Light weight bus frame

A lightweight, bus technology, applied in the direction of vehicle components, upper structure, lower structure, etc., to achieve the effect of firm structure, simple structure and few connection points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

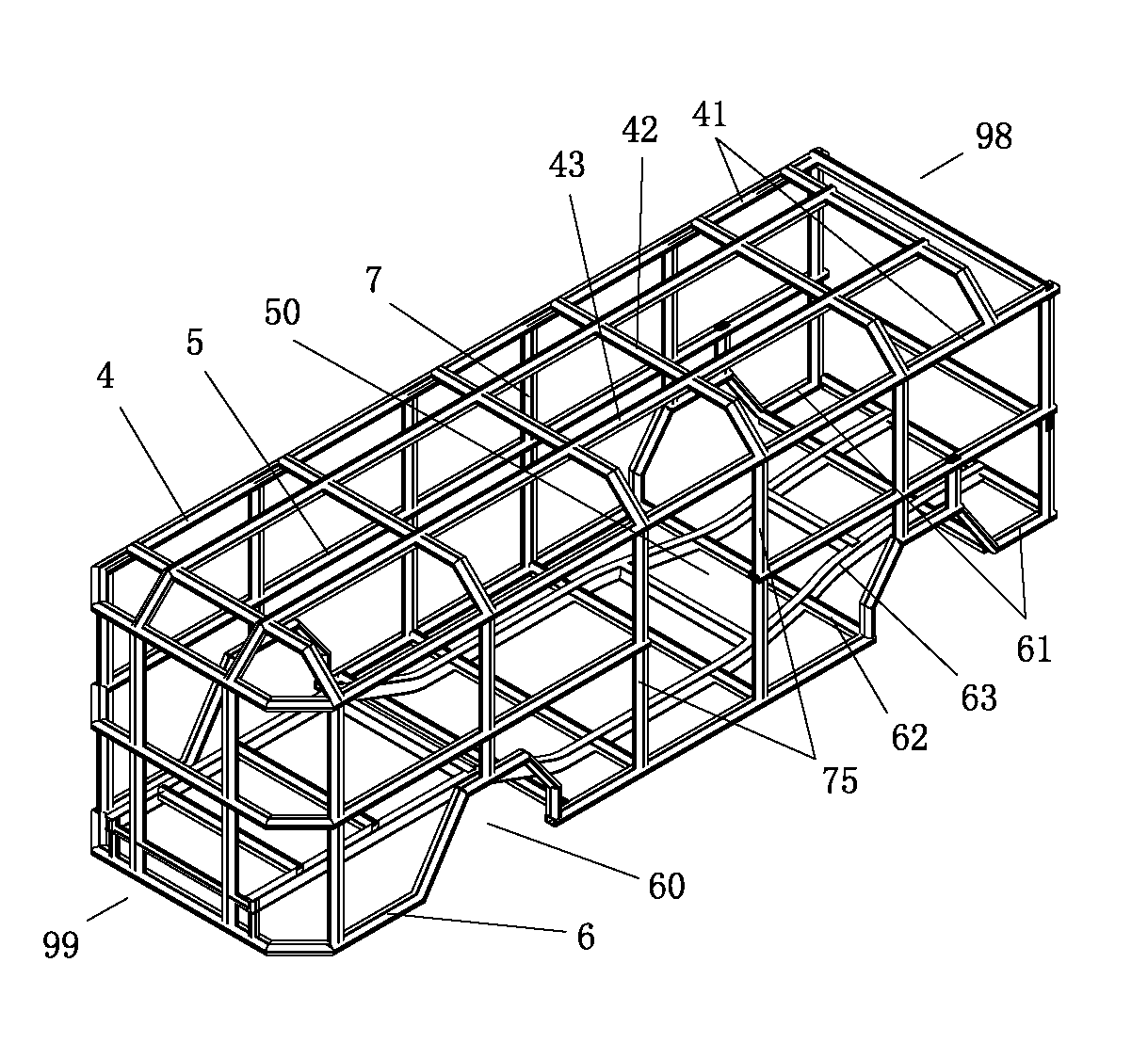

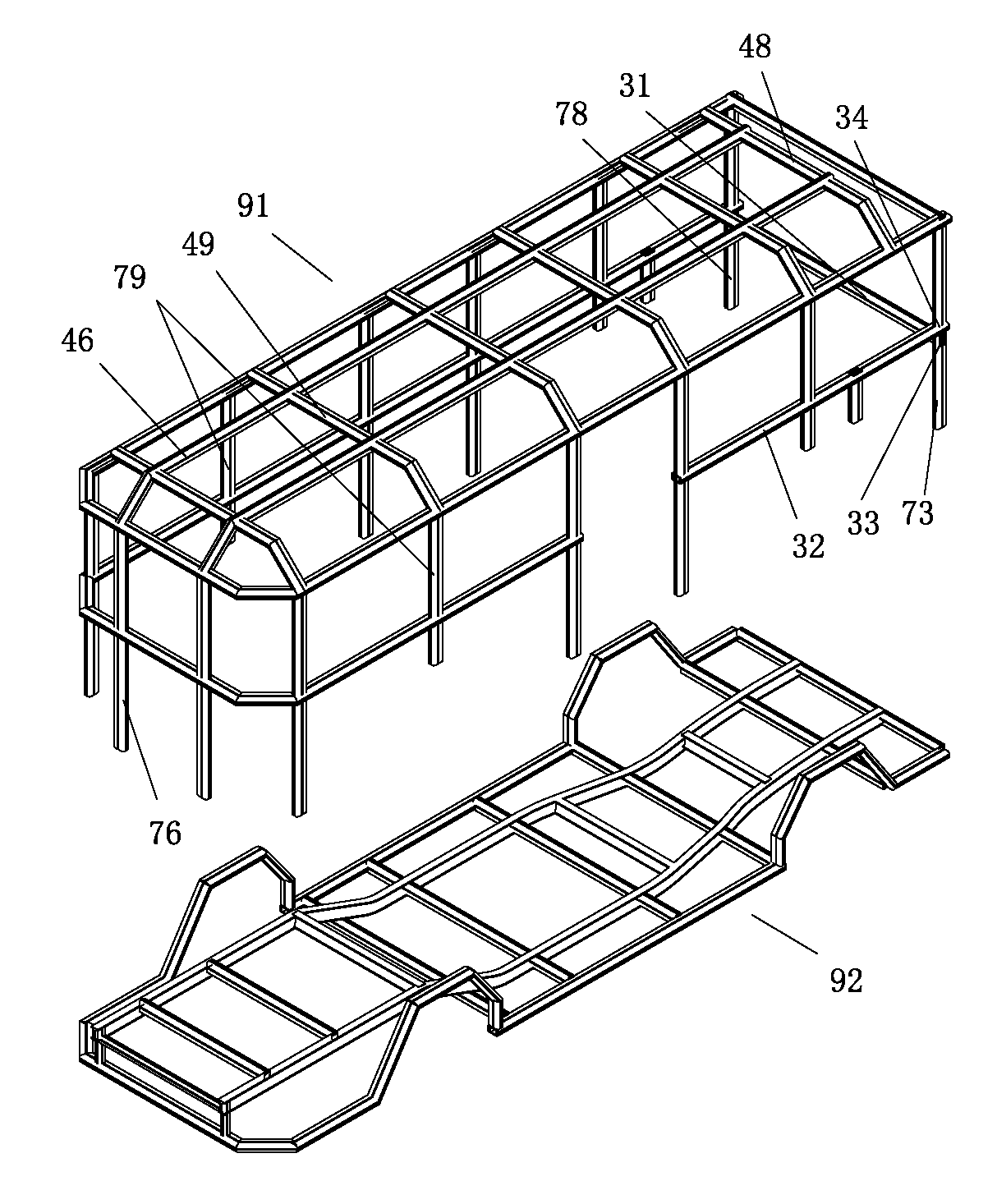

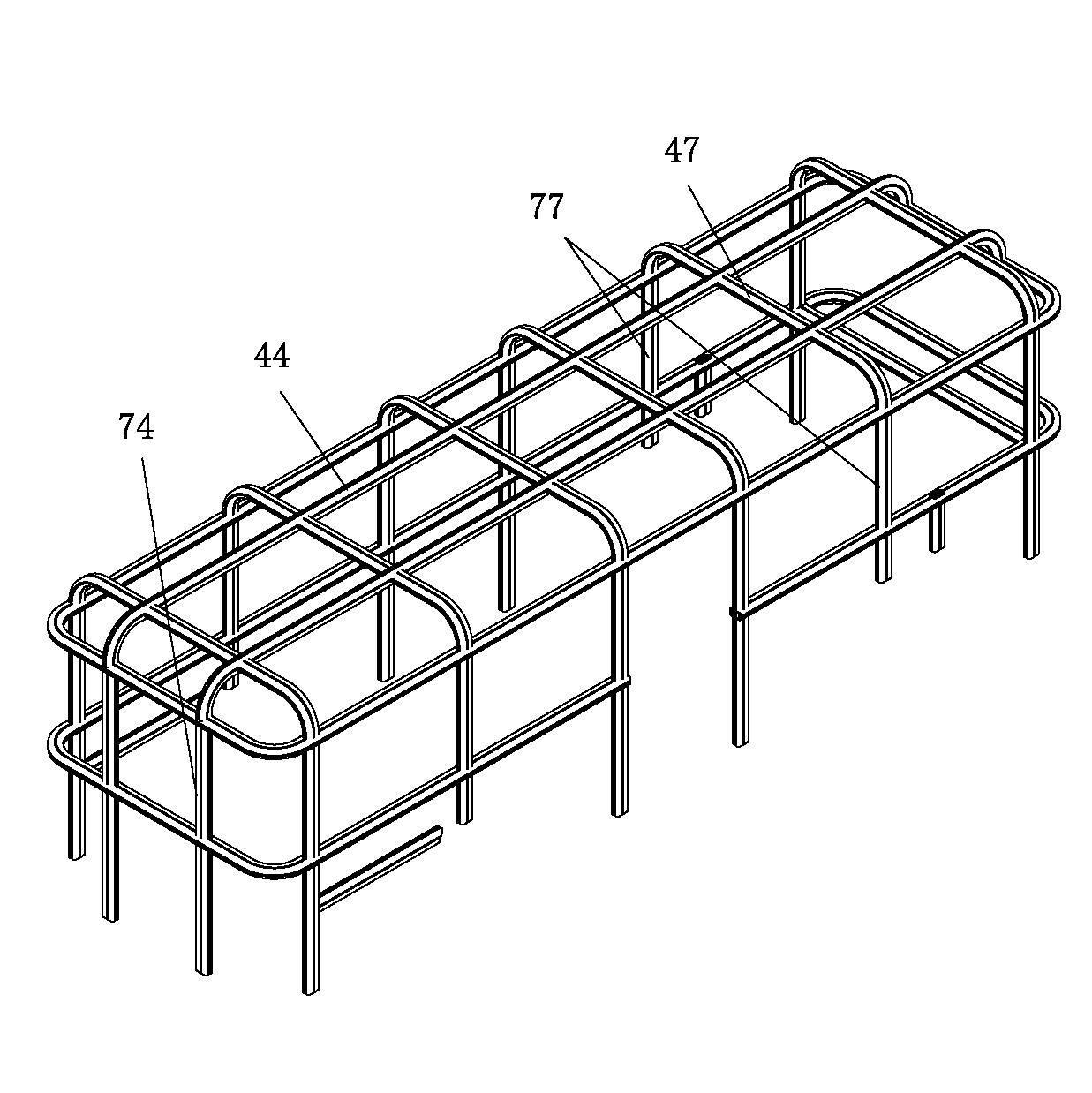

[0015] Lightweight bus frame such as figure 1 , comprising annular frames 4, 5, 6 surrounding the front 98, both sides of the car and the rear 99, the annular frames 4, 5, 6 are divided into a roof annular frame 4, a waist annular frame 5 and a bottom annular frame 6, The waist ring frame 5 is left empty at the door 50, and the bottom ring frame 6 arches upwards at the wheel placement 60 to accommodate the wheels. The roof is provided with a plurality of crossbeams 42 spanning between the two side frames 41 of the roof ring frame 4, and a longitudinal beam 43 is also provided to bridge the crossbeams 42. The longitudinal beams 43 on the roof have Multiple, for example, two in the figure. The bottom of the vehicle is provided with a plurality of crossbeams 62 spanning between the frame edges 61 on both sides of the annular frame 6 at the bottom of the vehicle, and a longitudinal beam 63 is also provided to bridge the various crossbeams 62 . The headstock 98, the two sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com