Irregular curved surface polishing equipment and application method thereof

An irregular and curved surface technology, applied in the field of irregular surface grinding methods and equipment, can solve the problems of poor commonality and insufficient automation, and achieve the effects of strong versatility, saving manpower and material resources, reducing defects and scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

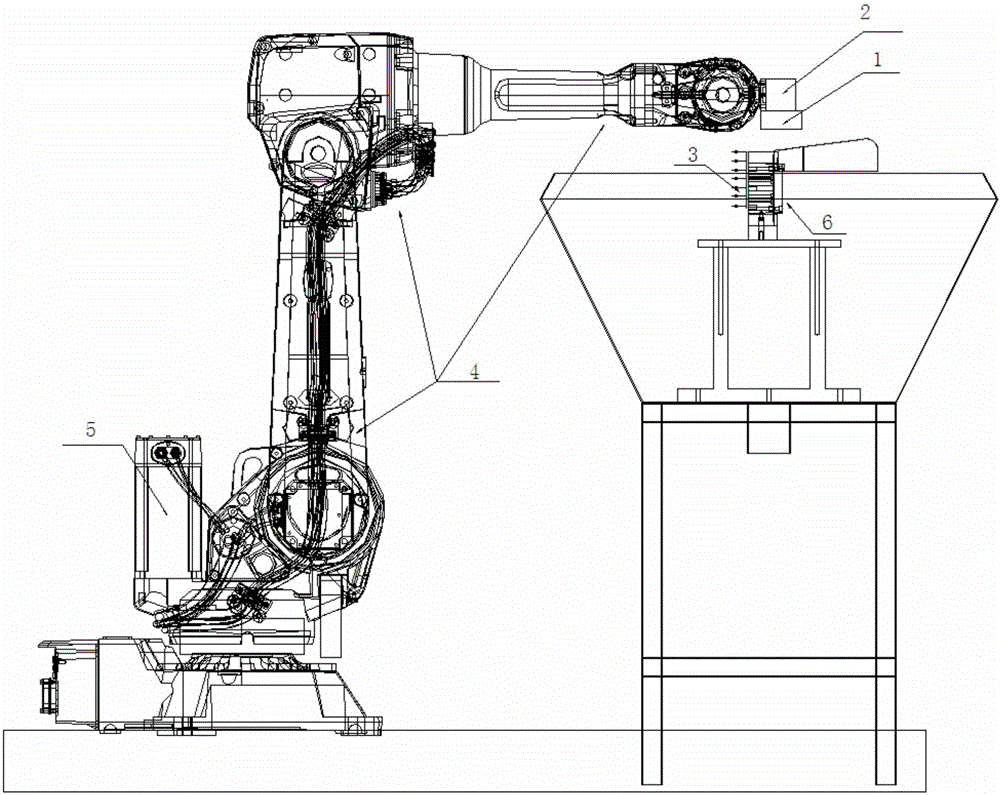

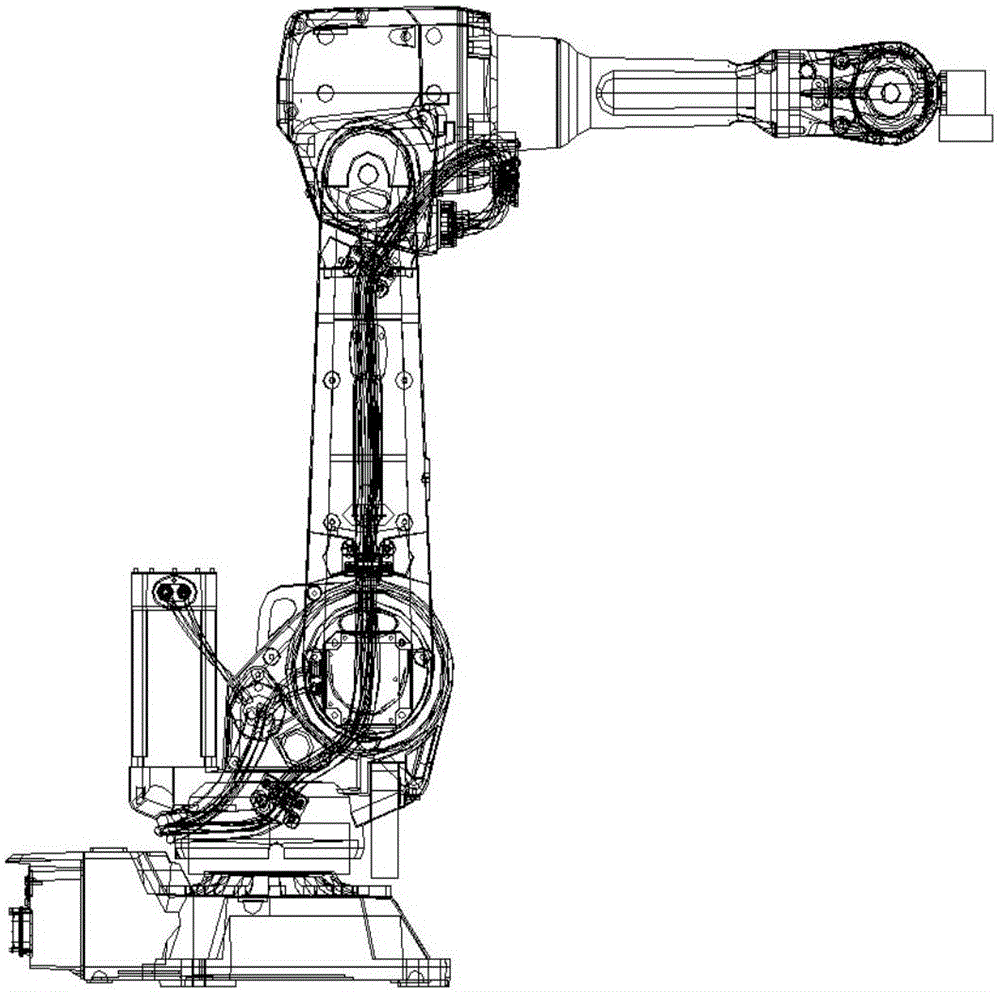

[0030] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0031] An irregular curved surface grinding equipment, including non-standard pneumatic grinding machine 1, used to grind irregular curved surfaces; tool chuck, used to fix processed products; vacuum adsorption, used to accurately position fixtures; six-axis manipulator, and pneumatic The grinding machine is connected; the control mechanism, the control mechanism includes a switch, the control control mechanism is used to control the grinding action of the six-axis manipulator, and the six-axis manipulator is programmed to automatically polish the irregular surface according to the product outline. The jig is a device for fixing the product, made of non-metallic material, and used for positioning the product. The six-axis manipulator is connected with the pneumatic grinding machine; the control mechanism is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com