Slip casting lattice pipe with double plug and construction process

A technology of grouting flower tube and double plug, which is applied in the direction of foundation structure engineering, soil protection, sheet pile wall, etc., can solve the problems of inflexible control of grouting range and non-concentrated grouting stress, etc., and achieve the concentration of grouting pressure , to ensure the effect of soil strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

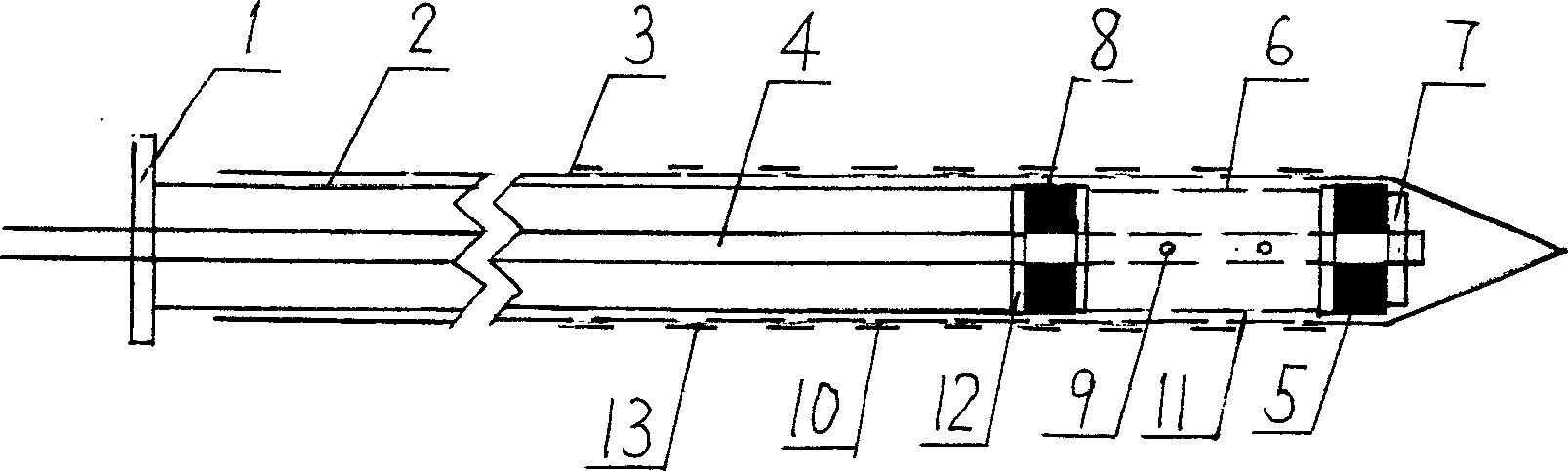

[0026] The embodiment of the double embolism grouting flower pipe is for example figure 1 As shown: the pipe body of the grouting flower tube 3 is cylindrical, the pipe head is conical, the pipe wall is pierced with a grouting hole 10, and there is a check valve 13 on the grouting hole, and the grouting flower pipe 3 is concentric in the body A grouting united core body mainly composed of a grouting core pipe, front and rear rubber grout stoppers, gaskets, connecting pipes, jacking pipes and jacking nuts is inserted.

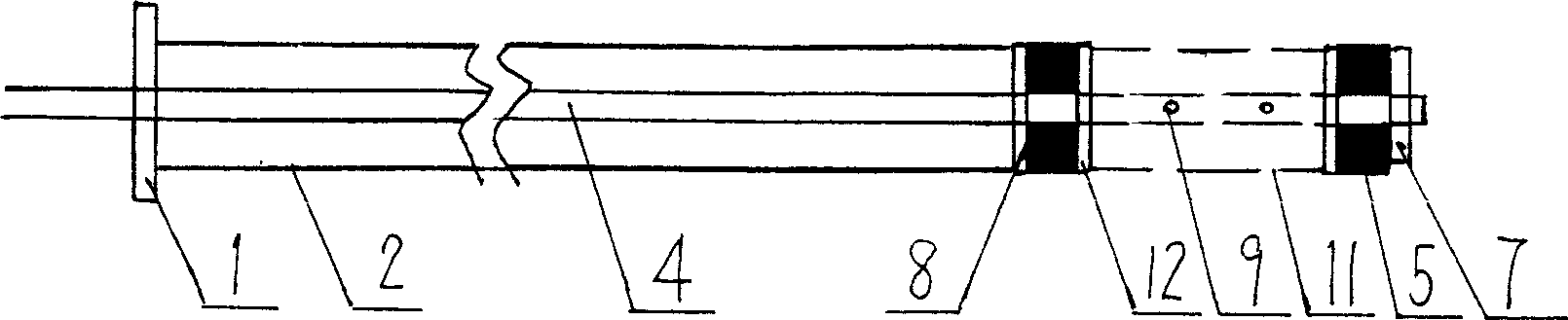

[0027] The structure of its grouting joint core is as follows: figure 2 As shown: the front section of the grouting core pipe 4 is pierced with evenly distributed grout holes 9, and the two ends of the pipe section pierced with the grout holes are tightly hooped with two sleeve-shaped rubber grout stoppers 5 and 8, of which the front rubber grout stoppers The front end of the slurry stopper 5 is fixed with a washer 7, and a connecting pipe 6 with a pipe wall a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com