Method for extracting effective components from natural materials

A technology of active ingredients and natural products, applied in the direction of molecular distillation, solid solvent extraction, etc., can solve the problems of large fluid and energy consumption, poor separation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

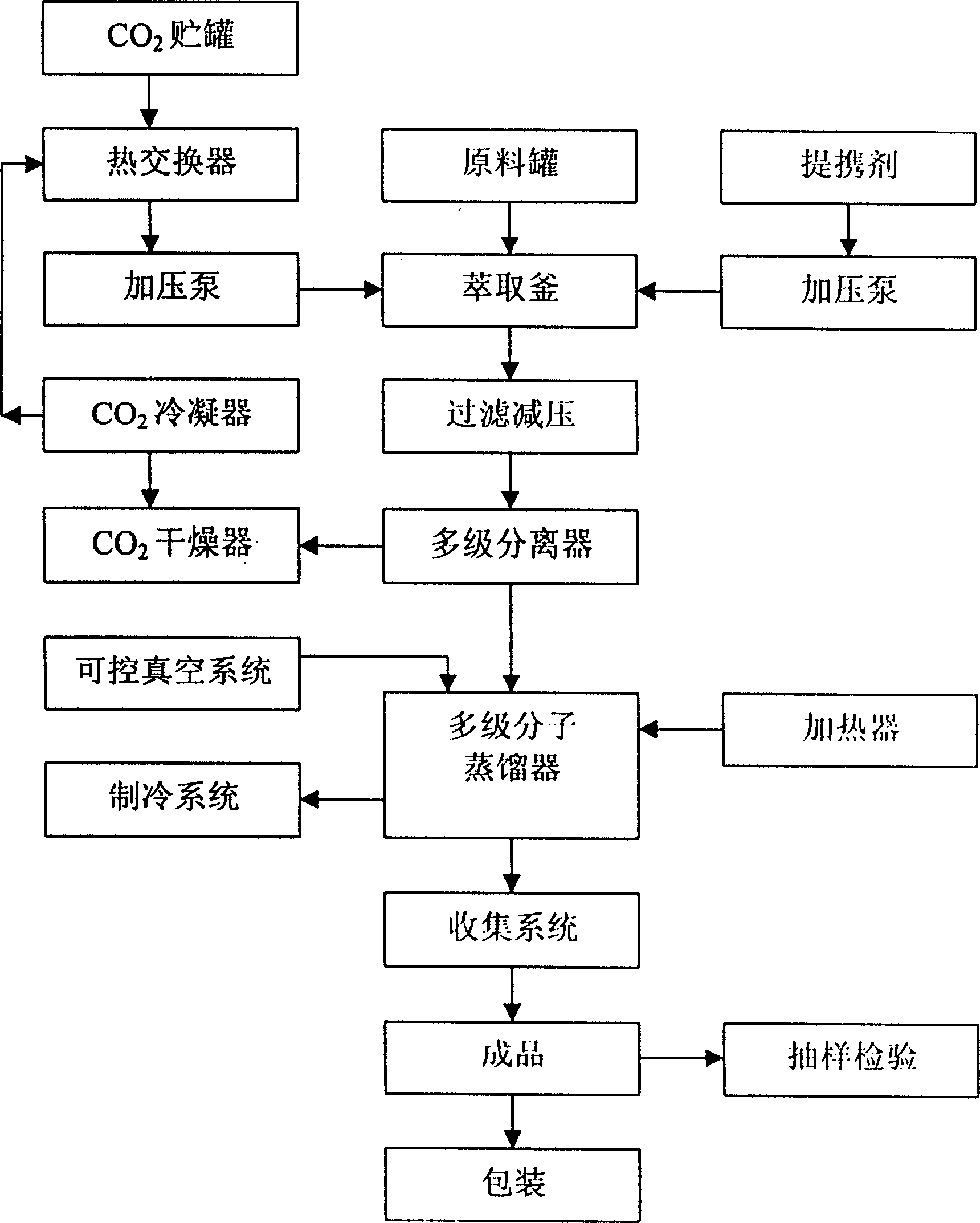

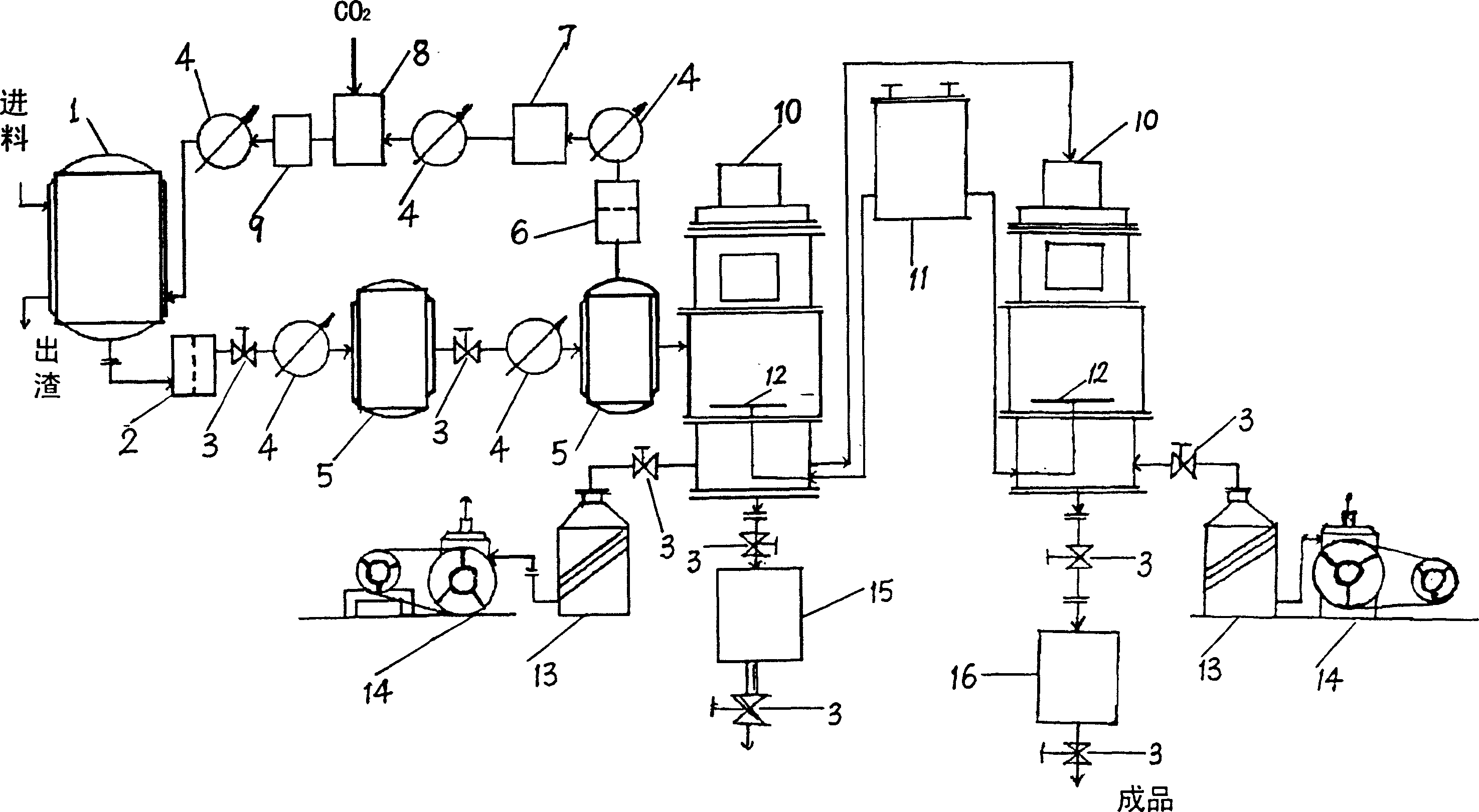

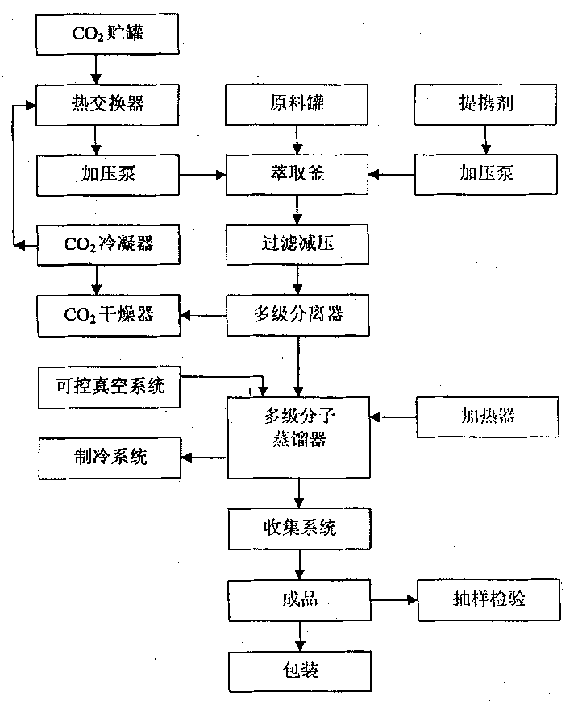

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1, the extraction of wheat germ oil and the separation of natural vitamin E

[0018] Wheat germ accounts for about 2%-3% of the whole grain mass, which contains 8%-12% high-quality vegetable fat, including a large amount of linoleic acid and other essential unsaturated fatty acids. And every 100 grams of wheat germ oil contains about 300 mg of natural vitamin E, which is the highest content in various vegetable oils. Extracting wheat germ oil by traditional technology not only has the problem of residual solvent, but also must go through refining steps such as degumming, decolorization, deacidification and deodorization to obtain commercial wheat germ oil. As for separating natural vitamin E, it is extremely difficult.

[0019] The present invention uses supercritical CO 2 Wheat germ tooth oil is extracted from wheat germ by fluid extraction technology. The system used is composed of extraction kettle - filter - pressure reducing valve - more than two sepa...

Embodiment 2

[0020] Embodiment 2, the separation of natural capsanthin and capsanthin

[0021]Capsanthin is a natural red pigment extracted from mature pepper skins. It is an ideal food coloring agent because of its bright color, non-toxicity and good thermal stability. The spicy substance in chili——capsicum, it can not only promote appetite and help digestion, but also dissolve fat and lose weight as a raw material for medicine. Due to the similar physical and chemical properties of capsanthin and capsanthin, it is extremely difficult to separate the two; after separation, the quality of the two products will be greatly improved, and the economic value will be great.

[0022] Adopt the method of the present invention to use supercritical CO 2 Fluid extraction of capsanthin containing capsicum, a certain amount of ethanol can be added as a carrier agent, and ethanol can also be used to pre-treat dried peppers. During extraction, the temperature of the extraction kettle is 30°--60°C. The ...

Embodiment 3

[0023] Example 3, the extraction of seabuckthorn oil and the refining of α-linolenic acid

[0024] Seabuckthorn is a wild plant, and its fruit is edible and also used as medicine. Seabuckthorn oil is rich in nutrients and a variety of biologically active ingredients beneficial to the human body, and has strong sterilization, pain relief, tissue regeneration promotion and cancer prevention effects. Seabuckthorn oil is rich in α-linolenic acid, and α-linolenic acid is the most basic and primitive substance in the process of life. However, it cannot be synthesized in the human body and can only be taken from food. Since my country has abundant seabuckthorn resources, but has not been well utilized in the past, it is of great significance to develop the extraction of seabuckthorn oil and the refining of α-linolenic acid.

[0025] Using supercritical CO 2 Seabuckthorn oil is extracted by fluid extraction technology. The device can be composed of an extraction kettle and three sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com