Environment-friendly building material and preparation method thereof

A building material, an environmentally friendly technology, applied in chemical instruments and methods, synthetic resin layered products, lamination devices, etc., can solve the problem of inability to prepare collagen fiber insulation materials, different lengths and thicknesses of collagen fibers, affecting finished products. Strength and other problems, to achieve the effect of short processing process, easy processing and reduction of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

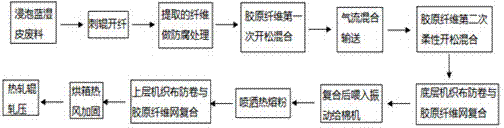

Method used

Image

Examples

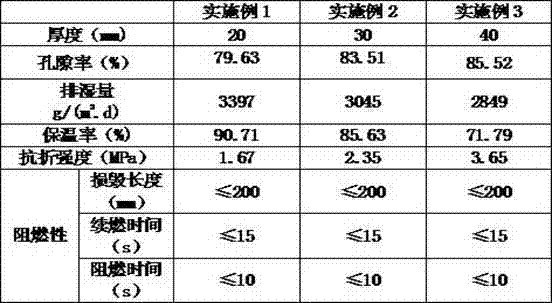

Embodiment 1

[0036] 1. Obtain collagen fibers from wet blue hide waste.

[0037] (1) Cut the waste wetblue hide into strips of 2×5 cm and soak them in a weakly alkaline aqueous solution containing sodium hydroxide. The percentages are respectively: sodium hydroxide is 0.1%, acetamide is 0.2%, glycerin is 0.1%, fatty alcohol polyoxyethylene ether is 0.5%, and the immersion time of this wet blue leather waste in this weak alkaline aqueous solution is 30 hours;

[0038] (2) drying the soaked wet blue hide waste with a spin dryer, and the moisture content of the dried wet blue hide waste reaches 70%;

[0039] (3) Send the dried wet blue hide waste into a licker-in roller opener for opening and tearing to obtain collagen fibers, the fiber pile length of which is 5 mm, and the fiber bundle linear density is 1.1 dtex;

[0040] (4) Send the collagen fibers into an antiseptic solution for antiseptic treatment. The preservative used in the antiseptic solution is a mixture of sodium sorbate and eth...

Embodiment 2

[0053] 1. Obtain collagen fibers from wet blue hide waste.

[0054] (1) Cut the waste wetblue hide into strips of 2×5 cm and soak them in a weakly alkaline aqueous solution containing sodium hydroxide. The percentages are respectively: sodium hydroxide is 0.3%, acetamide is 0.3%, glycerin is 0.3%, fatty alcohol polyoxyethylene ether is 0.7%, and the immersion time of this wet blue leather waste in this weak alkaline aqueous solution is 40 hours;

[0055] (2) drying the soaked wet blue hide waste with a spin dryer, and the moisture content of the dried wet blue hide waste reaches 80%;

[0056] (3) Send the dried wet blue hide waste into a licker-in roller opener for opening and tearing to obtain collagen fibers, the fiber pile length of which is 10mm, and the fiber bundle linear density is 3.3dtex;

[0057] (4) Send the collagen fibers into an antiseptic solution for antiseptic treatment. The preservative used in the antiseptic solution is a mixture of ethylparaben and butylp...

Embodiment 3

[0070] 1. Obtain collagen fibers from wet blue hide waste.

[0071] (1) Cut the waste wetblue hide into strips of 2×5 cm and soak them in a weakly alkaline aqueous solution containing sodium hydroxide. The percentages are respectively: sodium hydroxide is 0.5%, acetamide is 0.4%, glycerin is 0.5%, fatty alcohol polyoxyethylene ether is 1%, and the immersion time of this wet blue leather waste in this weak alkaline aqueous solution is 48 hours;

[0072] (2) drying the soaked wet blue hide waste with a spin dryer, and the moisture content of the dried wet blue hide waste reaches 90%;

[0073] (3) Send the dried wet blue hide waste into a licker-in roller opener for opening and tearing to obtain collagen fibers, the fiber pile length of which is 20 mm, and the linear density of fiber bundles is 6.6 dtex;

[0074] (4) Send the collagen fibers into an antiseptic solution for antiseptic treatment. The preservative used in the antiseptic solution is a mixture of ethylparaben, butyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com