Purification method of ion liquid

A technology of ionic liquid and purification method, applied in the field of purification of ionic liquid, can solve the problem of low purity of ionic liquid, etc., and achieve the effect of high-efficiency removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

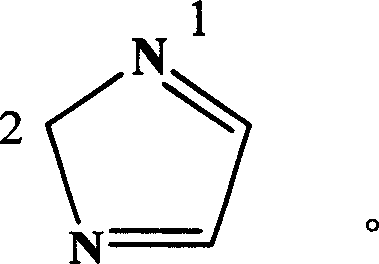

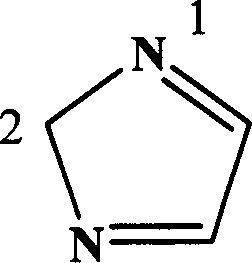

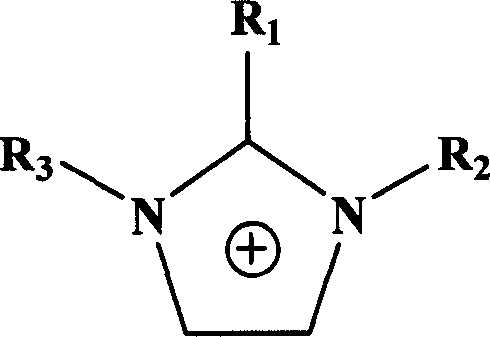

[0019] 1-methylimidazole and 1-bromoethane join in the reactor with the ratio of 1: 1.2 (mol / mol), in N2 atmosphere, react 24 hours under 65 ℃, the product that obtains, joins the inlet of molecular distillation unit In the feeder, turn on the vacuum pump to make the pressure reach 30Pa, preheat the raw material ionic liquid to 35°C, start the wiper, open the injection valve, control the feed rate at 1.44g / min, and carry out molecular distillation at 120°C. The collected heavy component is the purified ionic liquid, its mass accounts for 85.77% of the total mass, and the purity is 99.0% through NMR analysis. The light component accounts for 14.23% of the total mass. According to gas chromatography analysis, the content of 1-bromobutane is 87.92%, and the content of methylimidazole is 11.27%.

Embodiment 2

[0021] 1,2-dimethylimidazole and 1-bromopropane were added to the reactor in a ratio of 1:1.2 (mol / mol), and reacted for 24 hours under N2 atmosphere at 65°C, and the obtained product was added to the molecular distillation device In the feeder, turn on the vacuum pump to make the pressure reach 12Pa, preheat the raw material ionic liquid to 30°C, start the wiper, open the injection valve, control the feed rate at 1.32g / min, and carry out molecular distillation at 100°C . The collected heavy component is the purified ionic liquid, and its mass accounts for 86.01% of the total mass. According to NMR analysis, the purity is 99.1%. The light component accounts for 13.99% of the total mass. According to gas chromatography analysis, the content of 1-bromobutane is 84.72%, and the content of methylimidazole is 15.20%.

Embodiment 3

[0023] 1-methylimidazole and 1-bromoisopropane are added in the reactor with the ratio of 1: 1.2 (mol / mol), in N Atmosphere, reacted 24 hours under 65 ℃, the product that obtains, joins the inlet of molecular distillation unit In the feeder, turn on the vacuum pump to make the pressure reach 1Pa, preheat the raw material ionic liquid to 30°C, start the wiper, open the injection valve, control the feed rate at 1.44g / min, and carry out molecular distillation at 100°C. The collected heavy component is the purified ionic liquid, and its mass accounts for 85.49% of the total mass. According to NMR analysis, the purity is 99.3%. The light component accounts for 14.51% of the total mass. According to gas chromatography analysis, the content of 1-bromobutane is 89.23%, and the content of methylimidazole is 10.16%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com