Device and method for purifying delta-decalactone by vacuum batch distillation

A decanolactone and rectification technology, applied in fractionation, organic chemistry, etc., can solve the problems of long residence time of materials, difficulty in separating qualified products, decomposition, etc., achieve short heating time, reduce the probability of thermal decomposition, The effect of lowering the altitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

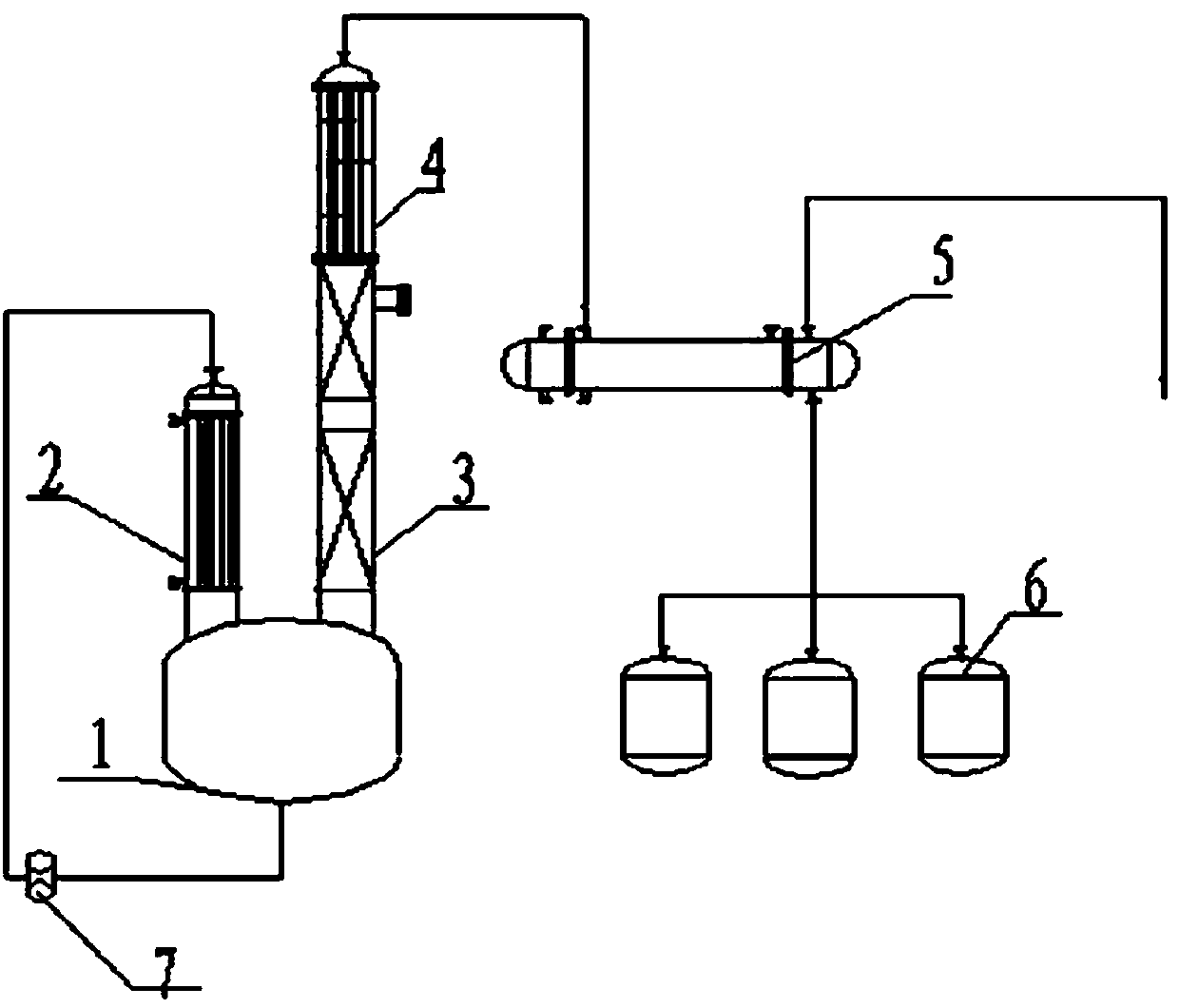

[0019] Depend on figure 1 It can be seen that the device for purifying butyl-decalactone by intermittent distillation under reduced pressure of the present invention comprises a tower still 1, and the tower body 3 is connected with an outlet on the top of the tower still 1, and the top of the tower body 3 is connected with a vertical 2 condenser 4, and the tower still 1 The other outlet of the upper part is connected to the falling film evaporator 2, the outlet of the falling film evaporator 2 is connected to the tower kettle 1 through a pipeline installed with a material circulation pump 7, and the outlet of the vertical condenser 4 is connected to the horizontal condenser through a pipeline. The inlet of the device 5 is connected, and the outlet of the horizontal condenser 5 is connected with the vacuum receiving tank 6 through a pipeline. Among them: the tower kettle 1 is a jacketed tube heater with an aspect ratio of 2-3, the tower body 3 is equipped with glass spring pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com