Wallboard installing component and method for installing decorative wallboard by using same

A technology for installing components and wall panels, which is used in building construction, covering/lining, construction, etc., can solve the problems of large load of decorative wall panels, damage to internal structures, affecting installation accuracy, etc. Installation and removal, the effect of high installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

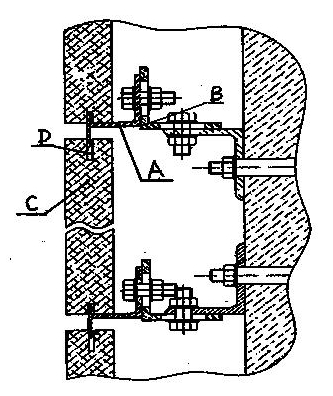

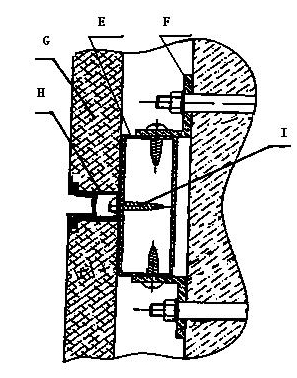

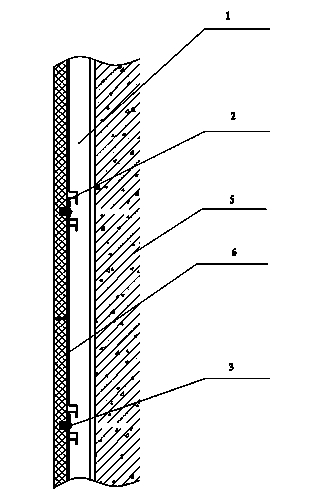

[0022] Such as Figure 3 to Figure 9 As shown, the wall panel installation component of the present invention includes a main keel 1 installed vertically and an auxiliary keel 2 installed horizontally on the main keel. The main keel 1 is a rectangular tube with an opening on the back. On the front of the main keel, a pair of grooves 1a, 1a' that are concave and extend downwards are continuously provided to form a pair of upward hooks on the main keel. 1b, 1b'; the auxiliary keel is a groove-shaped keel with downward folds at the bottom ends of the upper and lower side walls, and the two lower folds form a pair of buckle sides 2a, 2a'; the paired buckles of the auxiliary keel The strip edges 2a, 2a' are clamped in the paired grooves 1a, 1a' of the main keel to form a movable fit; a protruding fixed-point sleeve assembly 3 is installed on the front side 2d of the auxiliary keel through the installation hole 2e. On the side of the lower buckle of the auxiliary keel, there are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com