Workpiece Measuring System Based on Five-Axis CNC System

A technology of numerical control system and measurement system, applied in the field of measurement, can solve the problems of complex implementation of acquisition system, lack of versatility and scalability, and poor real-time performance of data acquisition, and achieves high measurement accuracy, low cost, and good real-time performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

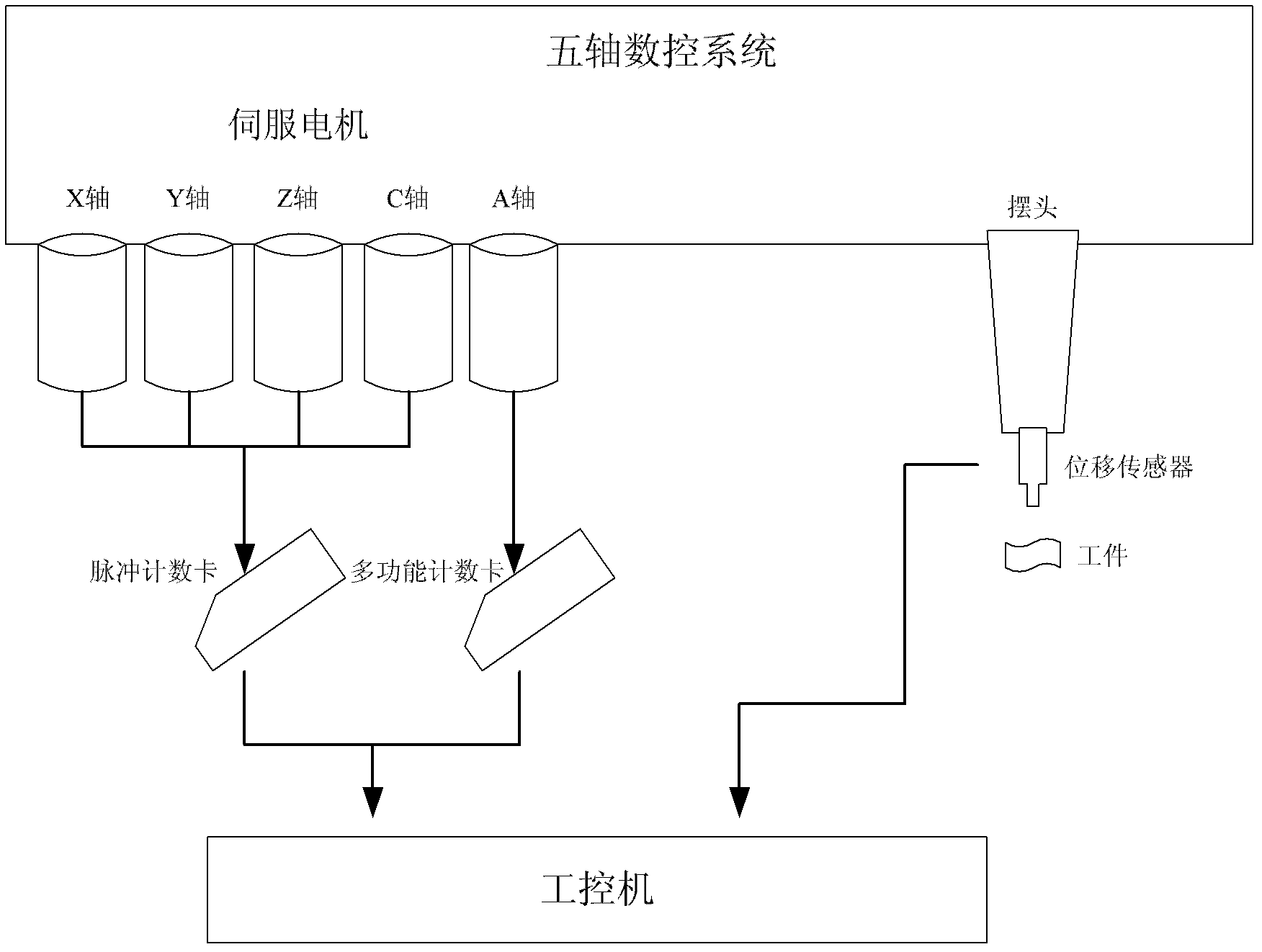

[0030] The workpiece measurement system based on the five-axis numerical control system of the present invention includes an industrial computer, a counting device and a displacement sensor. The feedback signal of the absolute encoder of the motion axis in the numerical control system is directly sent to the counting device, and the counting device transmits the collected data to the industrial computer. The displacement sensor sends the displacement signal of the detected workpiece surface to the industrial computer.

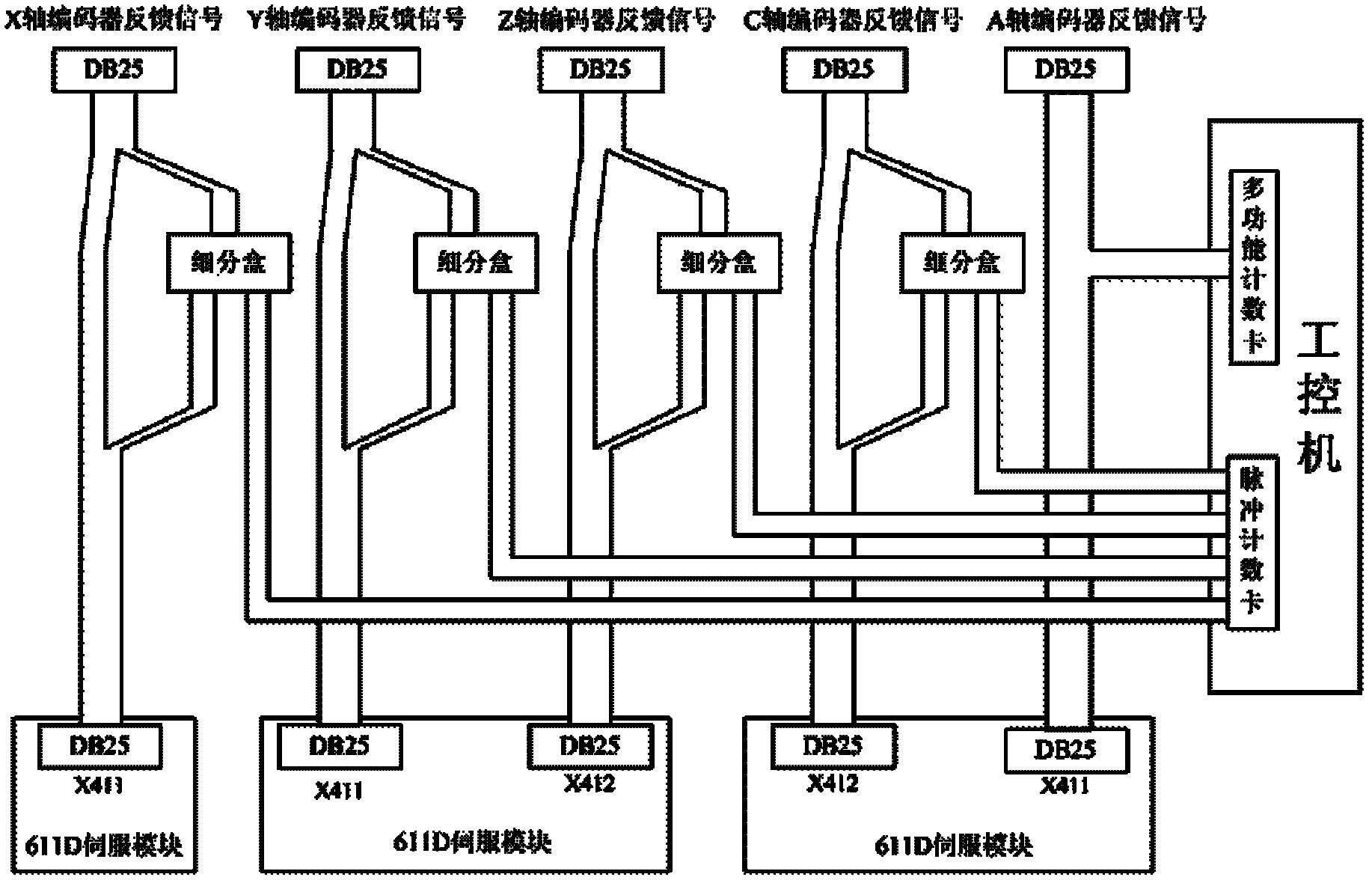

[0031] This embodiment takes Siemens 840D numerical control system as an example. Siemens 840D is a five-axis CNC system, including three feed axes of X, Y, and Z, and two rotation axes of A, C. The interface of each axis (DB25, including encoder signal and temperature sensor signal) is connected to the socket (x411 or x412) on the 611D digital servo module. The encoders of each axis of the numerical control system described in this embodiment are composed of:...

Embodiment 2

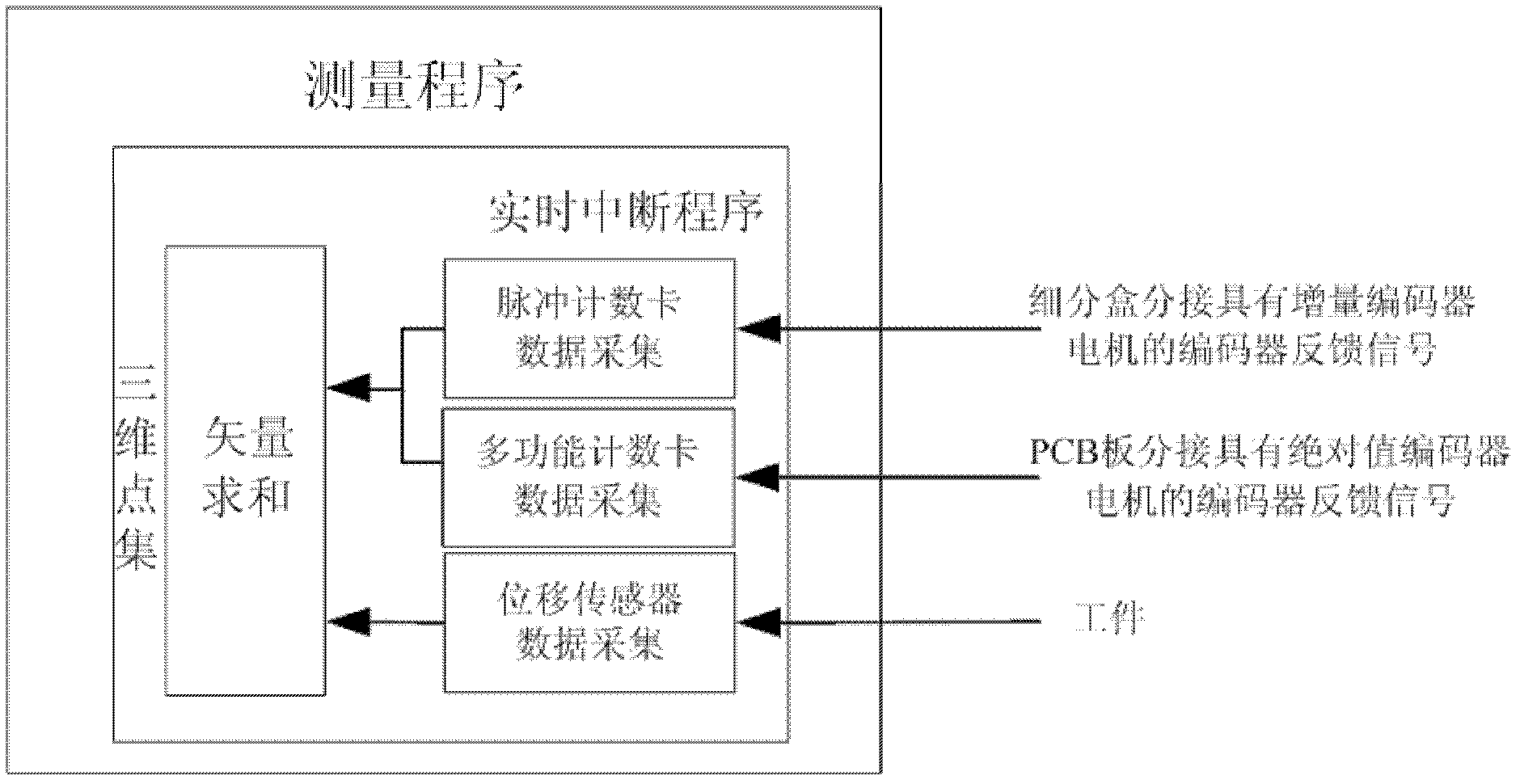

[0052] Such as figure 1 , 2As shown, the difference from Embodiment 1 is that in addition to the industrial computer, the counting device and the displacement sensor, there is also a subdivision box, and the subdivision box is one or more, and the numerical control system has an incremental encoder The feedback signal of the shaft is divided into two parallel branches through the subdivision box, and each subdivision box sends one signal (TTL) to the counting device; the other signal of each subdivision box is sent to the counting device in the original way The position signal of the incremental encoder is fed back to the servo driver of the numerical control system to form a position closed loop; the counting device has a pulse counting card and a multi-function counting card, wherein the pulse counting card receives the feedback signal of the incremental encoder through the subdivision box, and more The function counter card receives the feedback signal of the absolute enco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com