Moisturizing facial mask solution, preparation method of moisturizing facial mask solution and moisturizing facial mask

A facial mask liquid, wet face technology, applied in the field of moisturizing and moisturizing facial mask liquid and its manufacture, facial mask liquid and its manufacture, moisturizing and moisturizing facial mask field, can solve problems such as poor moisturizing effect, improve skin growth conditions, superior external environment , the effect of enhanced supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

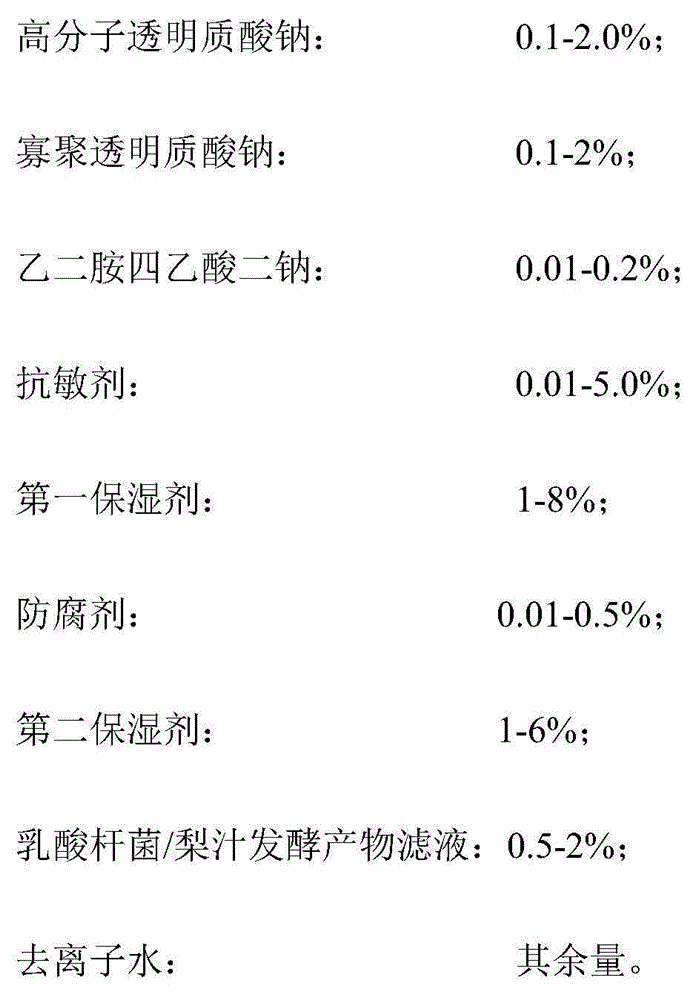

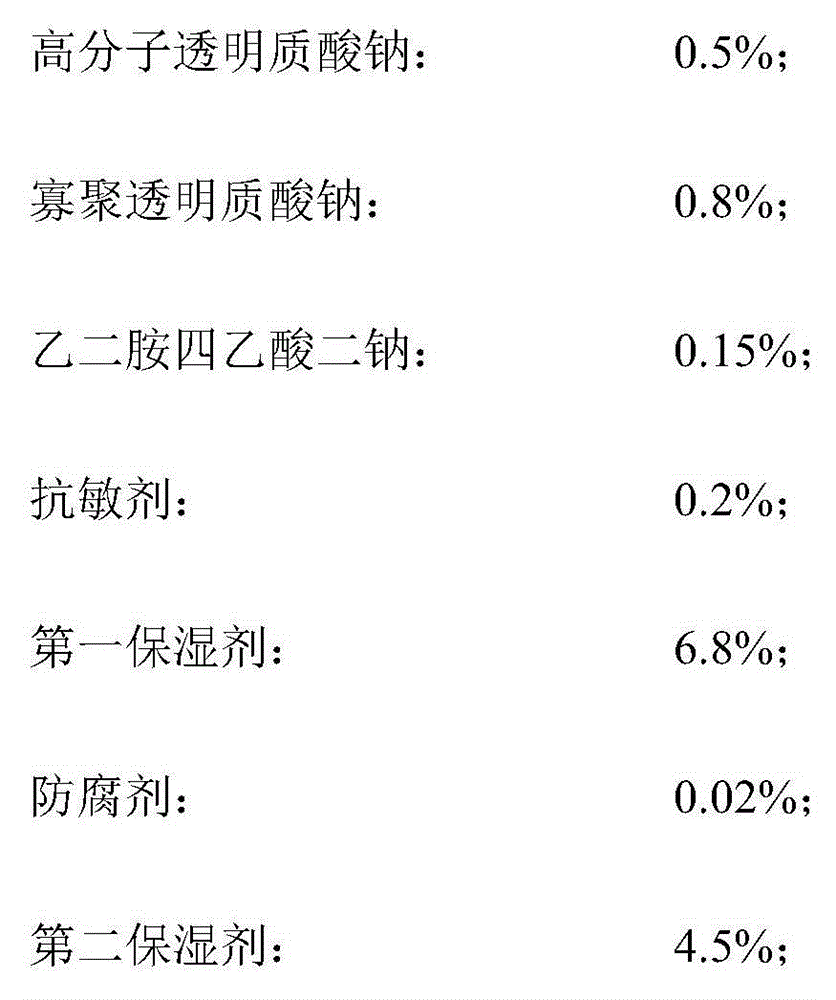

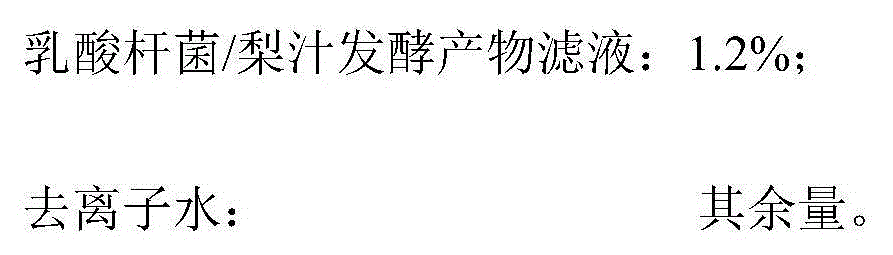

[0028] A hydrating and moisturizing facial mask liquid, which is made up of the following components by weight percentage: polymer sodium hyaluronate (molecular weight: 1600kDa): 0.5%, oligomeric sodium hyaluronate (molecular weight: 9500Da): 0.8%, EDTA- 2Na: 0.15%, dipotassium glycyrrhizinate: 0.20%, 1,3-butanediol: 6.8%, K220: 0.02%, dextran: 4.5%, Lactobacillus / pear juice fermentation filtrate: 1.2%, deionized Water: the remaining amount.

[0029] According to above-mentioned components and percentage by weight, the manufacture step of described mask liquid comprises:

[0030] a. Stir the high molecular weight sodium hyaluronate, oligomeric hyaluronate sodium, EDTA-2Na, dipotassium glycyrrhizinate, 1,3-butanediol and deionized water at 85°C at a speed of 3500rpm 40min until the components are mixed evenly;

[0031] b. Cool down the component mixture in step a to 45°C, add K220, dextran and lactobacillus / pear juice fermentation product filtrate, and stir at a speed of 3000...

Embodiment 2

[0033] A hydrating and moisturizing mask liquid, which is made up of the following components by weight percentage: polymer sodium hyaluronate (molecular weight: 1300kDa): 1.2%, oligomeric sodium hyaluronate (molecular weight: 5000Da): 0.3%, EDTA- 2Na: 0.03%, Tetrandrine: 0.38%, Chamomile Extract: 3%, Glycerol: 5%, 9010: 0.26%, Yeast Glucan: 3%, Lactobacillus / Pear Juice Ferment Filtrate: 0.6% 1. Deionized water: the remaining amount.

[0034] According to above-mentioned components and percentage by weight, the manufacture step of described mask liquid comprises:

[0035] a. Stir the high molecular weight sodium hyaluronate, oligomeric hyaluronate sodium, EDTA-2Na, tetrandrine, chamomile extract, glycerol and deionized water at 80°C for 40 minutes at 2500rpm until the components are mixed evenly;

[0036] b. Cool down the component mixture in step a to 50°C, add 9010, yeast dextran, and lactobacillus / pear juice fermentation product filtrate, and stir at a speed of 3000rpm fo...

Embodiment 3

[0038] A hydrating and moisturizing facial mask liquid, which is made up of the following components by weight percentage: polymer sodium hyaluronate (molecular weight: 1800kDa): 0.2%, oligomeric sodium hyaluronate (molecular weight: 2000Da): 1.8%, EDTA- 2Na: 0.08%, chamomile flower extract: 0.8%, acacia extract: 0.2%, rosemary extract: 1%, PEG-400: 1.2%, K145: 0.45%, aloe vera gel: 6%, Lactobacillus / Pear juice fermentation product filtrate: 1.9%, deionized water: balance.

[0039]Its manufacturing steps are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com