Continuous ink jet type code spraying machine control system with double ARM architectures

An ARM architecture and control system technology, applied in printing, printing devices, etc., can solve the problems of few product series, printing accuracy, printing speed and printing performance defects, and achieve good real-time performance, good anti-interference and reliability. Sexual, powerful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

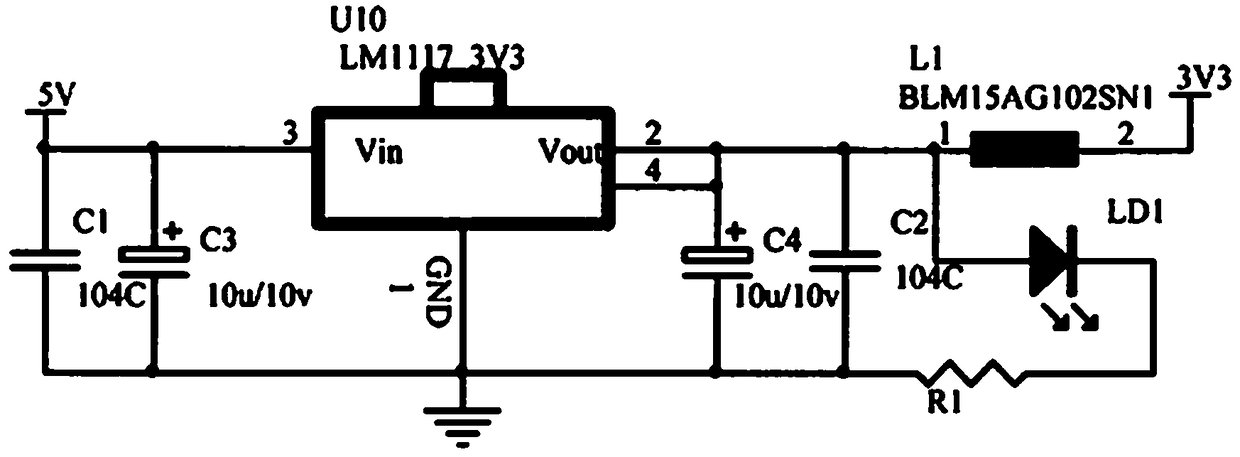

[0021] Such as figure 1 , The power supply circuit uses AMS1117 voltage regulator in this system to provide 3.3V working voltage to the system. AMS1117 is a low-power forward linear voltage regulator chip with the characteristics of high precision, high efficiency and high reliability, and its internal integrated overheat protection and current limiting circuit. AMS1117 has a wider input voltage range, higher conversion efficiency, smaller ripple factor and better temperature stability. The 5V power supply is used as the input of AMS1117, and a stable 3.3V voltage can be output after being stabilized.

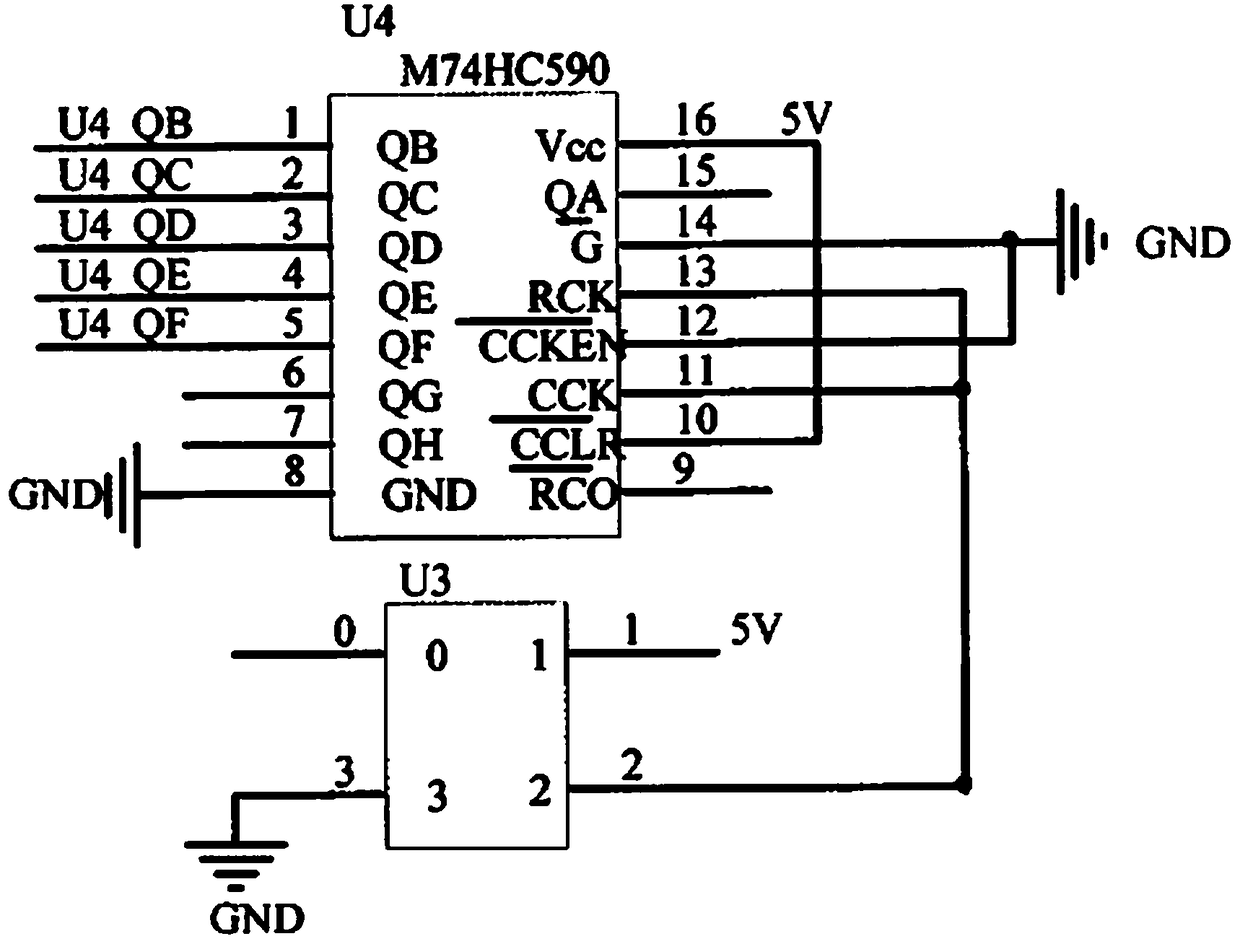

[0022] Such as figure 2 , The clock circuit uses an active crystal oscillator as the basic clock of the system, and uses hardware frequency division to obtain the required frequency. 74HC590 is an 8-bit high-speed binary counter, and its data is output in parallel. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com