Large high-vacuum air pumping set

An air pumping unit and high vacuum technology, applied in the field of vacuum pumping, can solve the problems of long start-up time, bulky water vapor pump, and high price, so as to save equipment cost and floor space, eliminate oil vapor pollution, and save air pumping The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

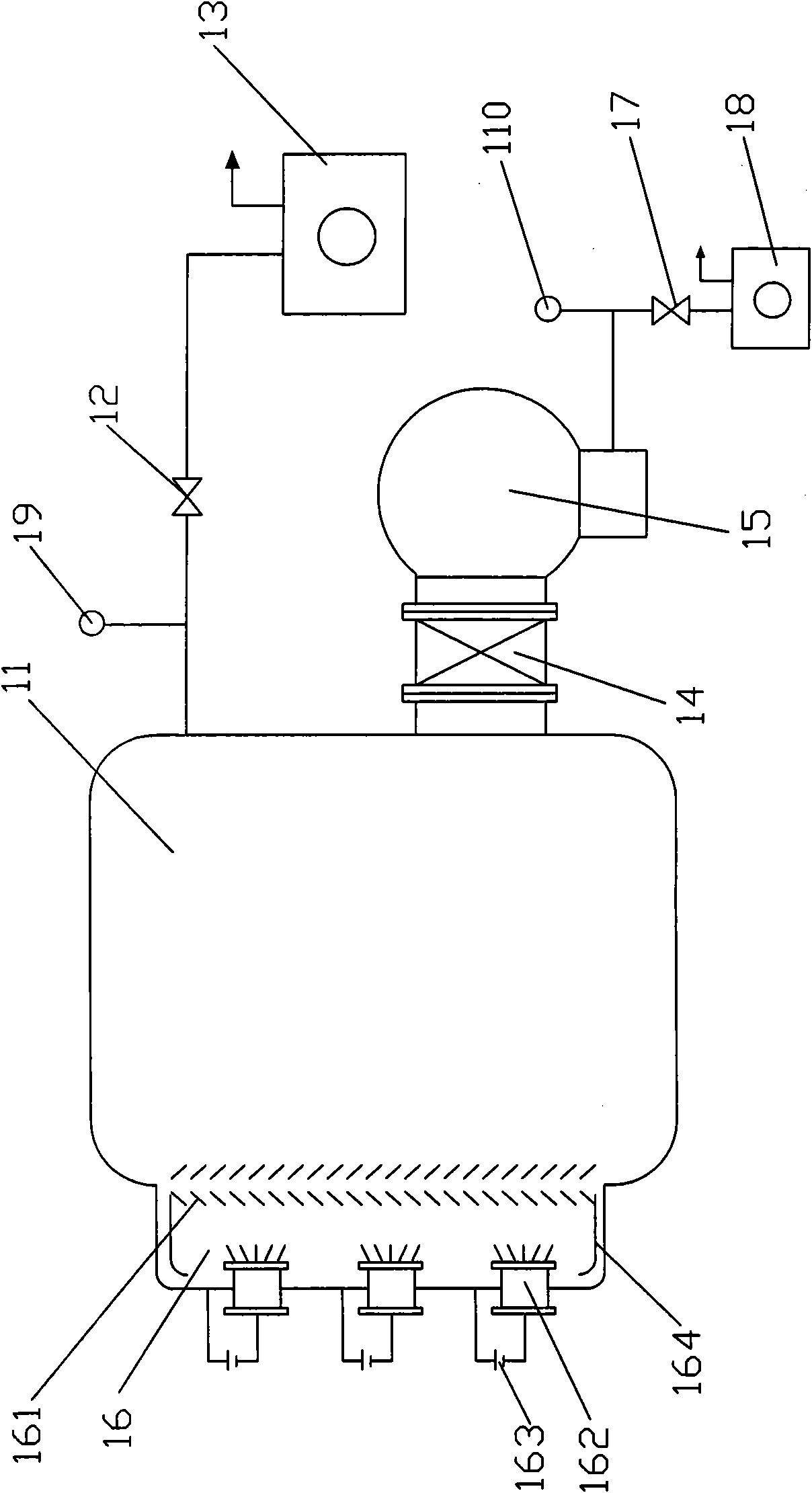

[0021] Embodiment 1. Large-scale high vacuum pumping unit

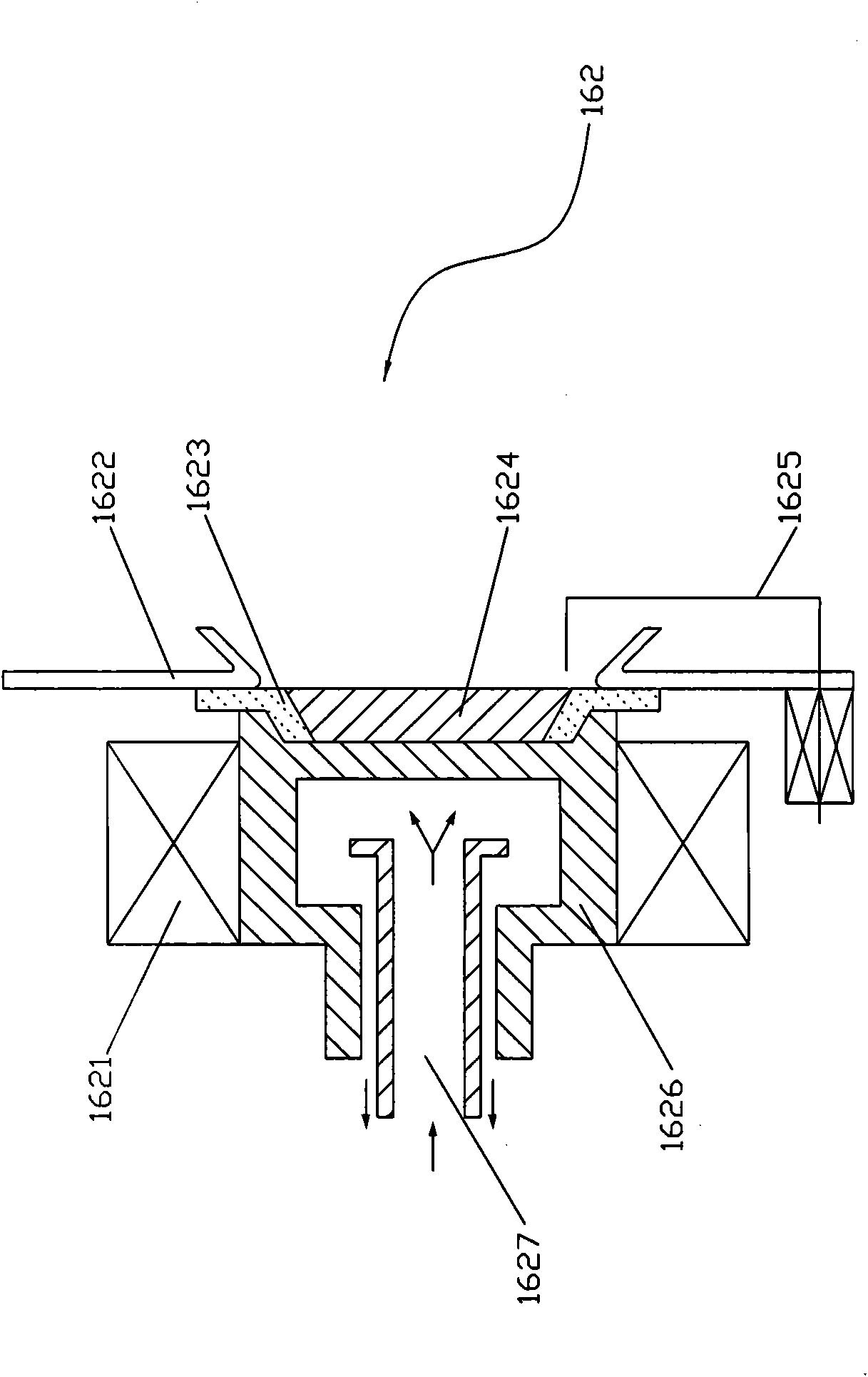

[0022] refer to figure 1 As shown, the large-scale high-vacuum pumping unit provided by the embodiment of the present invention includes a vacuum chamber 11, and the vacuum chamber 11 is respectively connected with a roughing pump 13, a traction molecular pump 15 and an arc titanium pump 16.

[0023] Specifically, the vacuum chamber 11 is connected to the rough pump 13 through a low vacuum valve 12, and the vacuum chamber 11 is connected to the arc titanium pump 16 through a half-fixed louvered gas collection plate 161, and the vacuum chamber 11 is connected to the arc titanium pump 16 through A high vacuum valve 14 is connected with a dragging molecular pump 15 , and the dragging molecular pump 15 is connected with a low pumping speed backing pump 18 through a low vacuum valve 17 .

[0024] Further, a vacuum gauge 19 is provided between the vacuum chamber 11 and the roughing pump 13, a vacuum gauge 110 is provided b...

Embodiment 2

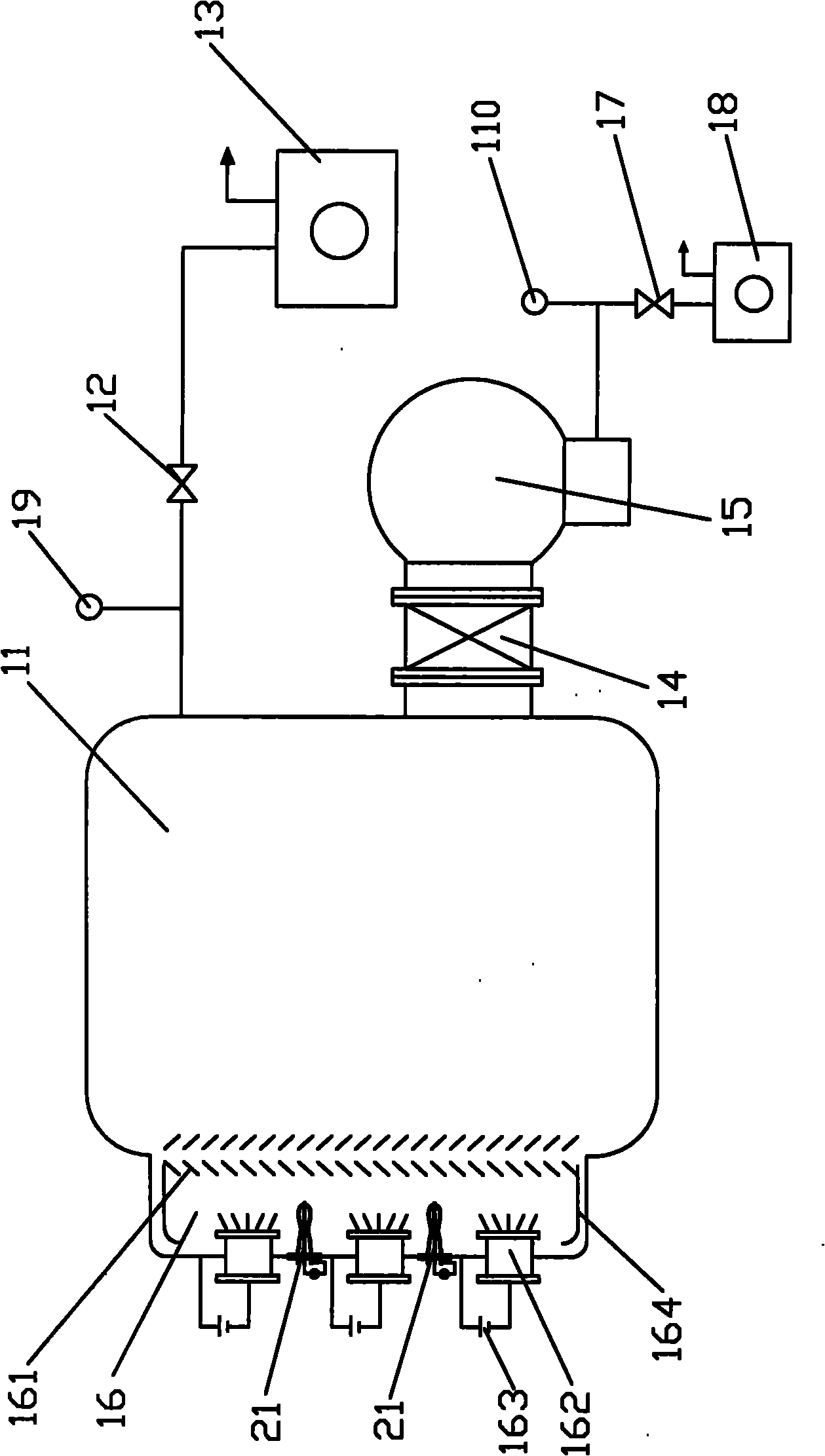

[0028] Embodiment 2: Large-scale high-vacuum pumping unit with sublimation titanium pump

[0029] like image 3 As shown, the structure of the second embodiment is substantially the same as that of the first embodiment, the difference being that several sublimation titanium pumps 21 ( image 3 2 are shown in ), once the arc evaporation source 162 stops discharging, the sublimation titanium pump 21 will take over. This measure can improve the vacuum degree of this embodiment by 2 to 4 orders of magnitude.

[0030] The pumping process of the large-scale high vacuum pumping unit provided by Embodiments 1 and 2 of the present invention is as follows:

[0031] When 100Pa≤the air pressure of the vacuum chamber≤atmospheric pressure, the rough pump 13 is used to draw air. Very short, one roughing pump 13 can be shared by multiple high-vacuum pumping units, saving equipment costs and floor space;

[0032] When 0.1Pa≤the air pressure of the vacuum chamber 11<100Pa, the traction molec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com