Hole axis detection tool and detection method thereof

A detection tool and detection method technology, applied in measurement devices, instruments, optical devices, etc., can solve the problems of difficult detection of joint axis position, inability to install finished products, and reduced aircraft reliability, so as to improve installation accuracy and ensure smooth The effect of installation and product quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with specific embodiments.

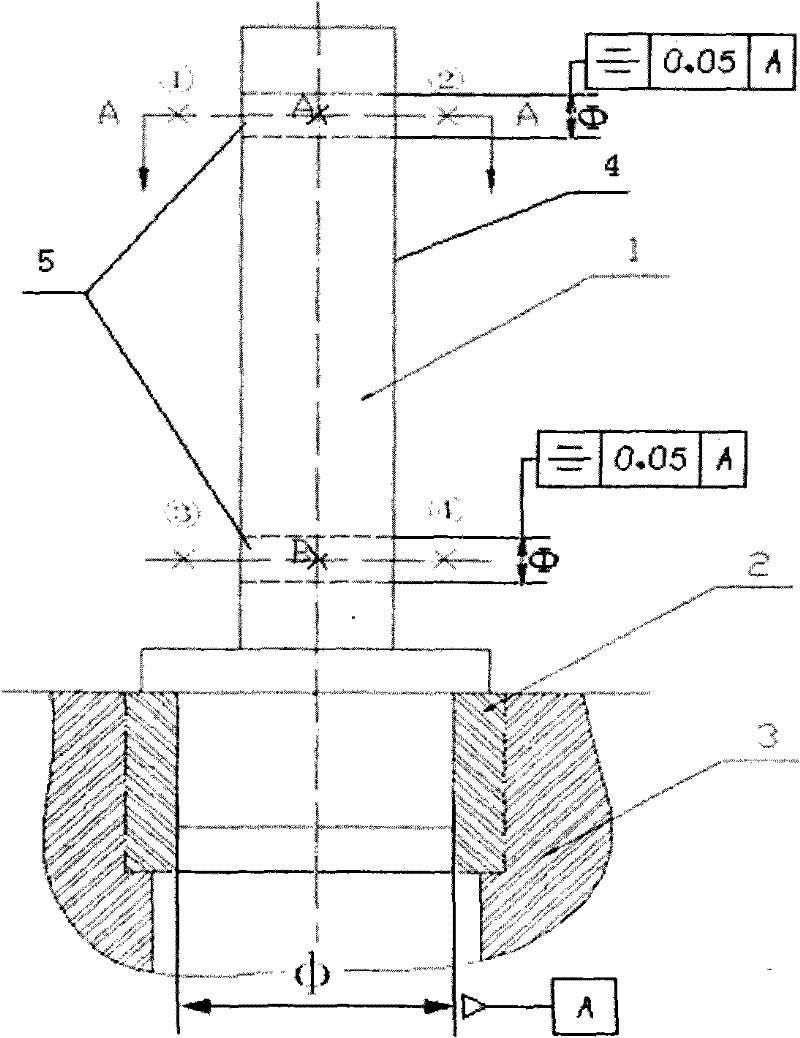

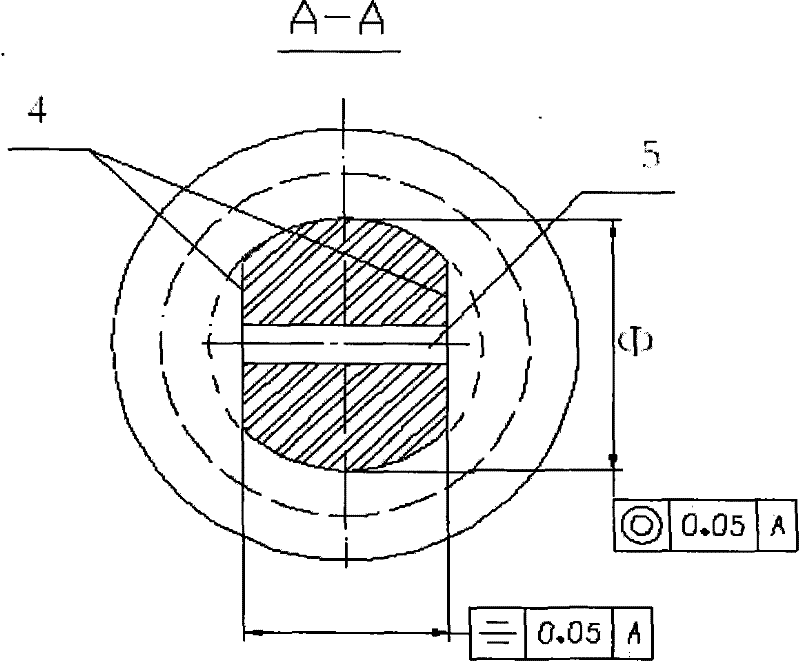

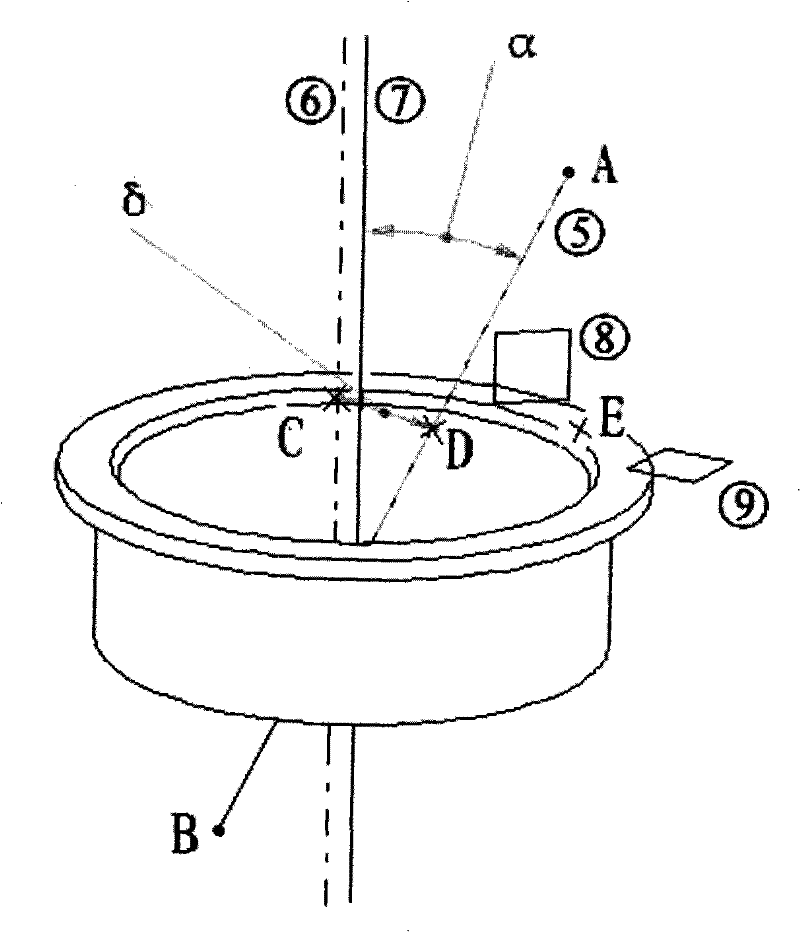

[0024] See also figure 1 , figure 2 and image 3 ,in, figure 1 It is a schematic diagram of the tool for detecting the axis of the hole position of the joint after assembly. figure 2 yes figure 1 A-A sectional view of, image 3 It is a diagram of the analysis method of the center point of the joint hole and the axis error after assembly. The axis detection tool of the present invention is a shaft 1, and the main precision requirements of the shaft 1 are that the coaxiality relative to the reference A is 0.05 mm, and the symmetry is 0.05 mm (for details, please refer to figure 1 , figure 2 Tolerance mark in ), the lower end of the shaft 1 has a shoulder 6 that fits with the end face of the bush 2, and is precisely matched with the inner hole of the bush 2 of the assembly joint 3. Two symmetrical planes 4 are processed on the upper part of the shaft 1 cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com