Roughing pump method for a positive displacement pump

A positive displacement pump and rough pumping technology, applied in the direction of rotary piston pump, liquid displacement machinery, pump, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

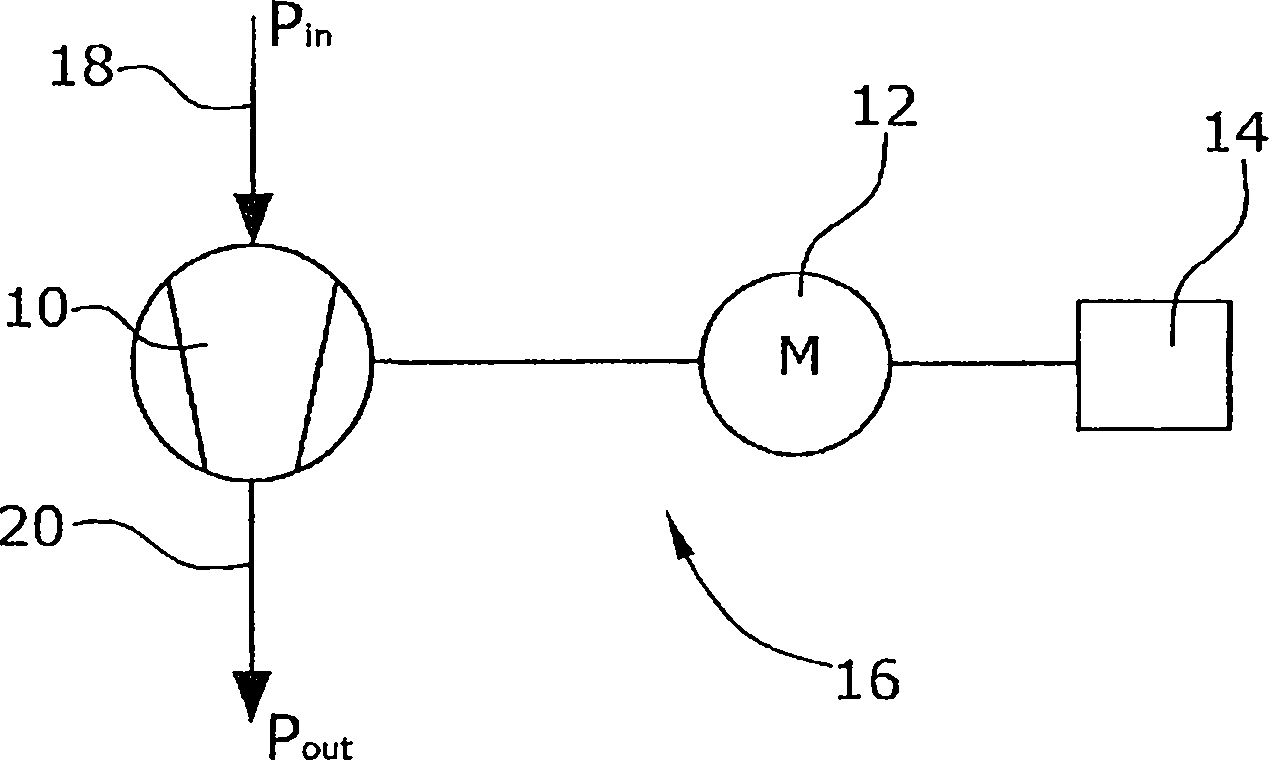

[0026] figure 1 The displacement pump device 16 shown in FIG. 1 is formed from a displacement pump 10 , a pump drive 12 for the displacement pump 10 and a control device 14 connected to the pump drive 12 . The displacement pump 10 is a Roots pump and the pump drive 12 is an electric motor. The control device 14 is an electronic converter with which the rotational speeds of the pump drive 12 and of the displacement pump 10 can be set.

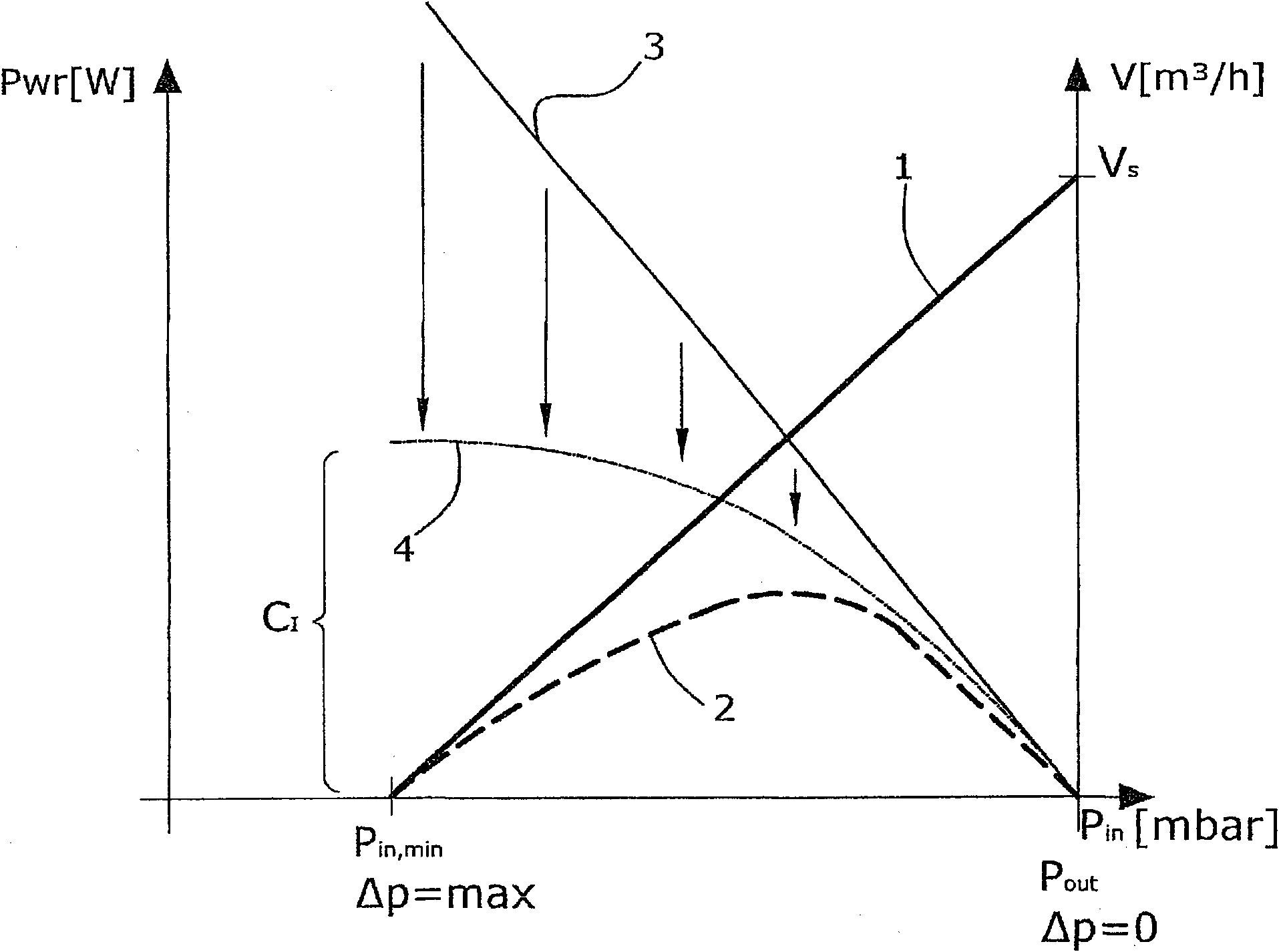

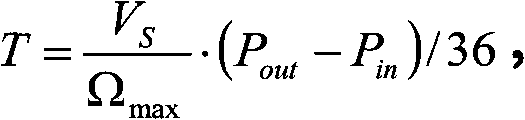

[0027] At the suction-side inlet 18 of the positive displacement pump 10, there is an inlet pressure P in the suction channel of the pump in . At the pressure-side outlet 20 of the positive displacement pump 10 , there is an outlet pressure P in the outlet channel of the positive displacement pump 10 out . as referenced below figure 2 As depicted, for the existing pressure P in and P out and the resulting differential pressure ΔP max =P out -P in , the positive displacement pump 10 is overcapacitated, so that by reducing the speed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com