Long-distance waste heat recovery system of drying tail gas

A waste heat recovery system and a technology for drying tail gas, applied in drying solid materials, drying, waste heat treatment, etc., can solve the problems of large consumption of drying medium, high attenuation rate of heat transfer, large power consumption of heat-carrying medium, etc. Good temperature uniformity, good heat transfer effect and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

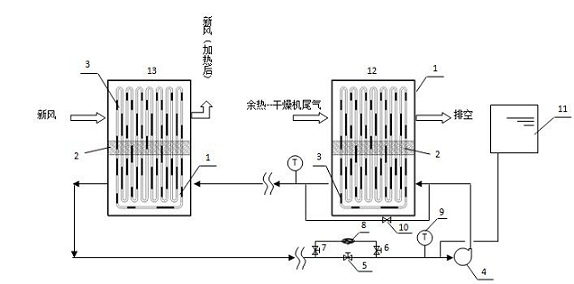

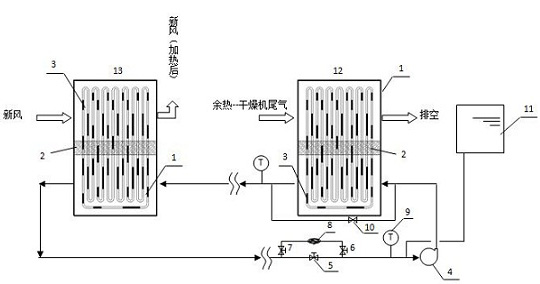

[0017] The waste heat of the exhaust gas of the dryer first flows through the evaporating section 1 of the primary oscillating flow heat pipe 12, and the heat is transferred to the condensing section 3 at the other end of the adiabatic section 2 through the pulsating heat pipe. Transfer to the heat transfer oil, after the heat transfer oil is warmed up, it is transported to the evaporation section 1 of the secondary oscillating flow heat pipe 13 through a long distance under the action of the circulation pump 4, and the heat released by the heat transfer oil is transferred to the condensation section of the secondary oscillating flow heat pipe 13 through the pulsating heat pipe 3. The heat pipe in the condensing section 3 transfers heat to the fresh air, and the heated fresh air returns to the drying process to realize waste heat recovery and reuse in this system.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com