Anti-cracking environment-protection paint and method for preparing the same

An environmentally friendly coating and anti-cracking technology, applied in the direction of coating, etc., can solve the problems of low production cost and cracking, and achieve the effects of low manufacturing cost, crack prevention and convenient implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

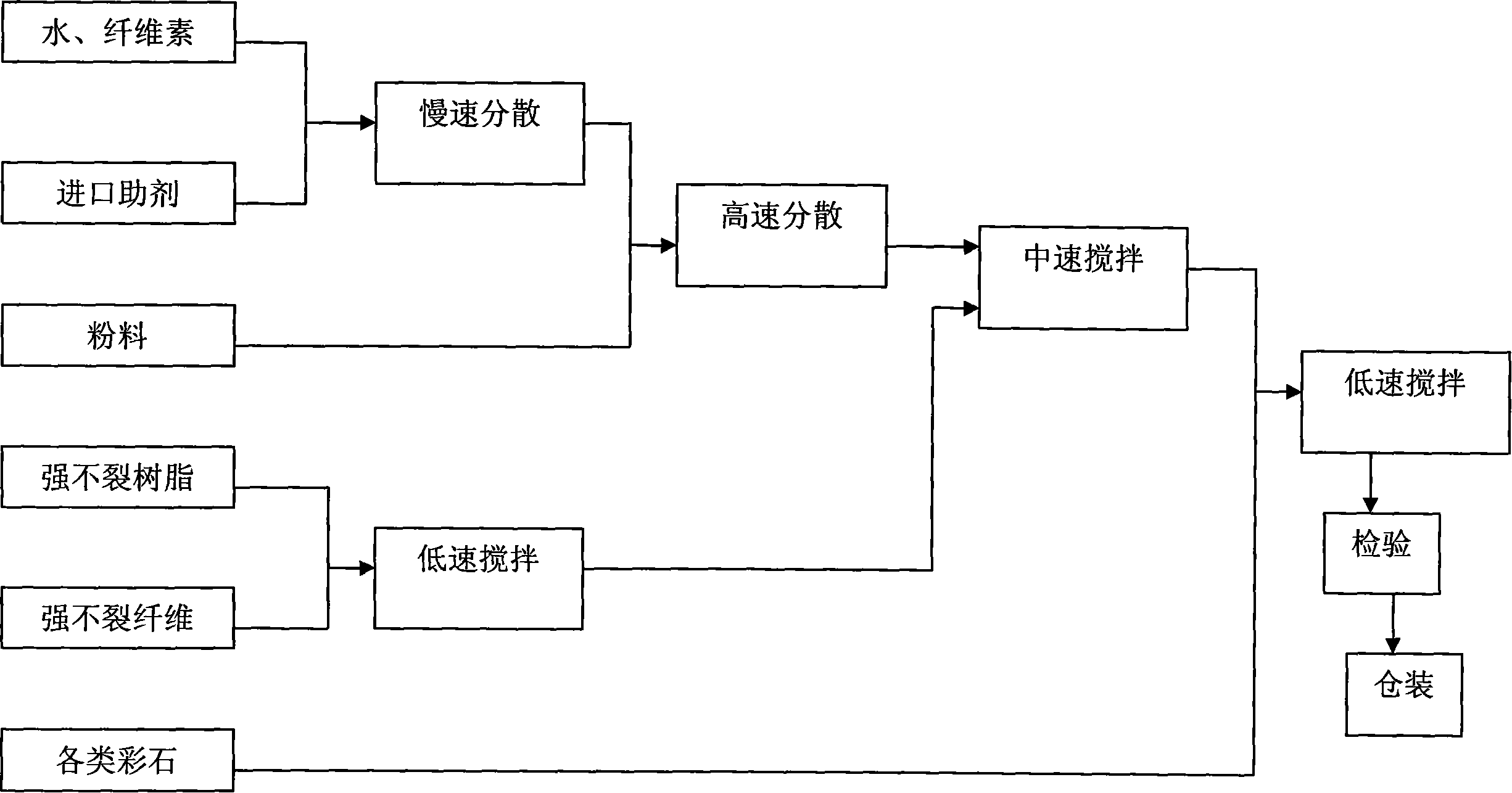

[0019] The anti-cracking environmental protection paint is composed of the following components in weight percentage ratio: 30% water, 5% additives, 20% powder, 20% pure acrylic elastic emulsion, 5% strong non-cracking fiber, and 20% colored stones. The specific process flow includes the following steps. In a stirring container, mix water, cellulose, and additives and disperse slowly for 10 minutes until they dissolve into a slightly transparent solution, then add powder and mix for 15 minutes at high speed. Pure acrylic elastic emulsion , Mix and stir the fibers at low speed for 10 minutes for later use, then add the above mixed solution into medium speed and mix for 10 minutes, then put in various colored stones, mix and stir for about 15 minutes at low speed, then inspect, and then pack and store.

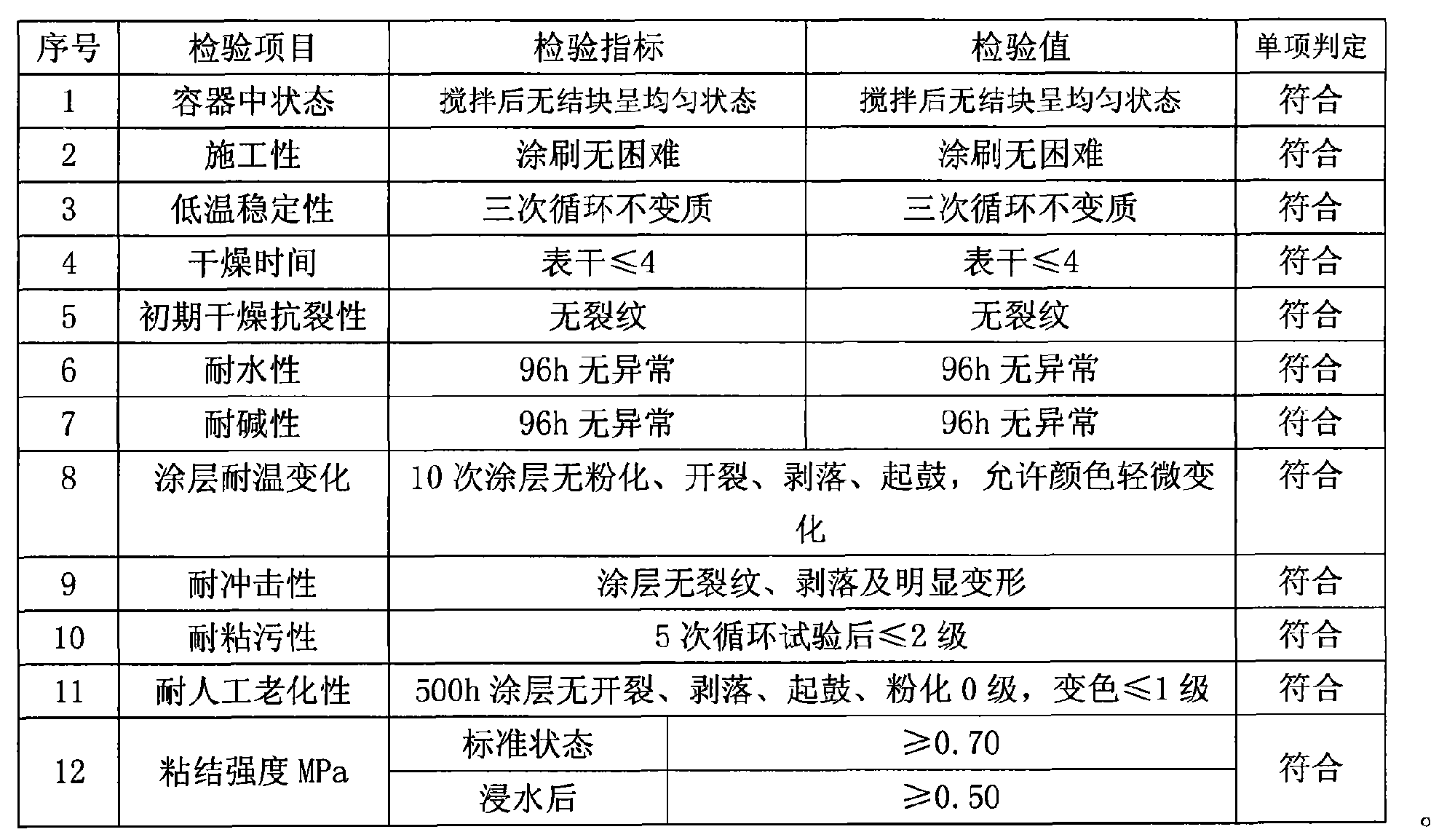

[0020] The special requirements of the high elasticity anti-cracking coating of the present invention, the film-forming material needs to adopt certain high elastic properties, h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com