Semi-permeable groyne and molding method thereof

A forming method and technology of breakwaters, which are applied in the direction of breakwaters, jetties, embankments, etc., can solve the problems of poor overall stability of the dike body, increased construction difficulty, and small installation workload on water, so as to improve safety and stability, and improve skid resistance Stability, the effect of improving the overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

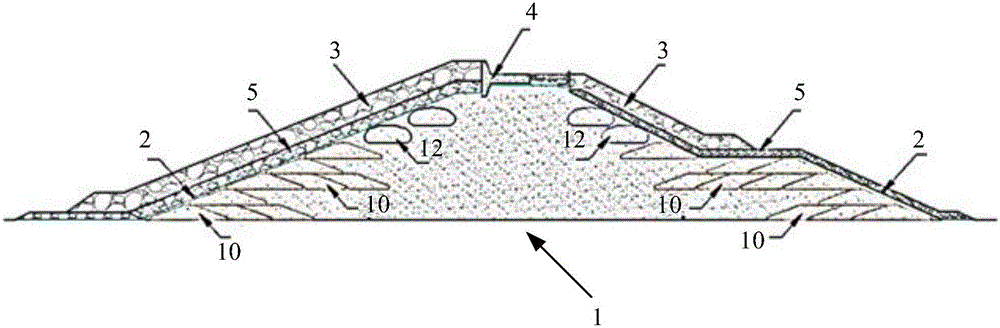

[0025] refer to figure 1 As shown, a kind of semi-permeable breakwater provided by the present invention is formed underwater, and it includes a dike body 1, an inverted filter layer 2, a protective surface structure 3 and a wave wall 4, wherein the dike body 1 is a part of the breakwater. The main body and the inverted filter layer 2 are laid on the dike body, and the protective surface structure 3 is laid on the inverted filter layer 2 to form a wave-resistant structure, and the wave-resistant wall 4 is installed and laid on the top of the dike body.

[0026] The breakwater is trapezoidal in shape, and it is formed by stacking a variety of fillers, including a multi-layer stacked protective structure. The inner core of the embankment is filled with sandy backfill or small gravel. The shape of the breakwater is pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com