Method for preparing high-pure lactic acid by using centrifugal molecular distillation technique

A molecular distillation and high-purity technology, applied in the field of high-purity lactic acid preparation, can solve problems such as large liquid film thickness, damage to heat-sensitive material components, and reduced liquid film thickness, so as to reduce production costs, shorten heating time, and heat transfer. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

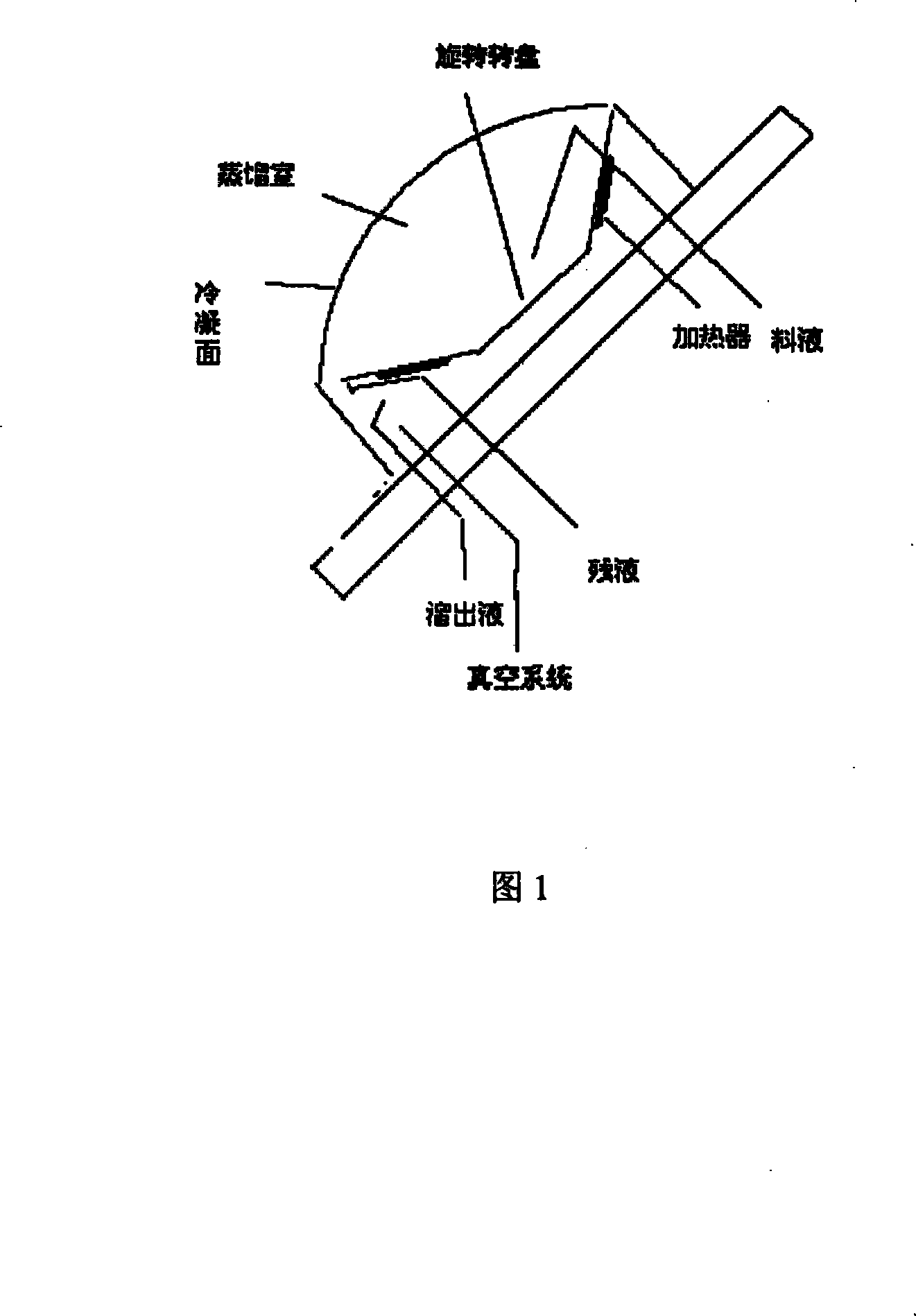

Image

Examples

Embodiment 1

[0017] The fermentation broth that has been decolorized by activated carbon and pretreated by bipolar membrane electrodialysis is used as raw material (the mass percentage of lactic acid is about 20%), and it is transported to a falling film thin film evaporator, and dehydrated at 60°C and a vacuum of 100pa Concentrate so that the mass percentage of lactic acid reaches 60%; send the concentrated lactic acid to the center of the conical surface of the centrifugal molecular distillation equipment at a uniform rate with a pump, and use centrifugal force (5000r / min) to form an extremely thin evaporating liquid on the rotating surface Membrane, under the conditions of distillation treatment temperature of 100°C and vacuum degree of 1Pa, high-purity lactic acid (98%) meeting the standard is obtained, and the product yield reaches 90%.

Embodiment 2

[0019] The fermentation broth that has been decolorized by activated carbon and pretreated by bipolar membrane electrodialysis is used as raw material (the mass percentage of lactic acid is about 20%), and it is transported to a falling film thin film evaporator, and dehydrated at 50°C and a vacuum degree of 80pa. Concentrate so that the mass percentage of lactic acid reaches 40%; send the concentrated lactic acid to the center of the conical surface of the centrifugal molecular distillation equipment at a uniform rate with a pump, and use centrifugal force (1000r / min) to form an extremely thin evaporating liquid on the rotating surface Membrane, under the conditions of distillation treatment temperature of 80°C and vacuum degree of 0.1Pa, high-purity lactic acid (98%) meeting the standard is obtained, and the product yield reaches 92%.

Embodiment 3

[0021] The fermentation broth that has been decolorized by activated carbon and pretreated by bipolar membrane electrodialysis is used as raw material (the mass percentage of lactic acid is about 20%), and it is transported to a falling film thin film evaporator, and dehydrated at 80°C and a vacuum of 80pa. Concentrate so that the mass percentage of lactic acid reaches 70%; send the concentrated lactic acid to the center of the conical surface of the centrifugal molecular distillation equipment at a uniform rate with a pump, and use centrifugal force (500r / min) to form an extremely thin evaporating liquid on the rotating surface Membrane, under the conditions of distillation treatment temperature of 100°C and vacuum degree of 10Pa, high-purity lactic acid (98%) meeting the standard is obtained, and the product yield reaches 91%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com