Method of industrial production of lactic acid by employing molecular distillation technology

A technology of molecular distillation and lactic acid, which is applied in the direction of molecular distillation, separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of high impurity content, insufficient purity of food-grade lactic acid, and inability to be used as a raw material for polylactic acid production to achieve purity Improvement and arsenic reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

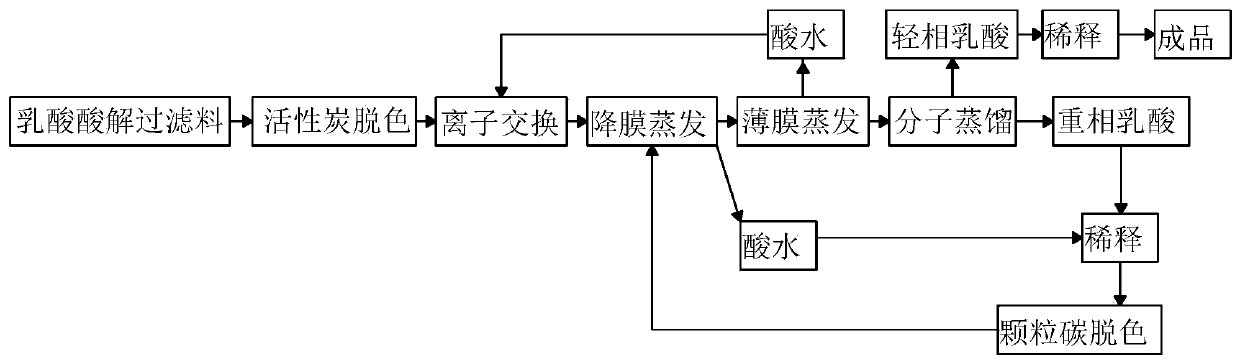

[0026] The present embodiment utilizes the method for the industrialized production of lactic acid of molecular distillation technology, comprises the following steps:

[0027] (A) Use activated carbon to decolorize the feed liquid (the mass fraction of lactic acid is 10-20%) of the lactic acid fermentation broth after acid hydrolysis and filtration;

[0028] (B) Perform ion exchange on the decolorized feed liquid;

[0029] (C) Perform falling film evaporation on the feed liquid after ion exchange; concentrate it into a lactic acid solution with a mass fraction of 80% lactic acid,

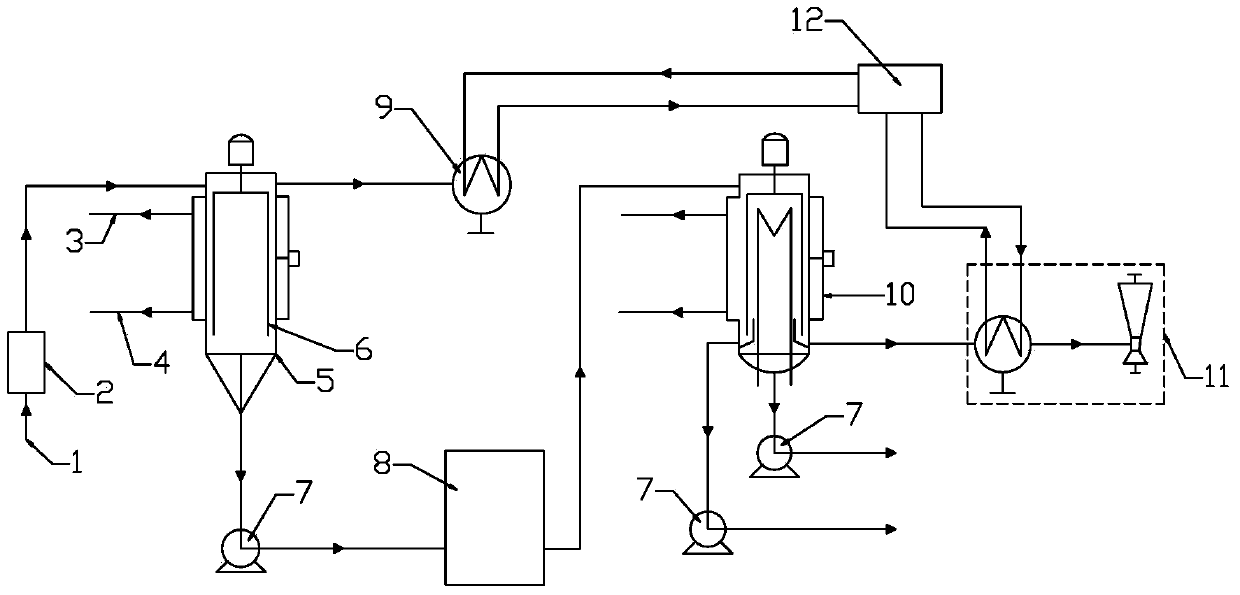

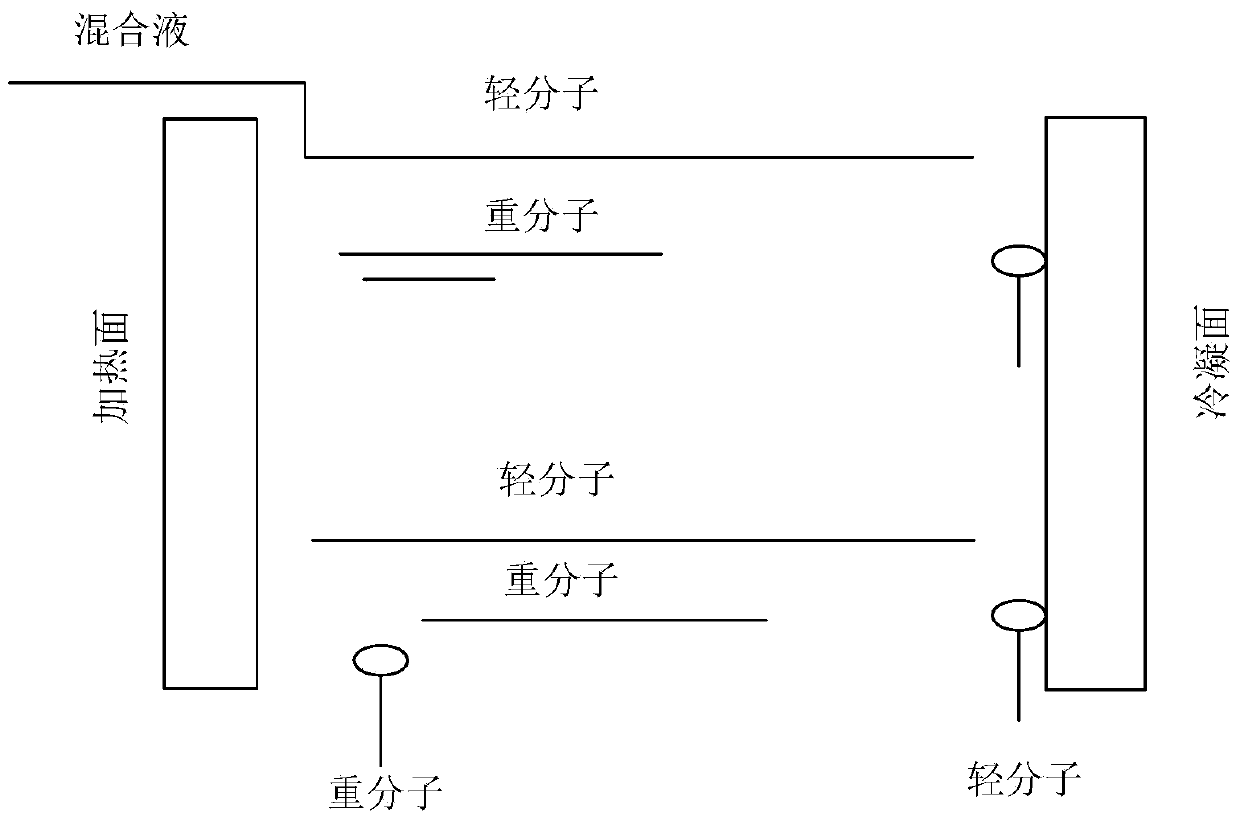

[0030] (D) Evaporate the lactic acid material obtained after falling film evaporation, so that the mass fraction of water in the lactic acid material is equal to 2%; in this embodiment, a wiped-film thin-film evaporator is used for thin-film evaporation, and the scraper speed is 45 rpm , the internal temperature of the steam jacket is 120°C, the feed rate is 3200kg / h, and the absolute pressure is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com