Method for printing miniature corrugated board by direct offset printing

A corrugated cardboard and offset printing technology, applied in printing, printing machines, rotary printing machines, etc., to achieve stable and reliable quality, reduce costs, and save resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

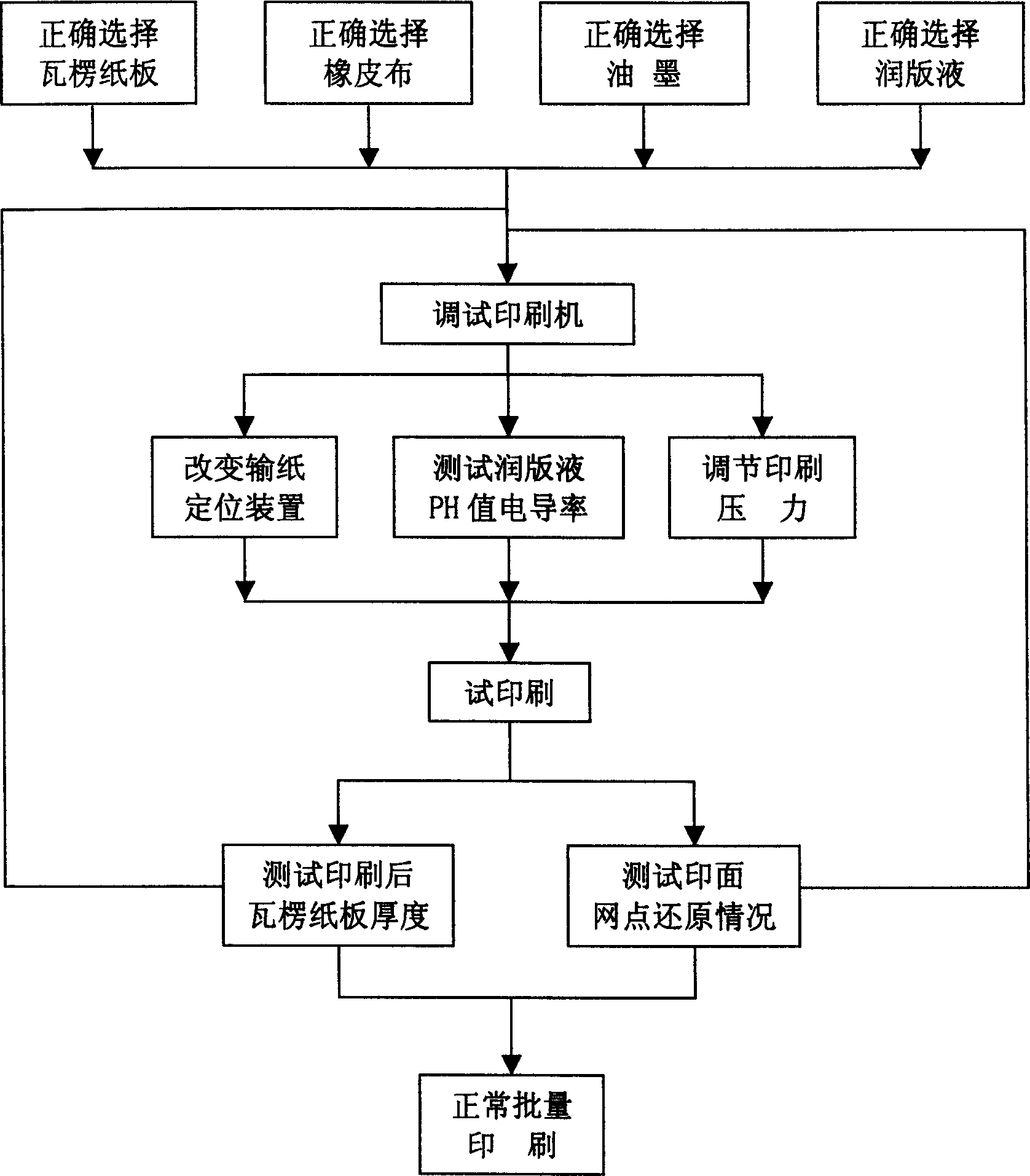

[0029] attached image 3 It is a block diagram of the printing process flow of the present invention, and each link of the flow diagram will be described in detail below.

[0030] I Reduce plastic deformation of corrugated cardboard through correct selection and application of corrugated cardboard

[0031] 1. Reasonable selection of corrugated cardboard

[0032] The quality of corrugated cardboard is the prerequisite for affecting the plastic deformation of corrugated cardboard. Since the peeling tension of the ink and the blanket on the paper surface is very large at the moment of separation in offset printing, it often causes the phenomenon of paper powdering and hair loss. High tensile strength, uniform texture of printing surface paper. The present invention selects the unit quality control of miniature corrugated cardboard at 380g / m 2 ~440g / m 2 , the material used is 185g / m 2 Recoat white cow card +90g / m 2 Corrugated base paper+140g / m 2 White cow card.

[0033] 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com