Semiconductor cooler-type centrifugal molecular distillation device

A technology of molecular distillation and refrigeration sheet, which is applied in the field of distillation, can solve the problems of auxiliary medium oxidation leakage, large footprint, complicated operation, etc., and achieve the effects of small footprint, compact device structure, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

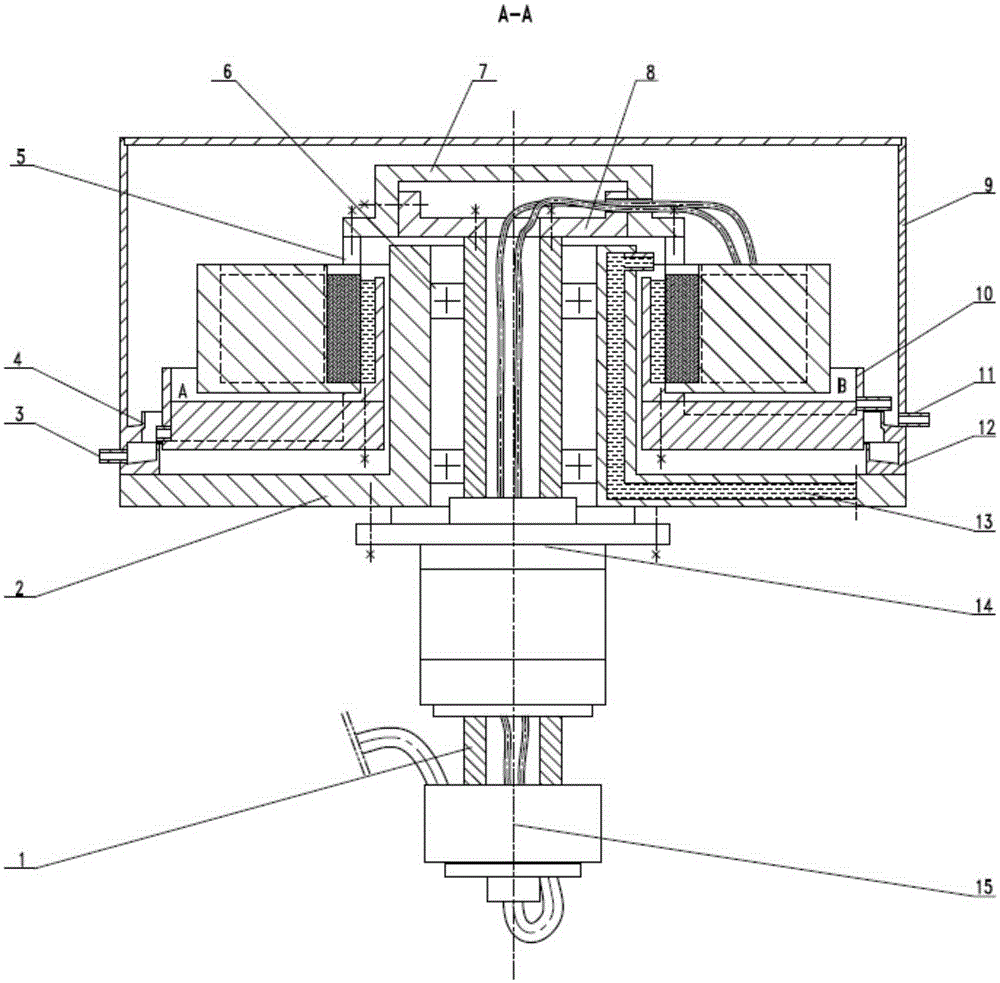

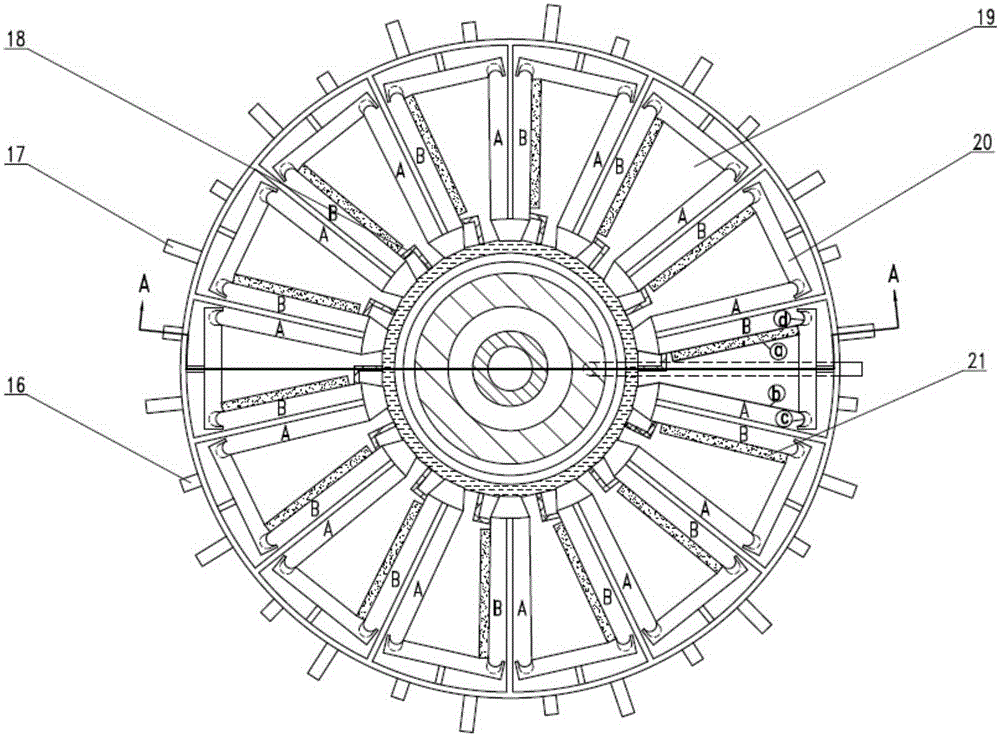

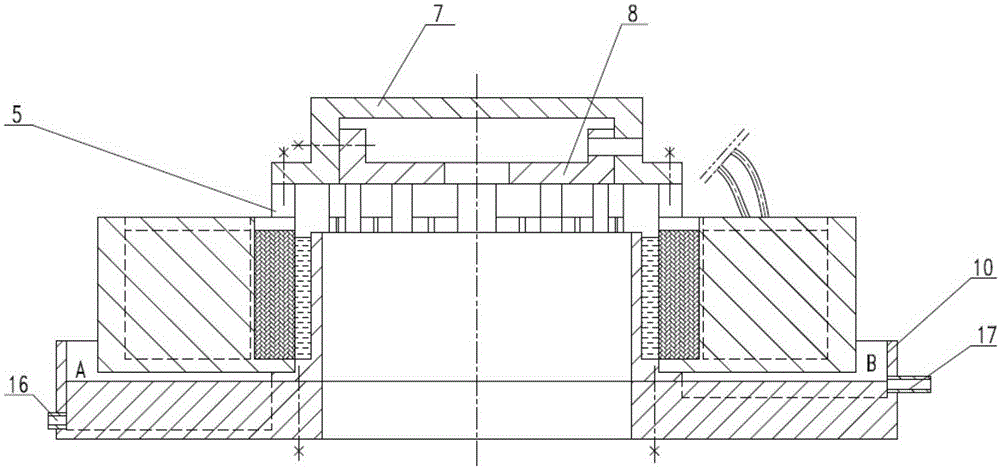

[0043] As shown in the attached figure, a semiconductor refrigeration chip type centrifugal molecular distillation device, when working, the mixed liquid of light and heavy components to be separated is transported to the high-speed rotating centrifuge through the liquid inlet channel (13) on the liquid inlet base (2). In the annular groove of the annular liquid storage tank (5) on the distillation rotor, under the action of centrifugal force, the mixed liquid in the annular groove passes through the grooves on each distillation body, and is evenly distributed in the heat of the semiconductor refrigeration sheet (21). surface or a surface, a very thin liquid film is formed, and in the vacuum environment of evacuation, the volatile light component fluid in the liquid film is due to the large mean free path of molecular motion, which is heated by the semiconductor refrigeration sheet (21) Under the action, it moves to the cold surface or b surface on the distillation body (19) in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com