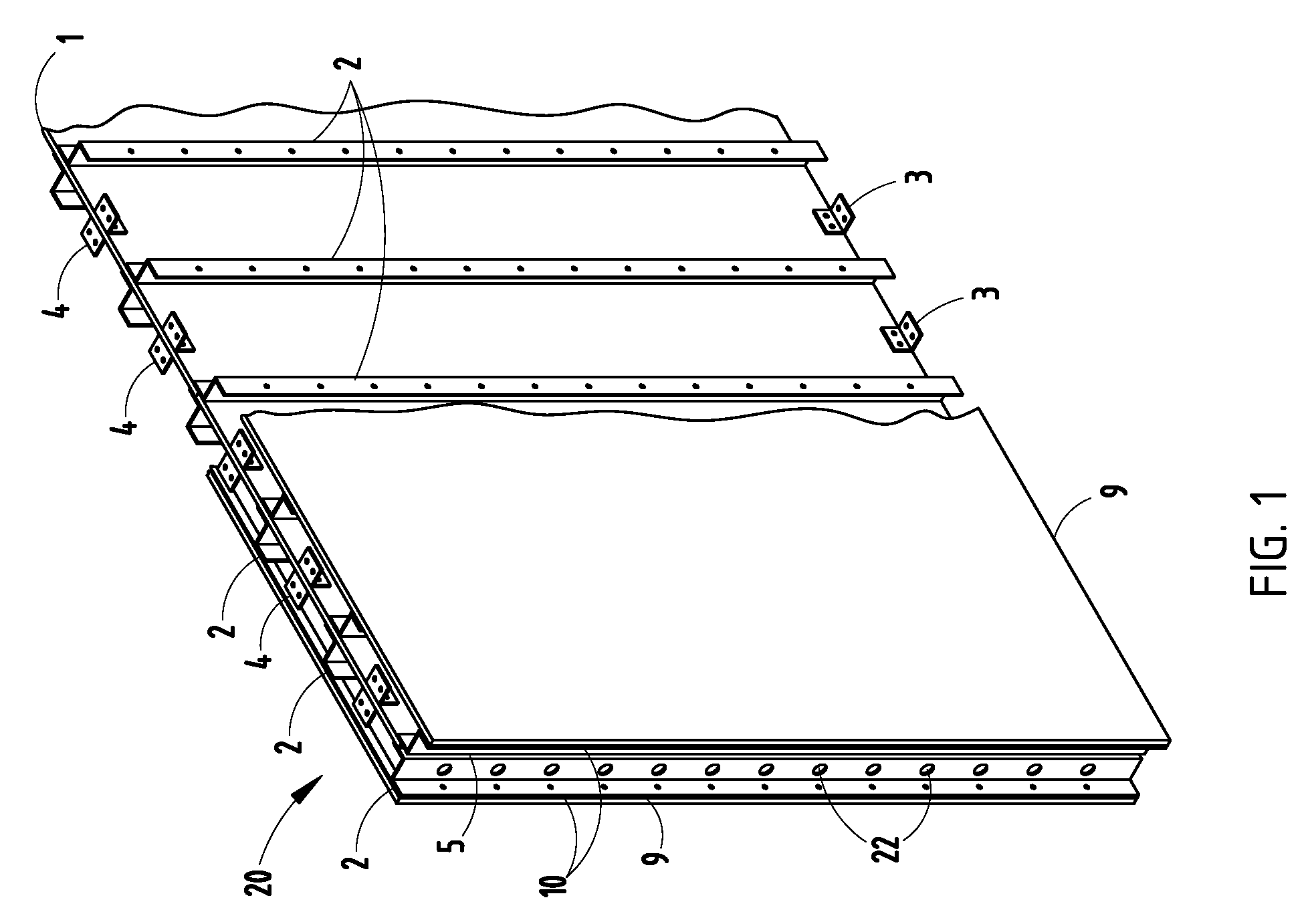

Panel barriers

InactiveUS20060097237A1Meet build requirementsRelieve pressureFencingTraffic restrictionsBuilding codeSurface plate

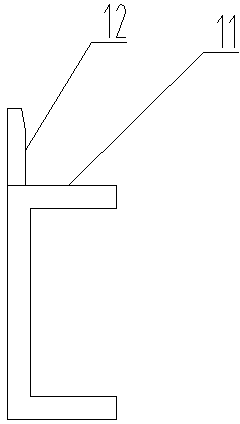

A panel barrier panel system is provided which employs aesthetically pleasing panels which tend to be brittle, but is able to meet or exceed building codes. The system employs a frame having a vertical member, a horizontal member and connectors extending from members. These connectors employ upper and lower supports for a panel. The lower supports employ protrusion to interact with a lower edge of the panel, to support the weight of the panel, with the upper supports sandwiching the panel for stabilizing it. Since these supports do not rely upon friction and pressure to support and secure the panel, they are less apt to crush or fracture the panels. Connectors are made to be flexible to absorb shock and stress, thereby further protecting the panels.

Owner:MCGREGOR ROBERT ROY

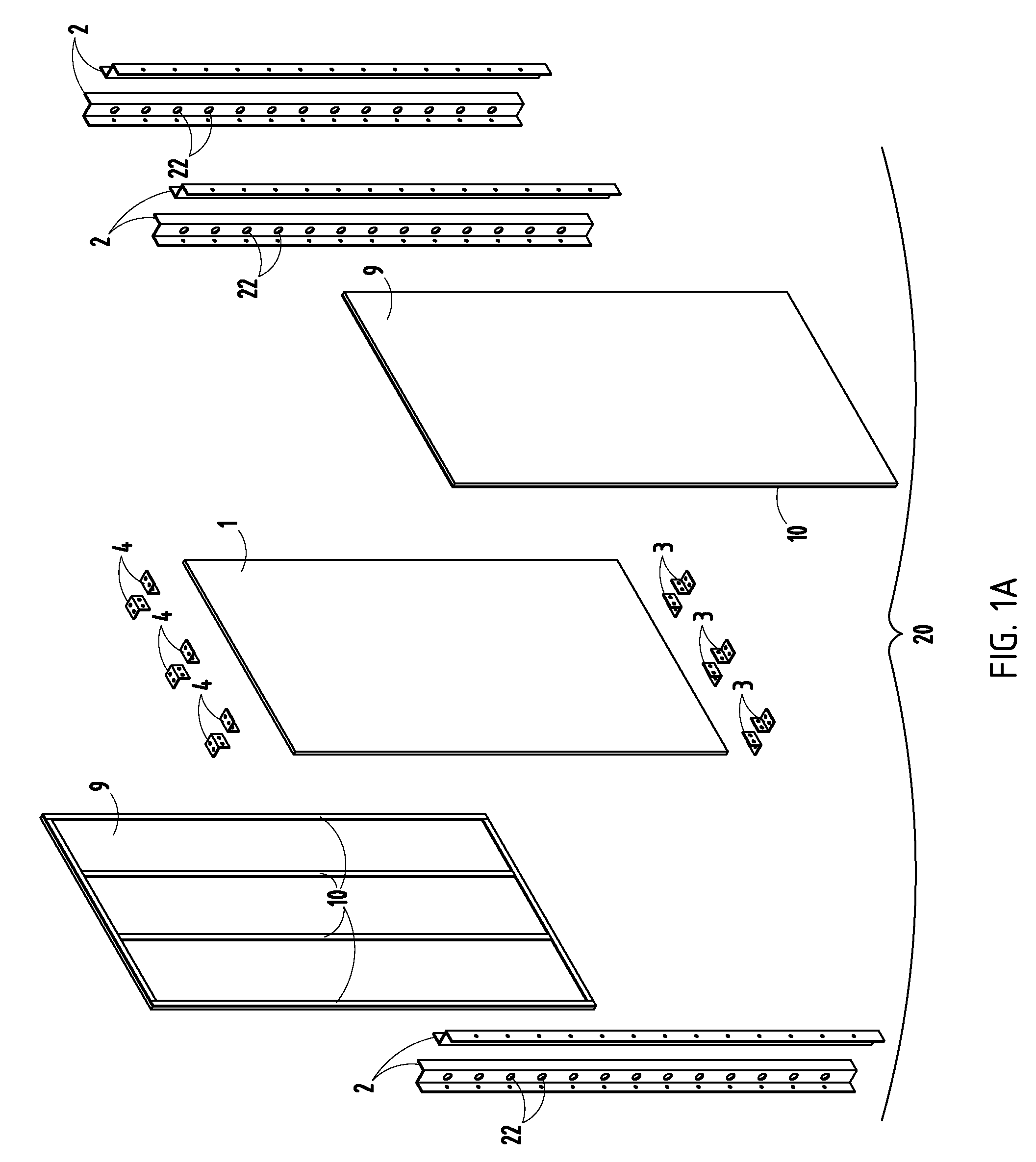

Relocatable building wall construction

InactiveUS20090282759A1Low noise transmission coefficientMeet build requirementsCeilingsWallsFiberMagnetic tape

A relocatable wall construction includes a center sheet (preferably magnesium oxide), vertical strips, floor and ceiling attachment strips, and tongue-and-groove connectors for joining adjacent aligned panels (also called vertical strips). Fasteners connect components together, and can include magnets, bolts, screws clips, and / or hook-tabs. Magnetic tape can be used for releasable attachment to outer sheets, along with fibrous sound-deadening material for noise reduction and slots for providing adjustment for non-uniform floors and ceilings.

Owner:PORTER WILLIAM H

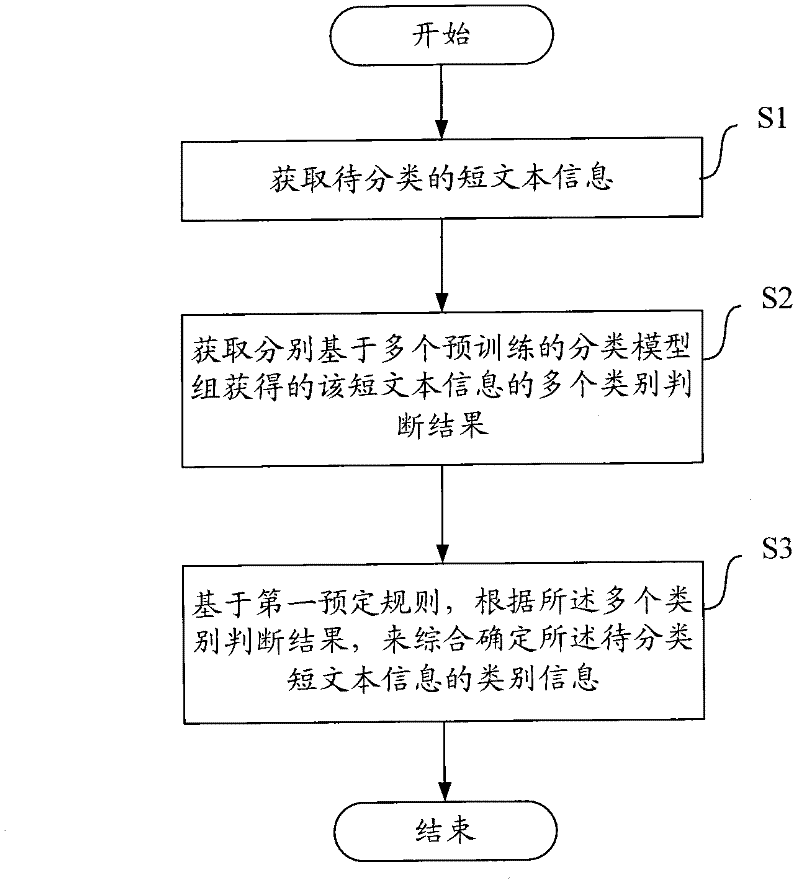

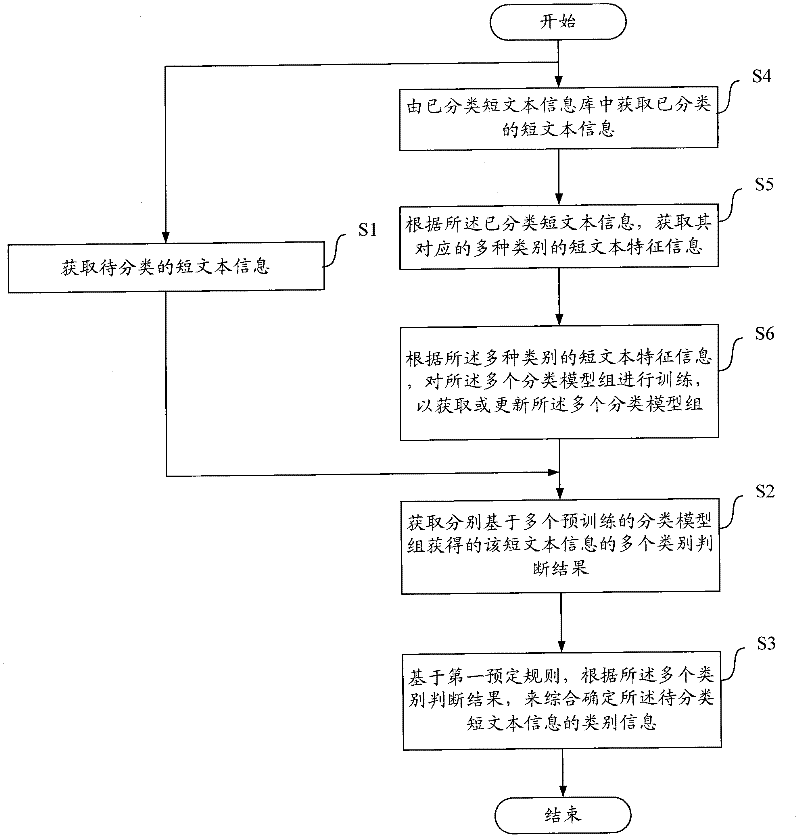

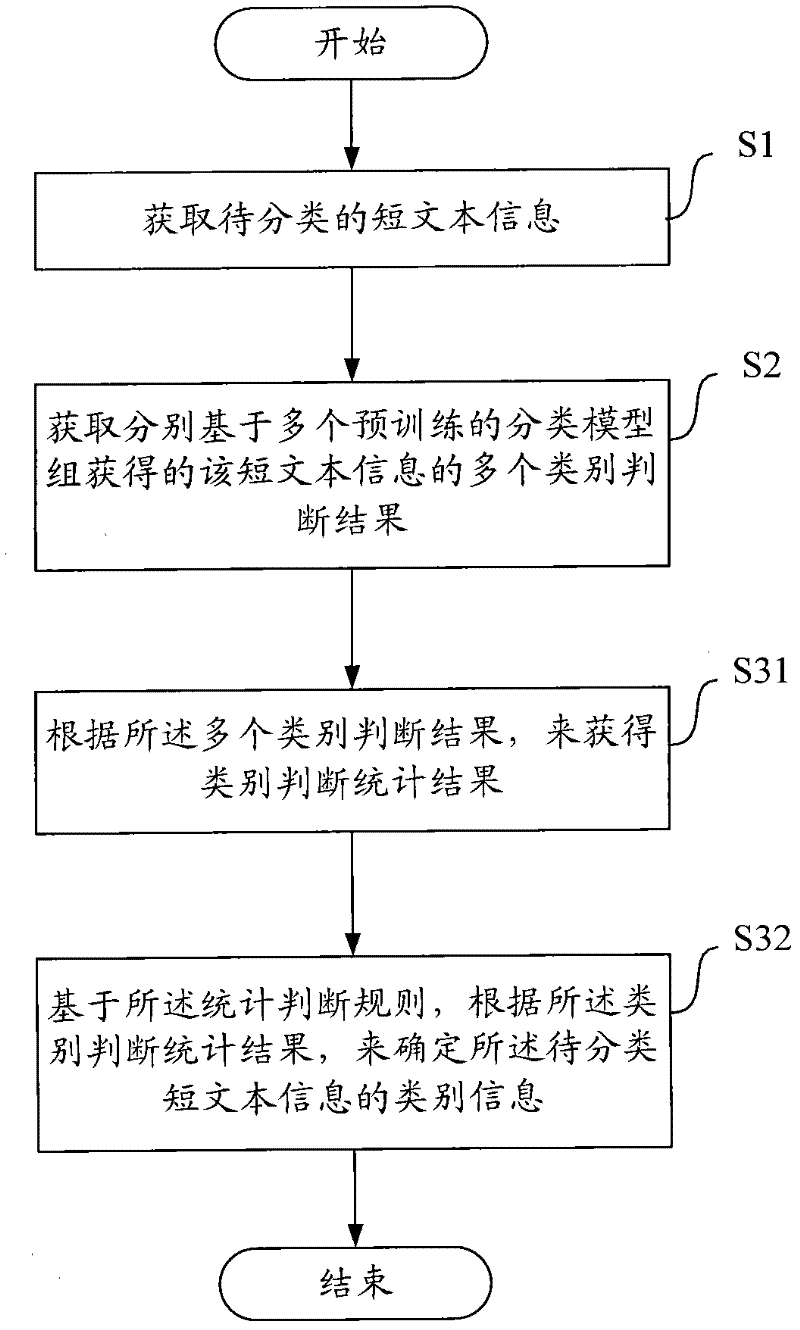

Method, device and computer equipment for identifying short text category information

InactiveCN102541958AMeet build requirementsImprove the accuracy of judgmentSpecial data processing applicationsText matchingData mining

The invention discloses a method, a device and computer equipment, which are used for identifying short text category information and are implemented by a computer. According to the technical scheme provided by the invention, the method comprises the following steps of: acquiring the short text category information to be classified; acquiring a plurality of category judged results of the short text information, which are acquired on the basis of a plurality of pre-trained classification model groups respectively; and on the basis of a first predetermined rule and according to the category judged results, comprehensively determining the category information of the short text information to be classified. Compared with the prior art, the invention has the following advantages that: 1) the category of the short text information is comprehensively judged through characteristic information of a plurality of short texts, so that the judgment accuracy is improved; 2) the automatic expansion of classified short text information is realized through iterative training and classification; and 3) the category information of the short text information can be acquired in real time by generating a short text matching dictionary.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

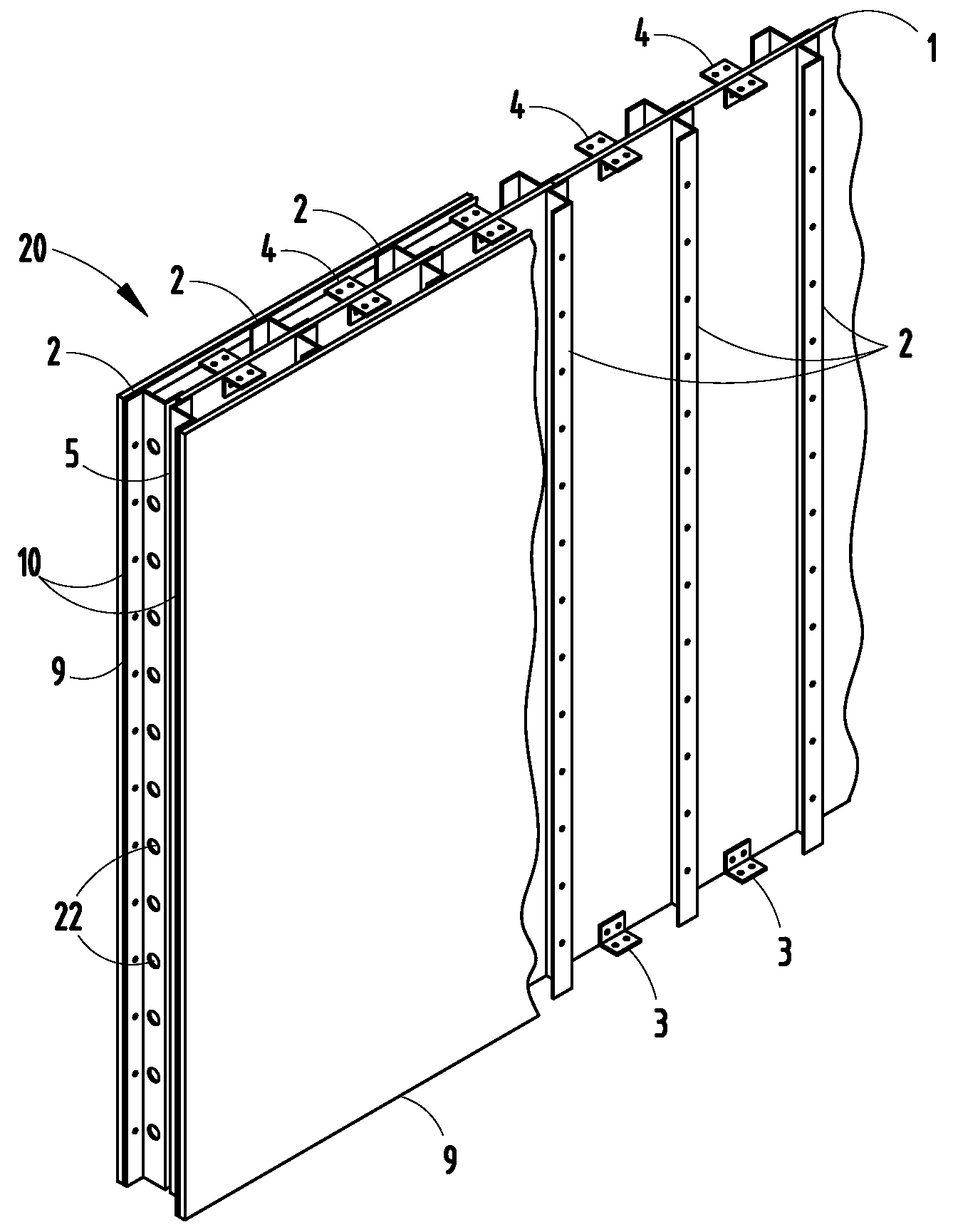

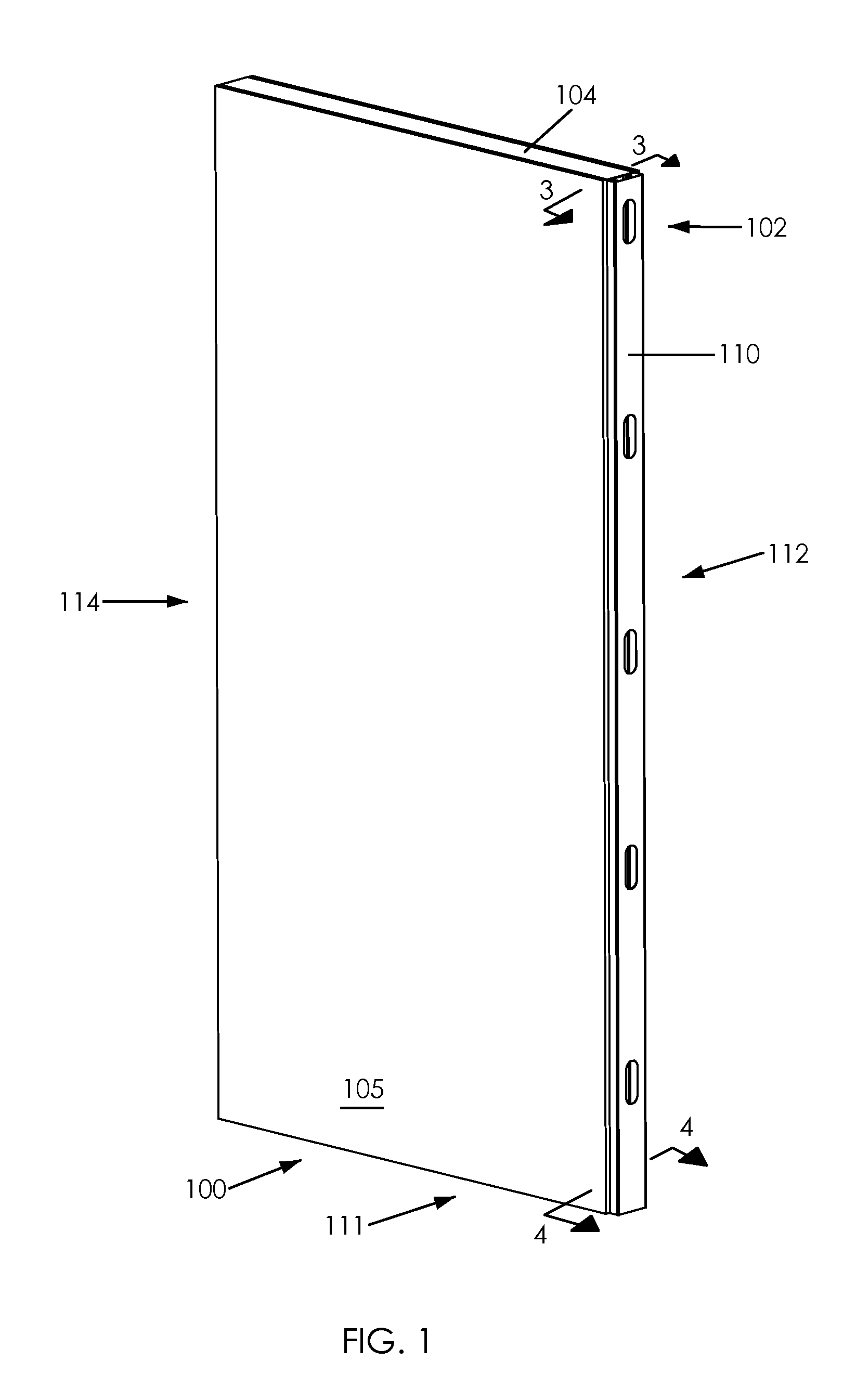

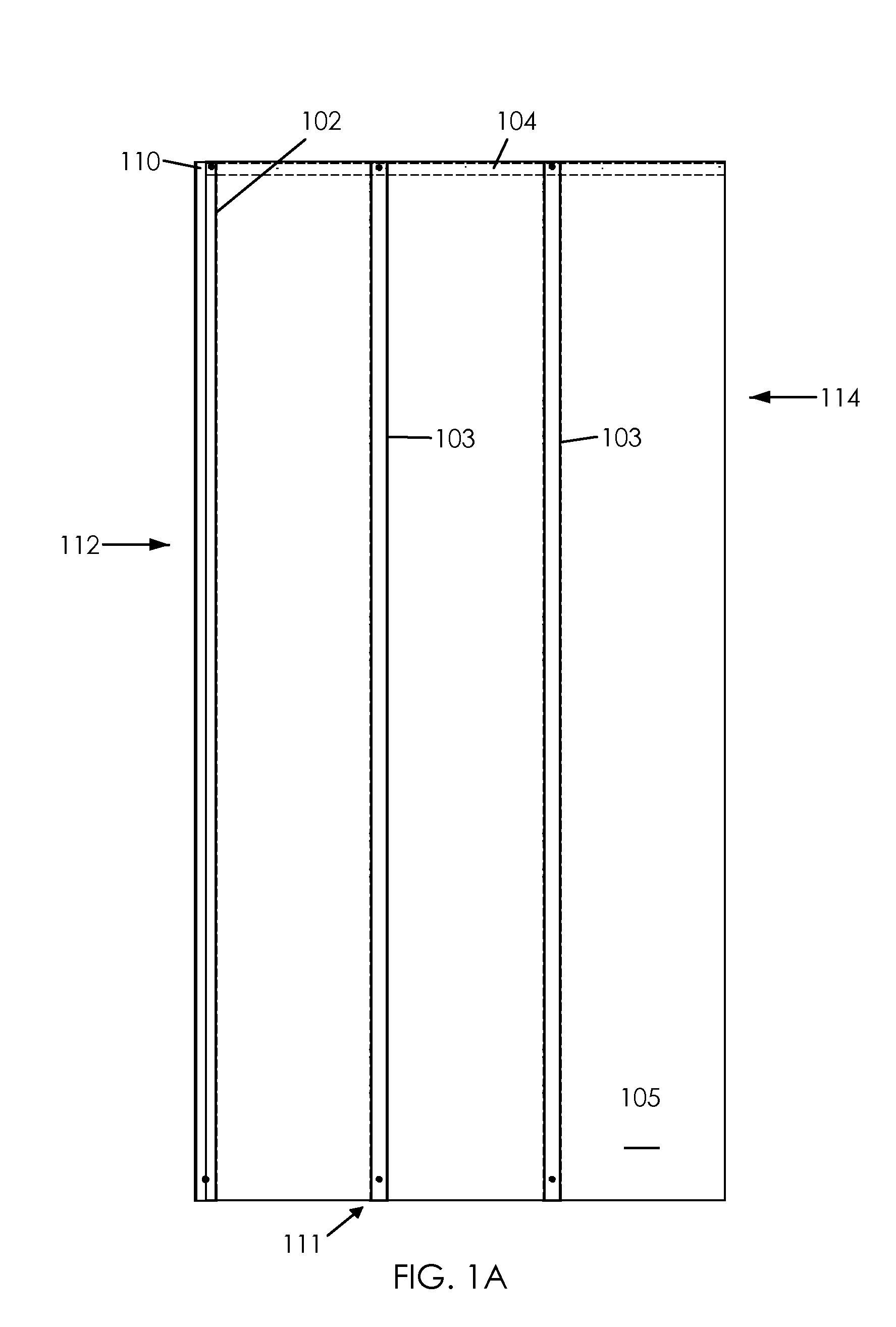

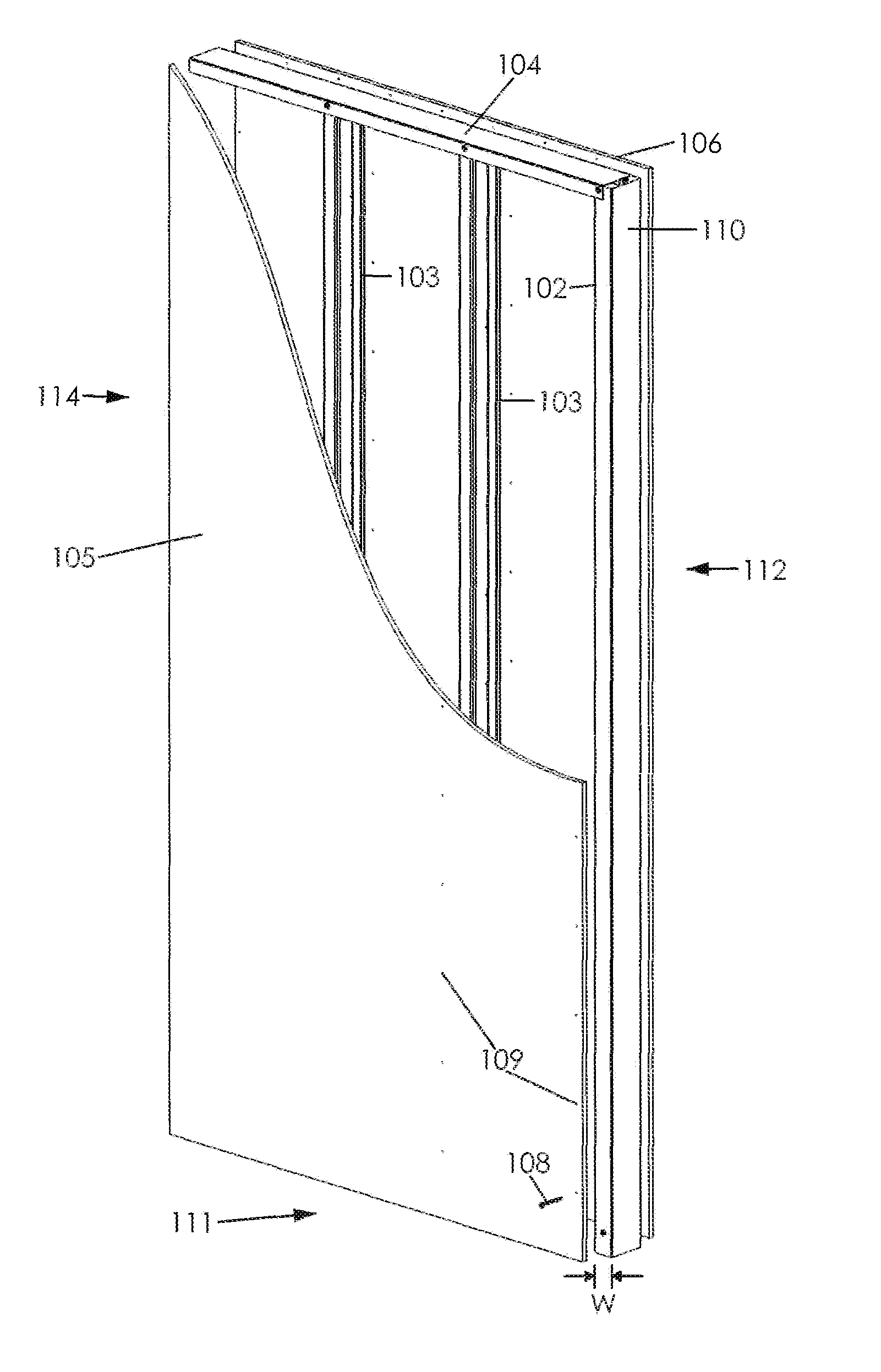

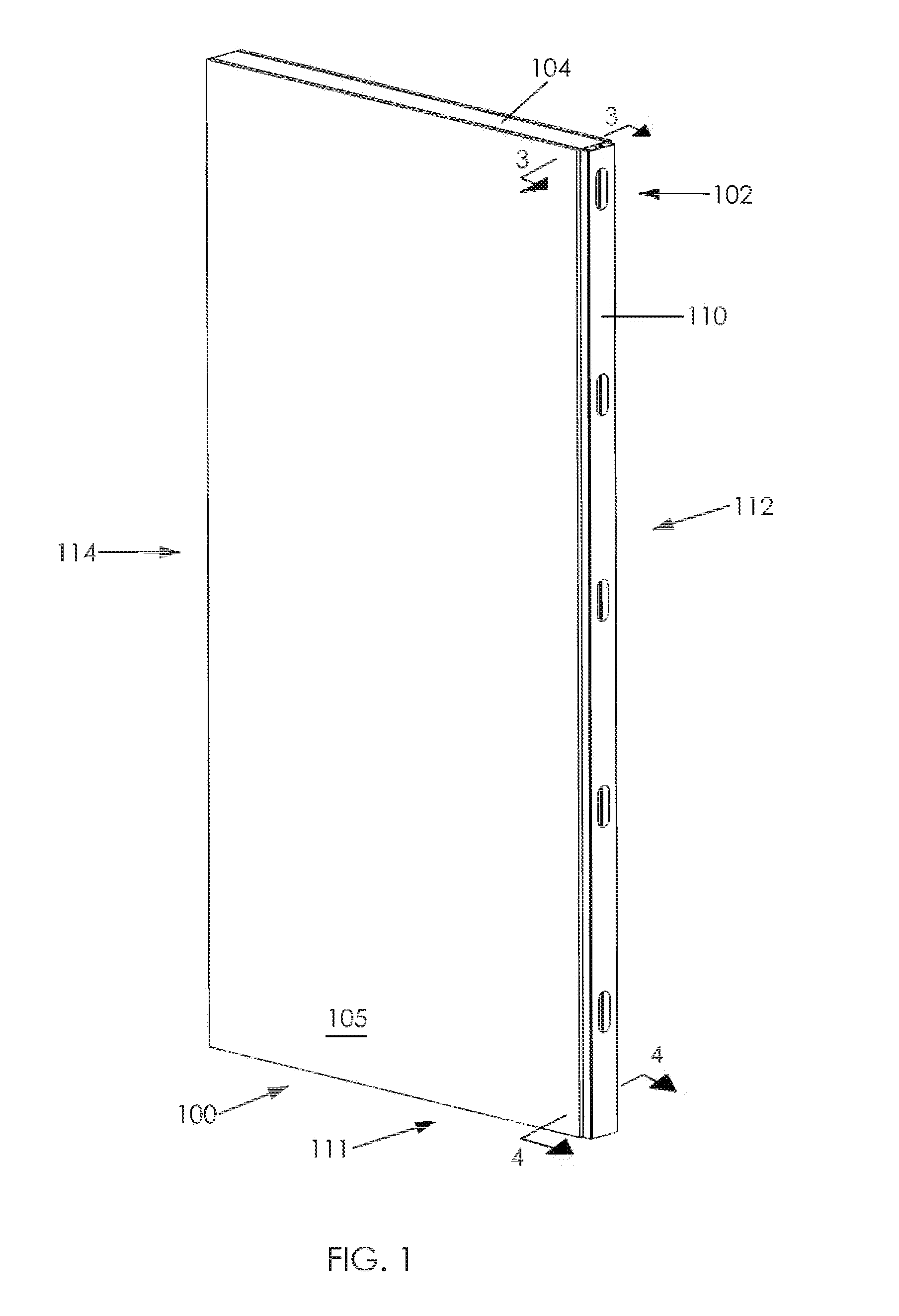

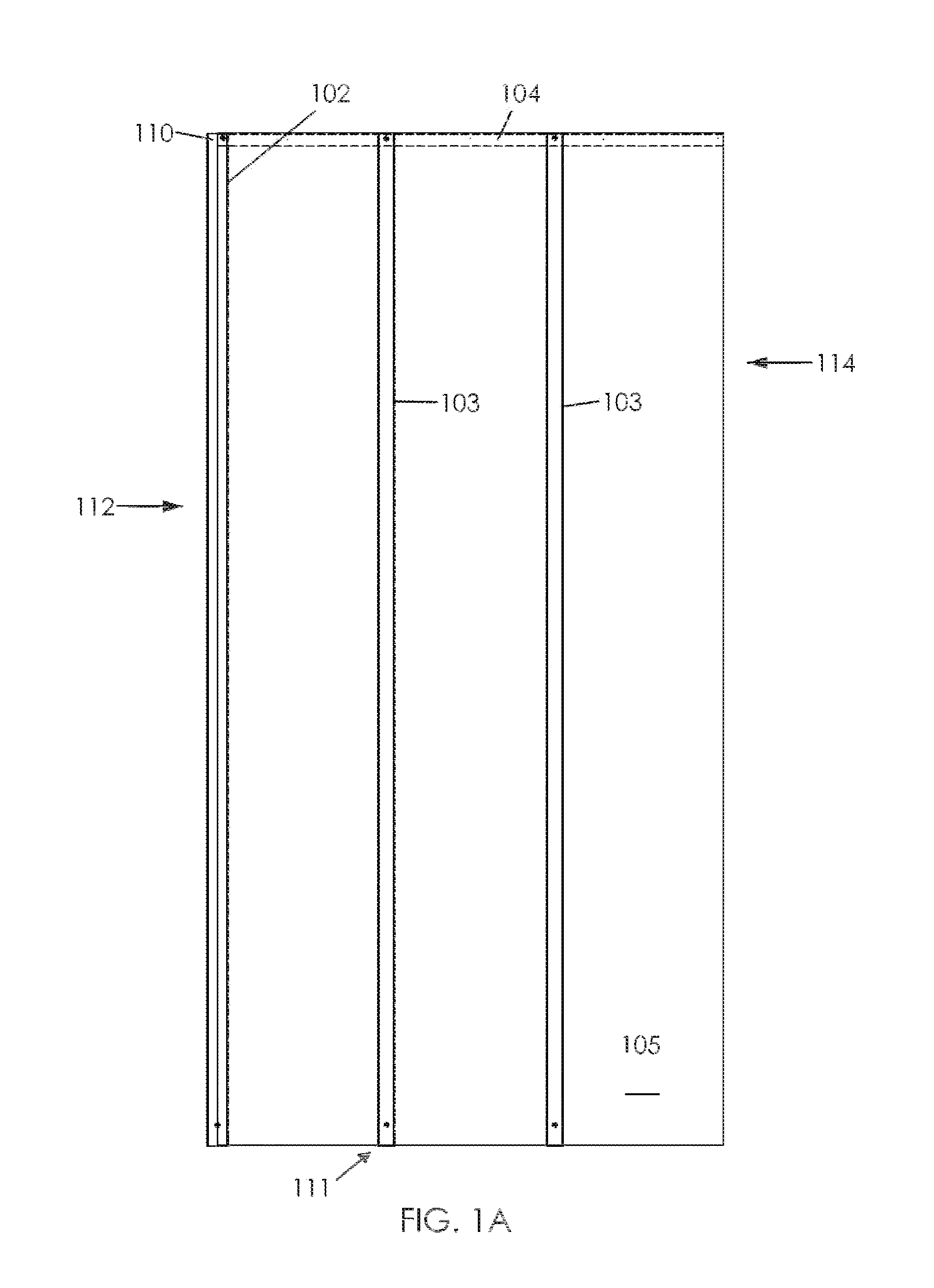

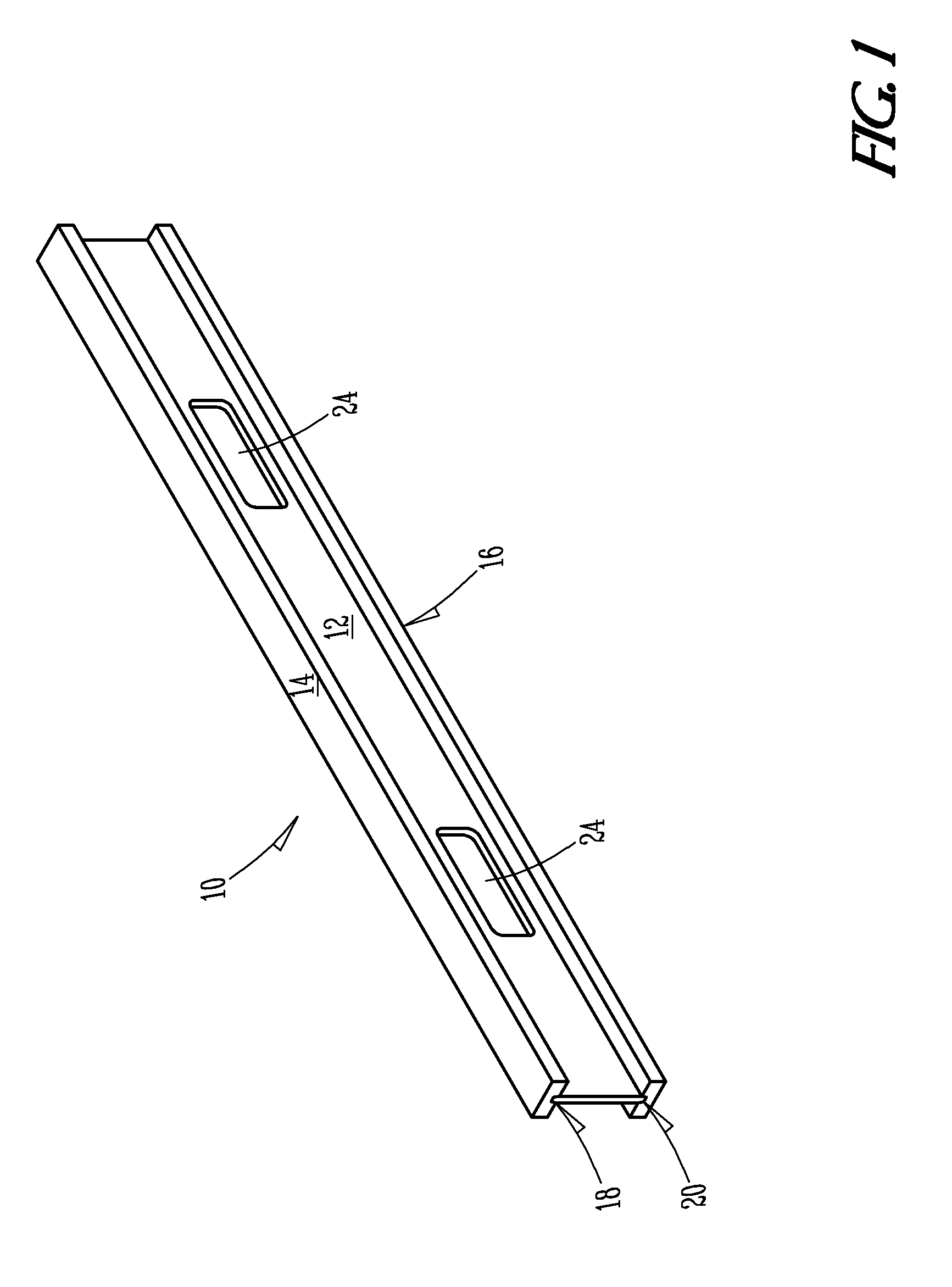

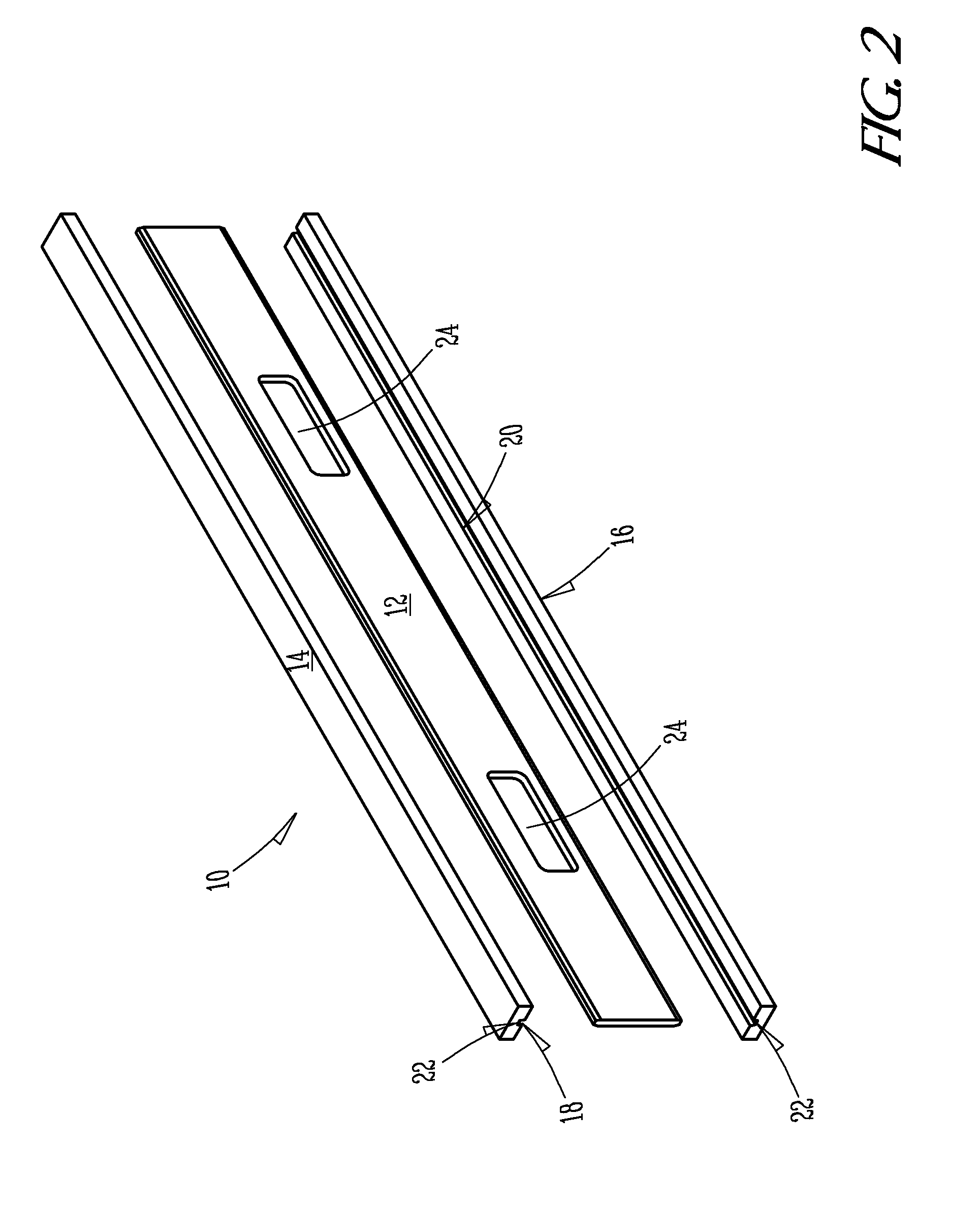

Structural wall panel for use in light-frame construction and method of construction employing structural wall panels

ActiveUS8997424B1Convenience to workEliminates much of the waste stream commonly generatedStrutsWallsWall plateBuilding construction

A structural wall panel includes an elongated shared structural framing member and one or more elongated intermediate structural framing members. An elongated top track is connected to a top end of each of the framing members. An inner sheet of suitable sheet material is secured to the framing members so as to form an inner face of the structural wall panel, while an outer sheet of suitable sheet material is secured to the framing members so as to form an outer face of the structural wall panel opposite the inner face. The elongated top track and inner and outer sheets are aligned on the framing members so as to form a male receiver at one lateral side of the panel and a female receiving structure along the opposite lateral side of the panel.

Owner:CONVERGENT MARKET RESEACH INC

Structural Wall Panels for Use in Light-Frame Construction and Methods of Construction Employing Structural Wall Panels

ActiveUS20150204068A1Convenience to workEliminates much of the waste stream commonly generatedWallsBuilding repairsWall plateBuilding construction

A structural wall panel includes an elongated shared structural framing member and one or more elongated intermediate structural framing members. An elongated top track is connected to a top end of each of the framing members. An inner sheet of suitable sheet material may be secured to the framing members so as to form an inner face of the structural wall panel, while an outer sheet of suitable sheet material may be secured to the framing members so as to form an outer face of the structural wall panel opposite the inner face. The elongated top track and inner and outer sheets are aligned on the framing members so as to form a male receiver at one lateral side of the panel and a female receiving structure along the opposite lateral side of the panel.

Owner:CONVERGENT MARKET RESEACH INC

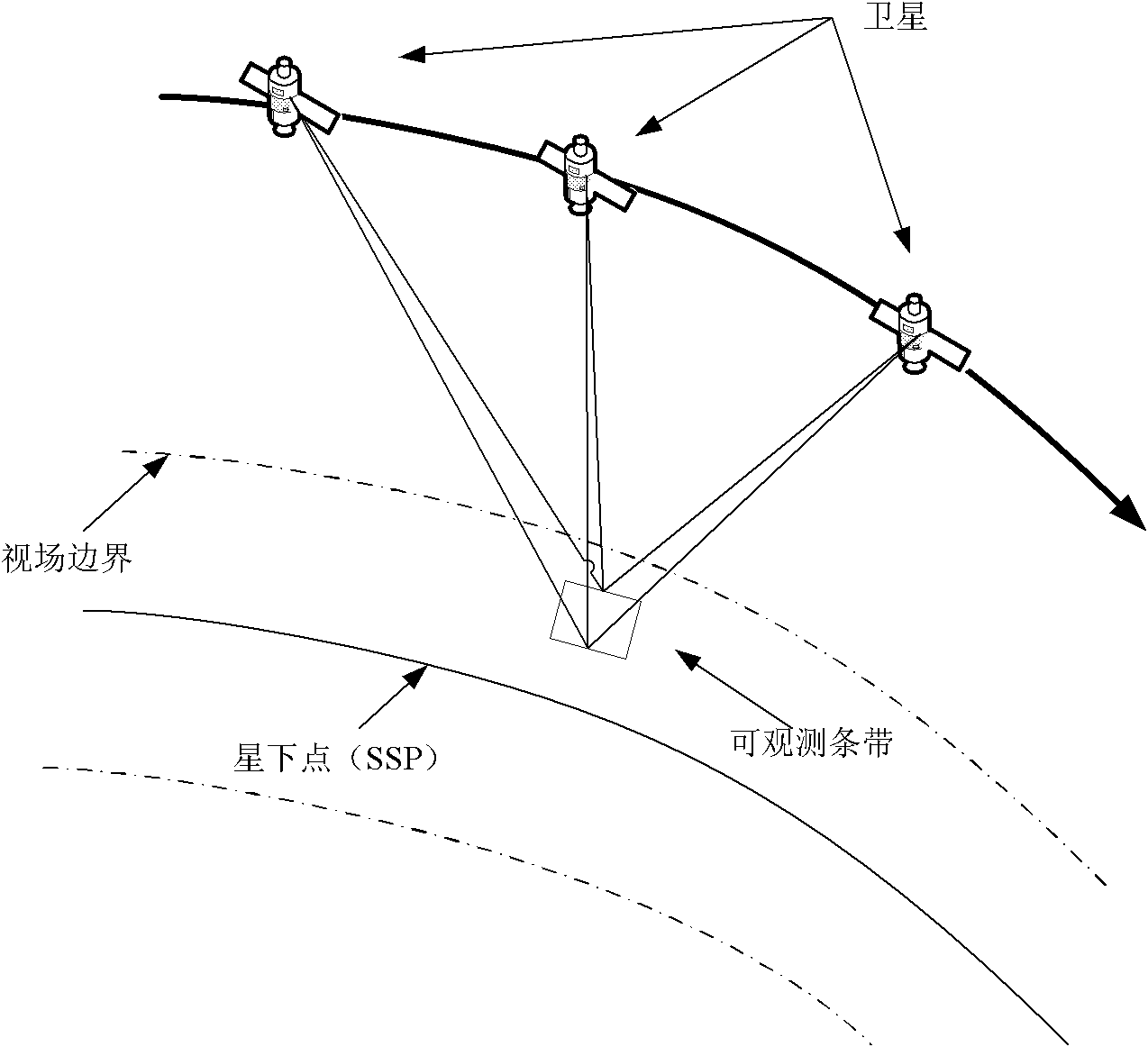

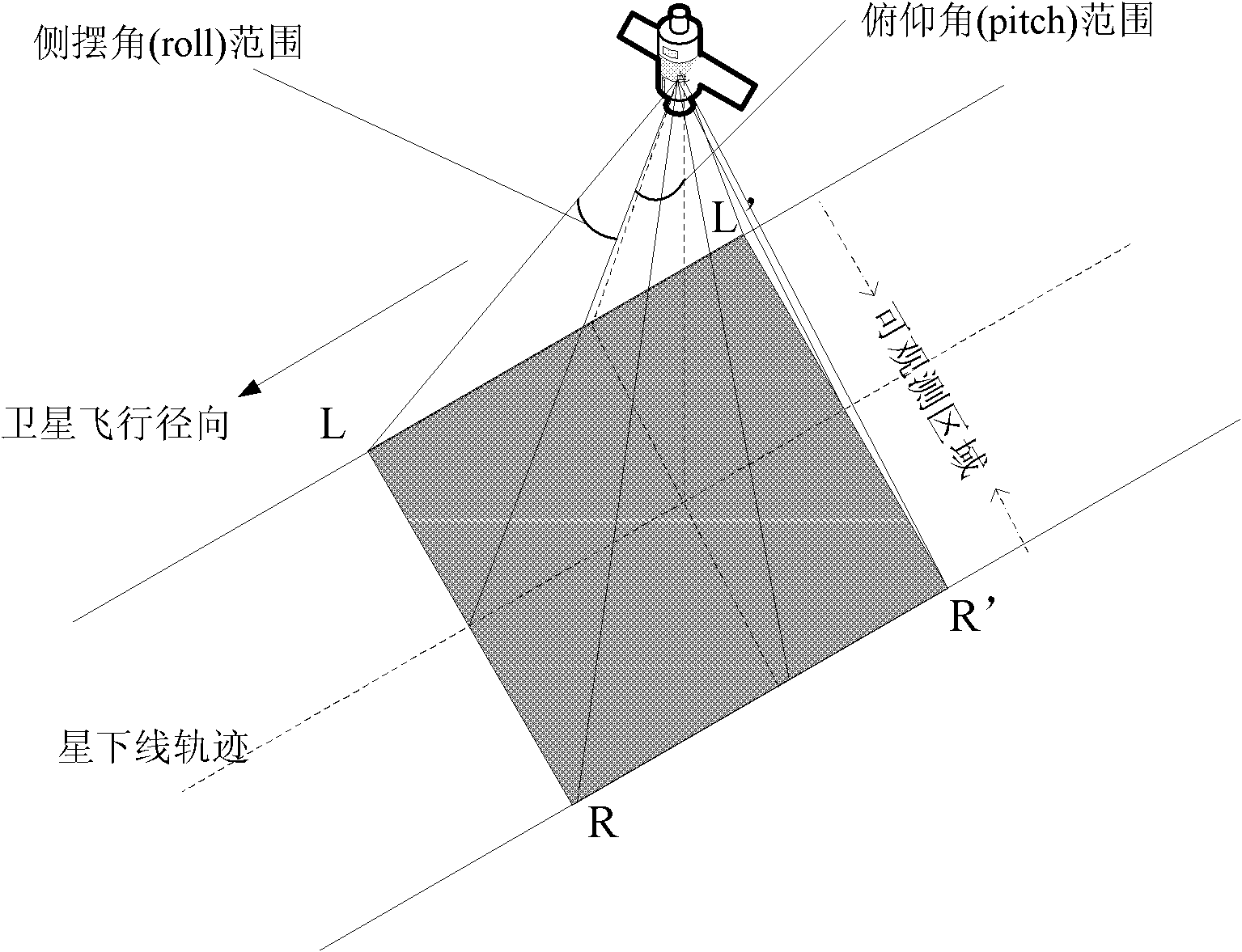

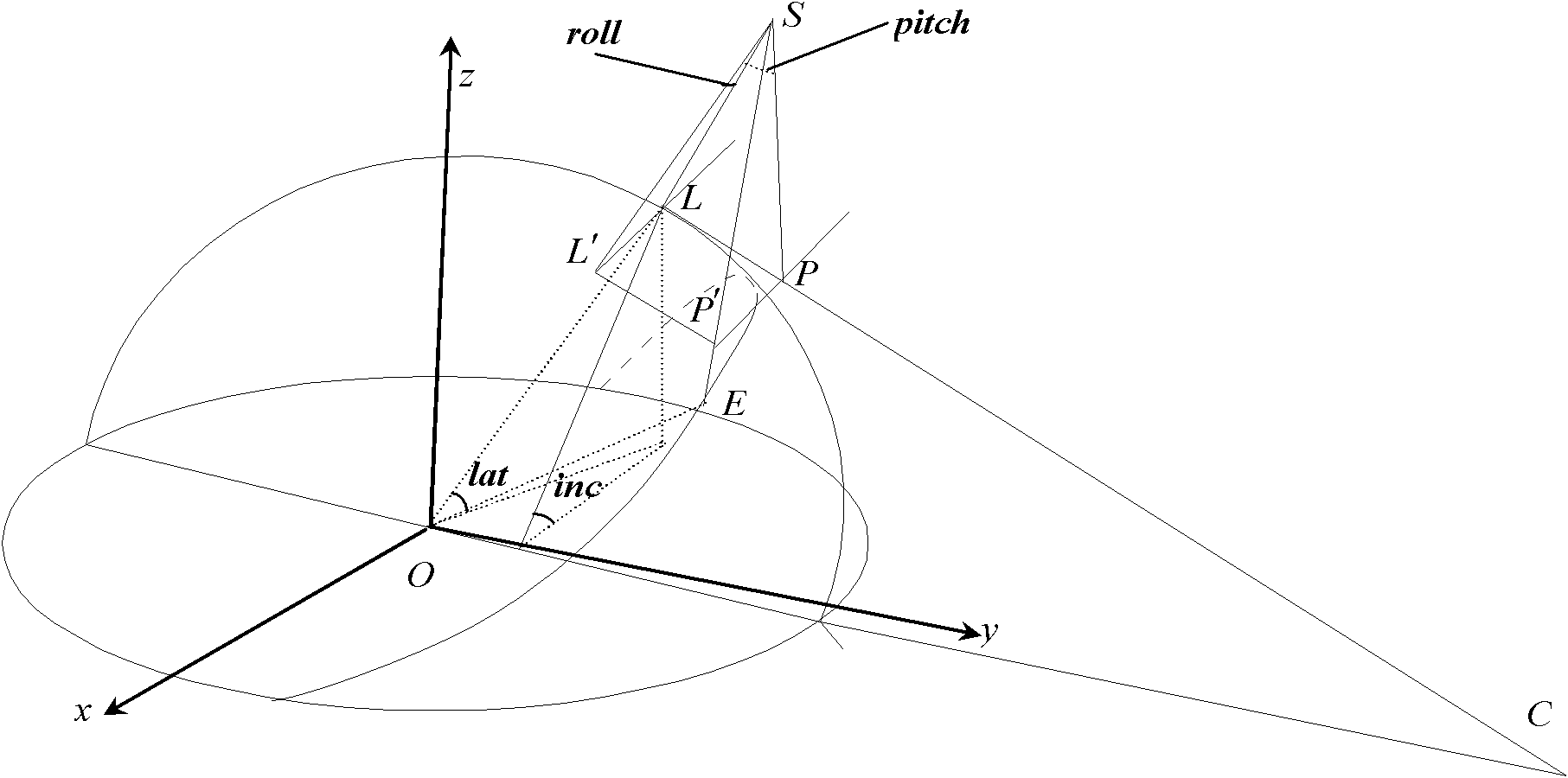

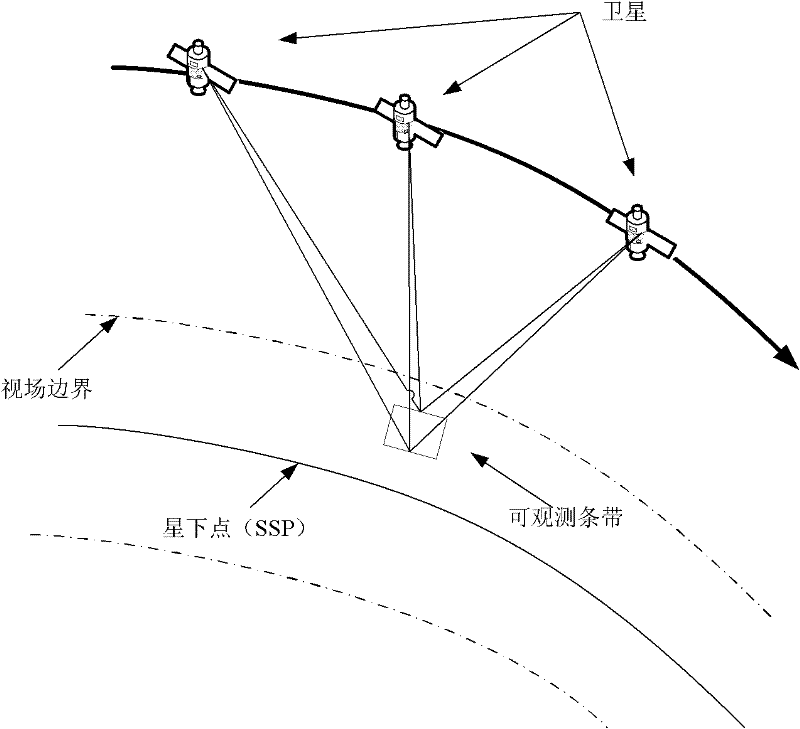

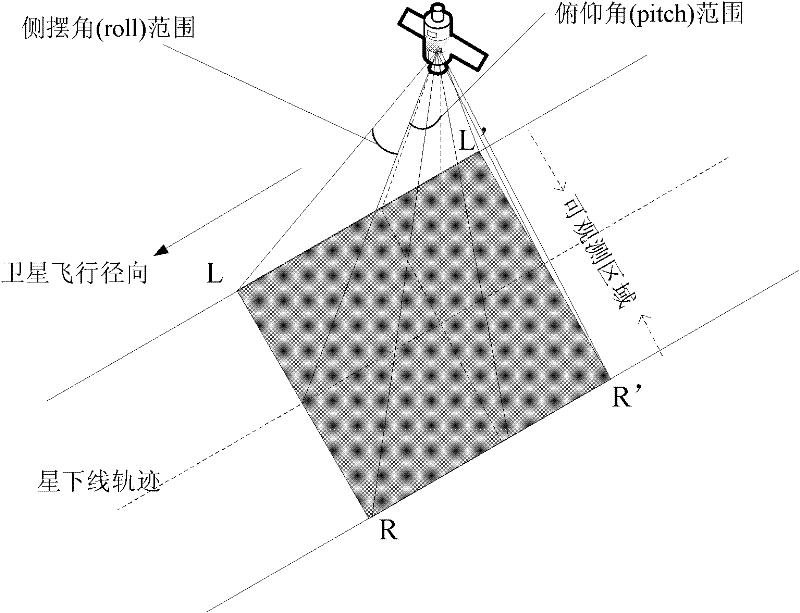

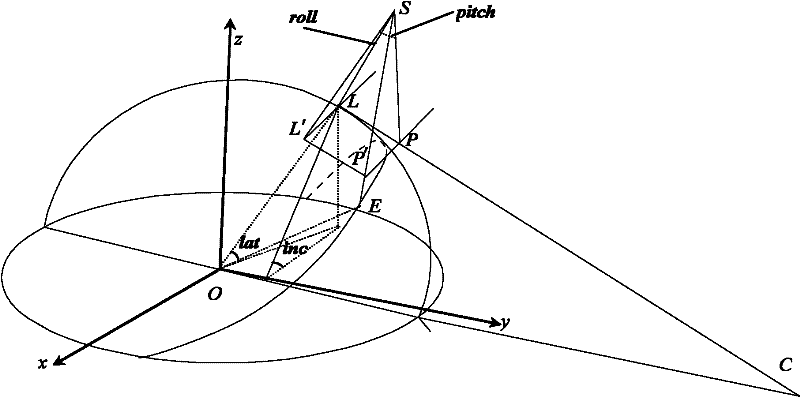

Smart satellite earth observation time window generating method based space analytic geometry

InactiveCN101866393AGenerate satisfactionSimple and fast operationSpecial data processing applicationsEarth observationRelational model

The invention relates to a smart satellite earth observation time window generating method based space analytic geometry, comprising the following six steps of: (1) establishing a space analytic geometry relational model, and using the model for carrying out coordinate transformation on the given substellar point and satellite coordinate; (2) initialization: pretreating the substellar point and target data, and forming substellar point target pair sequence; (3) angle inversion: carrying out angle inversion on each substellar point target in the substellar point target pair sequence, and obtaining a roll sequence and a pitch sequence corresponding to the substellar point target pair sequence; (4) rotation matrix inverse transformation: converting the roll sequence and the pitch sequence which are obtained in the step (3) into dynamic angle under a dynamic rotation coordinate system by inverse transformation; (5) obtaining smart satellite observation angle curve for observing the target by calculation of interpolation; and (6) intercepting a time window. The smart satellite earth observation time window generating method has the advantages of simple and convenient operation, high accuracy, easy implementation and the like, and can be applied under the background of rotation with three degrees of freedom of a smart satellite.

Owner:NAT UNIV OF DEFENSE TECH

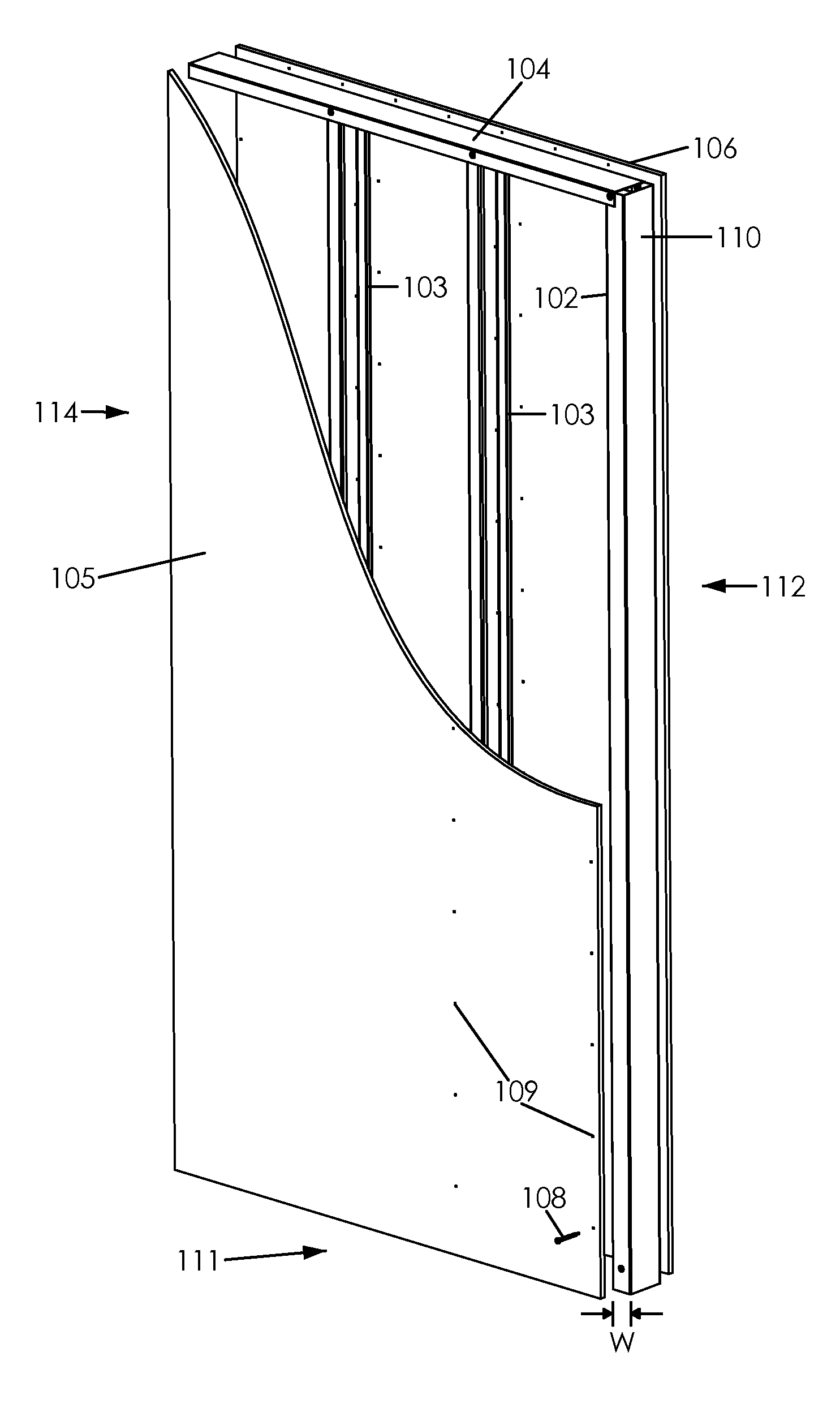

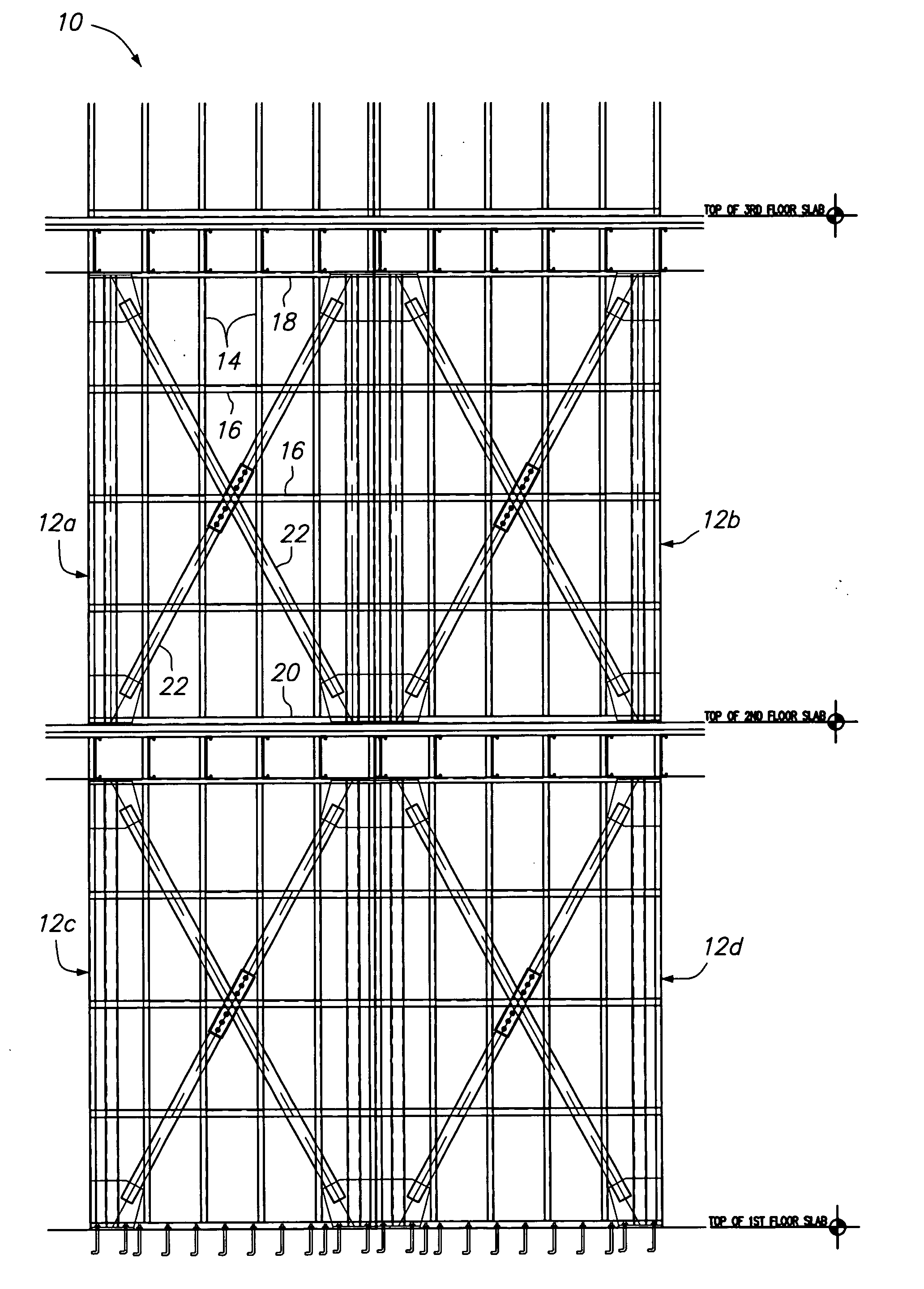

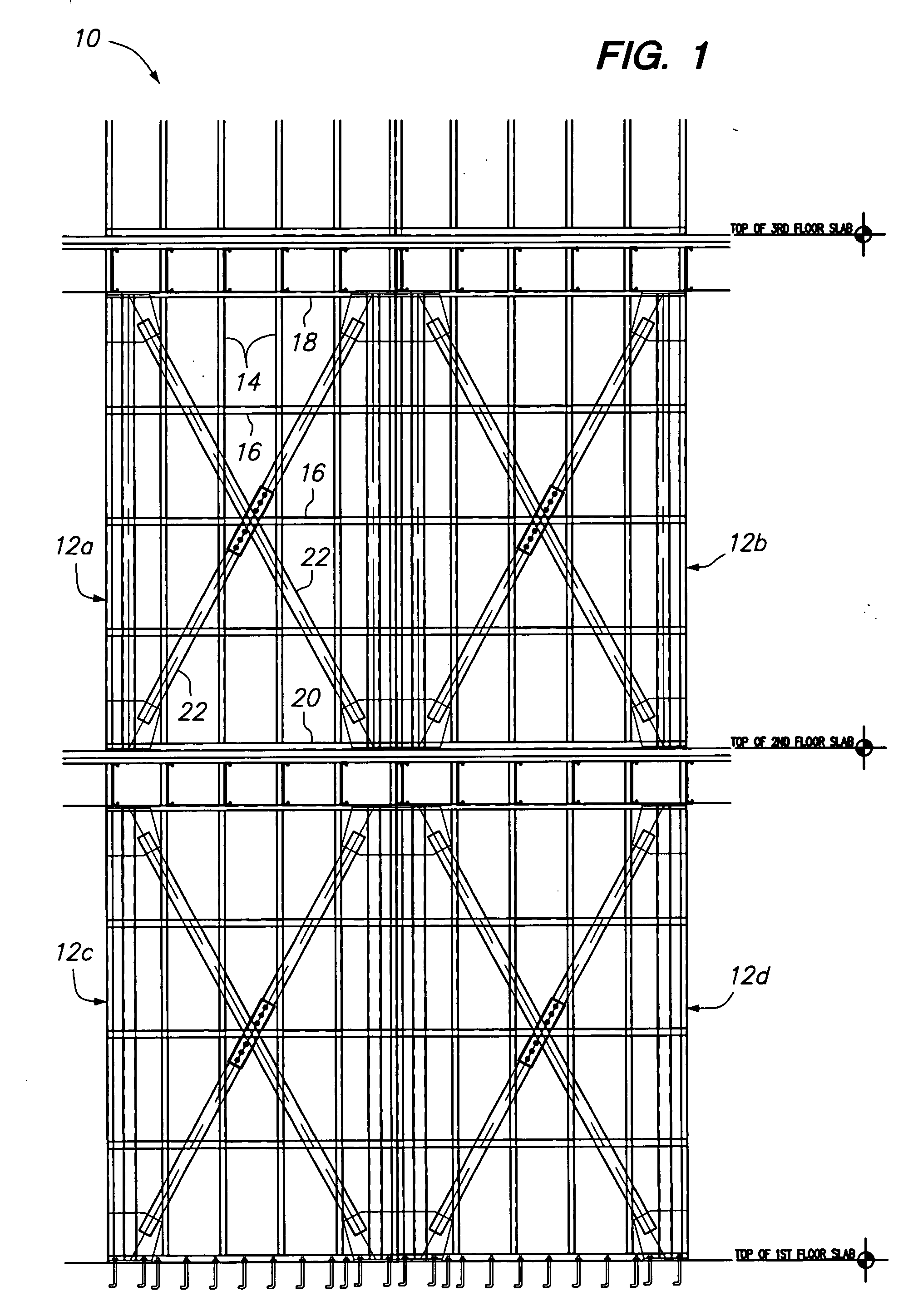

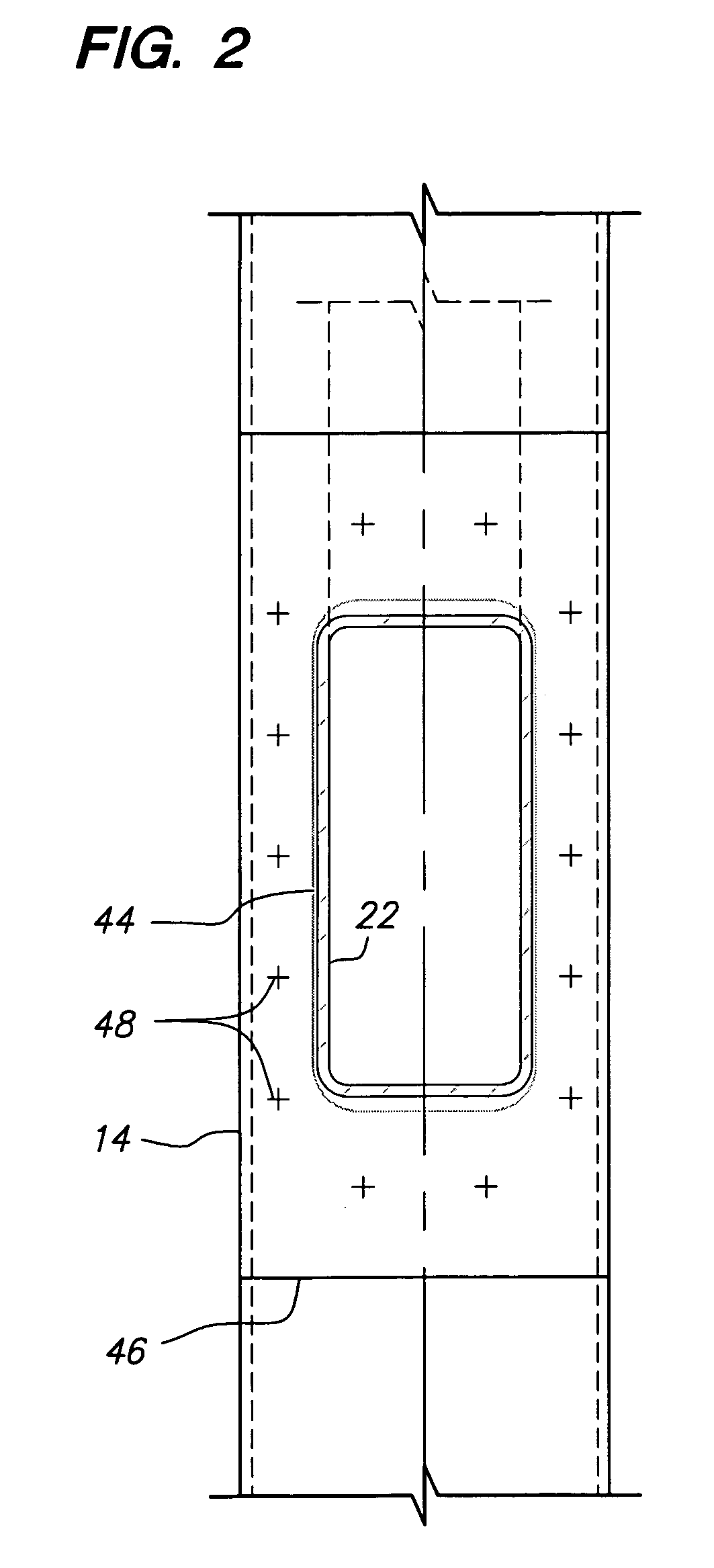

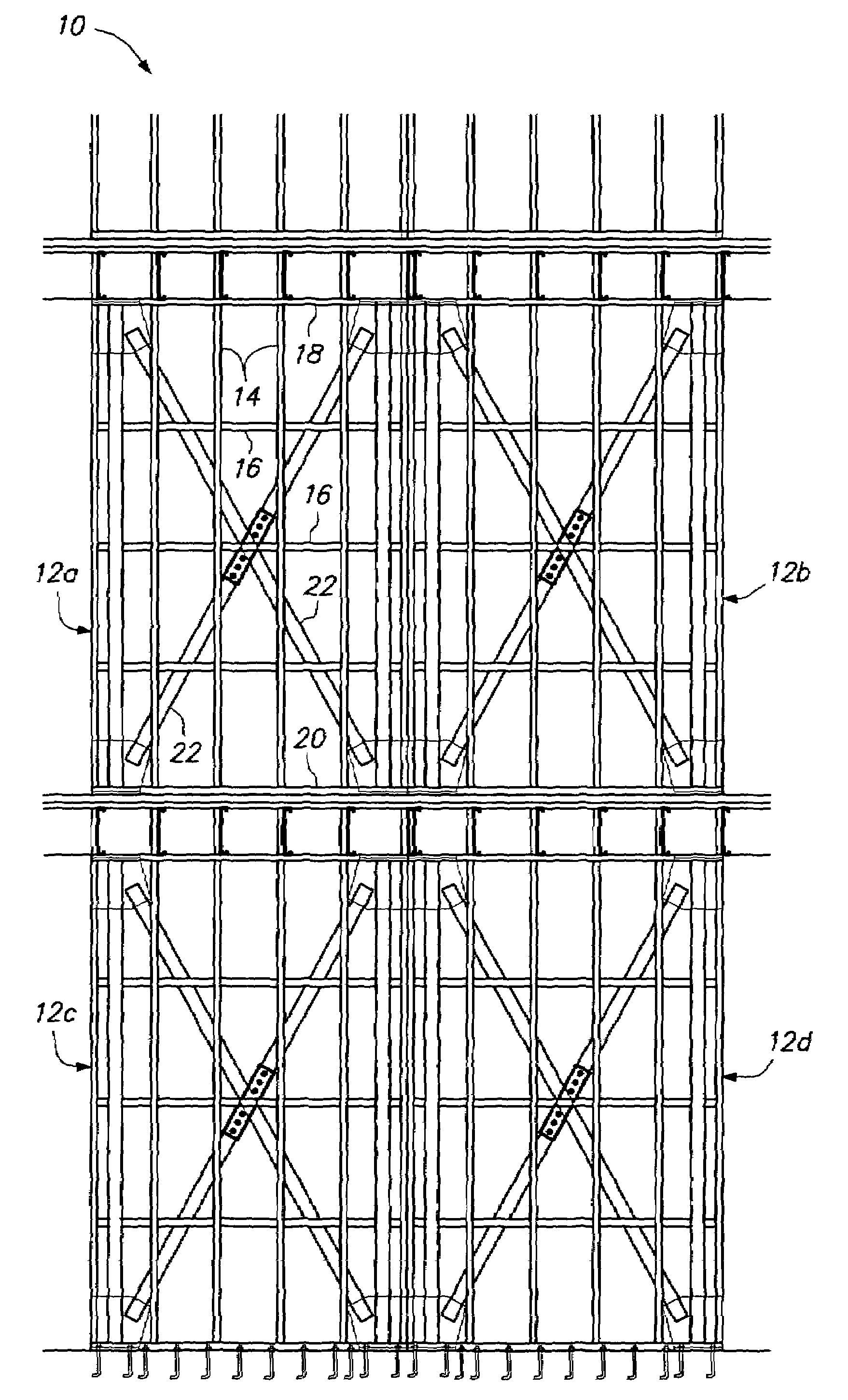

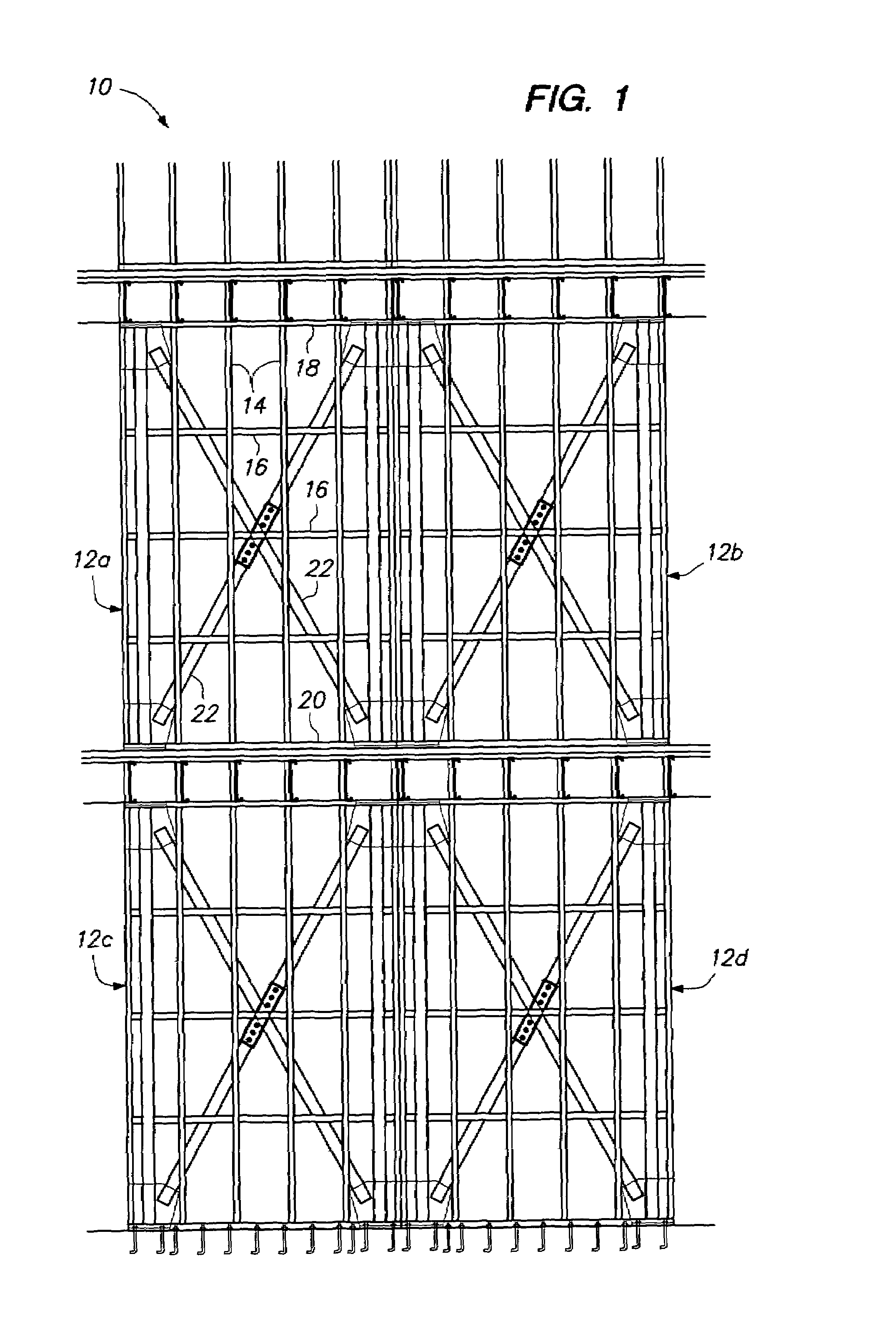

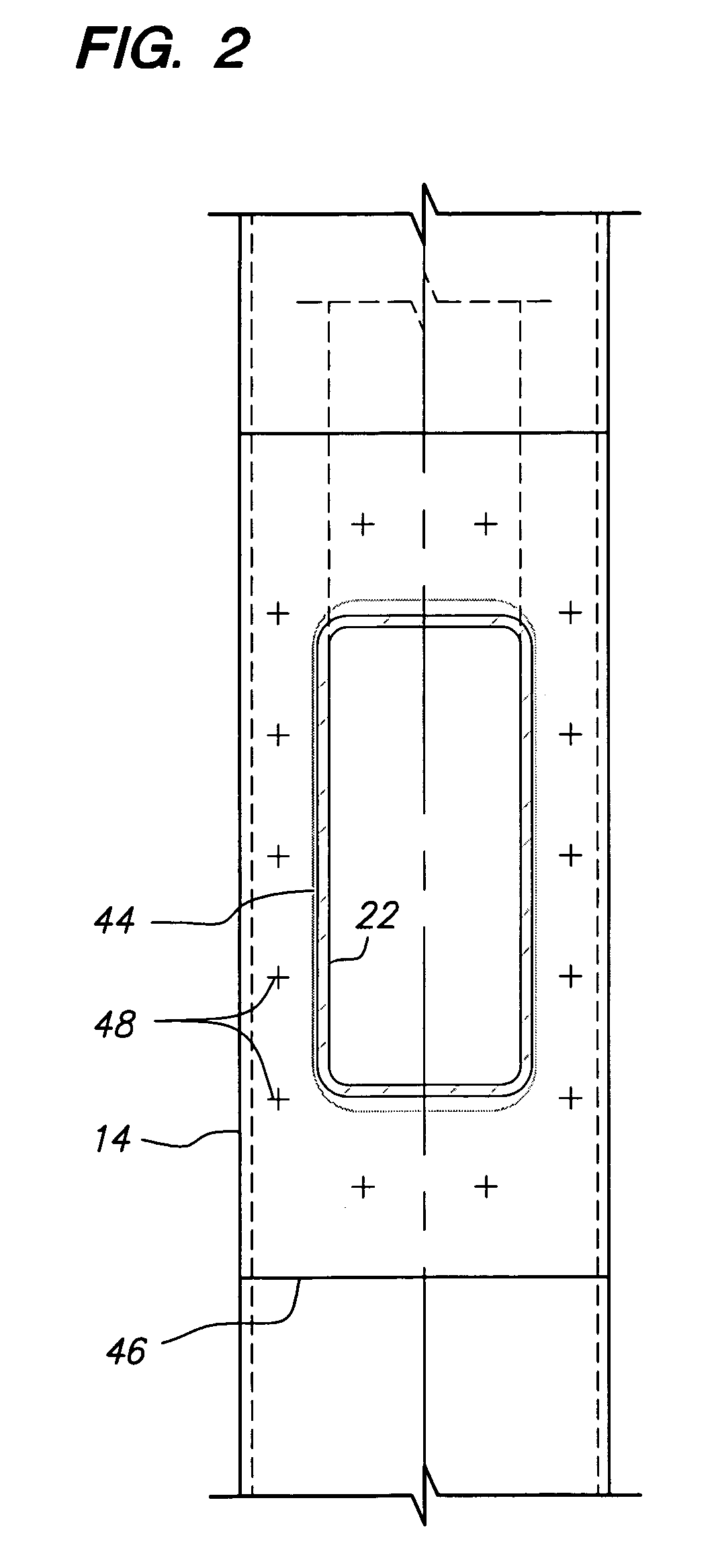

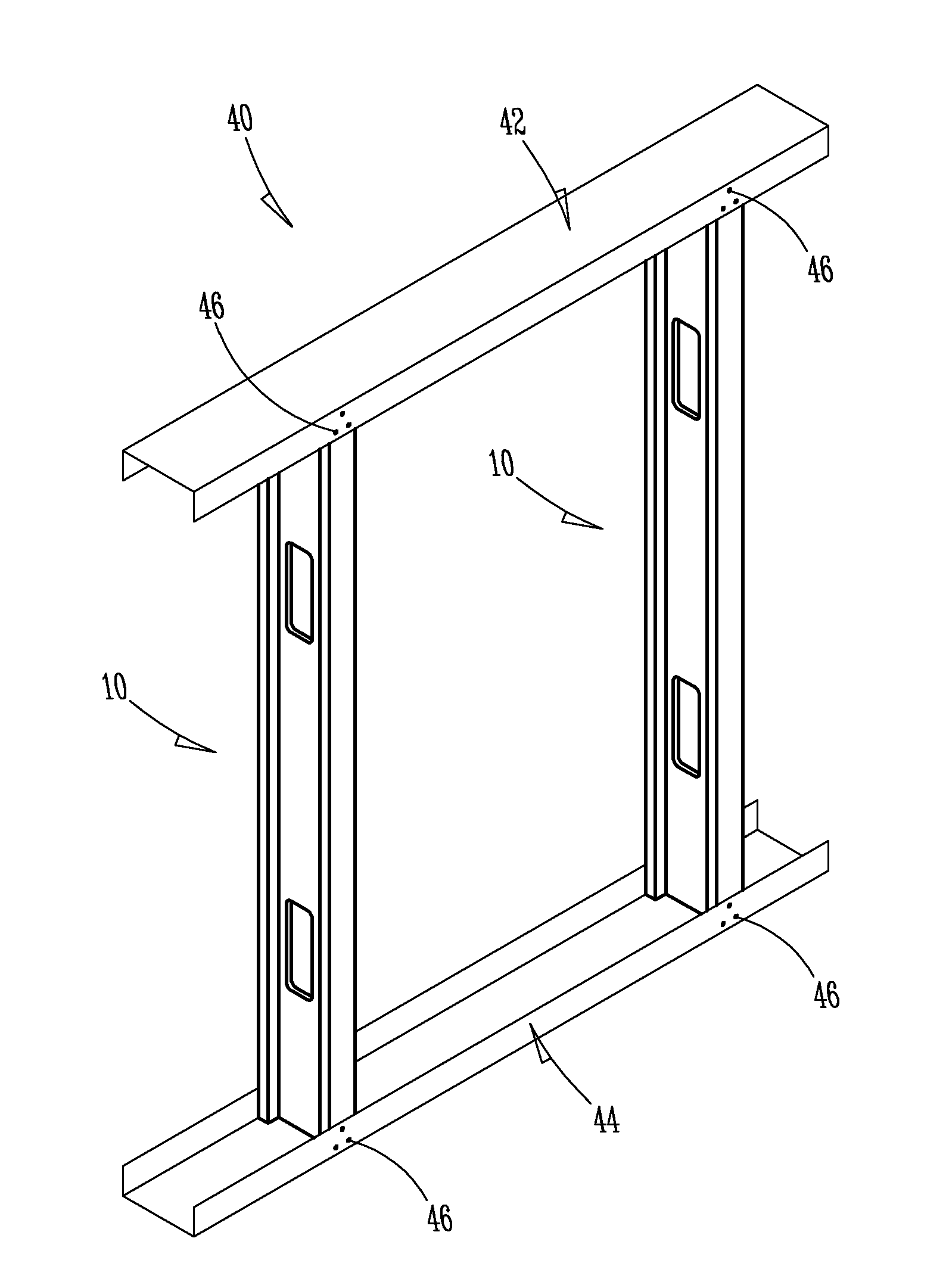

Structural braced frame wall panel system

InactiveUS20050229509A1Meet build requirementsMeet the requirementsStrutsBuilding repairsBraced frameWall stud

A metal panelized wall system having a plurality of generally parallel vertical wall studs with an opening formed in each one. A top horizontal member is connected to a top end of each of the vertical wall studs and a bottom horizontal member is connected to a bottom end of each of the vertical wall studs. Extending from the bottom horizontal member to the top horizontal member is at least one diagonal member. The diagonal member extends through the openings formed in the vertical wall studs such that loads from the vertical wall studs are not transferred to the diagonal member.

Owner:MAJLESSI KAMRAN REZA

Structural braced frame wall panel system

A metal panelized wall system having a plurality of generally parallel vertical wall studs with an opening formed in each one. A top horizontal member is connected to a top end of each of the vertical wall studs and a bottom horizontal member is connected to a bottom end of each of the vertical wall studs. Extending from the bottom horizontal member to the top horizontal member is at least one diagonal member. The diagonal member extends through the openings formed in the vertical wall studs such that loads from the vertical wall studs are not transferred to the diagonal member.

Owner:MAJLESSI KAMRAN REZA

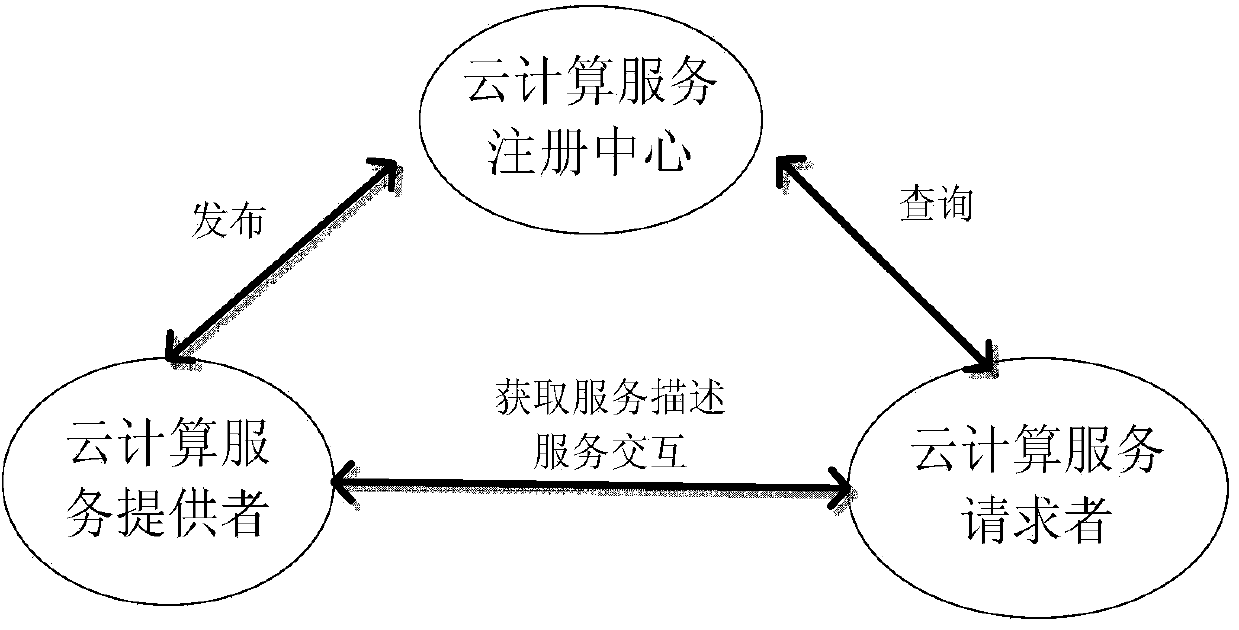

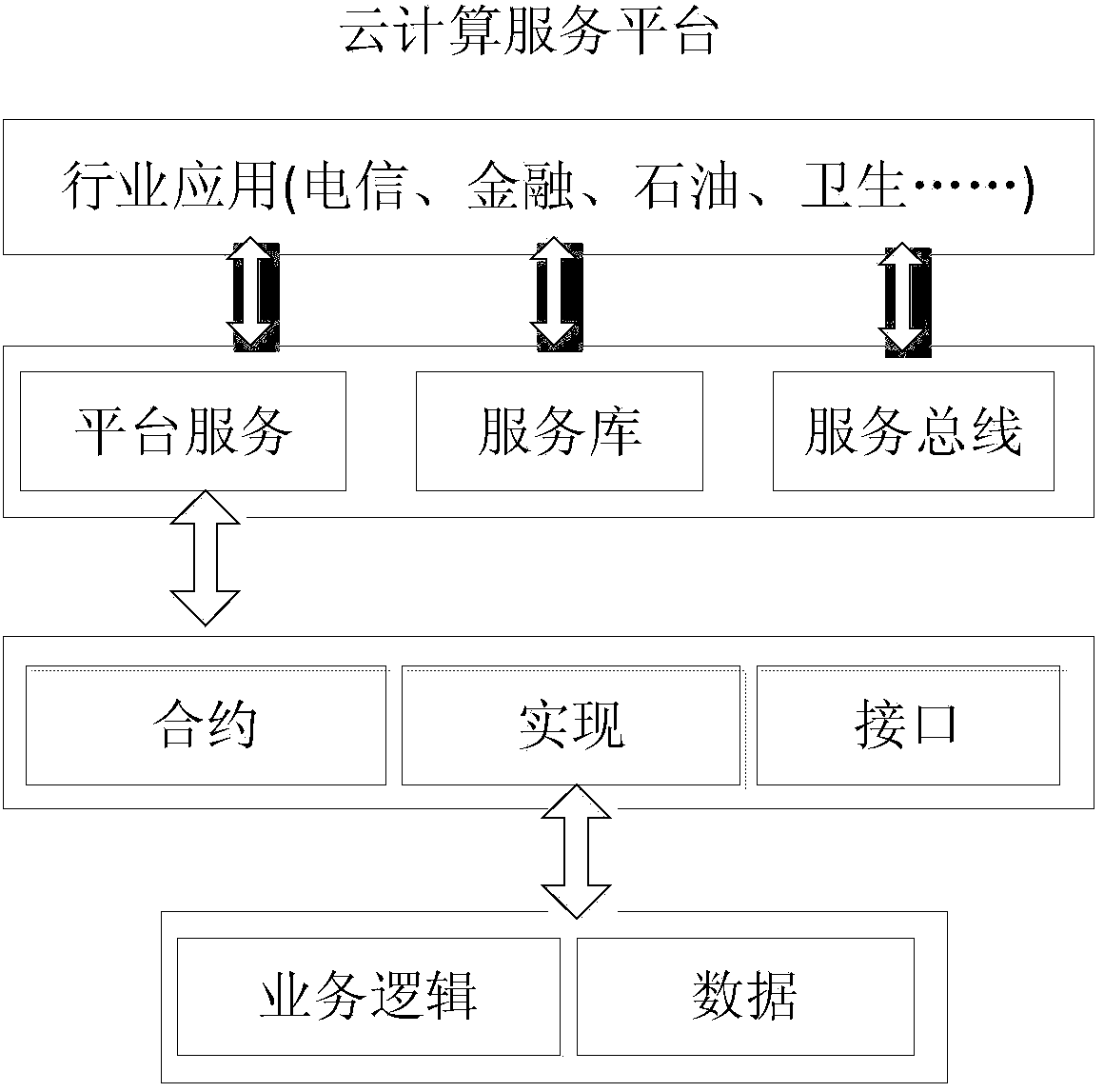

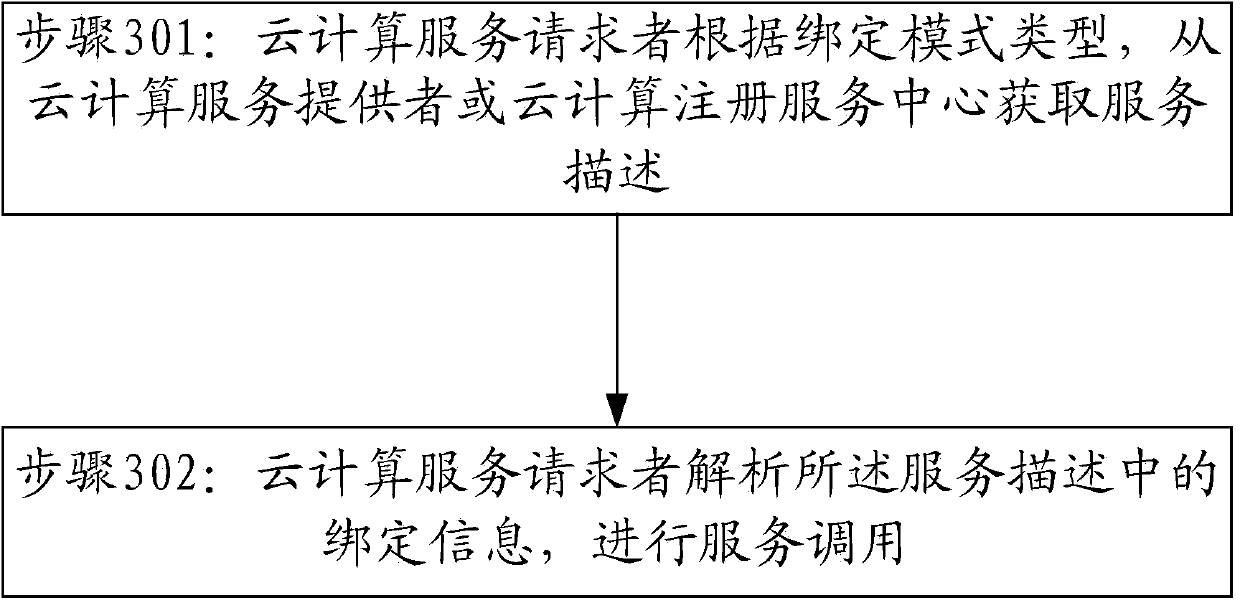

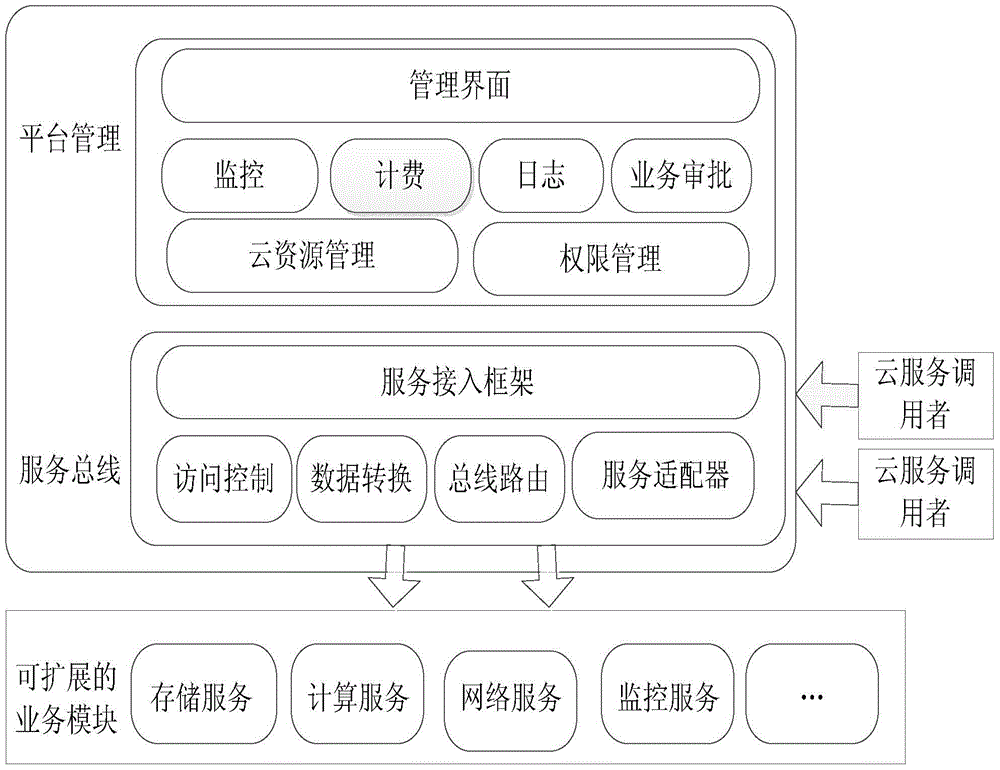

Construction method and system of cloud computing service platform

InactiveCN103701935AImprove scalabilityMeet build requirementsTransmissionLoose couplingLayered Service Provider

The invention provides a construction method and system of a cloud computing service platform, which is applied to the technical field of computer applications. The method comprises the following steps: a cloud computing service requester obtains service description from a cloud computing service provider or a cloud computing registration service center according to the type of binding mode, and analyzes binding information in the service description to perform service calling. According to the method provided by the invention, existing IT (information technology) infrastructures of an enterprise are protected with the help of an SOA (service-oriented architecture) and the loose coupling property thereof in the cloud computing service platform; by using a cloud computing service architecture of the SOA mode, the enterprise can add new services or update the existing services according to a modularization way to solve new business requirements, provide choices to provide the services through different channels, take the existing applications of the enterprise as the services and further protect existing IT infrastructure investment.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

Alternative I-Stud

An i-stud having a web and flanges comprising oriented strand board (OSB) and a method of assembling a wall utilizing the same, wherein the flanges are unitary and non-laminated. The method of assembling a wall may utilize a wall system comprising upper and lower frame members or may utilize existing structural members.

Owner:DEBOEF JR DUANE R

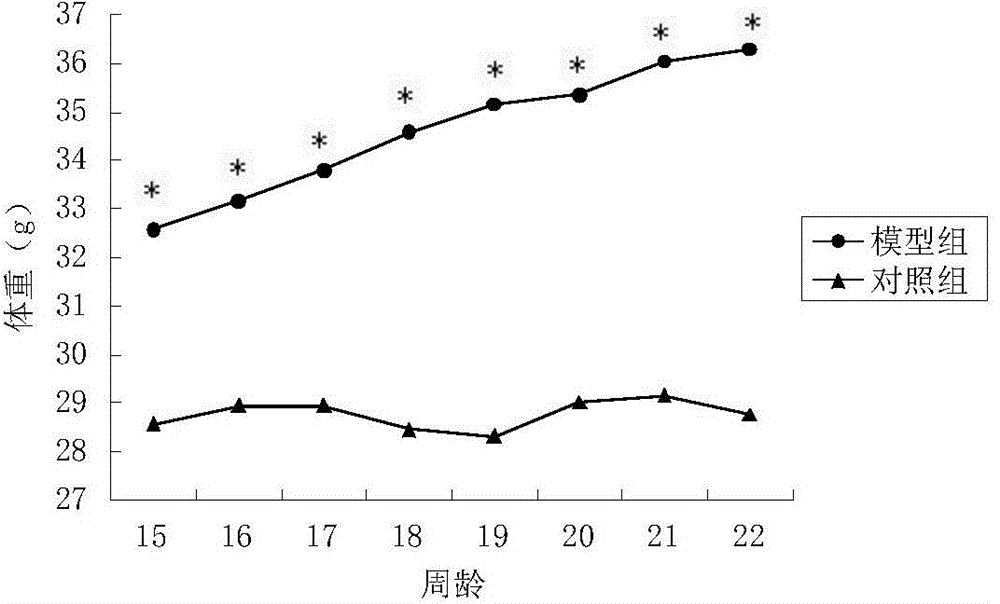

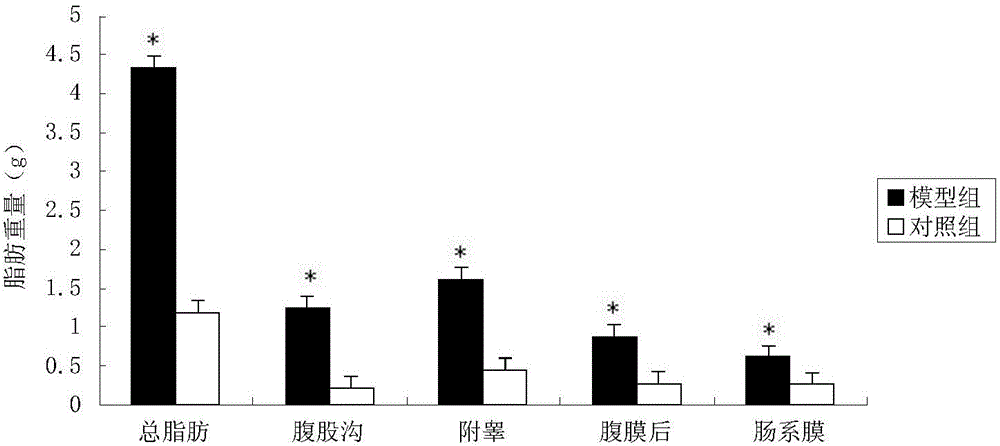

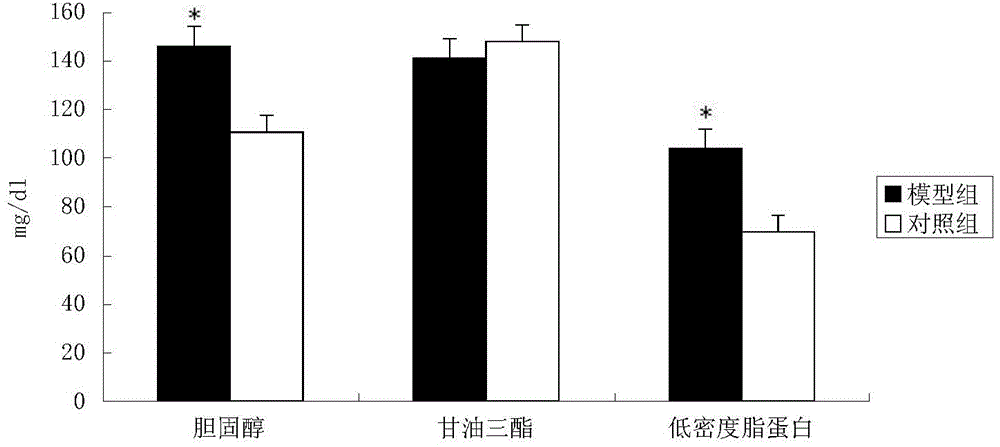

Purified feed used for constructing nutritional obesity animal model as well as preparation method and application of purified feed

The invention discloses a purified feed used for constructing a nutritional obesity animal model as well as a preparation method and application of the purified feed. The purified feed is prepared from the following raw materials in parts by weight: 200-300 parts of casein, 3-5 parts of cysteine, 100-150 parts of maltodextrin, 50-100 parts of sucrose, 30-80 parts of cellulose, 20-50 parts of soya-bean oil, 250-360 parts of lard oil, 10-15 parts of mineral salt premix compound, 10-20 parts of calcium hydrogen phosphate, 5-10 parts of calcium carbonate, 15-30 parts of potassium citrate, 10-15 parts of vitamin premix compound, 2-4 parts of choline bitartrate, and 0.06-0.08 part of food-grade methylene blue stain. According to the purified feed, the purified raw materials with clear components are adopted, so that the oil content can be increased, the proportioning is reasonable, the quality is stable, the food with the form and the taste is suitable for being eaten, and the purified feed can be used for constructing a rodent nutritional obesity model, has an obvious effect and is good in repeatability.

Owner:北京华阜康生物科技股份有限公司

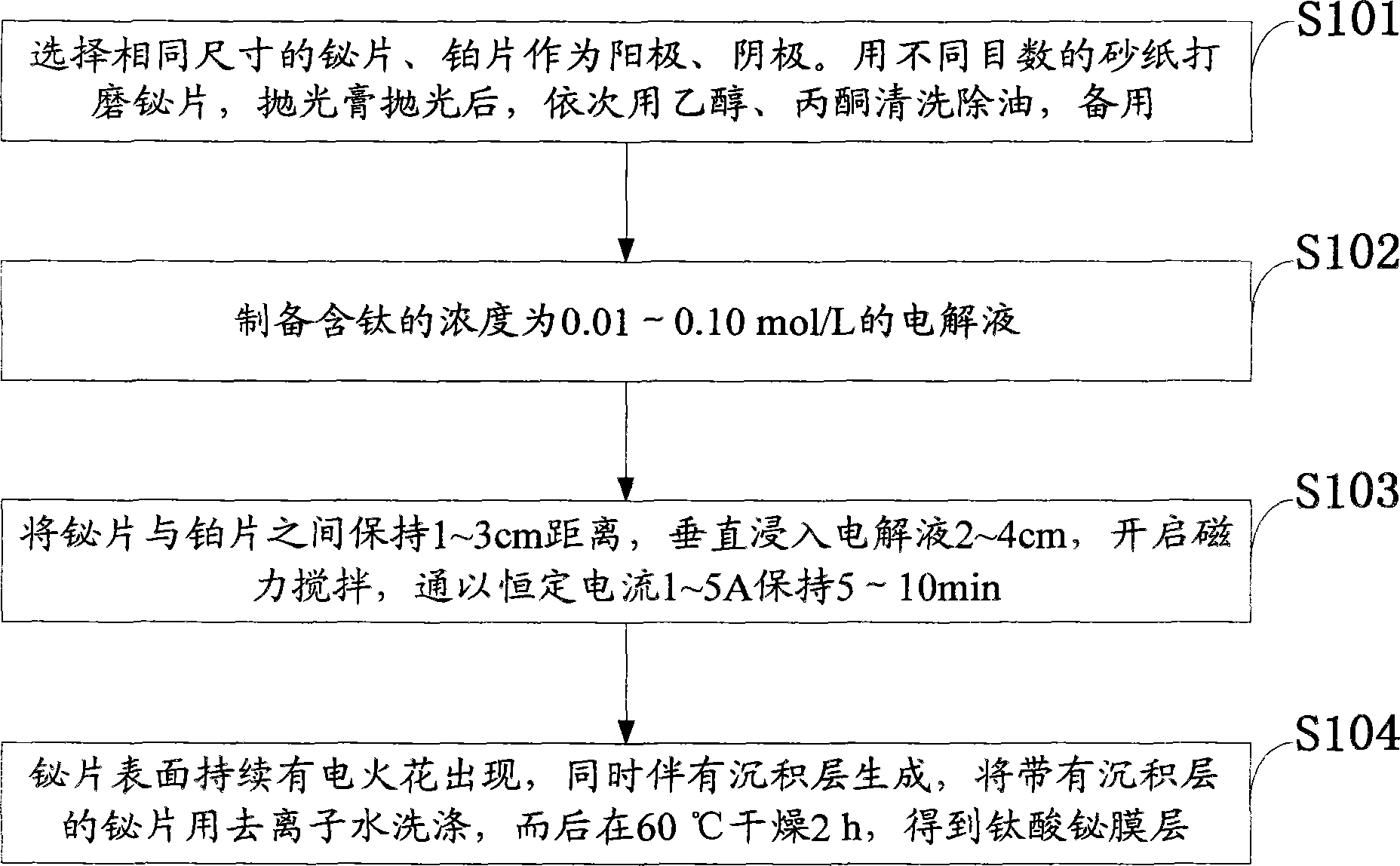

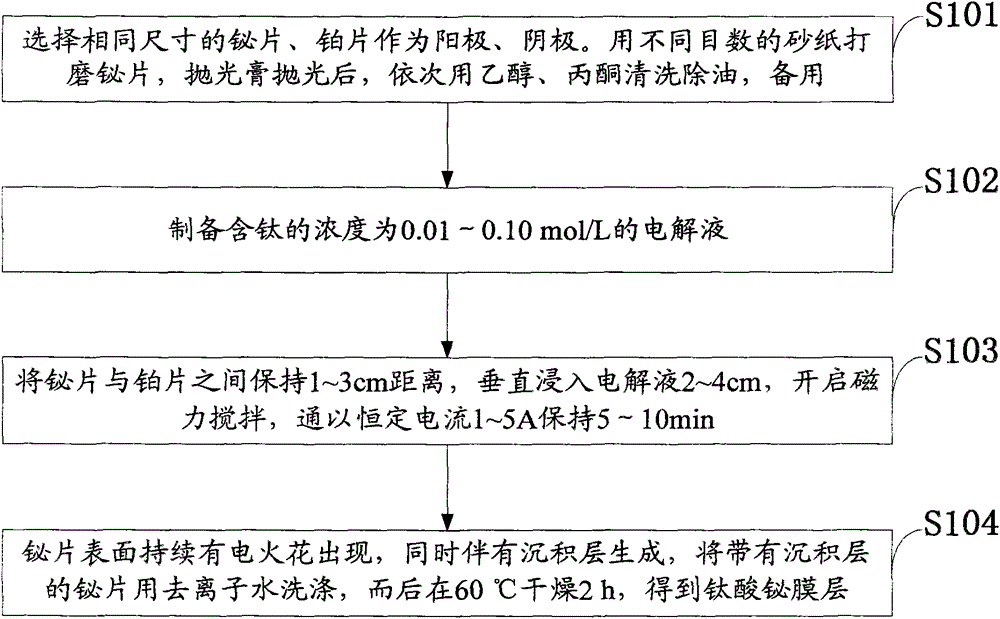

Preparation method for bismuth titanate film layer on basis of micro-arc oxidation technology

InactiveCN103409781AAvoid the use of organic solventsThe preparation process is simpleSurface reaction electrolytic coatingMicro arc oxidationIon

The invention discloses a preparation method for a bismuth titanate film layer on the basis of micro-arc oxidation technology. The preparation method comprises the following steps: a bismuth sheet and a platinum sheet which are the same in size are respectively used as an anode and a cathode; the bismuth sheet is burnished with several pieces of sand paper with different meshes and polished with a polishing paste, and the cleaning and oil removal of the bismuth sheet are performed sequentially via alcohol and acetone for standby; electrolyte with titanium concentration of 0.01-0.10 mol / L is prepared; the bismuth sheet keeps a distance of 1-3 cm from the platinum sheet, the bismuth sheet and the platinum sheet are vertically immersed into the electrolyte in a depth of 2-4 cm, magnetic agitation is started, and 1-5A constant current is electrified for 5-10 min; electric sparks are continuously generated on the surface of the bismuth sheet, a deposition layer is synchronously generated, and the bismuth sheet with the deposition layer is flushed with ion water and then dried at a temperature of 60 DEG C for 2 h, as a result, a bismuth titanate film layer is obtained. The bismuth titanate film layer preparation method is mild in synthesis conditions, can be completed under the conditions of normal temperature and normal pressure, and is quick in reaction speed and simple in operation steps; used bismuth is an environmental-friendly raw material, the process is safe, and no hazardous substance is leaked and discharged, so that environmental protection is facilitated.

Owner:QINGDAO AGRI UNIV

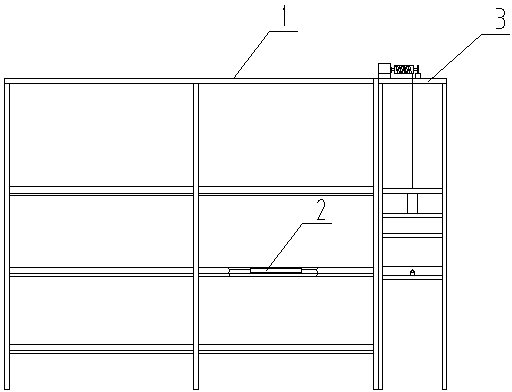

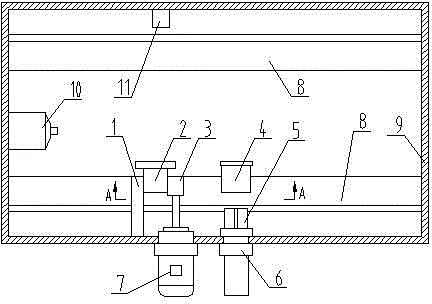

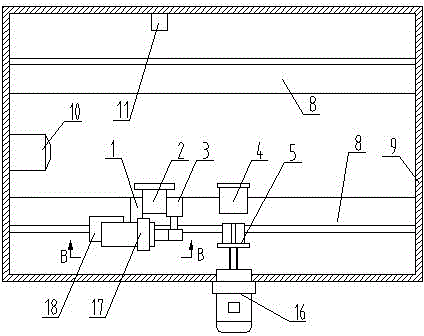

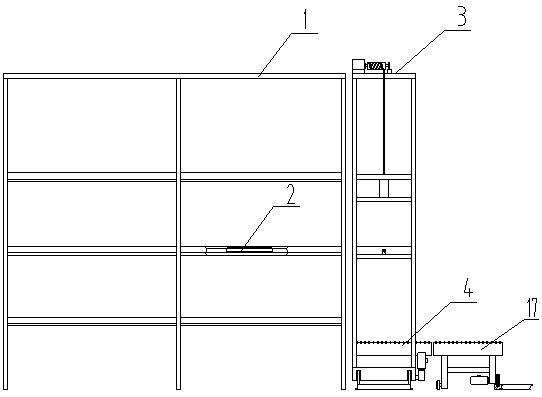

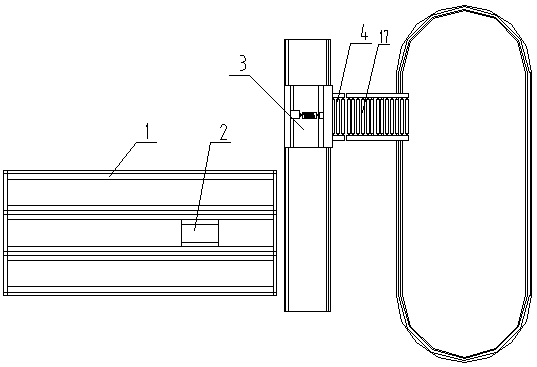

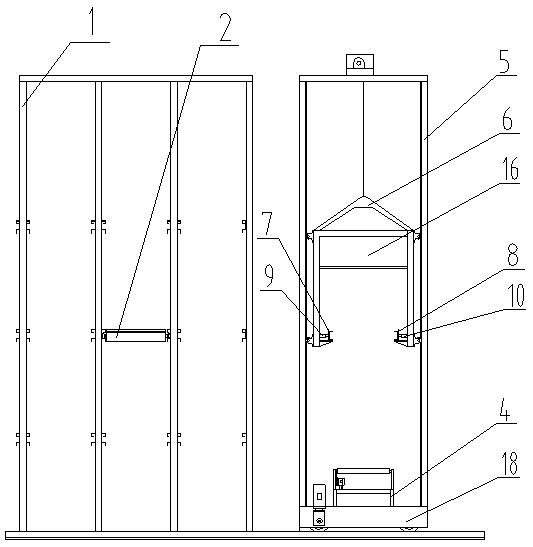

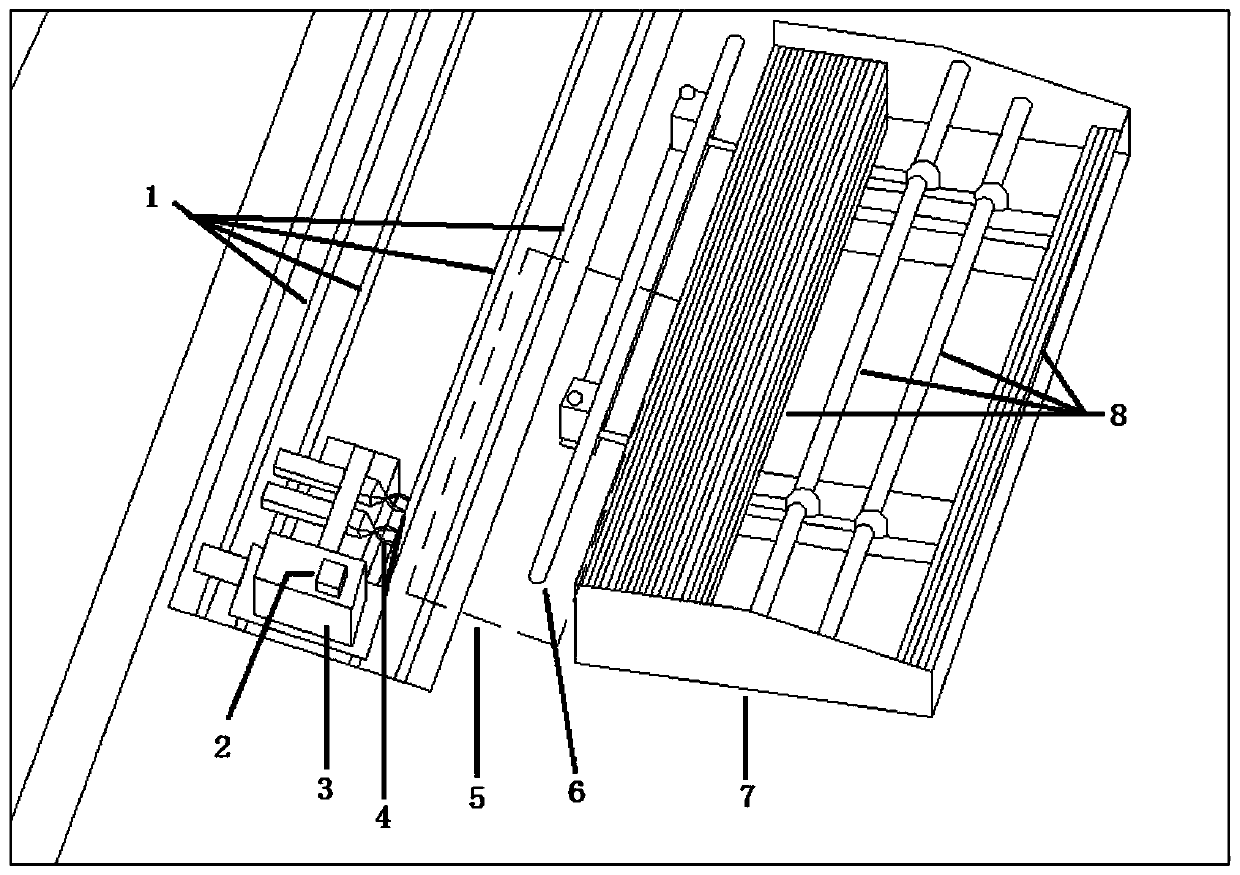

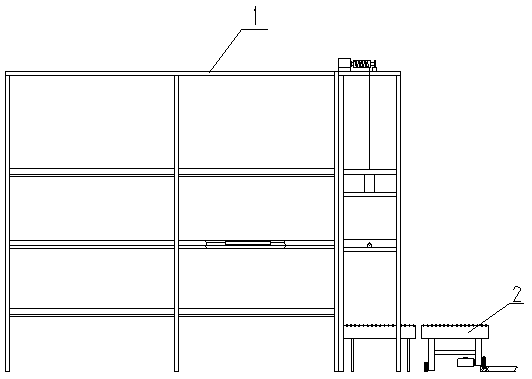

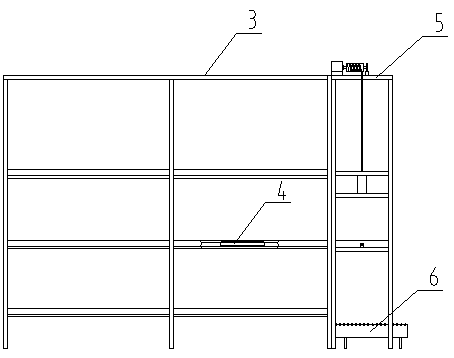

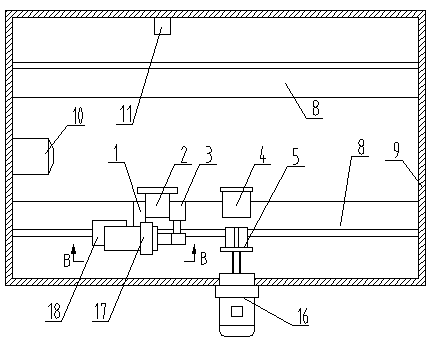

Shuttle-type stereoscopic warehouse unit

ActiveCN104925441AAccurate and reliableRealize automatic chargingStorage devicesMechanical conveyorsPush and pullLinear motion

The present invention discloses a shuttle-type stereoscopic warehouse unit. The stereoscopic warehouse unit comprises a column of multilayer penetrating type storage shelves (1), a shuttle vehicle (2) and an elevator (3). Goods are supported through two shuttle vehicle guide rails positioned at two sides of a lifting platform, the shuttle vehicle guide rails are driven by a transverse moving mechanism to transversely move in a reverse direction, the goods can be loaded and unloaded through reverse transverse moving of the shuttle vehicle guide rails and elevating motion of the lifting platform, transverse moving distance of the guide rails is short when the goods are loaded and unloaded, and consumed time of the transverse moving process is short. An automatic electrical connection device is installed in a charging room over the lifting platform, a stirring rod rotating around a rotation center stirs a positioning seat fixedly installed on the shuttle vehicle to enable the shuttle vehicle to tightly attached to a backplate, a plug is aligned to the center of a socket, automatic plugging of the plug and the socket is achieved in a manner that a linear motion mechanism pushes and pulls the plug, operation is convenient, and the shuttle vehicle can be automatically charged.

Owner:毕玉玲

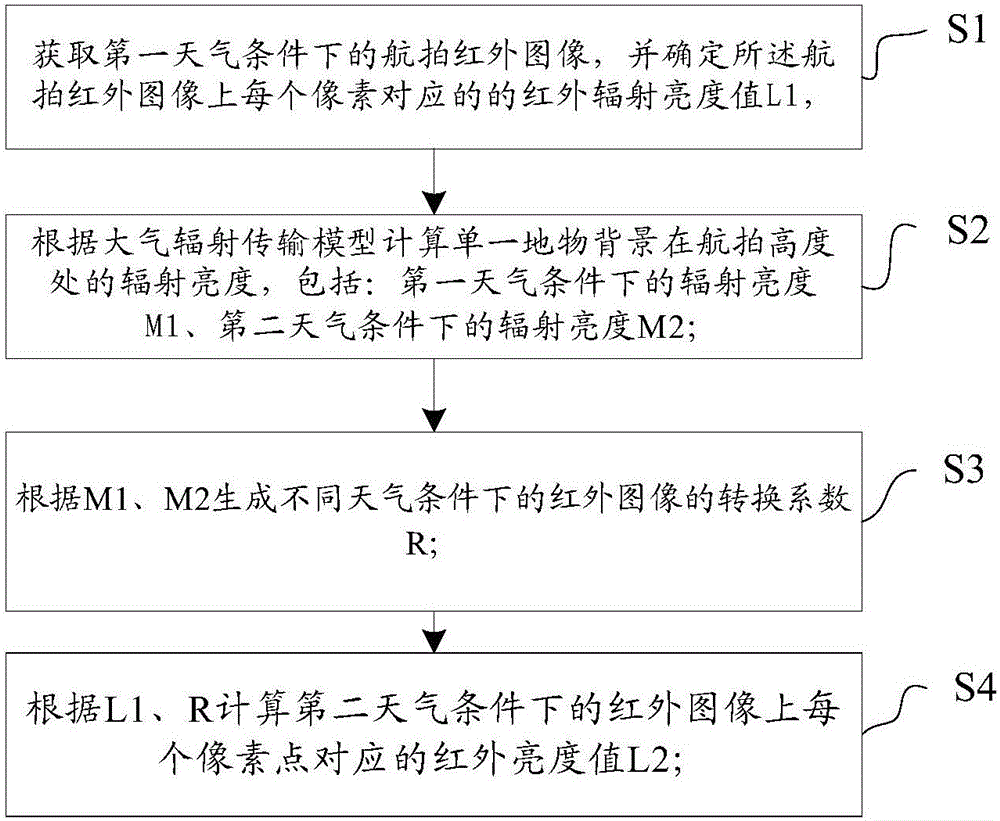

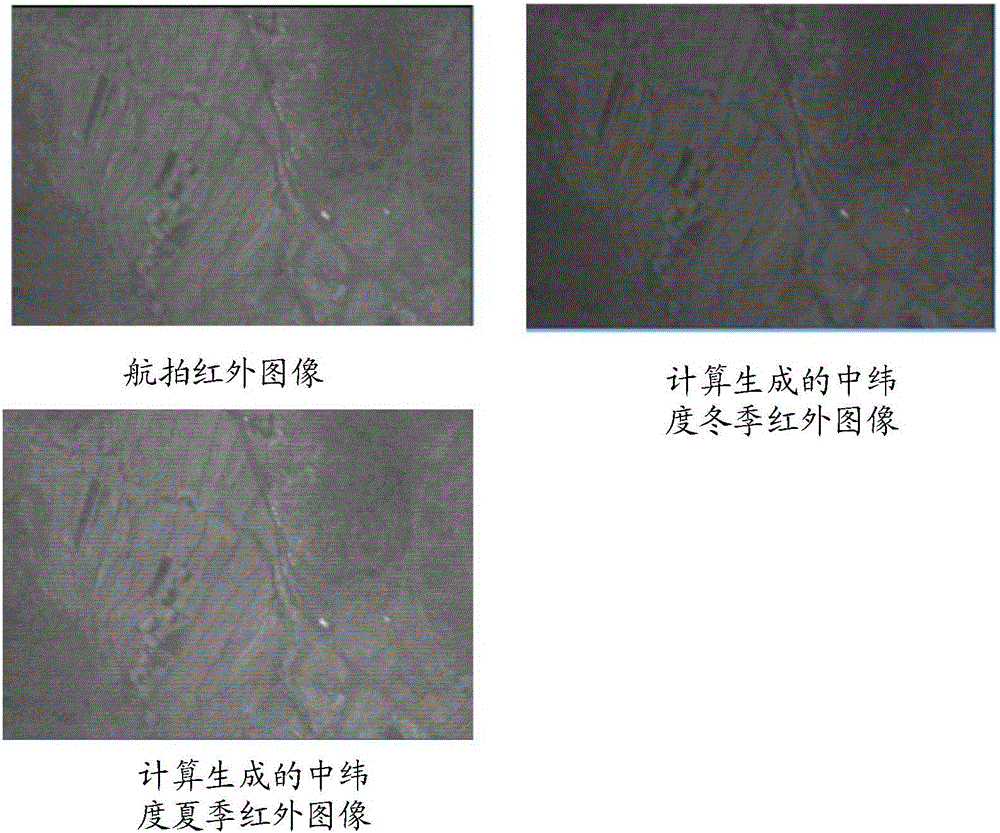

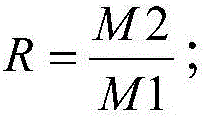

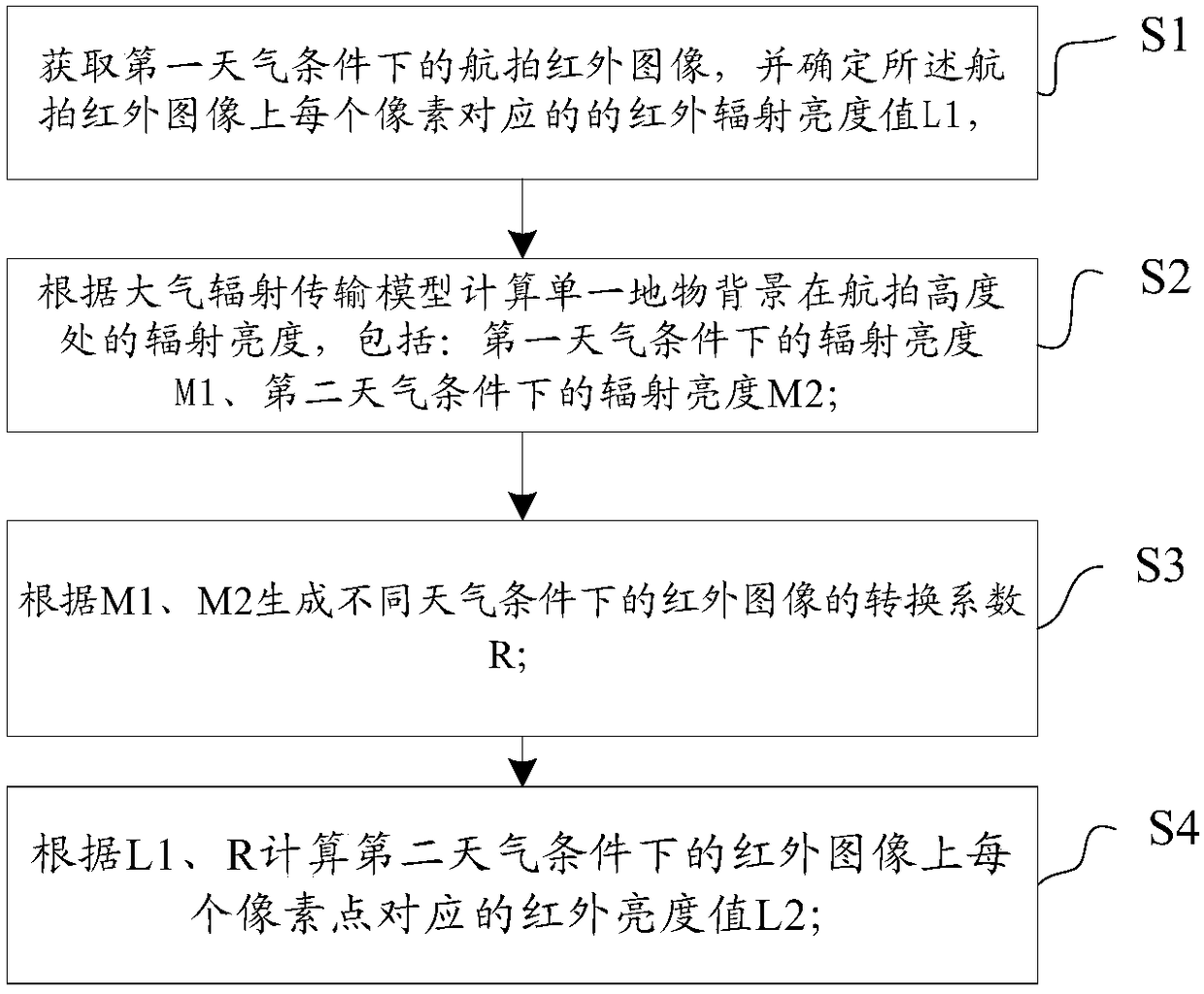

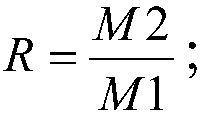

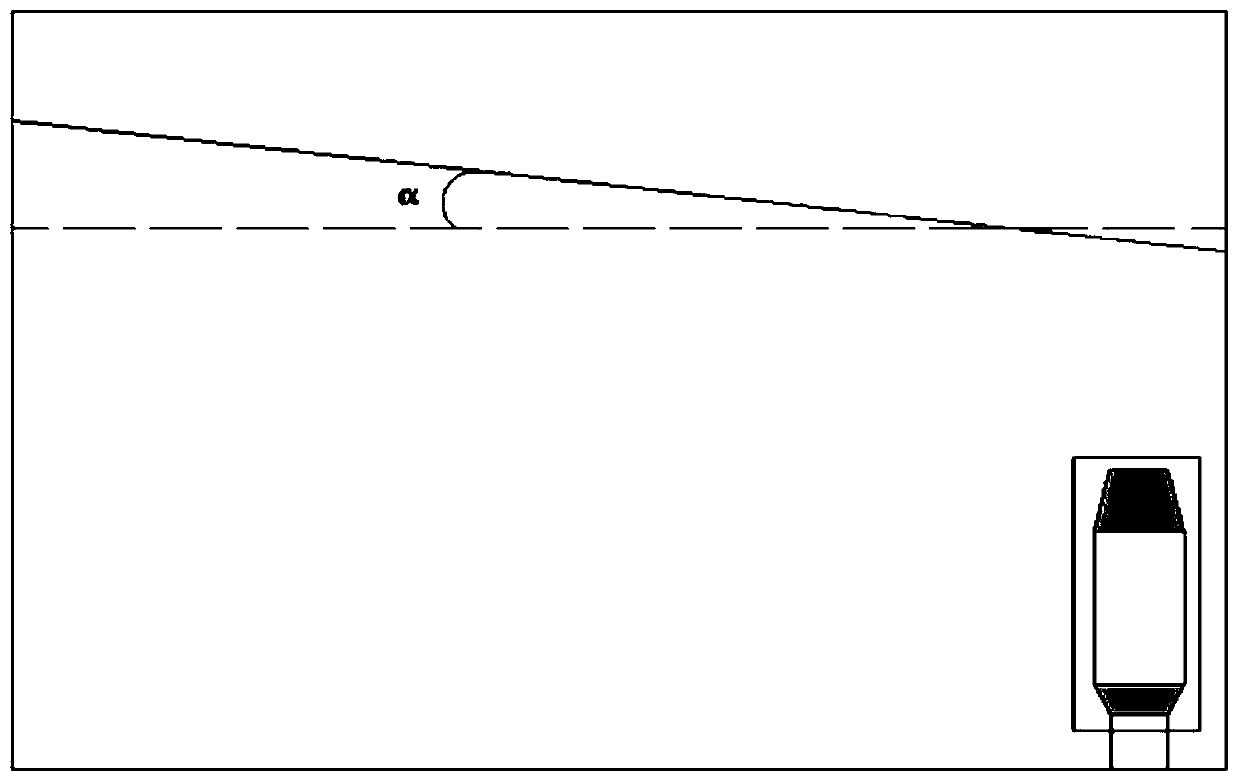

Method for acquiring infrared images on different weather conditions

ActiveCN105894447AMeet build requirementsAvoid classification and identification linksImage enhancementImage analysisConversion coefficientsCalculation error

Disclosed is a method for acquiring infrared images on different weather conditions. The method comprises steps of: S1, acquiring an aerially photographed infrared image on a first weather condition and determining an infrared radiation brightness value L1 corresponding to each pixel in the aerially photographed infrared image; S2, computing the radiation brightness of a single land feature background on the aerial photography height according to a MODTRAN simulation module, including the radiation brightness M1 on the first weather condition and the radiation brightness M2 on a second weather condition; S3, generating the conversion coefficients R of the infrared image on different weather conditions according to the M1 and the M2; and S4, computing the an infrared radiation brightness value L2 corresponding to each pixel in the infrared image on the second weather condition according to the L1 and the R. The method prevents classified identification of different land feature types and calculation errors due to uncertainty of surface reflectance and temperature, and increases computing speed.

Owner:BEIJING INST OF ENVIRONMENTAL FEATURES

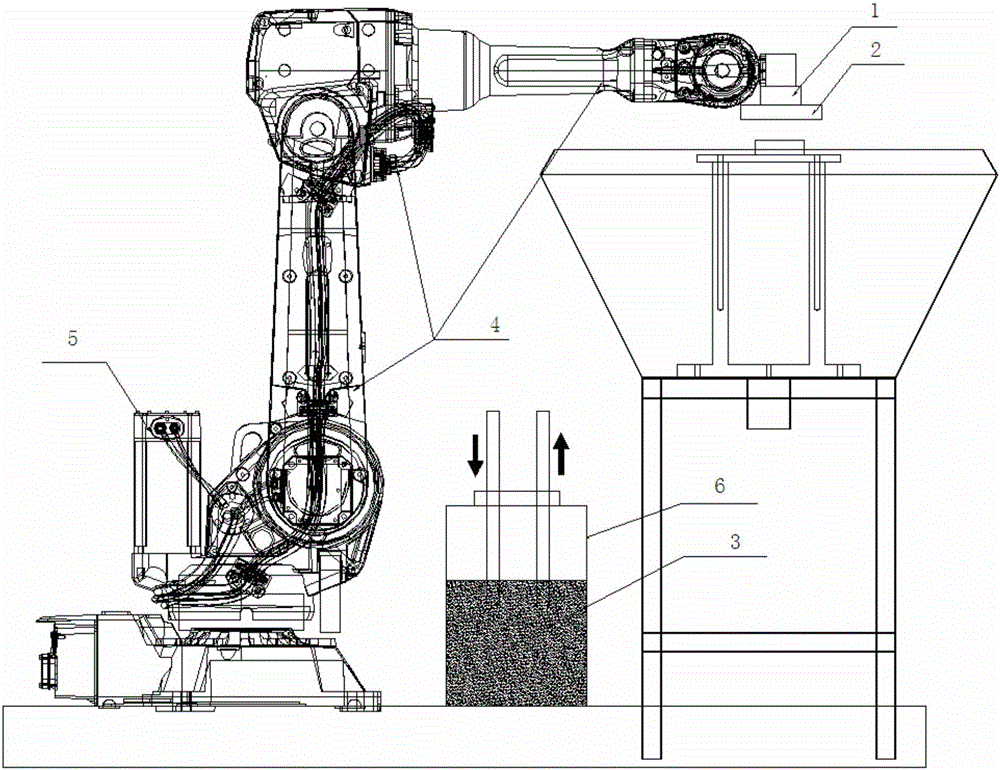

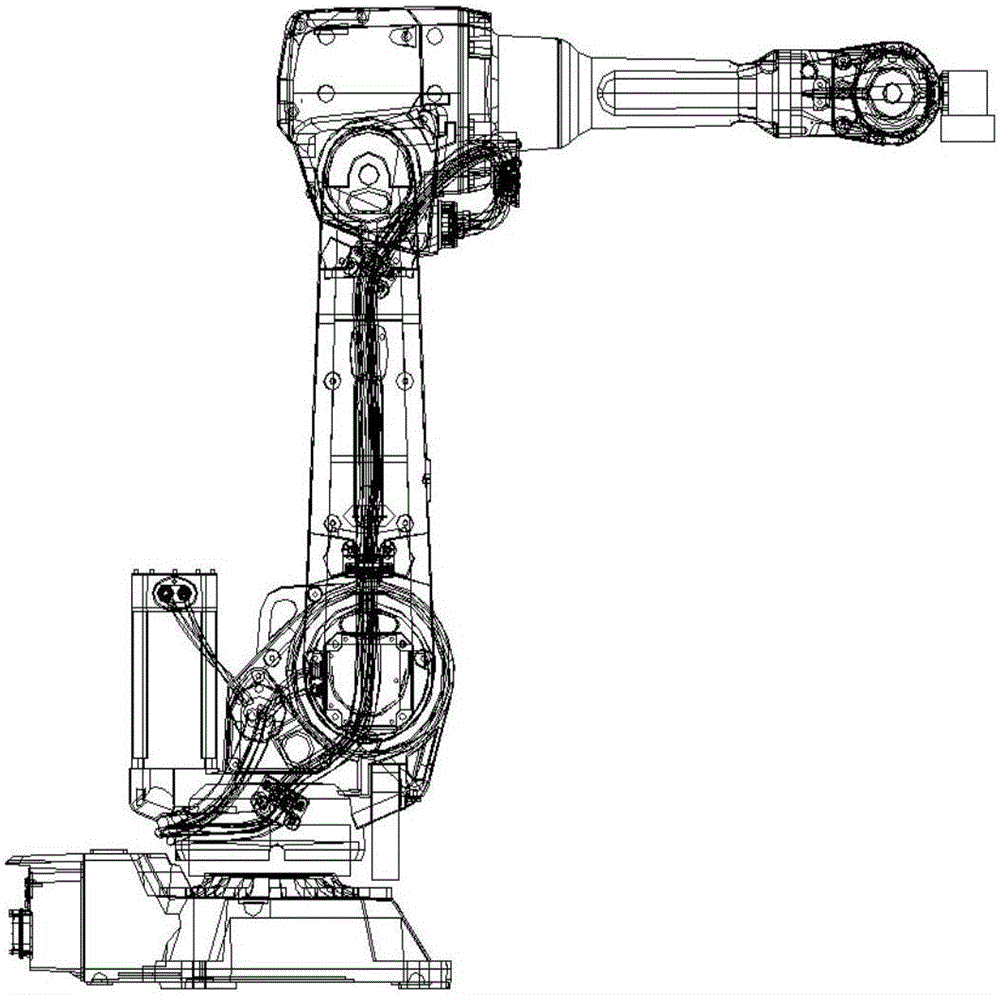

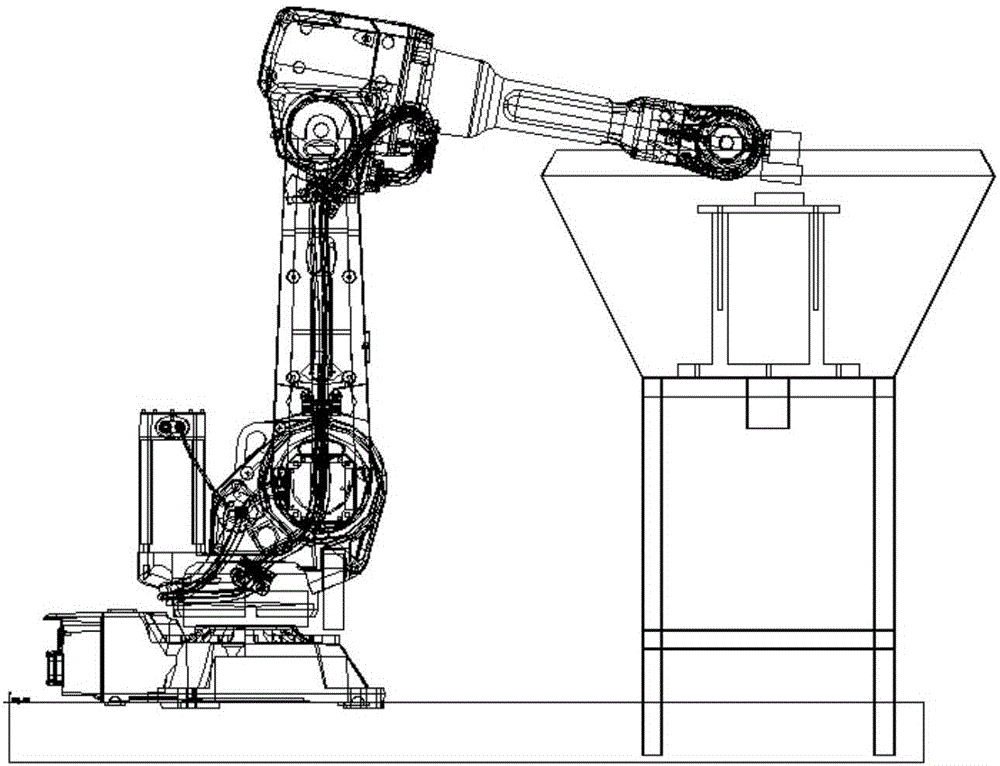

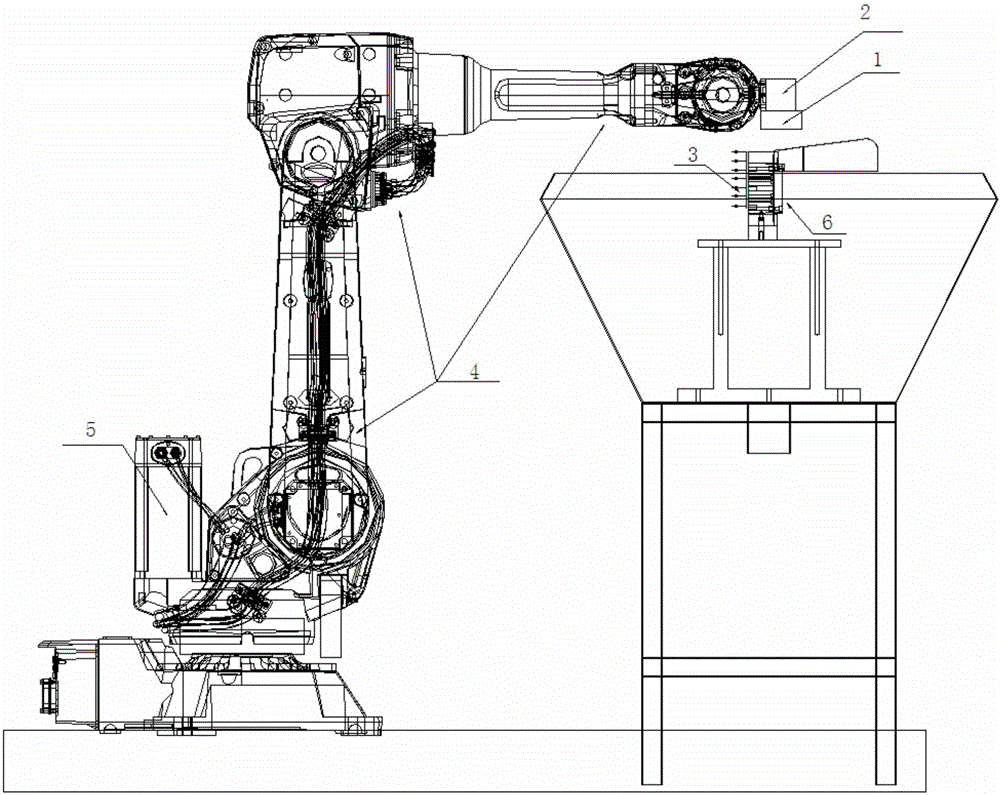

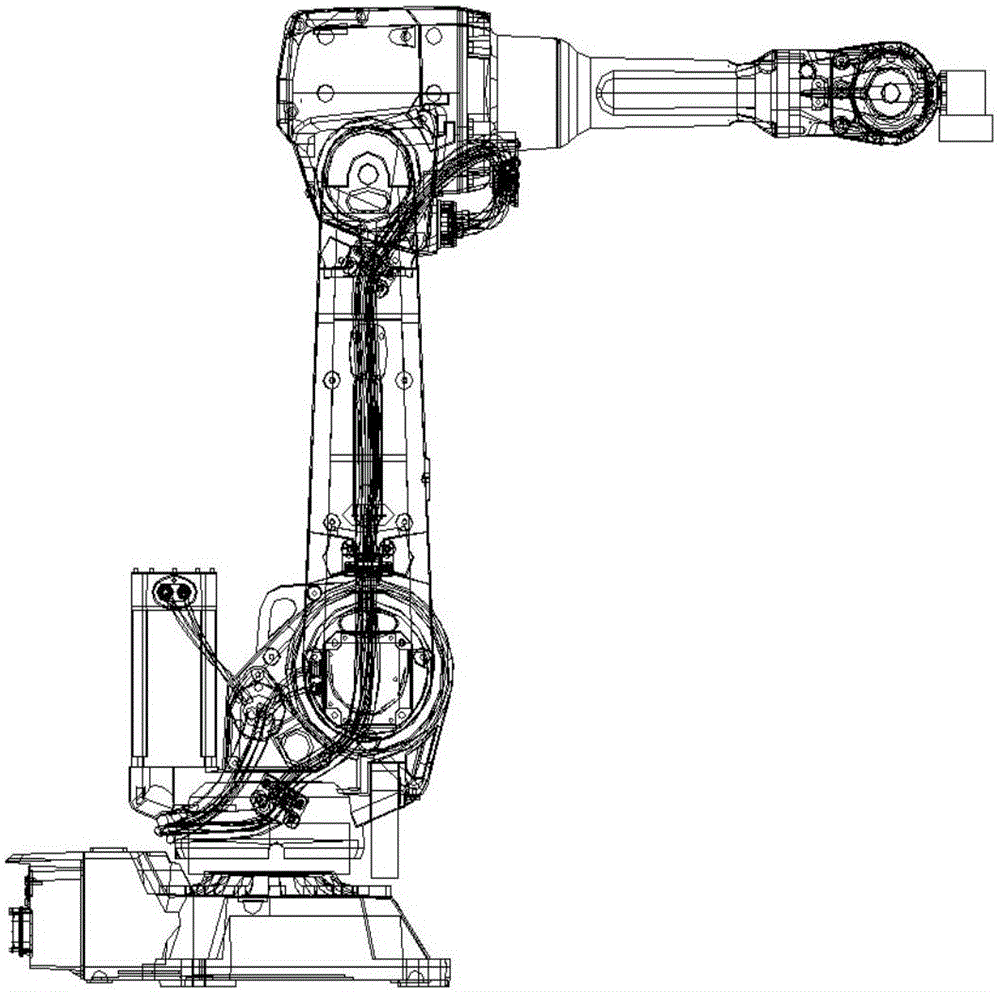

Aluminum alloy mirror polishing equipment and polishing method

InactiveCN106695520AHigh degree of automationImprove general performancePolishing machinesWaxTablet computer

The invention discloses aluminum alloy mirror polishing equipment. The aluminum alloy mirror polishing equipment is characterized by comprising a pneumatic polisher, a wool polishing disc, liquid polishing wax, a six-axis manipulator and a control mechanism, wherein the pneumatic polisher is connected with the six-axis manipulator, the wool polishing disc is arranged on the pneumatic polisher and is connected with the six-axis manipulator, the control mechanism is used for controlling the six-axis manipulator and the liquid polishing wax, the liquid polishing wax is stored in a pressure tank which is controlled by the control mechanism, the control mechanism can be used for compiling programs to control the movement of the manipulator according to the shape of a polished product, and the wool polishing disc and the liquid polishing wax are driven to polish a mirror of a workpiece by the manipulator. According to the aluminum alloy mirror polishing equipment and a polishing method, the special pneumatic polisher is matched with the wool polishing disc and the liquid polishing wax as well as the program control of the six-axis manipulator so as to complete the mirror polishing operation together, and the aluminum alloy mirror polishing equipment is suitable for the mirror polishing operation of shells of mobile phones, tablet computers and notebook computers of different sizes.

Owner:SUZHOU CHENGJIA PRECISION MFG CO LTD

Irregular curved surface polishing equipment and application method thereof

InactiveCN106695521AAccurate and stable positioningNo protection requiredPolishing machinesGrinding feed controlManipulatorProcedural approach

The invention discloses irregular curved surface polishing equipment and an application method thereof. The equipment is characterized by comprising a non-standard pneumatic polishing machine for polishing an irregular curved surface, a tool chuck for fixing a machined product, a vacuum absorber for precisely positioning a tool, a six-shaft manipulator connected with the pneumatic polishing machine and a control mechanism; the control mechanism includes a switch, and is used for controlling the polishing action of the six-shaft manipulator; and the six-shaft manipulator is controlled to automatically polish the irregular curved surface according to a program written according to the profile of the product. The irregular curved surface polishing equipment and the application method thereof use the non-standard pneumatic polishing tool for vacuum absorption and positioning of the tool, are accurate and stable in positioning, need no protection, can save materials and labors, and improve the product stability.

Owner:SUZHOU CHENGJIA PRECISION MFG CO LTD

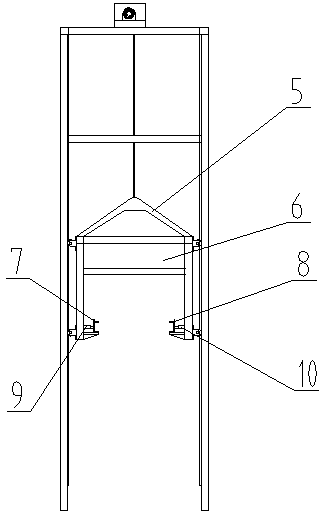

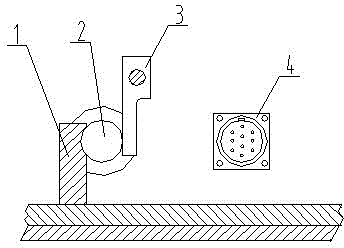

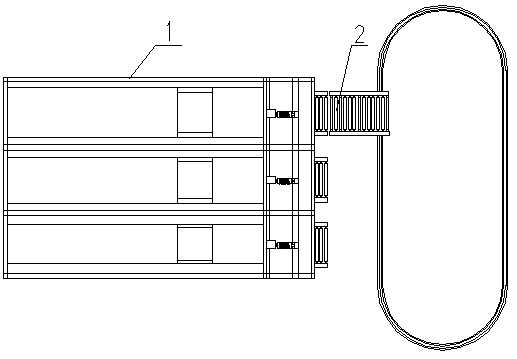

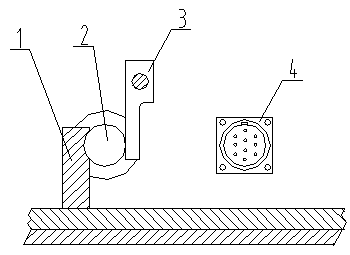

Automatic charging chamber for shuttle vehicle

ActiveCN104967168AAccurate and reliableAchieve alignmentBatteries circuit arrangementsSecondary cells charging/dischargingPush and pullElectricity

The invention discloses an automatic charging chamber for a shuttle vehicle. The automatic charging chamber is internally provided with an automatic electric connection device, the automatic electric connection device shifts a positioning base (2), which is fixedly installed on the shuttle vehicle, through a shifting lever (3) rotating around a rotation center, the shuttle vehicle is enabled to be attached to a backup plate (1), the shuttle vehicle is accurate and reliable in place, alignment of the centers of a plug (5) and a socket (4) is realized, and the plug (5) is pushed and pulled through a straight-line motion mechanism so as to realize automatic insertion and extraction of the plug (5) and the socket (4). The automatic charging chamber disclosed by the invention is convenient to operate, remote control for charging of the shuttle vehicle can be realized in the automatic charging chamber, and construction requirements of a full-automatic logistics conveying system can be met.

Owner:山东国锂新能源有限公司

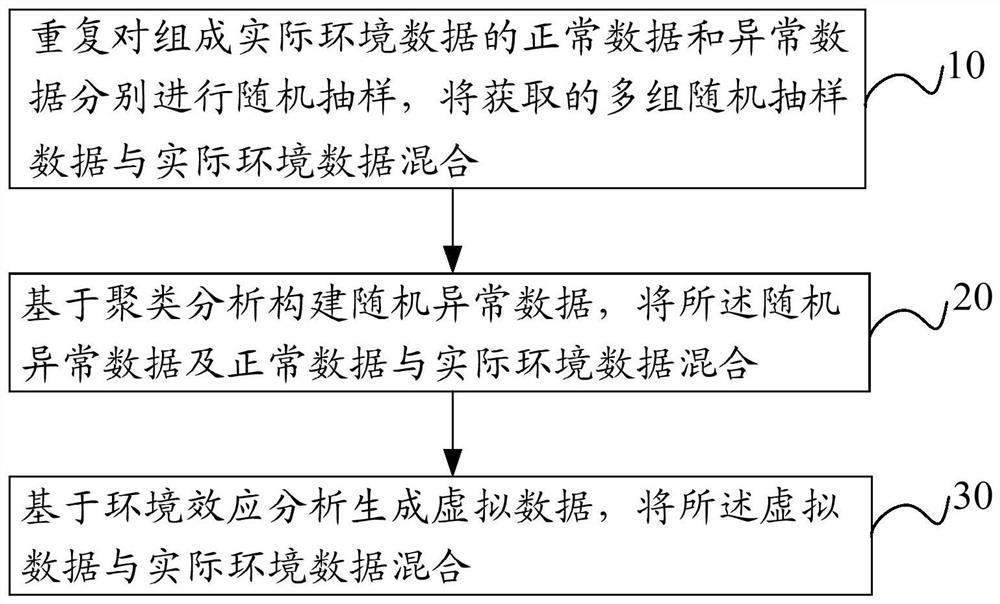

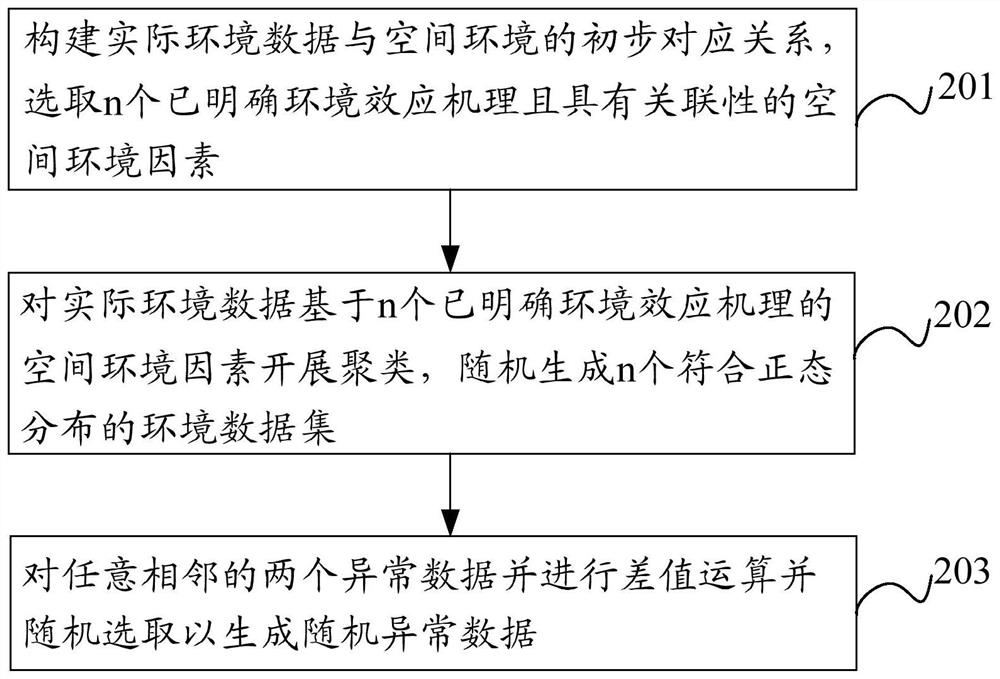

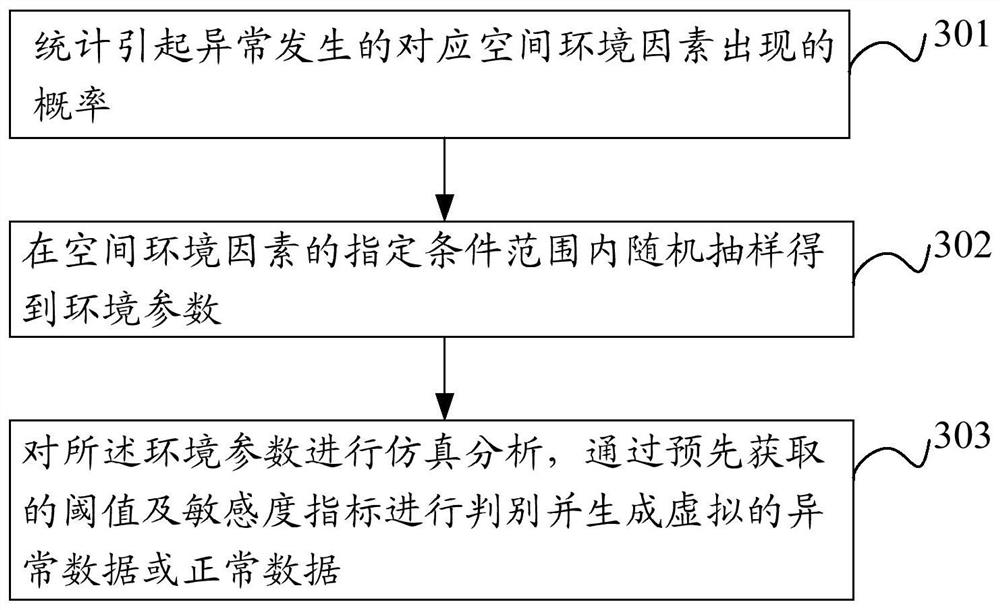

Abnormal data equalization processing method, device, equipment and storage medium

PendingCN111931424AImprove equalization performanceReduce overfittingCharacter and pattern recognitionDesign optimisation/simulationSpace environmentOverfitting

The invention discloses an abnormal data equalization processing method, a device, equipment and a storage medium. The method comprises the steps: repeatedly carrying out the random sampling of normaldata and abnormal data forming actual environment data, and mixing a plurality of groups of obtained random sampling data with the actual environment data; constructing random abnormal data based onclustering analysis, and mixing the random abnormal data and normal data with actual environment data; and generating virtual data based on the environmental effect, and mixing the virtual data with the actual environmental data. In the implementation process, the three steps can be randomly combined and carried out, the balance of abnormal data is greatly improved, the over-fitting problem of thecorrelation model can be reduced as much as possible, a more accurate analysis result is obtained, and the requirements for on-orbit spacecraft abnormal data analysis and space environment correlation model construction are met.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

A Method of Obtaining Infrared Images under Different Weather Conditions

ActiveCN105894447BMeet build requirementsAvoid classification and identification linksImage enhancementImage analysisConversion coefficientsCalculation error

Disclosed is a method for acquiring infrared images on different weather conditions. The method comprises steps of: S1, acquiring an aerially photographed infrared image on a first weather condition and determining an infrared radiation brightness value L1 corresponding to each pixel in the aerially photographed infrared image; S2, computing the radiation brightness of a single land feature background on the aerial photography height according to a MODTRAN simulation module, including the radiation brightness M1 on the first weather condition and the radiation brightness M2 on a second weather condition; S3, generating the conversion coefficients R of the infrared image on different weather conditions according to the M1 and the M2; and S4, computing the an infrared radiation brightness value L2 corresponding to each pixel in the infrared image on the second weather condition according to the L1 and the R. The method prevents classified identification of different land feature types and calculation errors due to uncertainty of surface reflectance and temperature, and increases computing speed.

Owner:BEIJING INST OF ENVIRONMENTAL FEATURES

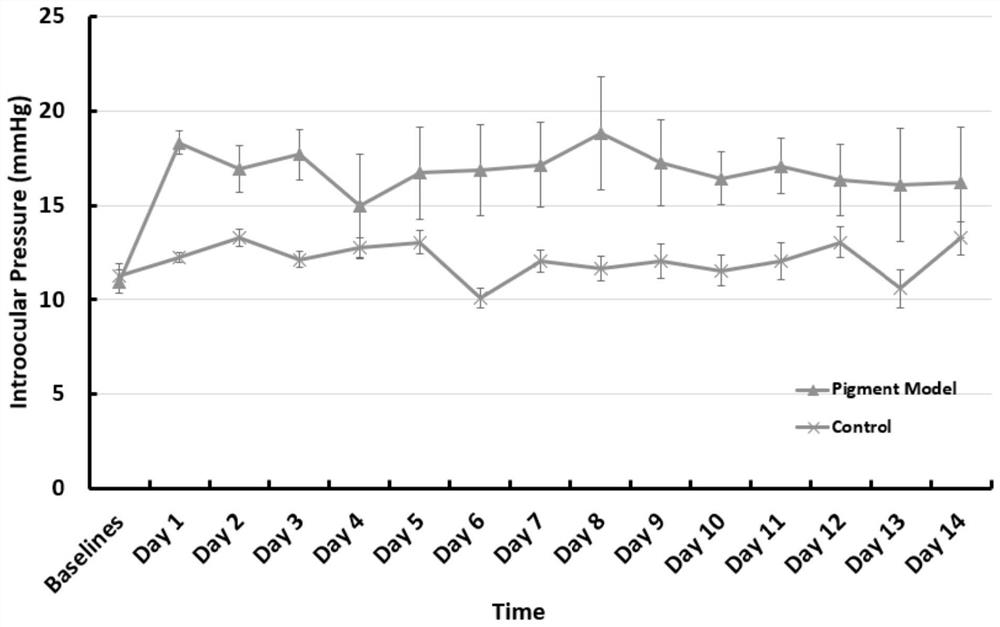

Pigmented glaucoma animal model building method and application thereof

InactiveCN113545318AMeet build requirementsIn line with pathological featuresAnimal husbandryIntra ocular pressureNerve pathology

The invention discloses a pigmented glaucoma animal model building method and application thereof. The method and the application thereof comprise the following steps: S1, selecting a rat model group; S2, preparing an iris pigment particle suspension; S3, performing measurement and data recording on intraocular pressure of the two groups of rats; and S4, performing optic neuropathology observation on the rats. According to a glaucoma animal model established by the invention, part of characteristics of human pigmented glaucoma can be conveniently and well simulated, and the obtained intraocular hypertension lasts for a long time; the method meets the pathological characteristics of pigmented glaucoma and the requirements of low cost, medium intraocular hypertension, long duration and stability of an optic nerve protection drug pharmacodynamic experimental animal model, has the characteristics of simplicity and convenience in operation and high success rate, and meets the establishment of a pigmented glaucoma model by medical science researchers.

Owner:三门峡市眼科医院

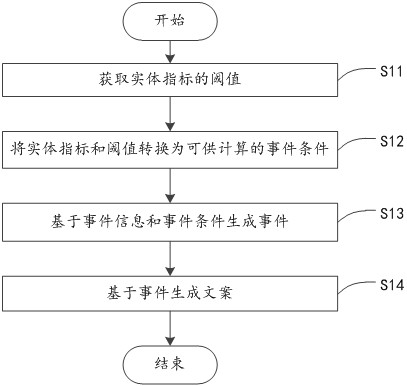

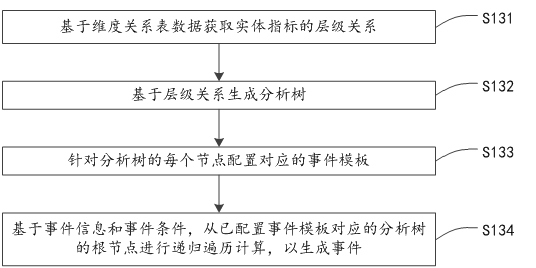

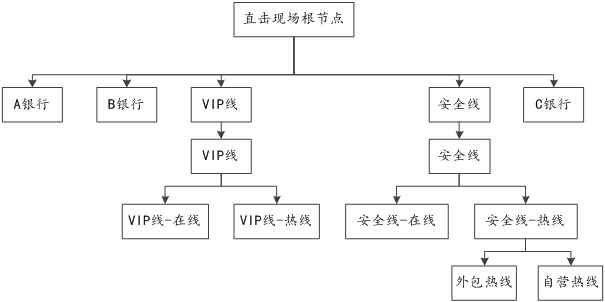

Document generation method and device, electronic equipment and storage medium

ActiveCN112287685AMeet build requirementsNatural language data processingCode compilationGeneration processData mining

The invention provides a document generation method and device, electronic equipment and a storage medium, and belongs to the technical field of language processing. The method comprises the steps that: a threshold value of an entity index is acquired, and the threshold value is used for limiting the entity index so as to limit modifiers during the logic generation of a document ; the entity indexand the threshold value are converted into event conditions for calculation; an event is generated based on event information and an event condition, wherein the event is a sentence or a combinationof multiple sentences of one node; and the document is generated based on the event. According to the method, the document generation process is abstracted into an event generation module, an event relation module, a document generation module and the like through cooperation of the entity index, the threshold value, the event and the event condition, so that document generation can be suitable for wider scenes, and the document generation requirements for accuracy and complex decision logic are met.

Owner:成都新希望金融信息有限公司

A shuttle logistics distribution warehouse

InactiveCN104960828BAccurate and reliableShort traverse distanceStorage devicesLogistics managementEngineering

Owner:浙江冒个泡电子商务有限公司

A method for preparing bismuth titanate film layer based on micro-arc oxidation technology

InactiveCN103409781BMeet build requirementsReduce usageSurface reaction electrolytic coatingMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a preparation method for a bismuth titanate film layer on the basis of micro-arc oxidation technology. The preparation method comprises the following steps: a bismuth sheet and a platinum sheet which are the same in size are respectively used as an anode and a cathode; the bismuth sheet is burnished with several pieces of sand paper with different meshes and polished with a polishing paste, and the cleaning and oil removal of the bismuth sheet are performed sequentially via alcohol and acetone for standby; electrolyte with titanium concentration of 0.01-0.10 mol / L is prepared; the bismuth sheet keeps a distance of 1-3 cm from the platinum sheet, the bismuth sheet and the platinum sheet are vertically immersed into the electrolyte in a depth of 2-4 cm, magnetic agitation is started, and 1-5A constant current is electrified for 5-10 min; electric sparks are continuously generated on the surface of the bismuth sheet, a deposition layer is synchronously generated, and the bismuth sheet with the deposition layer is flushed with ion water and then dried at a temperature of 60 DEG C for 2 h, as a result, a bismuth titanate film layer is obtained. The bismuth titanate film layer preparation method is mild in synthesis conditions, can be completed under the conditions of normal temperature and normal pressure, and is quick in reaction speed and simple in operation steps; used bismuth is an environmental-friendly raw material, the process is safe, and no hazardous substance is leaked and discharged, so that environmental protection is facilitated.

Owner:QINGDAO AGRI UNIV

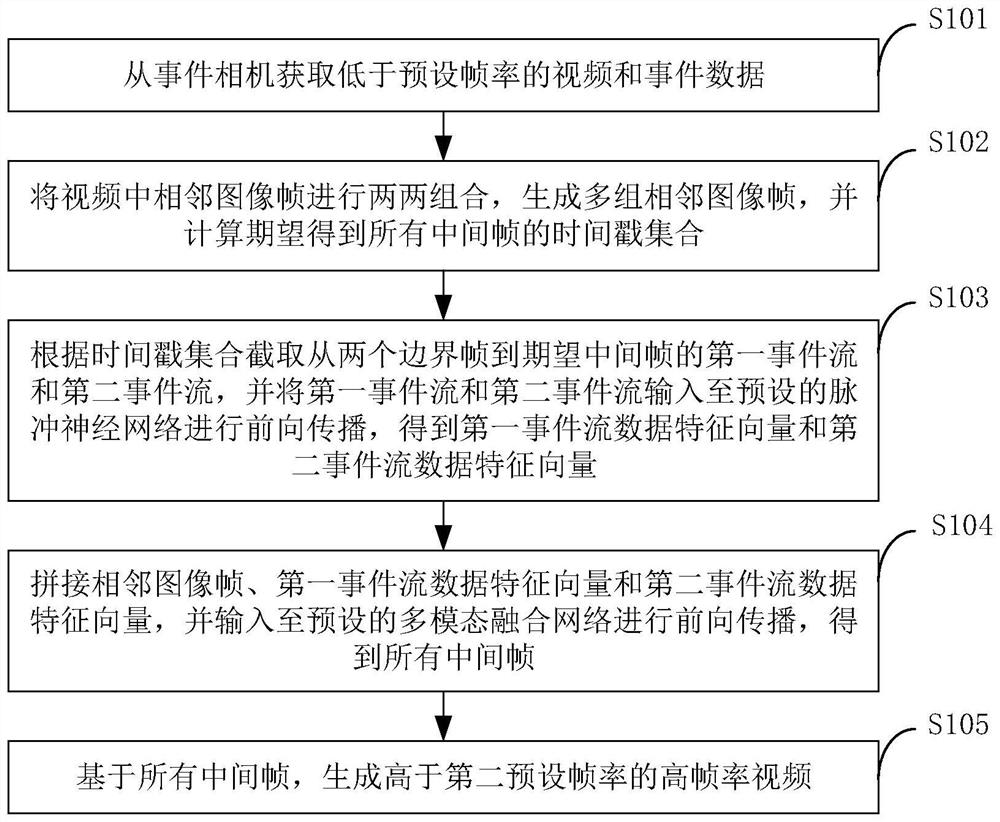

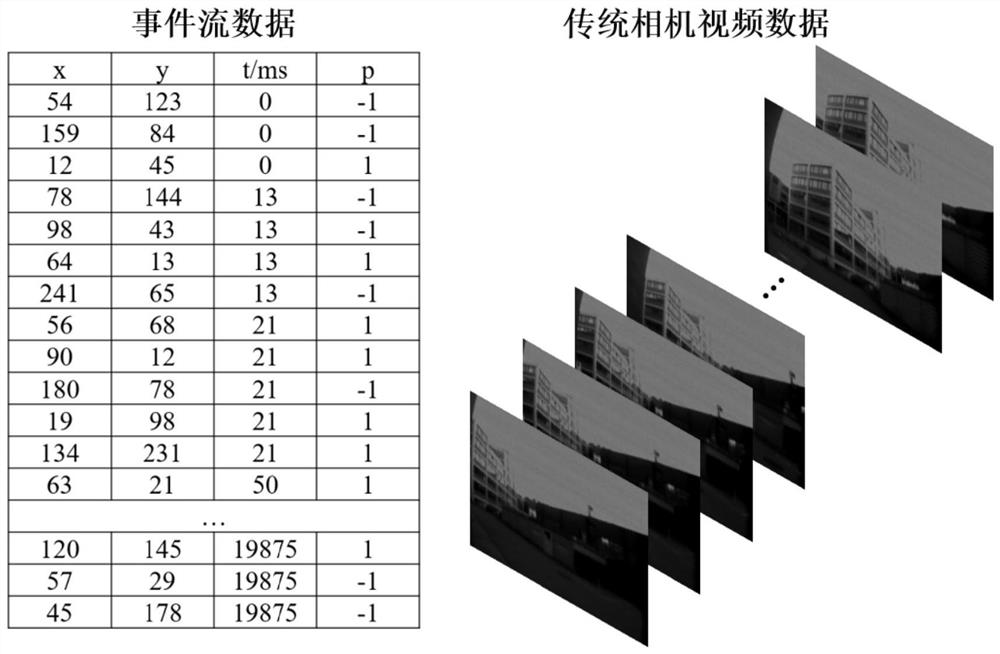

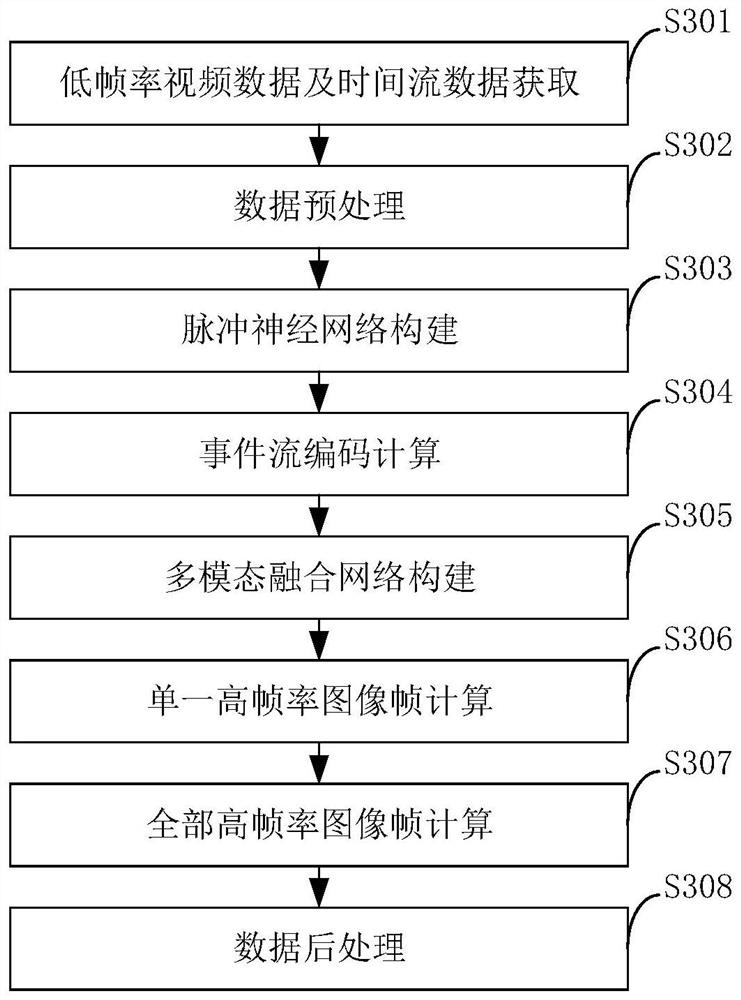

High-frame-rate video generation method and device based on data fusion

ActiveCN114885112APlay the effect of data denoisingMeet build requirementsNeural architecturesEnergy efficient computingFeature vectorHigh frame rate

The invention discloses a high-frame-rate video generation method and device based on data fusion, and the method comprises the steps: obtaining a low-frame-rate video and event data from an event camera; every two adjacent image frames in a video are combined, a timestamp set of all expected intermediate frames is calculated, a first event stream and a second event stream from two boundary frames to the expected intermediate frames are intercepted, and the first event stream and the second event stream are input into a preset pulse neural network for forward propagation. Obtaining a first event stream data feature vector and a second event stream data feature vector, splicing the first event stream data feature vector and the second event stream data feature vector with adjacent image frames, and inputting the spliced image frames into a preset multi-modal fusion network for forward propagation to obtain all intermediate frames; a high frame rate video is generated based on all the intermediate frames. Therefore, the technical problem that the quality of the generated image is low due to the fact that only the event stream is used as data input, the initial brightness value of each pixel point is lacked and the stability of brightness estimation only depending on the brightness change record is poor in the prior art is solved.

Owner:TSINGHUA UNIV

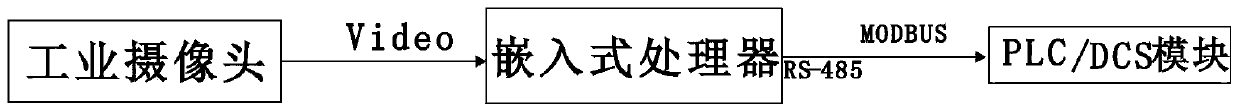

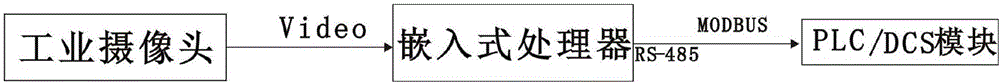

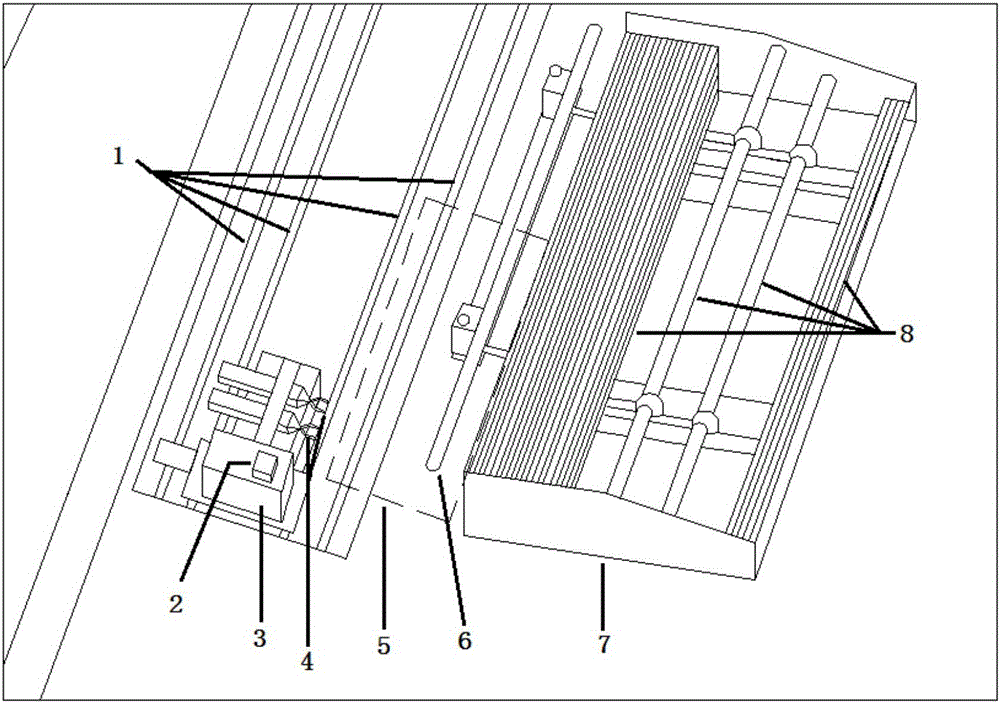

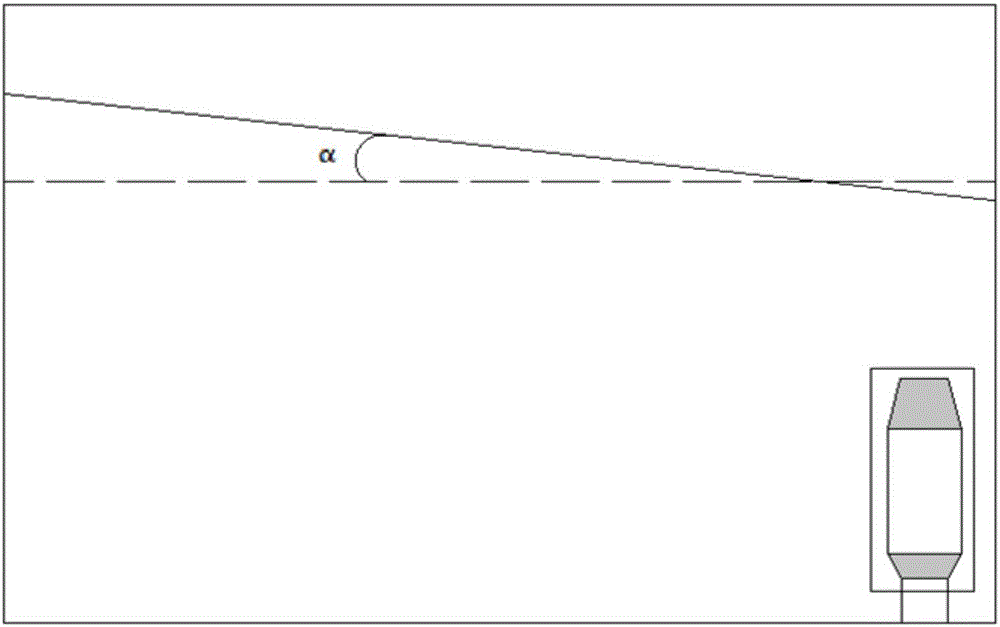

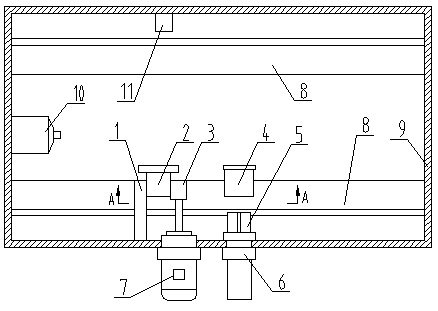

An automatic brazing method based on machine vision

ActiveCN106636510BMeet build requirementsImprove mechanizationBlast furnace componentsBlast furnace detailsMachine visionObject tracking algorithm

The invention discloses an automatic brazing rod changing method based on machine vision. The automatic brazing rod changing method comprises the following steps of: mounting an industrial camera and an embedded type processor, wherein an image acquisition area of the industrial camera covers an area of a mechanical hand and a brazing rod; processing the brazing rod according to an image acquired by the industrial camera, and separating the position of the brazing rod from background and detecting the position of the brazing rod by utilizing steps such as Gaussian filter, sharpening, edge detecting and linear detecting; judging whether the brazing rod is in place or not; detecting the position of a mechanical gripping arm by utilizing a target-detecting and target-tracking algorithm, tracking a motion state of the mechanical hand in real time, judging a relative position relationship of the mechanical hand and the brazing rod, and judging whether the mechanical hand is in place or not according to shielding degree of the mechanical hand and the brazing rod; and transmitting detected and analyzed results to a field controller, and controlling each part of an automatic brazing rod changing device. The automatic brazing rod changing method based on machine vision disclosed by the invention meets generation requirements of automatic equipment, and improves mechanical and automatic level of casthouse equipment.

Owner:CHINA THREE GORGES UNIV

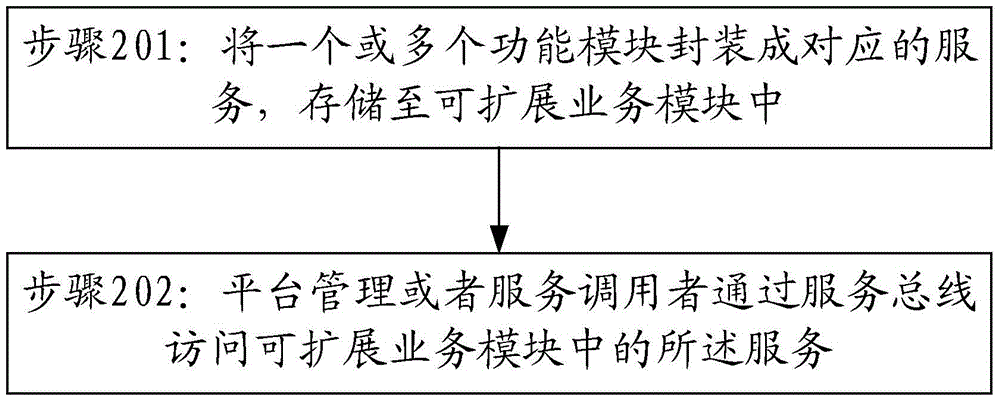

A method and system for constructing a cloud data center management platform based on SOA

The invention provides a method and a system for building a data center management platform based on an SOA (service-oriented architecture), which are applied to the technical field of computer application. The method comprises the following steps of packaging one or a plurality of function modules into corresponding services, and storing the corresponding services into an extensible service module; enabling a platform management or service invoker to access the services in the extensible service module through a service bus. The method and the system have the advantages that a cloud management platform of IaaS (Infrastructure as a Service) is built on the SOA, so the flexible architecture and system of the cloud management platform are realized, and the high cohesion and low coupling of the architecture of cloud management platform are realized; the dealing with loads in different periods is realized, or the fault restoration is realized; the flexible extensibility under the cloud calculation environment is realized, and the building of enterprise private clouds and public clouds is realized.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

A Shuttle Vertical Warehouse

ActiveCN104960827BAccurate and reliableRealize automatic chargingStorage devicesLifting equipmentStraight line mechanism

The invention discloses a shuttling type vertical storeroom which comprises a plurality of side-by-side shuttling type vertical storeroom units (1) and ground conveying equipment (2). Each shuttling type vertical storeroom unit comprises a row of multi-layer penetrating type storing goods shelves, a shuttling trolley, lifting equipment and transferring equipment. Goods are supported through two shuttling trolley guiding tracks on the two sides of a lifting table. The shuttling trolley guiding tracks are pushed to move horizontally in the reverse direction through a horizontally-moving mechanism. Reverse moving of the shuttling trolley guiding tracks and lifting moving of the lifting table are combined, and goods loading and unloading can be completed. During goods loading and unloading, guiding track horizontal moving distance is short, and consumed time during horizontal moving is short. An automatic electric connecting device is arranged in a charging room above the lifting table, a stirring rod which rotates around a rotating center stirs a locating base fixedly arranged on the shuttling trolley, so that the shuttling trolley is attached to an abutting plate, aligning of a plug and a socket center is achieved, a straight line moving mechanism pulls and pushes the plug, so that automatic plugging of the plug and the socket is achieved, and automatic charging of the shuttling trolley is achieved.

Owner:南京百顺储存设备有限公司

Smart satellite earth observation time window generating method based on space analytic geometry

InactiveCN101866393BGenerate satisfactionSimple and fast operationSpecial data processing applicationsEarth observationRelational model

The invention relates to a smart satellite earth observation time window generating method based space analytic geometry, comprising the following six steps of: (1) establishing a space analytic geometry relational model, and using the model for carrying out coordinate transformation on the given substellar point and satellite coordinate; (2) initialization: pretreating the substellar point and target data, and forming substellar point target pair sequence; (3) angle inversion: carrying out angle inversion on each substellar point target in the substellar point target pair sequence, and obtaining a roll sequence and a pitch sequence corresponding to the substellar point target pair sequence; (4) rotation matrix inverse transformation: converting the roll sequence and the pitch sequence which are obtained in the step (3) into dynamic angle under a dynamic rotation coordinate system by inverse transformation; (5) obtaining smart satellite observation angle curve for observing the targetby calculation of interpolation; and (6) intercepting a time window. The smart satellite earth observation time window generating method has the advantages of simple and convenient operation, high accuracy, easy implementation and the like, and can be applied under the background of rotation with three degrees of freedom of a smart satellite.

Owner:NAT UNIV OF DEFENSE TECH

Automatic brazing rod changing method based on machine vision

ActiveCN106636510AMeet build requirementsImprove mechanizationBlast furnace componentsBlast furnace detailsMachine visionObject tracking algorithm

The invention discloses an automatic brazing rod changing method based on machine vision. The automatic brazing rod changing method comprises the following steps of: mounting an industrial camera and an embedded type processor, wherein an image acquisition area of the industrial camera covers an area of a mechanical hand and a brazing rod; processing the brazing rod according to an image acquired by the industrial camera, and separating the position of the brazing rod from background and detecting the position of the brazing rod by utilizing steps such as Gaussian filter, sharpening, edge detecting and linear detecting; judging whether the brazing rod is in place or not; detecting the position of a mechanical gripping arm by utilizing a target-detecting and target-tracking algorithm, tracking a motion state of the mechanical hand in real time, judging a relative position relationship of the mechanical hand and the brazing rod, and judging whether the mechanical hand is in place or not according to shielding degree of the mechanical hand and the brazing rod; and transmitting detected and analyzed results to a field controller, and controlling each part of an automatic brazing rod changing device. The automatic brazing rod changing method based on machine vision disclosed by the invention meets generation requirements of automatic equipment, and improves mechanical and automatic level of casthouse equipment.

Owner:CHINA THREE GORGES UNIV

An automatic charging chamber for a shuttle car

ActiveCN104967168BAccurate and reliableAchieve alignmentBatteries circuit arrangementsSecondary cells charging/dischargingPush and pullLogistics management

The invention discloses an automatic charging room of a shuttle car. An automatic electrical connection device is installed in the automatic charging room. The automatic electrical connection device is fixedly installed on the shuttle car by turning a lever (3) rotating around the rotation center. The positioning seat (2) makes the shuttle car close to the backing plate (1), the shuttle car is in place accurately and reliably, and the center of the plug (5) and the socket (4) is aligned, and the plug (5) is pushed and pulled by the linear motion mechanism ) realizes the automatic plugging and unplugging of the plug (5) and the socket (4), which is convenient to operate, and the remote control of charging that the shuttle car can realize in the automatic charging chamber of the present invention meets the construction requirements of a fully automatic logistics transportation system.

Owner:山东国锂新能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com