Preparation of Perilla leaf clean oil

A technology of perilla leaf and perilla leaf powder, which is applied in the fields of fat oil/fat refining, molecular distillation, essential oil/fragrance, etc., to achieve high production efficiency, good flavoring effect, and rich smoke aroma effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

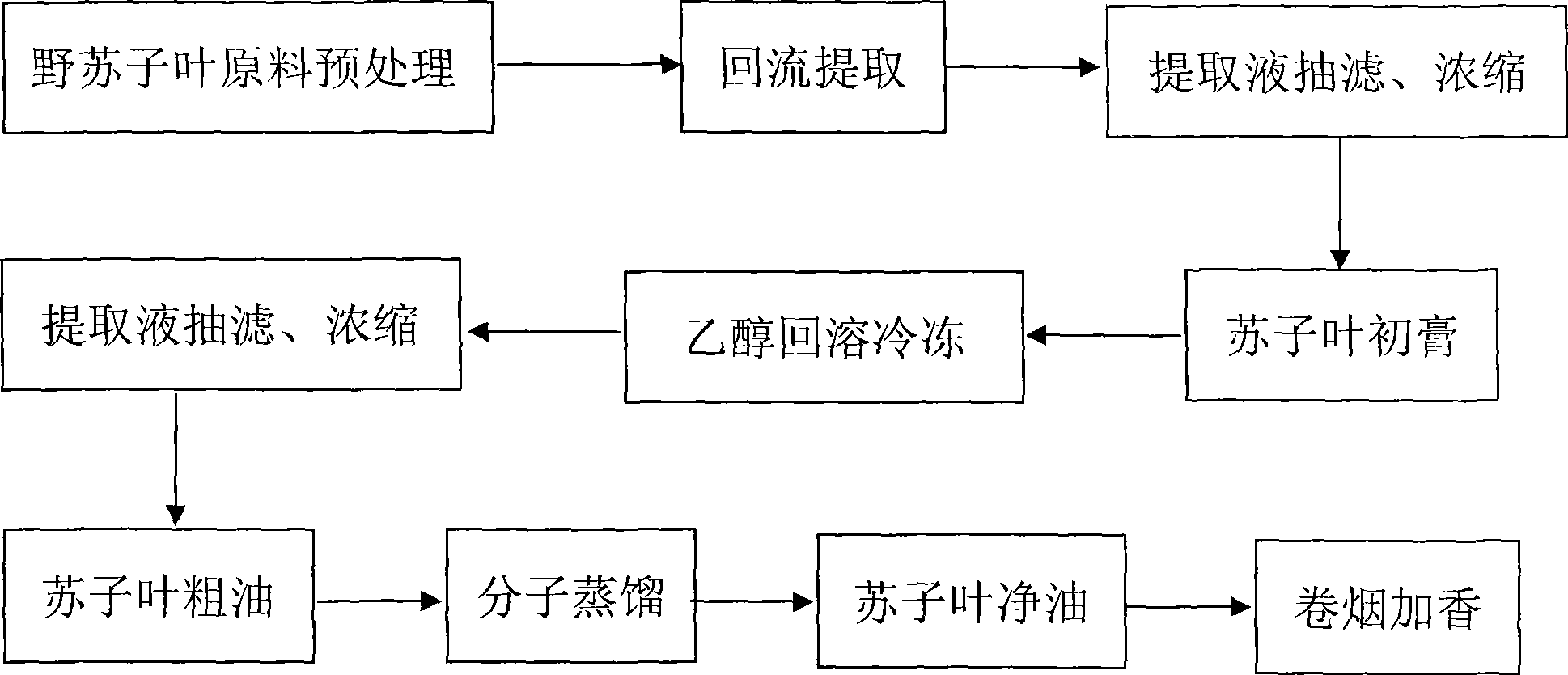

Image

Examples

Embodiment 1

[0017] A preparation method of perilla absolute oil and its application in cigarette flavoring, including perilla leaf raw material pretreatment, organic solvent reflux extraction and concentration, remelting and freezing, suction filtration concentration, molecular distillation separation and purification, absolute oil GC / MS Analysis and aroma application, the specific process steps are as follows:

[0018] (1) Perilla leaves are dried and pulverized at 40° C. to pass through a 20-100 mesh sieve to obtain perilla leaves powder.

[0019] (2) Put the perilla leaf powder obtained in step (1) into a reflux extraction tank, add ethanol, concentrate after reflux extraction for 72 hours, and obtain the primary ointment of perilla leaves.

[0020] (3) Add ethanol to the initial extract of perilla leaves obtained in step (2), redissolve and freeze for 12 to 24 hours, then concentrate by suction to obtain perilla leaf crude oil.

[0021] (4) Selectively separate and purify the perilla...

Embodiment 2

[0026] A preparation method of perilla absolute oil and its application in cigarette flavoring, which comprises the steps of putting perilla leaf powder into a refluxing extraction tank, adding ethanol, refluxing and extracting for 48 hours, and concentrating to obtain primary perilla leaf ointment; Add ethanol to remelt and freeze for 24 hours, then concentrate by suction filtration to obtain perilla leaf crude oil; use molecular distillation technology for selective separation and purification, and enrich the components below 120°C to obtain perilla leaf absolute oil, which is analyzed by GC / MS After identifying its main components, it is then used to flavor cigarettes.

Embodiment 3

[0028] A preparation method of perilla absolute oil and its application in cigarette flavoring, which comprises the steps of putting perilla leaf powder into a refluxing extraction tank, adding ethanol, refluxing and extracting for 36 hours, and concentrating to obtain perilla leaves primary cream; Add ethanol to remelt and freeze for 24 hours, then concentrate by suction filtration to obtain perilla leaf crude oil; use molecular distillation technology for selective separation and purification, and enrich the components below 160°C to obtain perilla leaf absolute oil, which is analyzed by GC / MS After identifying its main components, it is then used to flavor cigarettes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com