Device for combining and assembling air conditioner discharge set

A combined assembly and air outlet technology, applied in the direction of assembly machines, metal processing, metal processing equipment, etc., can solve the problems of low production efficiency, low installation accuracy, and weak connection, etc., and achieve high production efficiency, high installation accuracy, and connection firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

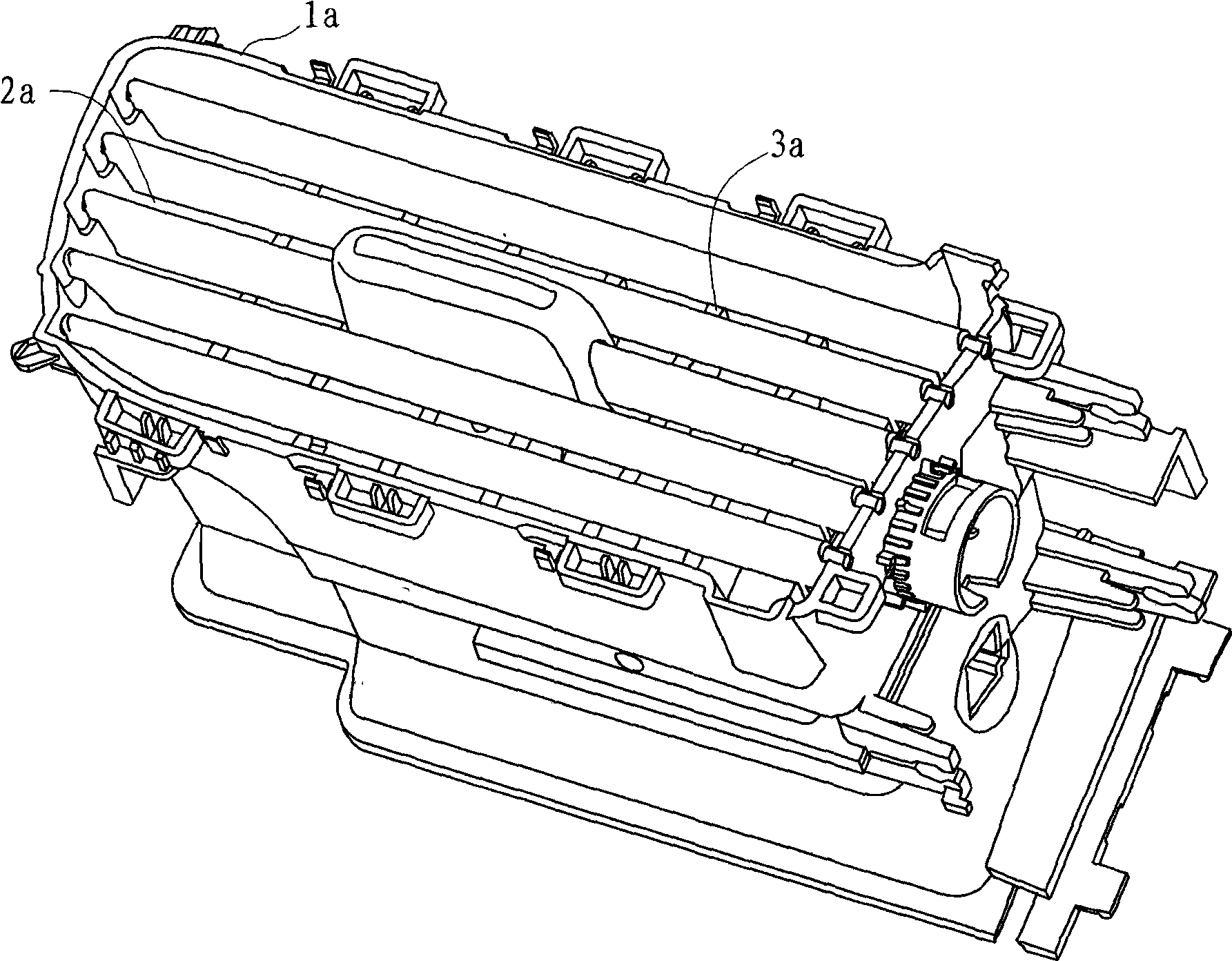

[0072] Such as Figure 4 As shown, the air conditioner air outlet assembly assembly device in this embodiment includes a base 100, a vertical blade installation mechanism 103, a horizontal blade installation mechanism 104, a housing installation mechanism 9 and a controller (not shown in the figure). The base 100 is a substantially square substrate, and four feet 102 are provided at the lower four corners, so that the substrate and the bottom surface have a certain height.

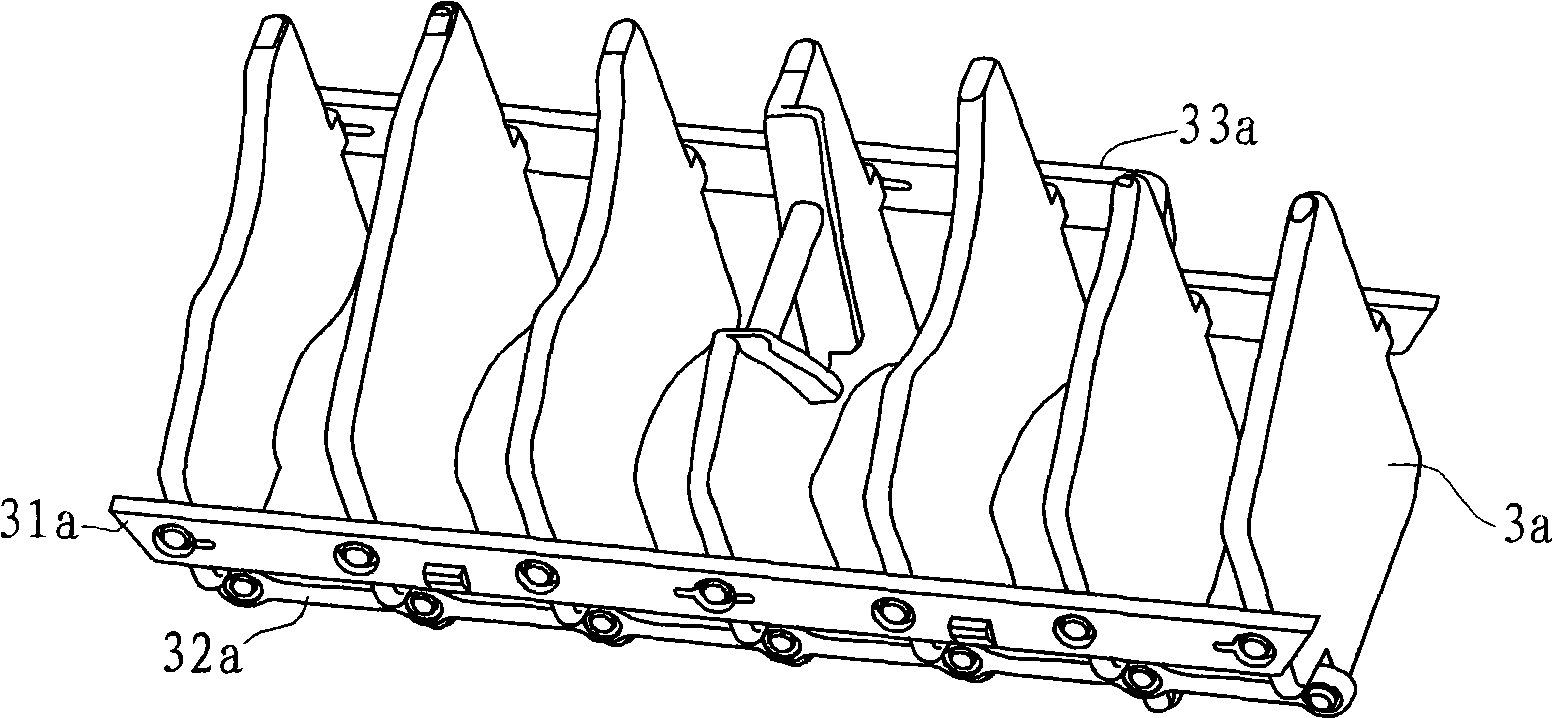

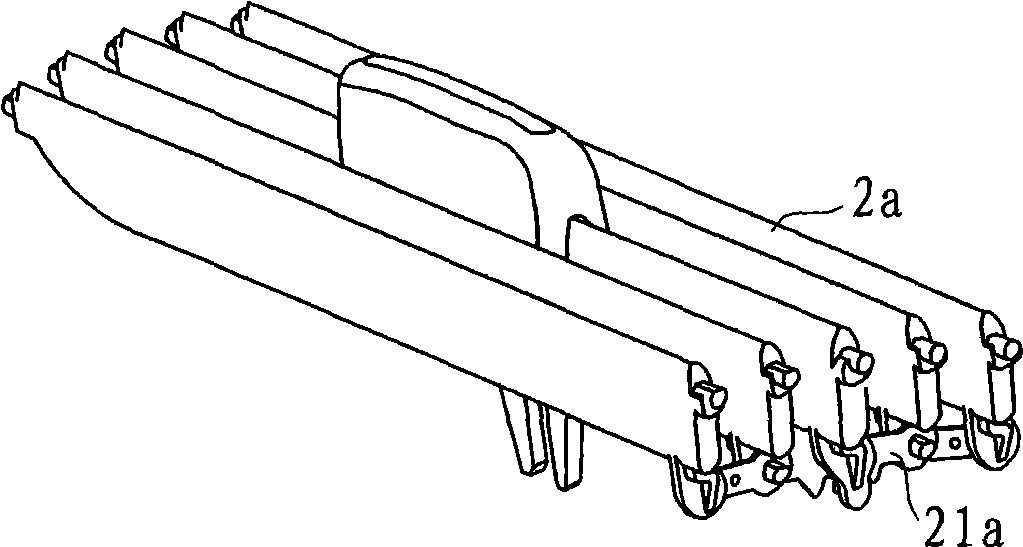

[0073] combine Figure 5 As shown, the vertical blade installation mechanism 103 is provided on one side of the base 100, and specifically includes a vertical clamping base 12, a vertical base cylinder 14c, a vertical blade clamping mechanism 1, and a vertical connecting rod installation mechanism. The vertical base cylinder 21c is used to drive the vertical clamping bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com