Humidifier

A humidifier and atomizer technology, applied in air humidification systems, instruments, heating methods, etc., can solve problems such as hidden dangers to the elderly or children, unfavorable maintenance, cleaning, and inability to take out the water storage tank, so as to achieve convenient disassembly. And the effect of cleaning scale, neat and high-grade appearance, and performance optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

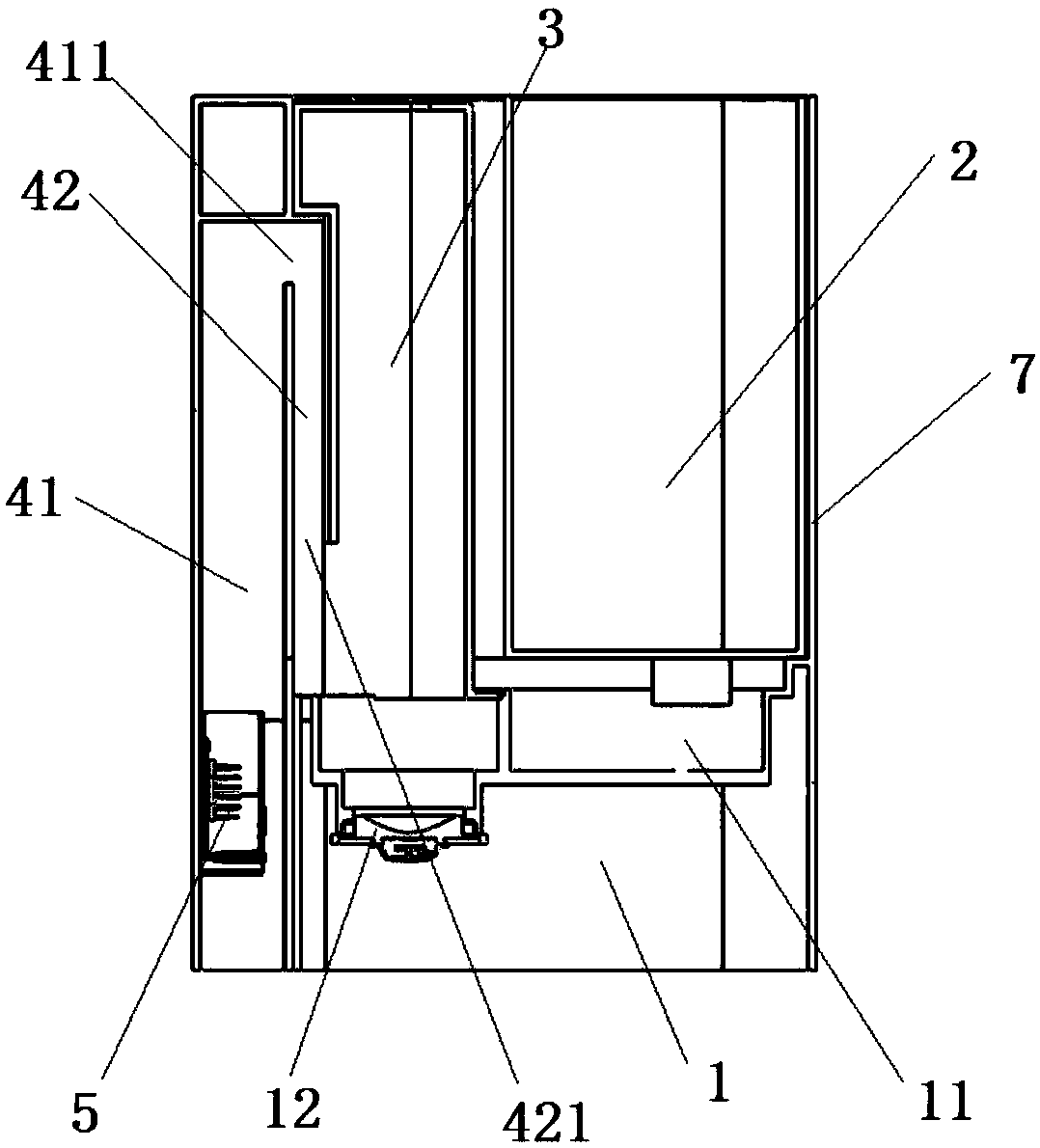

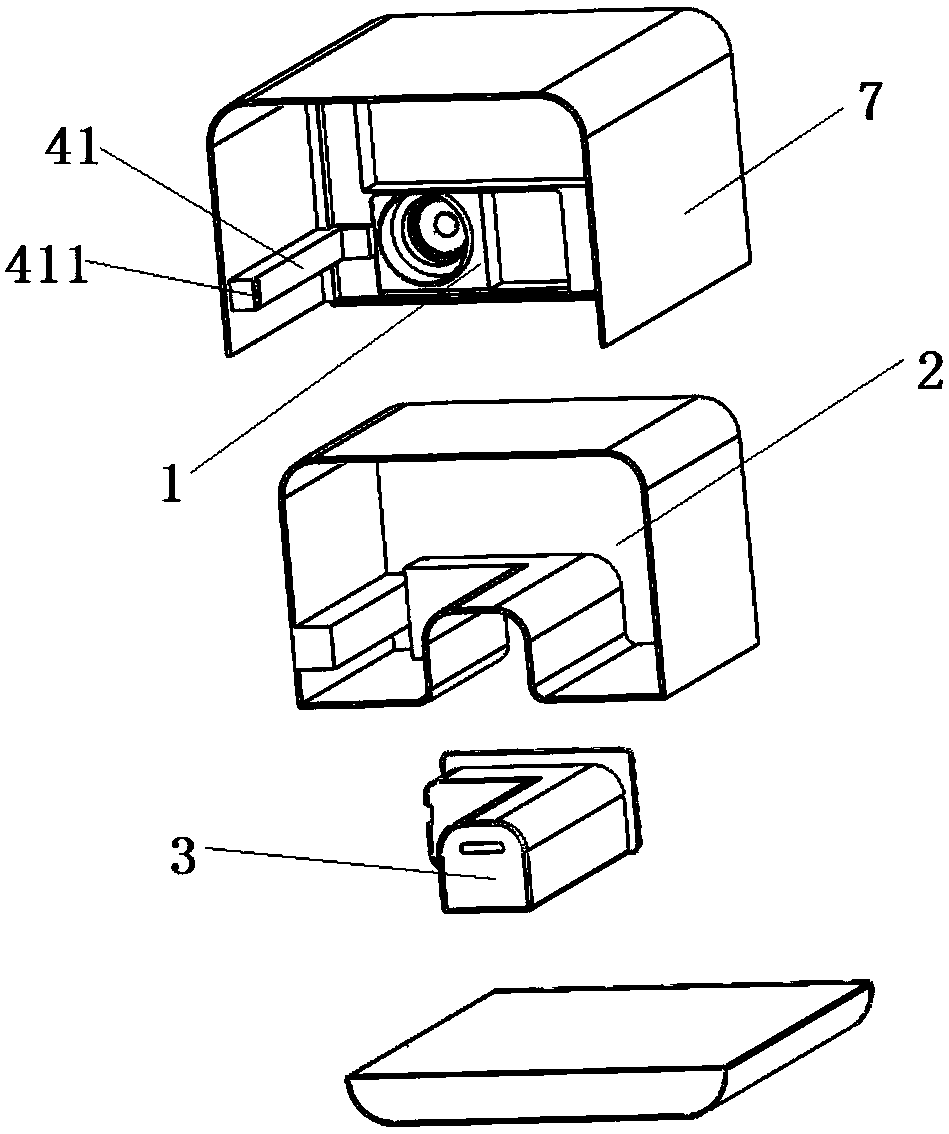

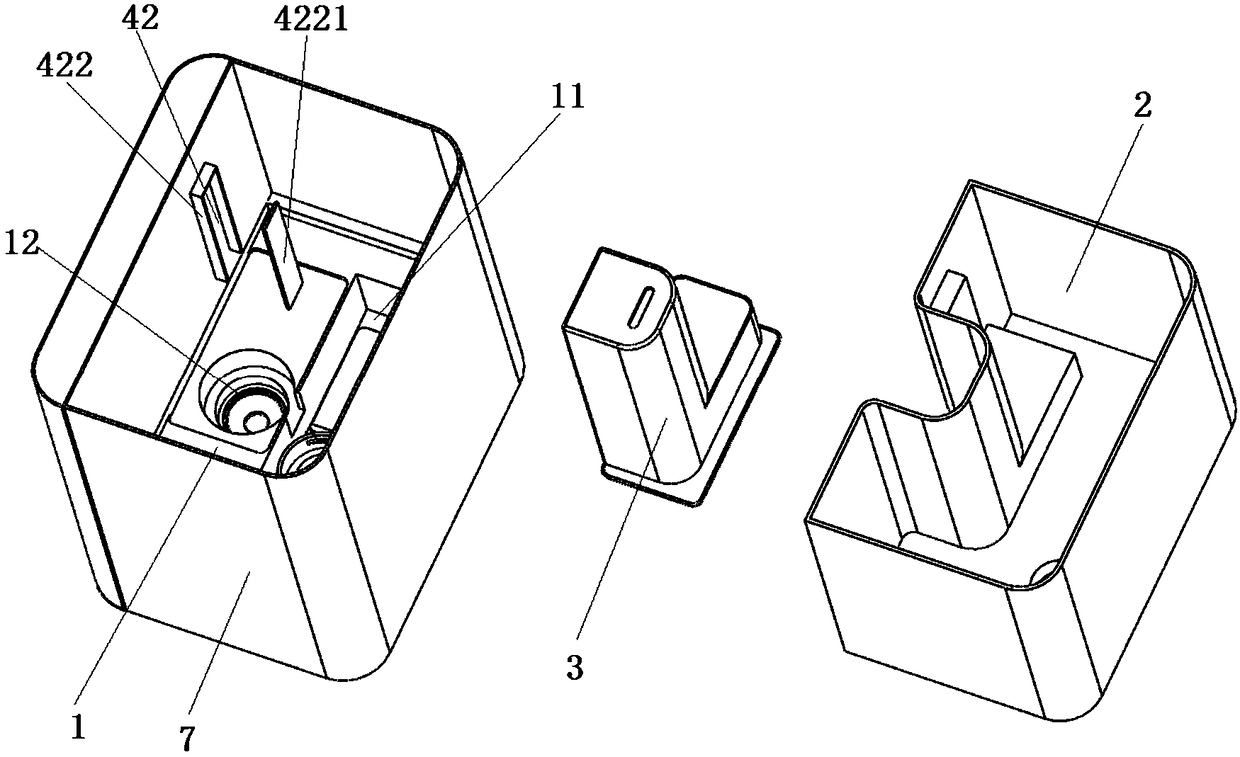

[0047] see Figure 8 to Figure 12 As shown, the water outlet control device includes a detection and driving mechanism 211 and a water outlet 212. The water outlet 212 is arranged at the water outlet. The water outlet 212 has a first water outlet 21201 and a second water outlet 21202 connected in series. The first water outlet 21201 and the second water outlet hole 21202 are respectively provided with a valve body, the valve body acts according to the signal generated by the detection and driving mechanism 211 and opens or closes the first water outlet hole 21201 and the second water outlet hole 21202, and the valve body can separately close the first water outlet hole 21201 and the second water outlet hole 21202 The water outlet hole 21201 and the second water outlet hole 21202. The first water outlet hole 21201 and the second water outlet hole 21202 are connected in series so that the water in the water tank 2 first passes through the first water outlet hole 21201 and then p...

Embodiment 2

[0053] Except as follows, the structure described in this embodiment is the same as in Example 1:

[0054] see Figure 10 As shown, the linkage mechanism 21220 is a soft link set on the top of the second valve core 21222, the soft link is inserted into the bottom of the first valve core 21221, the first water sealing part 21231 is located below the first water outlet hole 21201, the second The second water sealing element 21232 is located below the second water outlet hole 21202 . Preferably, the first water sealing member 21231 is fixedly connected to the top of the first valve core 21221 , and the second water sealing member 21232 is fixedly connected to the top of the second valve core 21222 .

[0055] In the above technical solution provided by the invention, when the detection and driving mechanism generates a water shortage signal, the float located in the reservoir moves downward and drives the lever connected to it to move around the axis, and the side of the lever co...

Embodiment 3

[0057] Except as follows, the structure described in this embodiment is the same as in Example 1:

[0058] see Figure 11 As shown, the linkage mechanism 21220 includes an inclined-plane body arranged on the second valve core 21222 and an inclined-plane chute arranged on the first valve core 21221. The inclined-plane body is inserted into the inclined-plane chute and can drive the first valve core 21221 to move. The first spool 21221 and the second spool 21222 are arranged at an angle. Preferably, the first valve core 21221 is set in a horizontal direction, and the second valve core 21222 is set in a vertical direction, that is, the first valve core 21221 and the second valve core 21222 are set at 90°. Preferably, the first water sealing member 21231 is located in front of the first water outlet hole 21201 , and the second water sealing member 21232 is located above the second water outlet hole 21202 . Preferably, the first water sealing member 21231 is fixedly connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com