Ultra-high speed vacuum pump system with first stage turbofan and second stage turbomolecular pump

一种涡轮分子泵、涡轮风扇的技术,应用在用于弹性流体的泵送装置的部件、泵、轴流泵等方向,能够解决购置成本再生或更换维护成本处理室污染、设计困难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

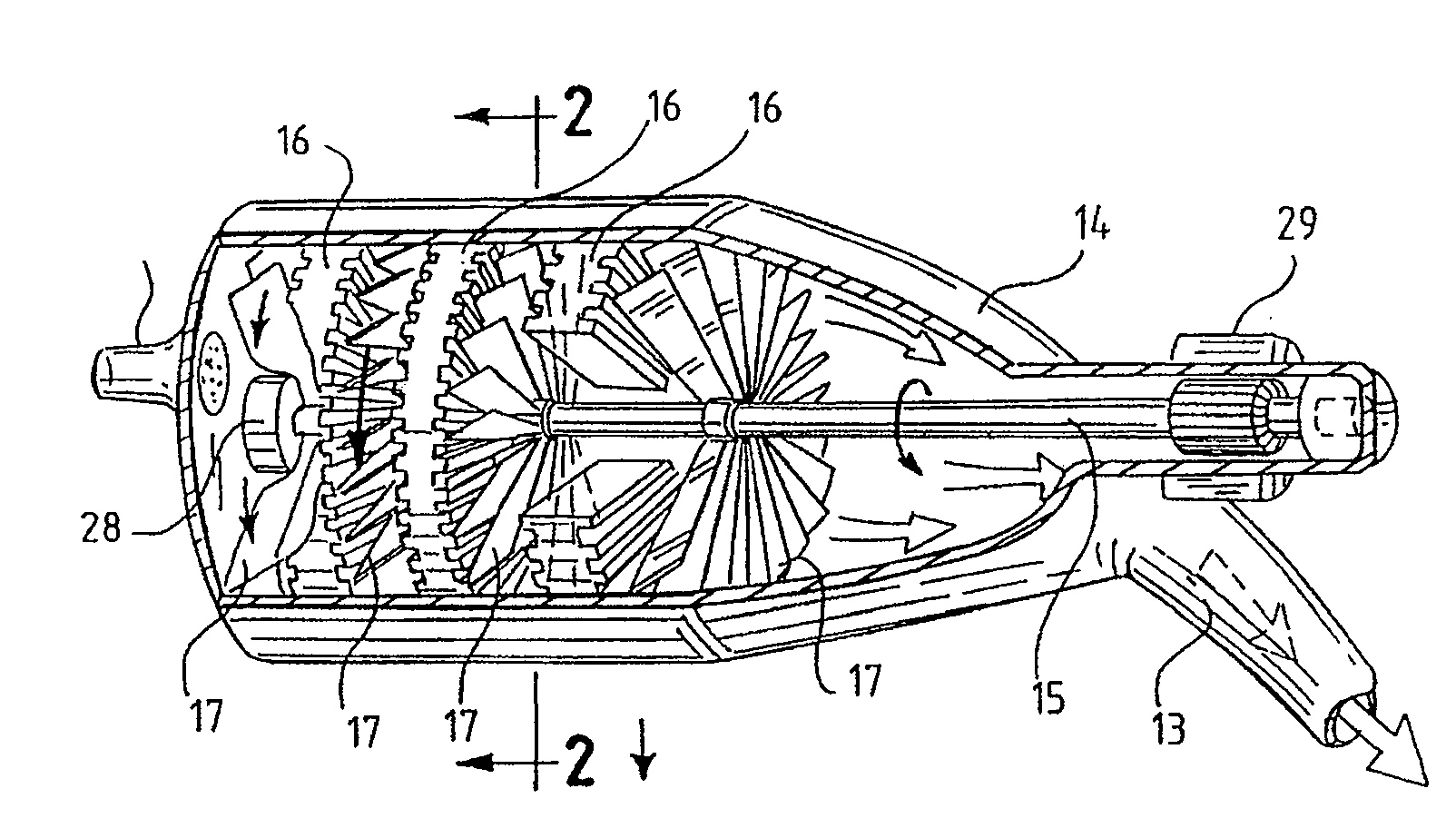

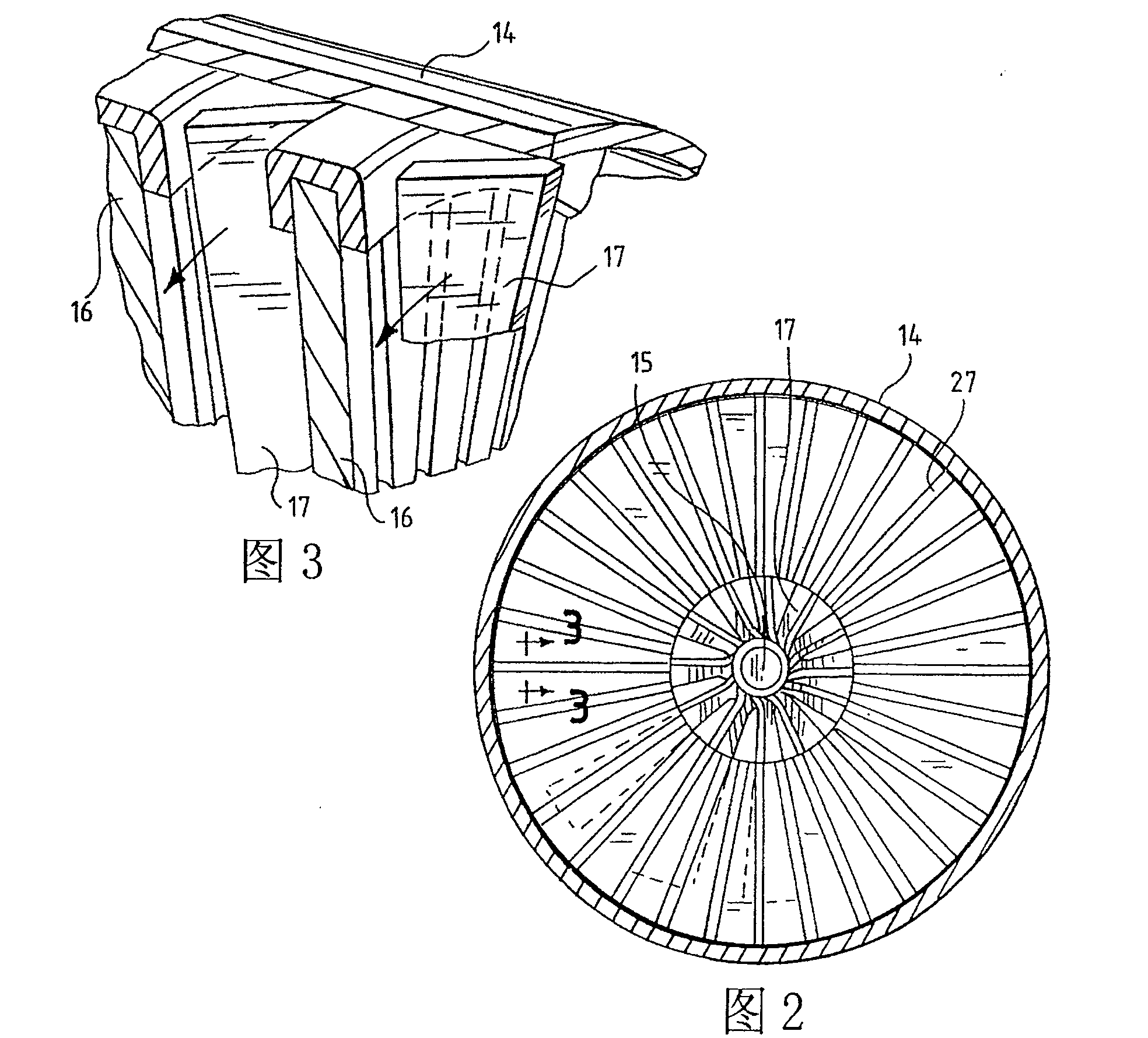

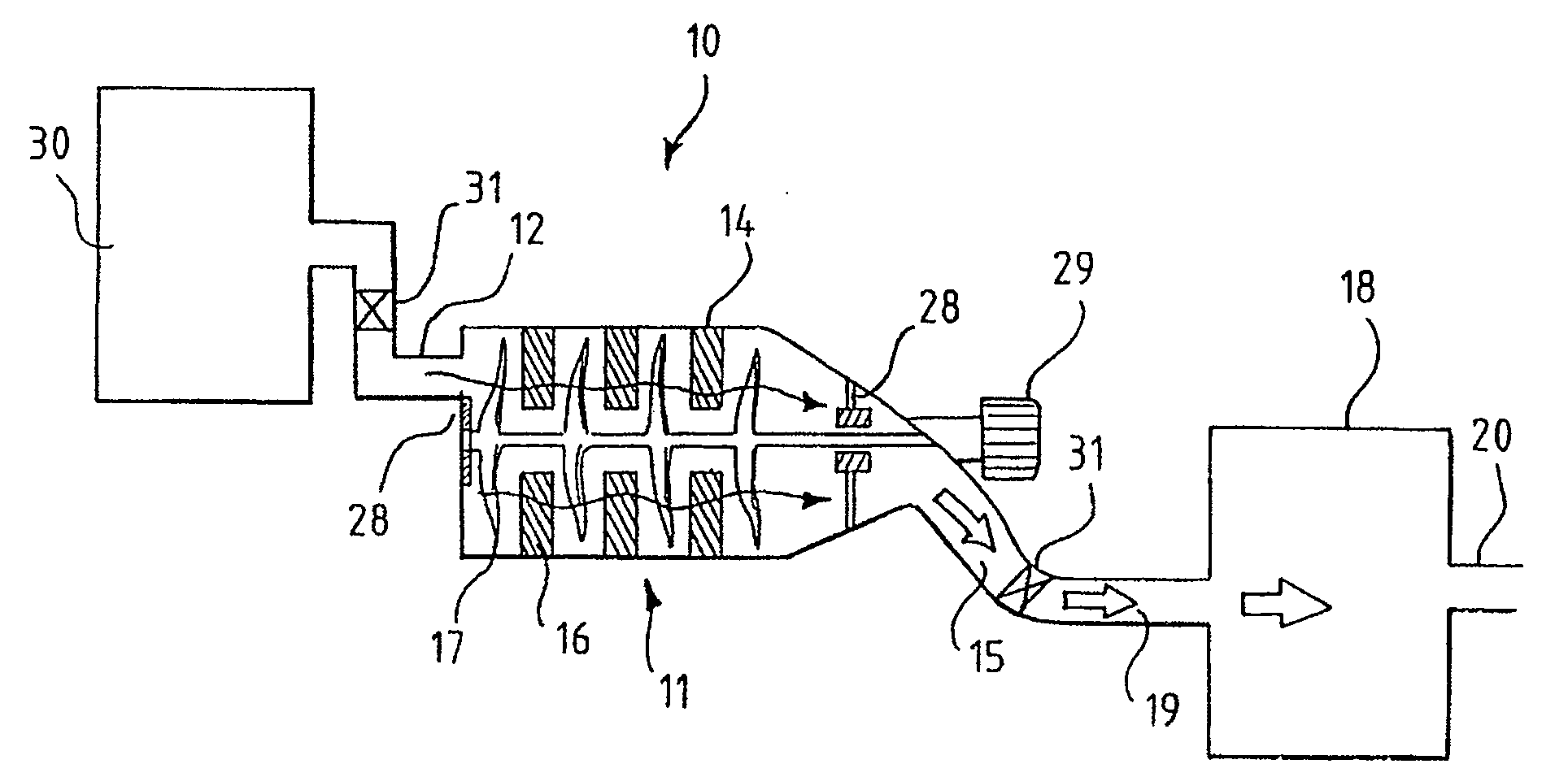

[0038] Such as figure 1 An embodiment of an ultrahigh-speed vacuum pump turbofan 11 is shown in , which is preferably used as an ultrahigh-speed input stage backed by a conventional turbomolecular pump. Turbofan 11 directs fluid flow into a turbofan inlet 12 and through a turbofan outlet 13 . Preferably, if Figure 4 and Figure 5 As shown, the outlet is in fluid communication with at least one additional turbofan or turbomolecular pump. Also preferably, as Figure 4 and Figure 5 As shown, the turbofan inlet 12 is in fluid communication with an evacuation or process chamber 30 . The turbofan 11 is characterized by a super high suction speed and a moderate compression ratio.

[0039] Typical pumping speeds are greater than 10,000 liters / second. More preferably, the pumping speed is 10,000 liters / second to 40,000 liters / second. In a preferred embodiment, the turbofan 11 has a suction speed of about 25,000 liters / second per 1.0 meter diameter of the turbofan.

[0040] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com