Molecular distillation device

A molecular distillation and equipment technology, applied in the field of molecular distillation equipment, can solve the problems of high operation and maintenance costs, difficult vacuum sealing, complex structure, etc., and achieve low equipment manufacturing and operation and maintenance costs, saving power resources, and high thermal energy utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

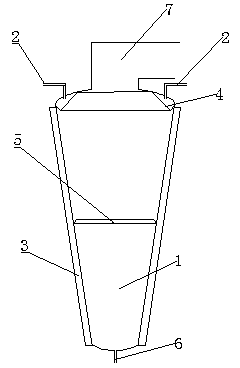

Embodiment 1

[0021] Embodiment 1: It includes a molecular distillation equipment body 1 and a vacuum tube 7. The molecular distillation equipment body 1 is an inverted body circular platform with an upper ring larger than the lower ring, and the two generatrices opposite to the inverted body annular platform intersect The formed angle is 45°-85°. Preferably: the cone angle of the inverted circular truncated cone is 60°-70°. The circular frustum is hollow, and the wall thickness of the frustum is uniform. The same is true for the circular frustum involved in the following embodiments. The two opposite generatrices refer to the two waists of a trapezoid obtained by vertically cutting the circular platform with a plane along the center of the circular platform. The same is true for the relative busbars referred to in the following embodiments.

[0022] The top of the molecular distillation equipment body 1 is connected to the top head, the top head is connected to the material feeding pipe...

Embodiment 2

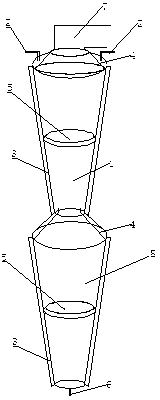

[0027] When the product output is small, one molecular distillation equipment body can be used as the molecular distillation equipment body; when the product output is large, two or more molecular distillation equipment bodies can be welded into a large molecular distillation equipment. Such as image 3 As shown: the upper and lower molecular distillation equipment bodies 1 and 8 are connected in series, and the bottom port of the upper molecular distillation equipment body 1 is connected to the top port provided on the top head of the lower molecular distillation equipment body 8 .

[0028] The top end of the upper molecular distillation equipment body 1 is provided with a top port to connect with the vacuum tube 7. The inlet of the vacuum tube 7 is located in the upper circular ring of the upper distribution circular platform composed of the material distribution tank plate 4. The upper molecular distillation equipment body The top head of 1 is connected to the material feed...

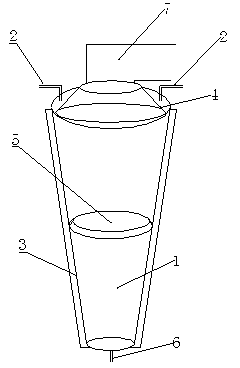

Embodiment 3

[0030]Embodiment 3: A condensing system 9 is provided in the inner cavity of the molecular distillation equipment body 1, the top head of the molecular distillation equipment body 1 is connected to the material feeding pipe 2, and the inner wall of the top head head of the molecular distillation equipment body 1 is connected to the inner wall of the molecular distillation equipment body 1 by There is an annular gap between the lower end of the distribution ring-shaped circular platform composed of the material distribution channel plate 4 and the side wall of the molecular distillation equipment body 1, and the outlet of the material feeding pipe 2 is in the material distribution In the material distribution tank formed by the tank plate 4 and the inner wall of the molecular distillation equipment body 1, the middle part of the side wall of the molecular distillation equipment body 1 is connected to the lower end of the ring-shaped circular platform composed of the material redi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com