Waste rolling oil regeneration device

A regeneration device and rolling oil technology, applied in the direction of molecular distillation, lubricating composition, etc., can solve the problems of wasting resources, polluting the environment, and increasing the viscosity of rolling oil, and achieve reasonable structural design, high purity, and high regeneration efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

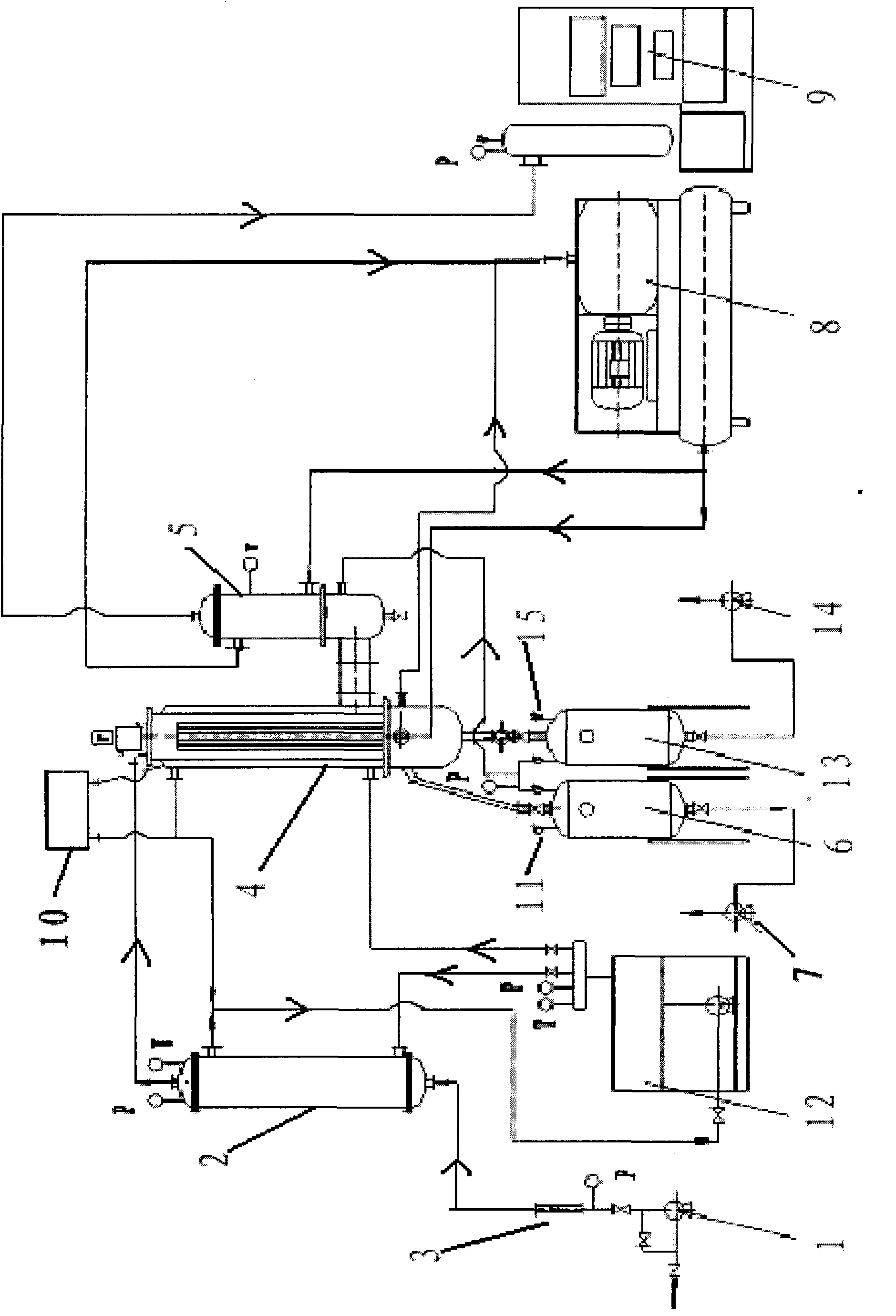

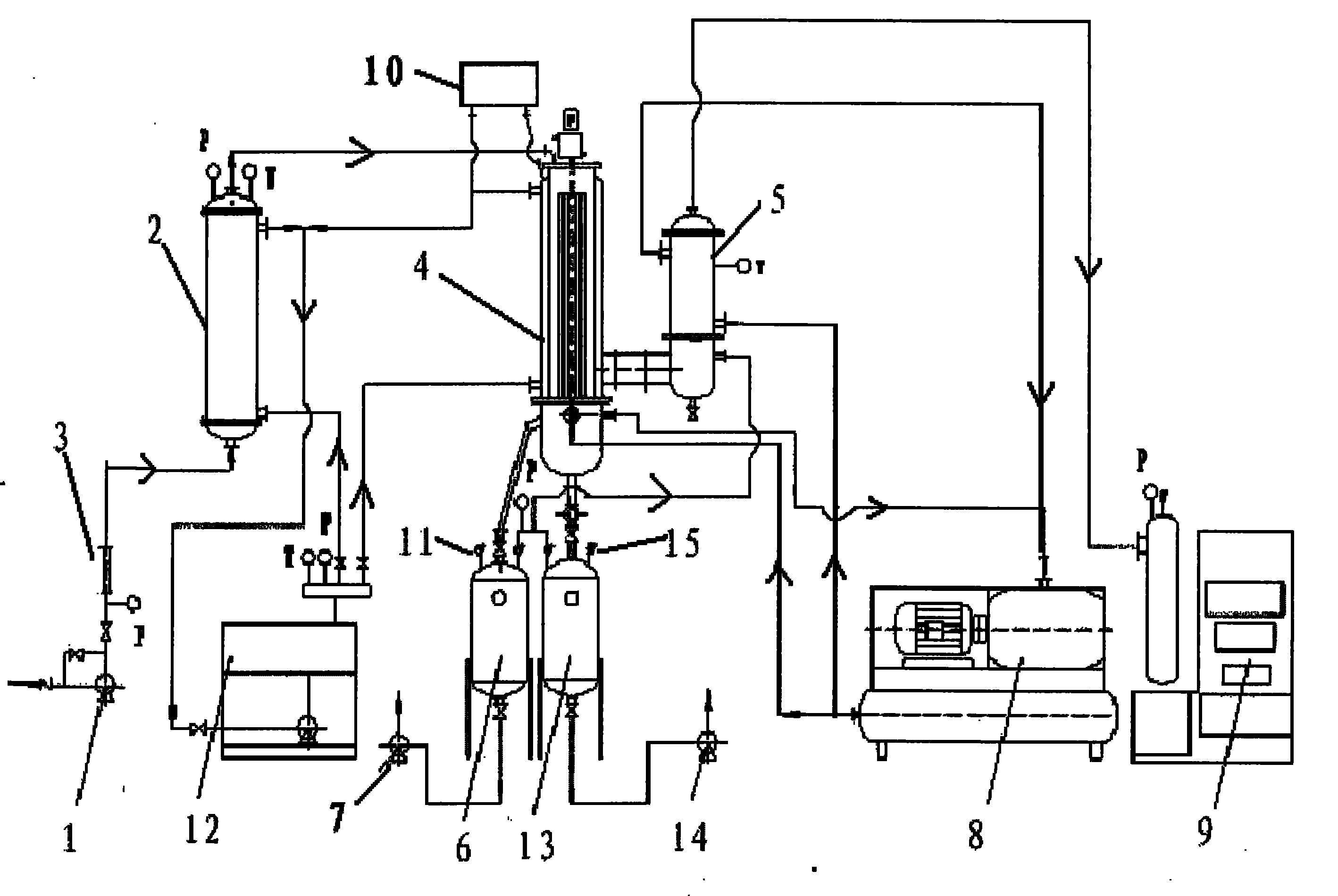

[0016] The waste rolling oil regenerating device of this embodiment includes an oil inlet pump 1 for supplying waste rolling oil. The oil inlet pump 1 is connected with a heat exchanger 2 for heating the waste rolling oil. A flow meter 3 for measuring waste rolling oil is arranged between them, and the output end of the heat exchanger 2 is connected with a thin-film distiller 4 for separating rolling oil and heavy oil, and the input ends of the heat exchanger 2 and the thin-film distiller 4 The heat conduction oil furnace 12 is connected in circulation, and the thin film distiller 4 is connected with a condenser 5 for collecting gas rolling oil, and the condenser 5 is connected with a vacuum degree used to meet the requirements of the thin film evaporator 4, so that the rolling oil evaporates below the flash point The vacuum unit 9 of the thin film distiller 4 is connected with a heavy oil tank 6 for collecting unevaporated heavy oil and a product oil tank 13 for collecting fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com