Plate-shaped heat pipe and its processing technique

A plate-shaped heat pipe and heat pipe technology, applied in the field of heat pipes, can solve the problems of complex packaging and maintenance process, application limitation, vibration temperature difference, etc., and achieve the effect of reducing material consumption, material cost, and plate thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

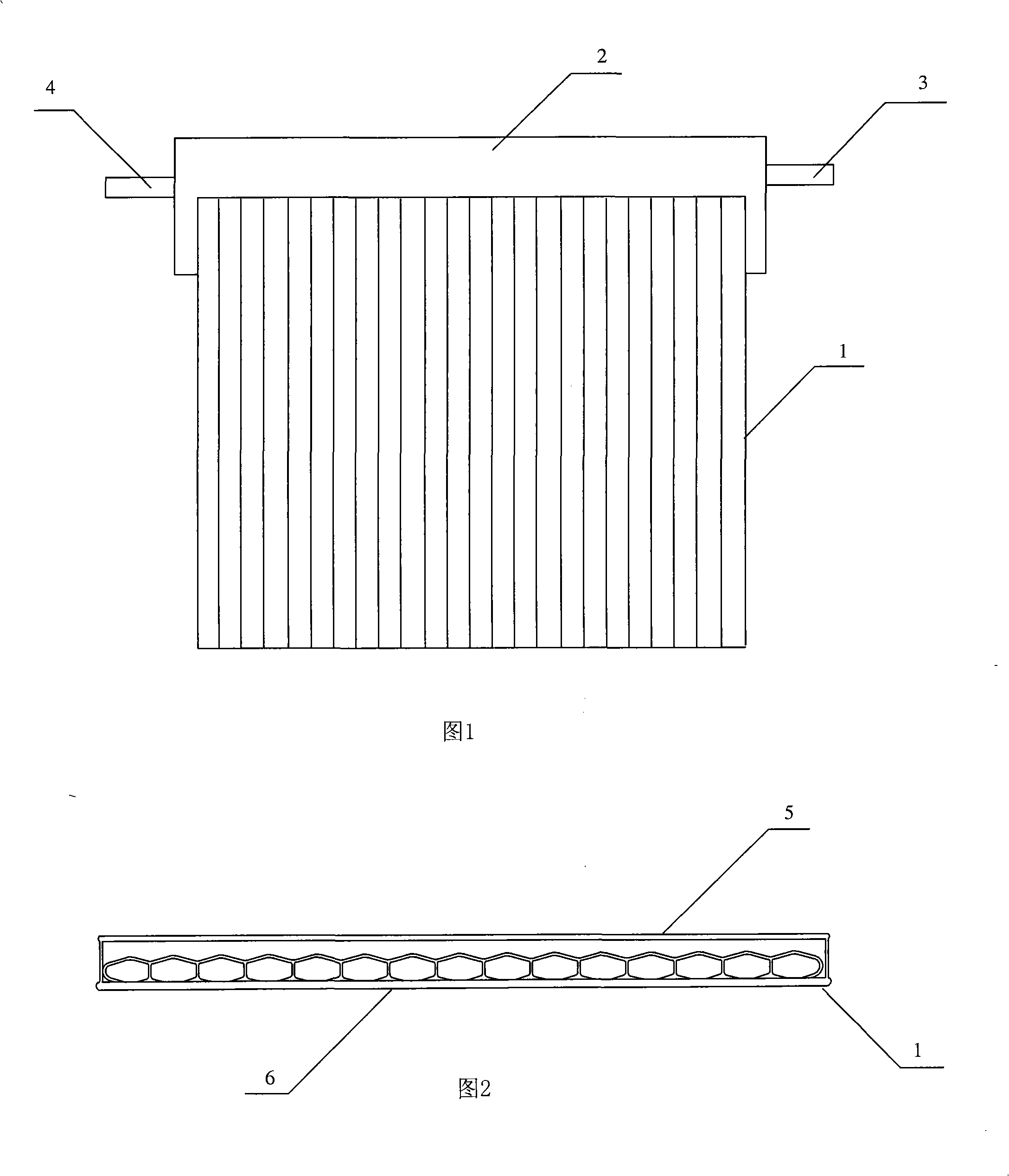

[0028] As shown in Figure 1, it is a structural schematic diagram of a plate-shaped heat pipe of the present invention as a solar heat collector.

[0029] In this embodiment, the solar heat collector includes a heat-absorbing plate 1 of a flat structure, a heat exchanger 2 and its inlet and outlet—water pipes 3 and water pipes 4, wherein the heat-absorbing section of the heat-absorbing plate 1 is exposed to the sun to absorb sunlight, The heat releasing section is arranged in the heat exchanger 2 , and the heat releasing section condenses and releases heat in the heat exchanger 2 and heats the stored water in the heat exchanger 2 .

[0030] The sun-facing side of the heat-absorbing section is the light-absorbing surface, and its outer surface can be provided with a heat-absorbing coating that can efficiently absorb solar energy to improve the heat-absorbing efficiency ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com