Preparation method for W-Cu composite materials of fiber and particle hybrid structure

A composite material and particle technology, applied in the field of preparation of fiber and particle hybrid structure copper-tungsten composite material, can solve the problems of aggravating ablation and wear, difficult to achieve continuous skeleton structure, insufficient strength of tungsten skeleton, etc., and achieve high temperature strength. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Step 1, prepare composite material green body:

[0037] Weigh 70% of W powder and 30% of Cu powder according to mass percentage, the sum of the mass percentages of the above components is 100%, put W powder and Cu powder in a drum mixer with a ball-to-material ratio of 0.5:1 at 400r / min Mix at a rotating speed for 6h;

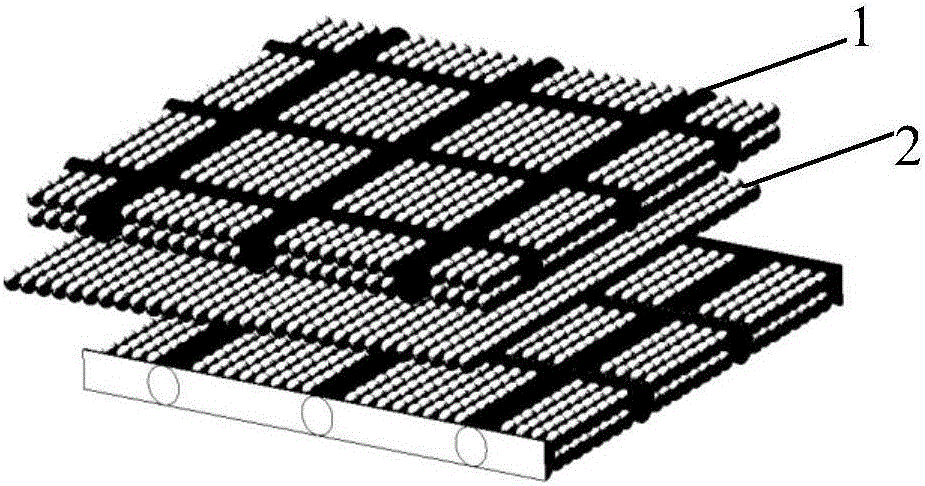

[0038] After the mixed composite powder is sieved to remove impurities, it is laid out layer by layer with the pickled tungsten fiber net in the cold pressing mold, and the interval between the pressed tungsten fiber net is 2mm, and it is pre-pressed at 200MPa, and the pressure is maintained for 90s. A composite green body is formed.

[0039] The tungsten fiber mesh is woven from tungsten fibers with a wire diameter of 60 μm, and its specification is 100 mesh. Before laying layers, the tungsten fiber mesh is pickled with HF to remove the oxide film on its surface.

[0040] Step 2, heat pressing:

[0041] Put the green body obtained in step 1 into a pr...

Embodiment 2

[0045] Step 1, prepare composite material green body:

[0046] Weigh 90% of W powder and 10% of Cu powder according to mass percentage, the sum of the mass percentages of the above components is 100%, put W powder and Cu powder in a drum mixer with a ball-to-material ratio of 0.7:1 at 400r / min Mix at a rotating speed for 7 hours;

[0047] After the mixed composite powder is sieved to remove impurities, it is layered with the pickled tungsten fiber net in the cold pressing mold, and the distance between the pressed tungsten fiber net is 3mm, and it is pre-pressed at 400MPa, and the pressure is maintained. After 30s, a composite material green body is formed.

[0048] The tungsten fiber mesh is woven from tungsten fibers with a wire diameter of 40 μm, and its specification is 30 mesh; the tungsten fiber mesh is pickled with HF before laying layers to remove the oxide film on its surface.

[0049] Step 2, heat pressing:

[0050] Put the green body obtained in step 1 into a pre...

Embodiment 3

[0054] Step 1, prepare composite material green body:

[0055] Weigh 85% of W powder and 15% of Cu powder according to mass percentage, the sum of the mass percentages of the above components is 100%, put W powder and Cu powder in a drum mixer with a ball-to-material ratio of 1:1 at 400r / min Mix at a rotating speed for 8 hours;

[0056]After the mixed composite powder is sieved to remove impurities, it is layered with the pickled tungsten fiber net in the cold pressing mold, and the distance between the pressed tungsten fiber net is 1mm, and it is pre-pressed, the pre-pressure is 340MPa, and the After pressing for 60s, a composite material green body is formed.

[0057] The tungsten fiber mesh is woven from tungsten fibers with a wire diameter of 40 μm, and its specification is 30 mesh; the tungsten fiber mesh is pickled with HF before laying layers to remove the oxide film on its surface.

[0058] Step 2, heat pressing:

[0059] Put the green body obtained in step 1 into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com