Collagenous fiber regenerated leather low in production cost and manufacturing method thereof

A collagen fiber and production cost technology, applied in the direction of non-woven fabrics, textiles and papermaking, etc., can solve the problem that the space for reduction is not too large, and achieve the effects of increased cloth running speed, good stabbing effect, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

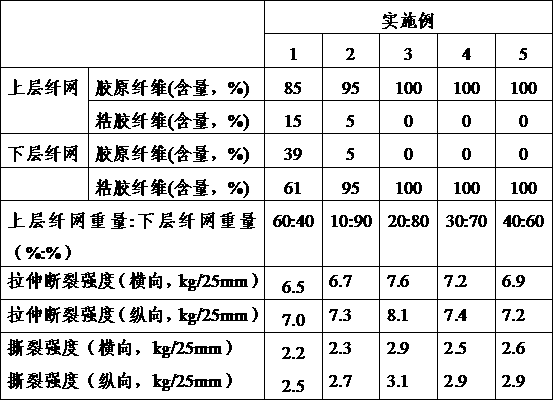

[0036] The invention relates to a collagen fiber regenerated skin with low production cost, which is composed of a lower layer of fiber web and an upper layer of fiber web tightly connected to the surface of the lower layer of fiber web, wherein the material composition and weight percentage of the lower layer of fiber web are: collagen fiber 0~ 39%, viscose fiber 61~100%; the material composition and weight percentage of the upper fiber web are: collagen fiber 85~100%, viscose fiber 0~15%. In Examples 1 to 5, the material composition of the lower fiber web, the material composition of the upper layer fiber web, and the respective weight percentages of the upper and lower layer fiber webs in the total weight of the upper and lower layer fiber webs are shown in Table 1.

[0037] In embodiment 1, the manufacture method of the collagen fiber regenerated skin of this low production cost comprises the following steps successively:

[0038] (1) Defibrilation: Defibril the pig, sheep...

Embodiment 2

[0043] In embodiment 2, the method of this collagen fiber regenerated skin is similar to the method described in embodiment 1, only difference is: since the lower layer fiber web accounts for 90% of the upper and lower layer fiber web gross weight in the present embodiment, therefore In step (3), it is enough to use an air-laid machine to lay the fibers forming the upper fiber web on the upper surface of the lower fiber web to form an upper fiber web, thereby achieving high cloth speed and high production efficiency; wherein, carding The web laying machine is responsible for 90% of the final fiber web weight, and the air-laid machine is responsible for 10% of the final fiber web weight.

Embodiment 3

[0044] In embodiment 3, the method of this collagen fiber regenerated skin is similar to the method described in embodiment 1, and difference is: at first, because upper and lower web all only contain a kind of fiber respectively, so in step (2), The fibers that make up the upper and lower fiber webs only need to be opened by one opener, and then they can enter the web laying process. There is no need for fiber mixing and fiber opening before opening. Secondly, because the lower layer of fiber web accounts for 80% of the total weight of the upper and lower layer of fiber webs in the present embodiment, so in step (3), it is enough to form the fibers of the upper layer of fiber web on the lower layer of fiber web with two air-laid machines. The upper surface is laid into the upper fiber web, so as to achieve high cloth speed and production efficiency; among them, the carding machine is responsible for 80% of the weight of the final fiber web, and the two air-laid machines are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com