Glass fiber and PTFE (Polytetrafluoroethylene) fiber blended filter material and preparation method thereof

A fiber blending and glass fiber technology, which is applied in the field of blended filter material and its preparation, can solve the problems of inability to meet the actual needs of filtration, poor comprehensive performance of glass fiber, limited application scope, etc., and achieves stable dust capture effect and film coating fastness High, the effect of improving overall flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0028] The glass fiber and PTFE fiber blended filter material of the present invention and its preparation method are described below in conjunction with the examples.

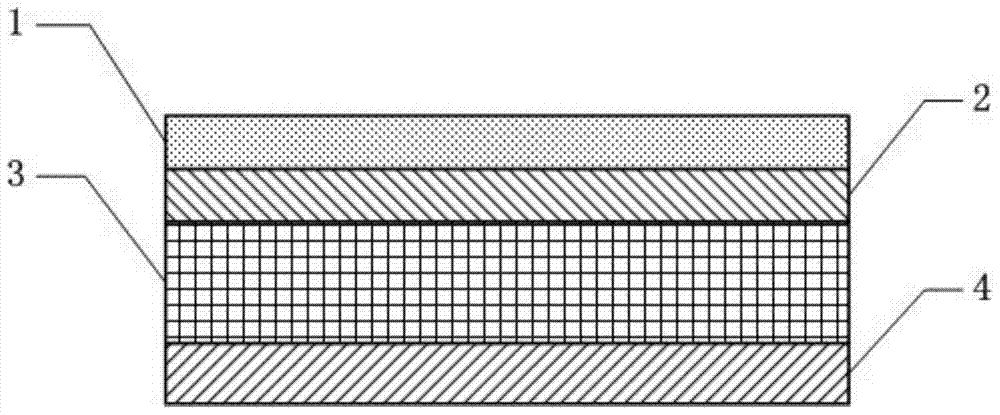

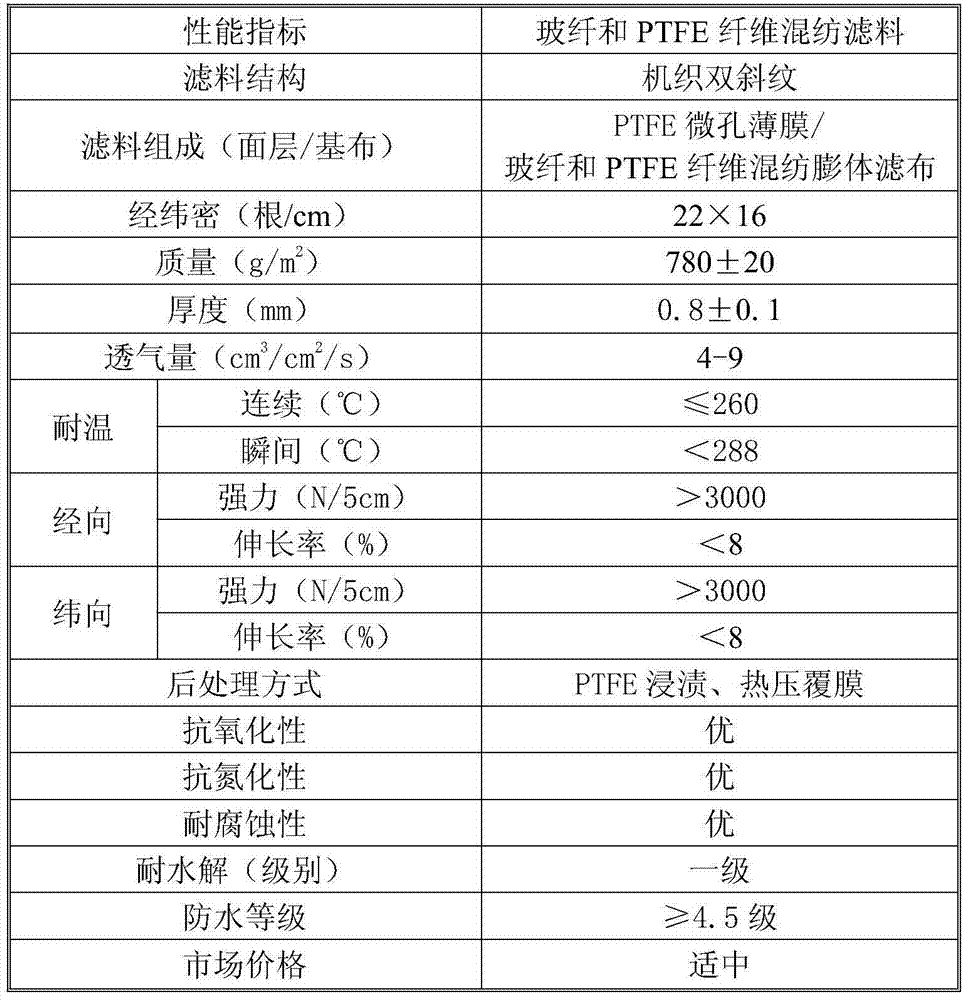

[0029] Such as figure 1 As shown, the glass fiber and PTFE fiber blended filter material of the present invention includes a four-layer structure from the dust-facing layer to the air-cleaning layer. The surface layer (dust-facing layer) is a polytetrafluoroethylene microporous membrane layer 1, and the second layer is polytetrafluoroethylene. Fluoroethylene impregnated treatment layer 2, the third layer is glass fiber and PTFE blended expanded cloth layer 3, the fourth layer is polytetrafluoroethylene impregnated treatment layer 4, the blended filter material has high filtering precision and has surface filtering effect.

[0030] The surface layer of this filter material is a smooth and dense polytetrafluoroethylene microporous membrane. The filtration method realizes "surface filtration", which is beneficia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com