Recovery method for ionic liquid solvent generated from homogeneous acylation reaction of cellulose

An ionic liquid solvent, acylation reaction technology, applied in molecular distillation and other directions, can solve the problems of not involving the ionic liquid solvent waste liquid recovery, polluting the ionic liquid solvent, low ionic liquid concentration, etc., achieving low cost and simple process. , the effect of high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

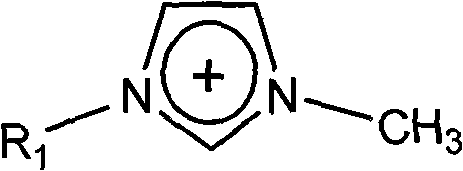

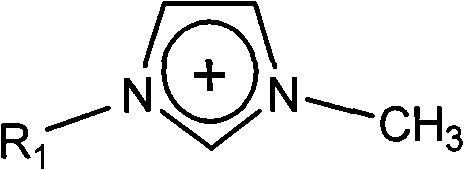

[0035] Weigh 500 g of the ionic liquid solvent 1-butyl-3-methylimidazolium tetrafluoroborate waste liquid after preparing cellulose acetate, add 5 g of activated carbon, and stir at 30 ° C for 30 min; Ethylene membrane filtration; then add to the rotary evaporator, under the condition of 60°C and 2kpa, distill under reduced pressure for 3 hours, then add the resultant to the feeder of the wiped film molecular distillation apparatus, and turn on the feeder heating device , set the heating temperature to 50°C, turn on the evaporation temperature device of the wiped film molecular distillation apparatus, set the evaporation surface temperature to 80°C, turn on the circulating cooling pump, set the condensation temperature to -15°C, and keep it for 20 minutes, turn on the vacuum pump , make the pressure reach 1Pa, start the wiper, make the rotating speed of the wiper rotor be 275r / min, open the injection valve, control the feed rate at 10ml / min, start dripping molecular distillatio...

Embodiment 2

[0038] Weigh 500 g of the ionic liquid solvent 1-allyl-3-methylimidazolium chloride waste liquid after preparing cellulose acetate, add 10 g of activated carbon, stir at 50 ° C for 60 min, and then use a 0.45 μm polytetrafluoroethylene membrane Filter, then add to a rotary evaporator, distill under reduced pressure at 90°C and 10kpa for 6 hours, then add the resultant to the feeder of the wiped-film molecular distillation device, turn on the feeder heating device, set the temperature 70°C, turn on the evaporation temperature device of the wiped film molecular distillation apparatus, set the temperature to 100°C, turn on the circulating cooling pump, set the condensation temperature to -10°C, and keep it for 20 minutes, turn on the vacuum pump to make the pressure reach 50Pa, start the scraping Membrane device, make the rotating speed of the scraping membrane rotor be 385r / min, open the injection valve, feed speed control at 5ml / min, start dripping molecular distillation to obta...

Embodiment 3

[0041]Weigh 500 g of the ionic liquid solvent 1-butyl-3-methylimidazolium iodide salt waste liquid after preparing cellulose acetate, add 25 g of activated carbon, stir at 80 ° C for 120 min, and then filter with a 1 μm polytetrafluoroethylene membrane, Then add it to the rotary evaporator, distill under reduced pressure at 110°C and 30kpa for 15 hours, then add the resultant to the feeder of the molecular distillation device, turn on the heating device of the feeder, set the temperature at 80°C, and turn on the molecule Set the temperature of the evaporation temperature device of the distillation apparatus to 110°C, turn on the circulating cooling pump, set the condensation temperature to 15°C, and keep it for 20 minutes, turn on the vacuum pump to make the pressure reach 100Pa, start the wiper, and make the speed of the wiper rotor be 385r / min, open the injection valve, control the feed rate at 1ml / min, start dripping molecular distillation to obtain distillate, collect the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole radius | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com