Automatic assembling tightening machine for special glass bottle and bottle cap

An automatic assembly and glass bottle technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low positioning accuracy of pneumatic turntable, unstable product quality, and inaccurate control of mechanical claw clamping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

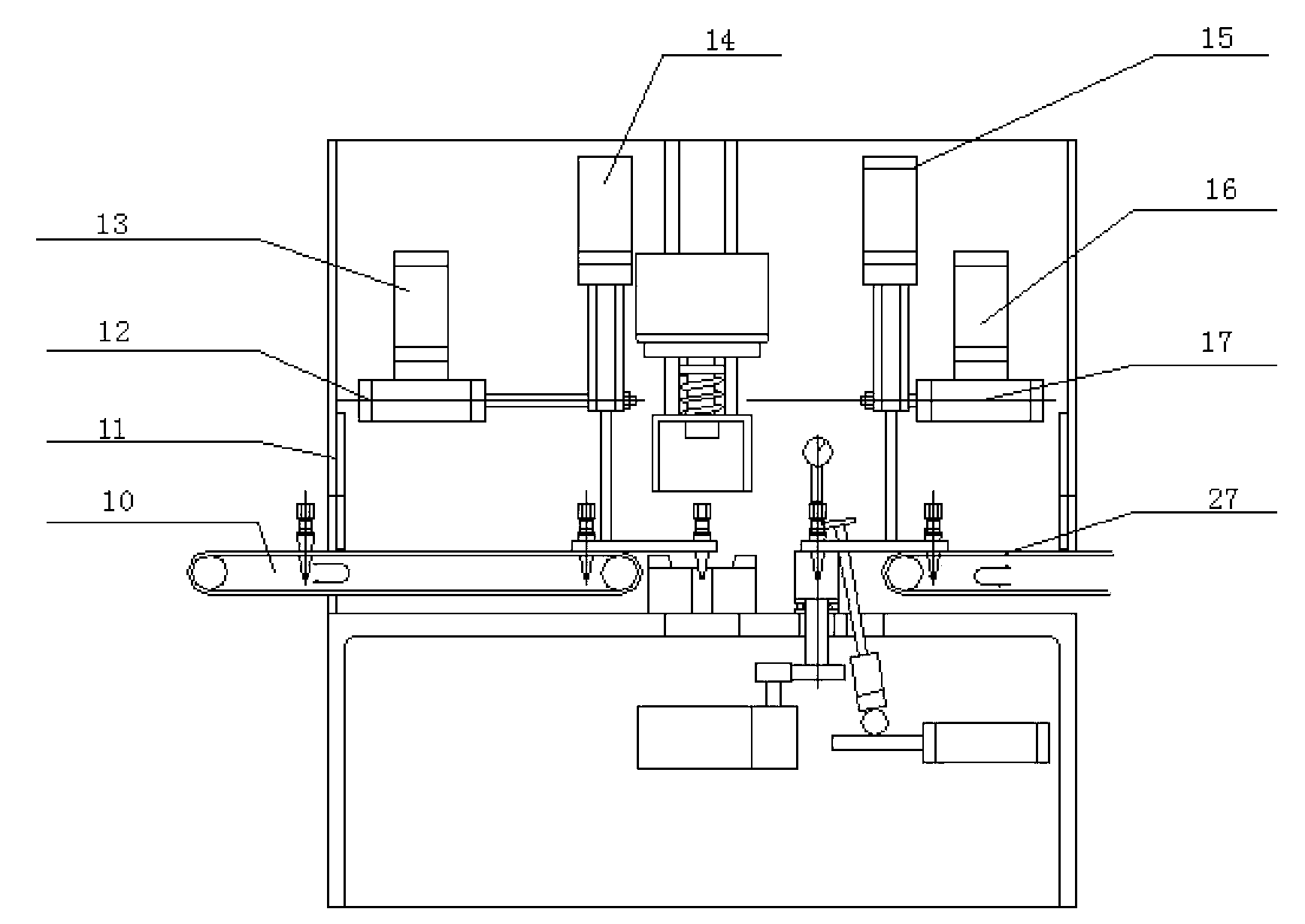

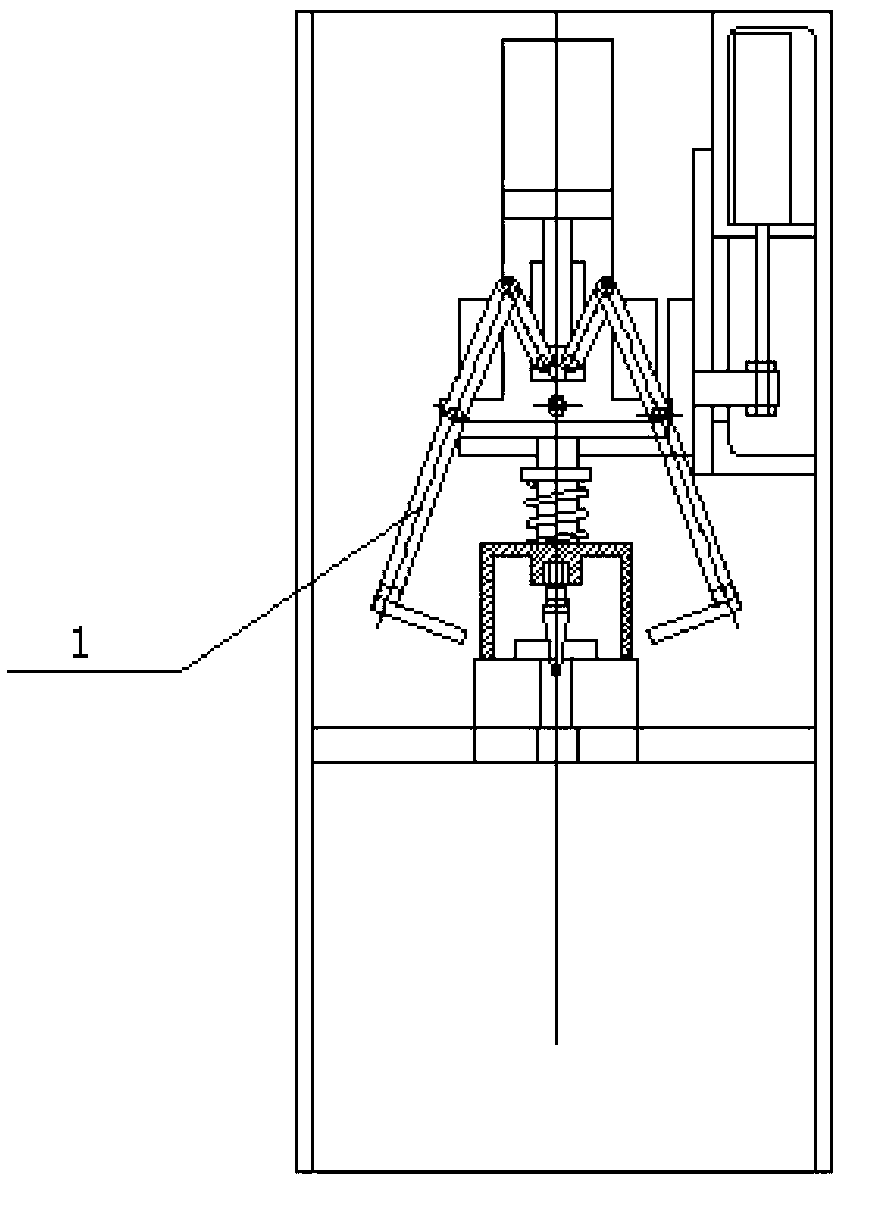

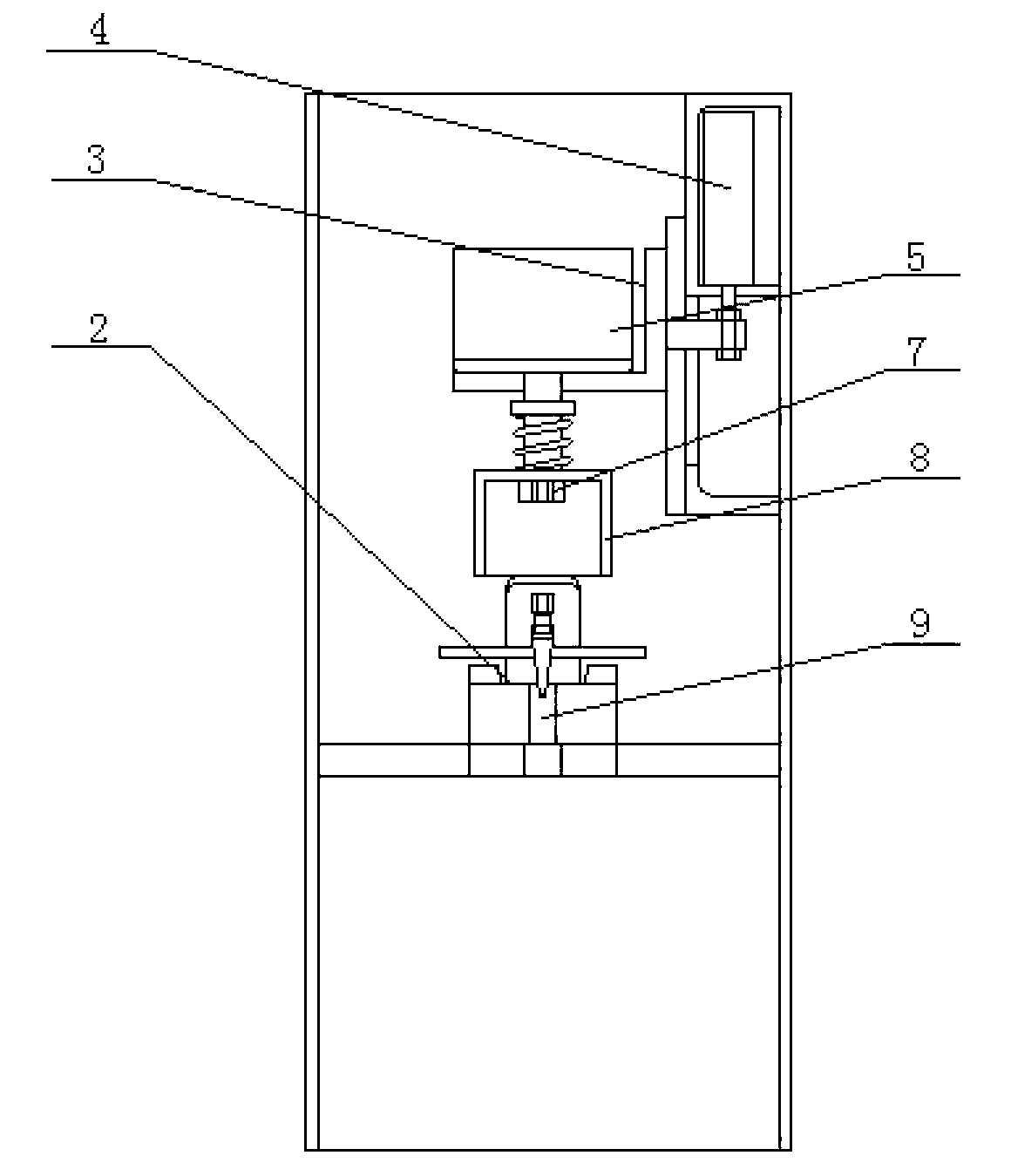

[0021] This embodiment is an automatic assembly and tightening machine for special glass bottles and bottle caps.

[0022] refer to Figure 1-Figure 4 , the tightening machine of the present invention includes a control system, a feeding mechanism, a tightening mechanism, a detection mechanism, a glue cleaning mechanism, and a conveying mechanism. The feeding mechanism transports the glass bottle product to the tightening mechanism in a correct posture; The height of the glass bottle product determines whether the glass bottle product is qualified; the glue cleaning mechanism will continue the glue cleaning process on the detected glass bottle product at the testing mechanism station; the conveying mechanism is used to transfer the tested glass bottle product to qualified or unqualified The product collection place; the control system adopts PLC + industrial computer to realize the automatic control of the production process and the position detection monitoring and alarm func...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com