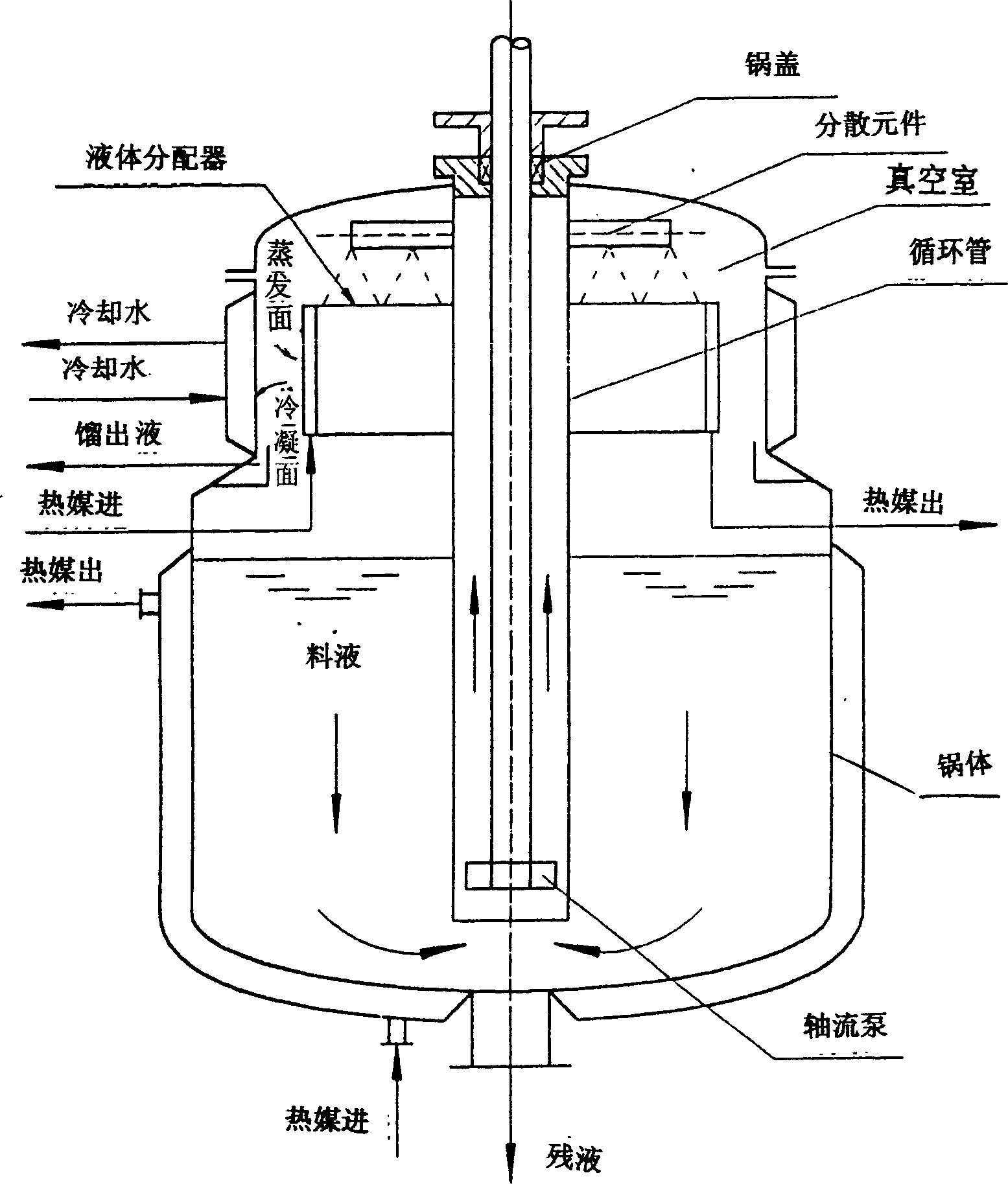

Internally circulating falling-film molecular distillator

A molecular distillation and falling film technology, applied in molecular distillation and other directions, can solve the problems of complex production devices, equipment costs and operating costs restricting the application of molecular distillation technology, and achieve a wide range of applications, low maintenance costs, and low operating costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The internal circulation falling film molecular distillation equipment is suitable for the removal of small molecules of polymer compounds in the polymerization reaction and the purification and concentration of polymers. It can replace falling film, wiped film, and centrifugal molecular distillation equipment for batch methods. When the production device replaces the continuous production device, the cost of the device is low, the investment is low, and the operation and maintenance are convenient, so that the molecular distillation technology can be widely used in industrial production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com