Molecular distiller

A technology of molecular distillation and scraping film, which is applied in the field of molecular distillation to achieve the effects of suppressing overheating, reducing the probability of thermal decomposition, and reducing the requirements for processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

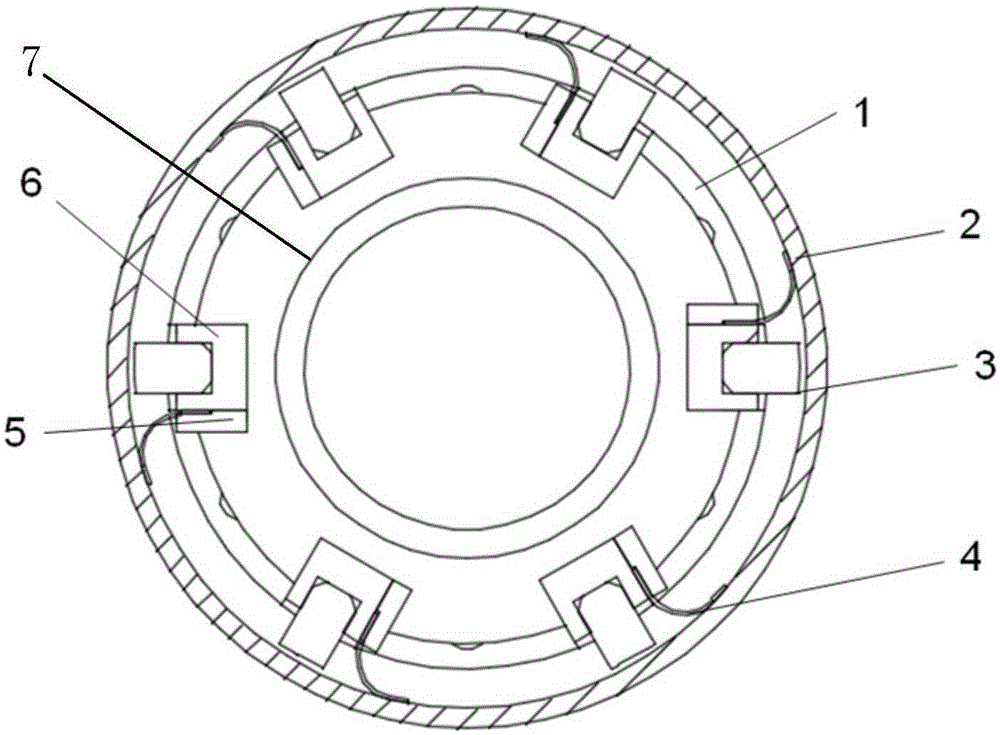

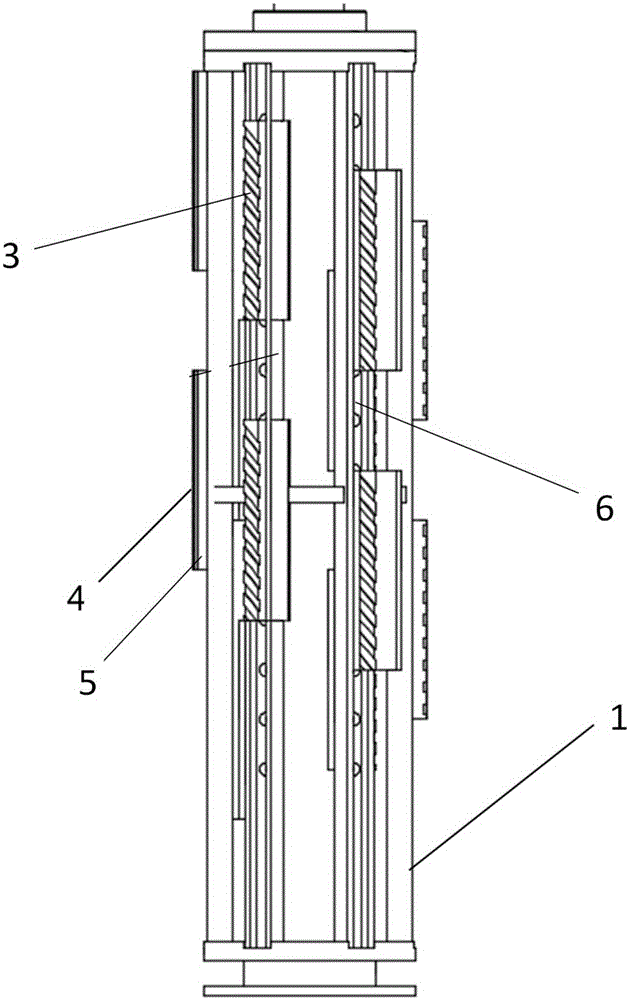

[0027]The first embodiment of the present invention relates to a molecular still, see figure 1 and figure 2 As shown in combination, it includes: a motor (not shown in the figure), a distillation cylinder 2, a heating jacket (not shown in the figure) positioned at the outside of the distillation cylinder 2, and a condenser 7 and a wiper film arranged in the middle of the distillation cylinder 2 Device 1, film wiper 1 is driven by a motor and installed in the distillation cylinder 2 close to the inner wall of the distillation cylinder. And, this molecular distiller also includes: several scraping film groups that are arranged on the scraper 1, and each scraping film group at least includes a scraper 3 and a flexible scraper 4, and the flexible scraper 4 is arranged on the top of the scraper 3 At the rear end, the scraper 3 and the flexible scraper 4 slide according to the rotation direction of the film wiper 1; wherein, the scraper 3 and the inner wall of the distillation cyl...

Embodiment 2

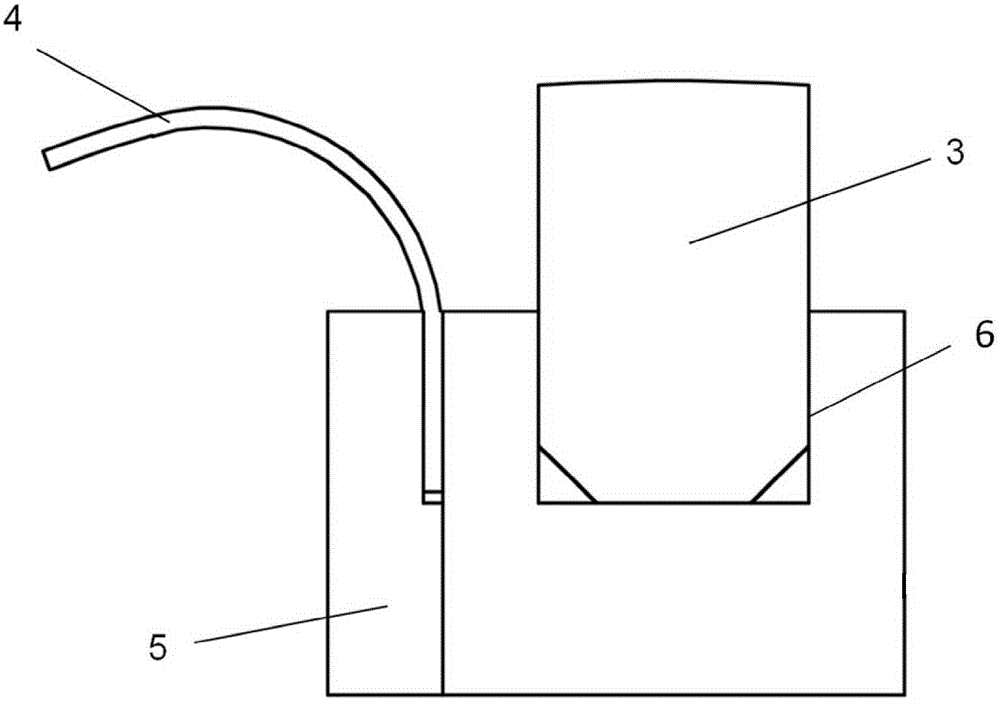

[0037] A second embodiment of the present invention relates to a molecular still. The second embodiment is further expanded on the basis of the first embodiment, the main difference is: in the second embodiment of the present invention, see image 3 As shown, the flexible scraper 4 is partly bent towards the side away from the rotation direction of the film wiper 1 , wherein the curved portion of the flexible scraper 4 is a convex curved surface on the side opposite to the inner wall of the distillation cylinder 2 . Further speaking, the curved portion of the flexible scraper 4 forms an outwardly convex self-adaptive curved surface relative to the inner wall of the distillation cylinder 2 , which fully adheres to the inner wall. In the process of scraping the film, the material itself can lubricate between the flexible scraper 4 and the inner wall, thereby avoiding the abrasion caused by the contact between the flexible scraper 4 and the inner wall.

[0038] like figure 2 A...

Embodiment 3

[0041] A third embodiment of the present invention relates to a molecular still. The third embodiment is further expanded on the basis of the second embodiment, the main difference is that: in the third embodiment of the present invention, the wiper 1 includes several strips equidistantly arranged around the axis of the distillation cylinder 2 The mounting groove 6, the upper fixing plate and the lower fixing plate for fixing the mounting groove 6. Wherein, each installation groove 6 is provided with at least one wiper film group. Utilizing the installation groove 6 and the fixing plate can provide effective support for the scraping film group under the premise of ensuring the distillation efficiency. Specifically, in order to reduce the mechanical disturbance of the distiller, a positioning mechanism, such as a positioning ring or a positioning wheel, may also be installed in the middle or bottom of the film wiper 1 . The wiper 1 can automatically adjust the axis of rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com