Full liquid type composite type cold air units

A compound and flooded technology, applied in refrigerators, refrigeration components, compressors, etc., can solve the problems of uniform refrigerant distribution, low unit efficiency, and high condensing pressure, so as to prolong operating time, improve energy saving effect, and ensure operation efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

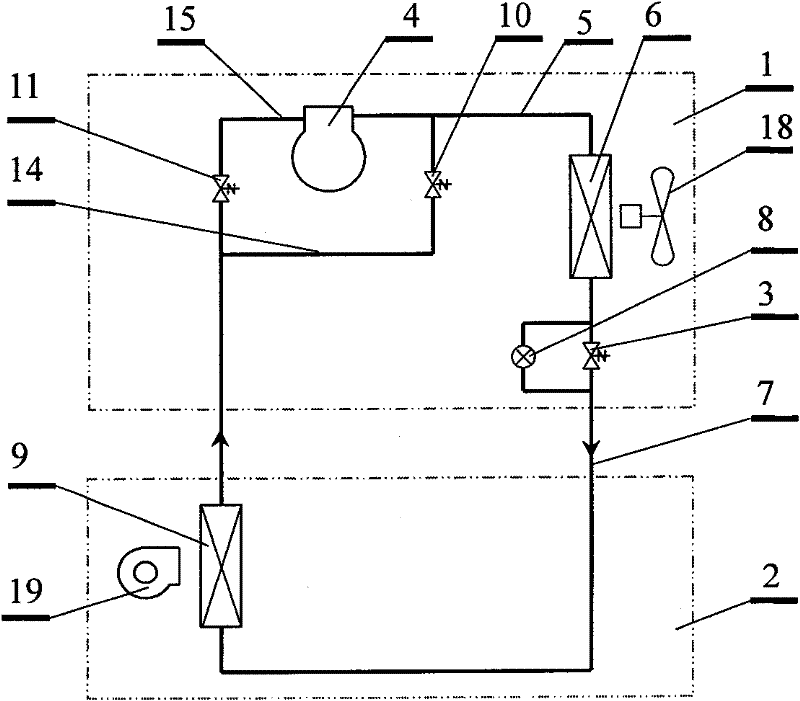

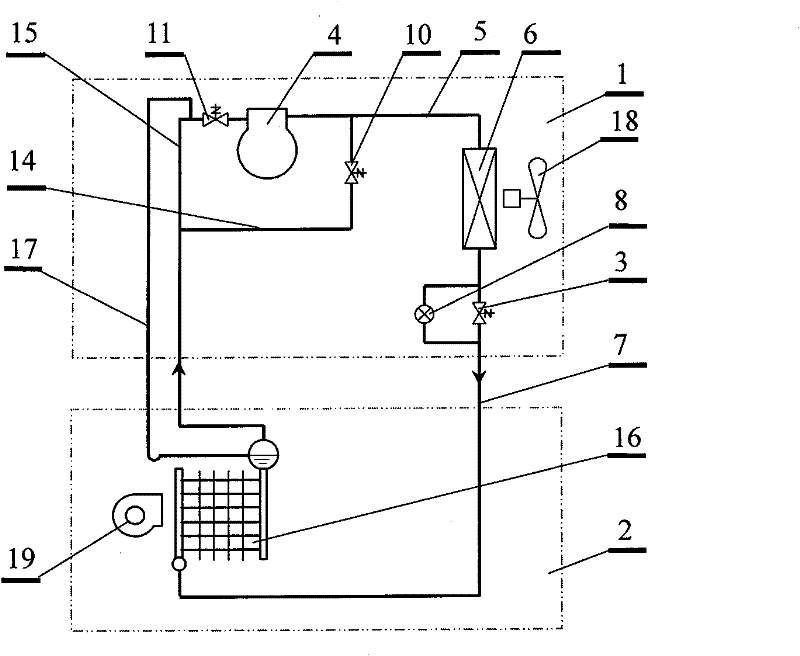

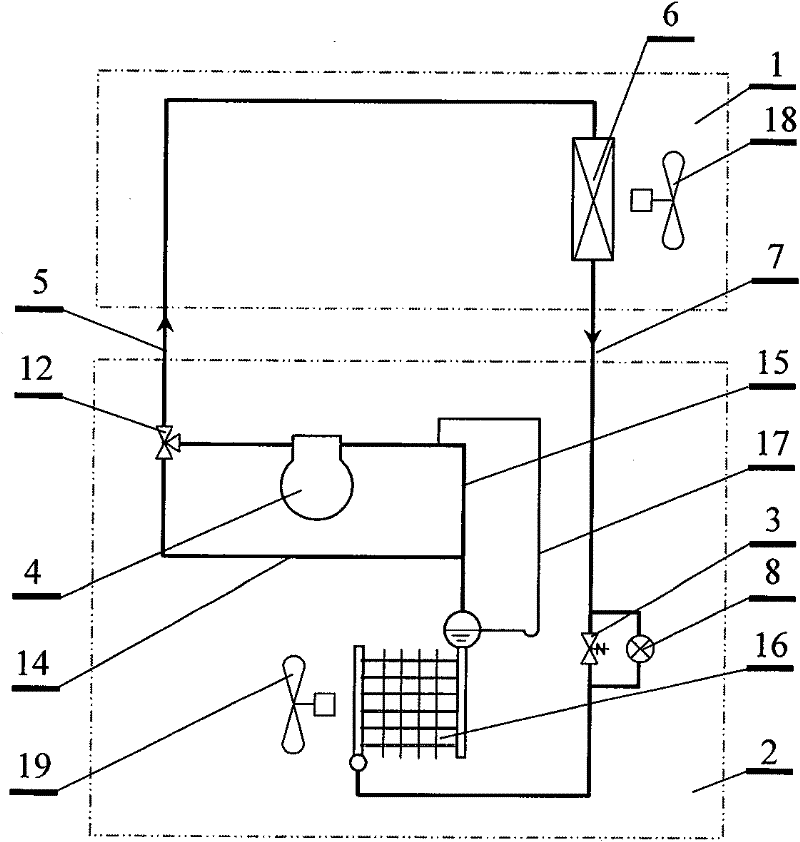

[0033] figure 2 A structural schematic diagram of a flooded composite air cooler unit disclosed in the present invention is given. The flooded composite air cooler unit includes a compressor 4, a condenser 6, an evaporator, a liquid connecting pipe 7, and a The liquid pipe solenoid valve 3 on the pipe 7, the throttling device 8 connected in parallel to the two ends of the liquid pipe solenoid valve 3, the gas connecting pipe 5, the compressor branch 15, the refrigeration solenoid valve 11 connected in series on the compressor branch 15, and The heat pipe branch 14 connected in parallel with the compressor branch 15 and the heat pipe solenoid valve connected in series on the heat pipe branch 14; the evaporator, the heat pipe branch 14, the gas connection pipe 5, the heat pipe solenoid valve 10, the condenser 6, the liquid pipe Solenoid valve 3 and liquid connection pipe 7 form refrigerant natural circulation circuit; The evaporator, compressor branch 15, refrigeration solenoid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com