Assembling type reaction frame device for shield launching and propulsion

A reaction frame and assembled technology, applied in shaft equipment, shaft lining, tunnel lining, etc., can solve problems such as poor applicability, engineering accidents, difficulty in ensuring the roundness of segments, etc., to ensure smooth implementation, convenient installation, The effect of high installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

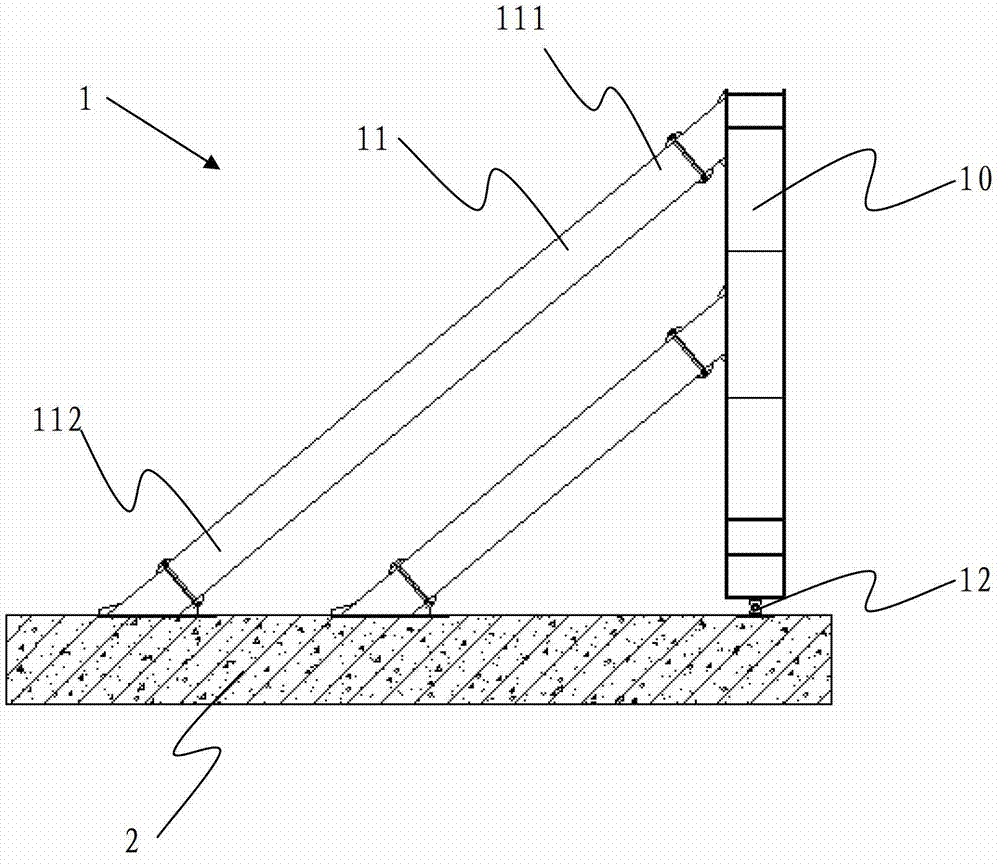

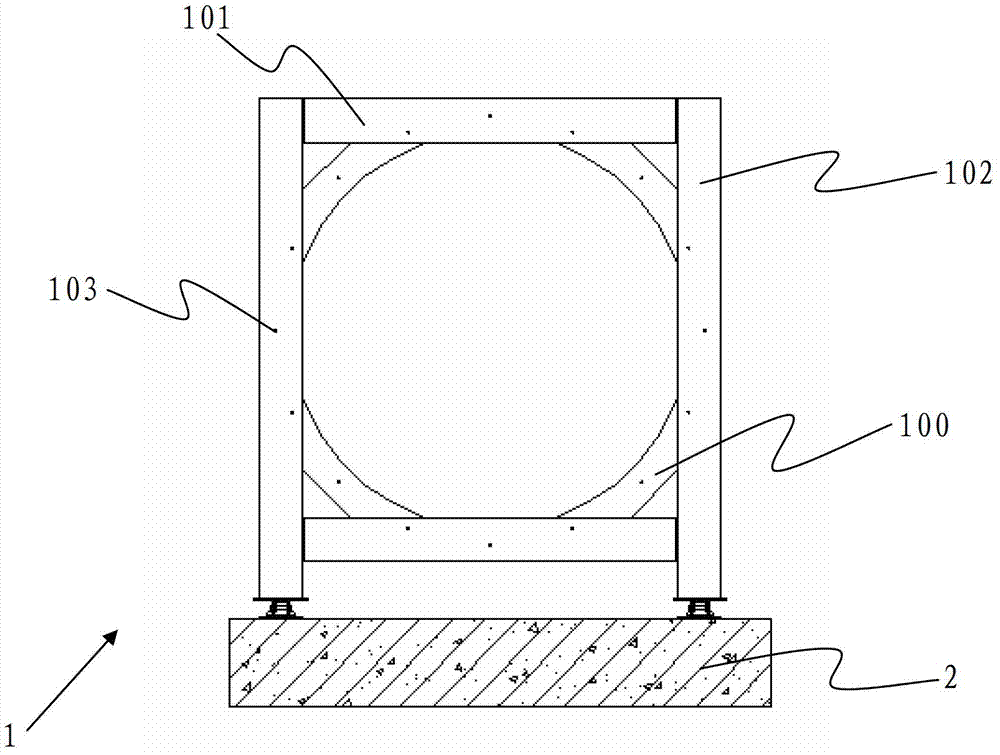

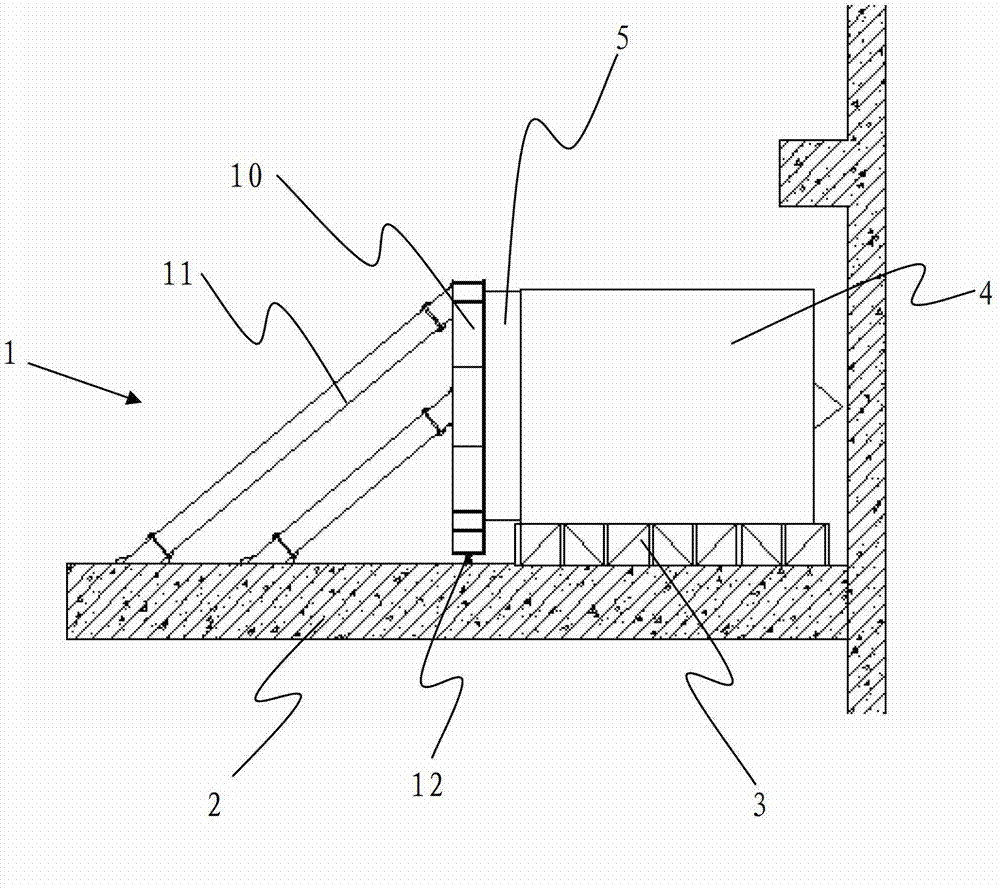

[0022] refer to figure 1 As shown, the assembled shield launching propulsion reaction force frame device 1 of the present invention is arranged on the working well floor 2 near the exit door of the launching shaft, and is mainly supported by a frame 10 and a plurality of support frames 10 Rods 11 are formed, wherein the first end 111 of the support rod 11 is connected to both sides of the frame 10 by bolts, the second end 112 of the support rod 11 is connected to the working well floor 2, and the bottom of the frame 10 is connected to the working well floor through a hinge 12 2, so that the frame 10 can rotate freely around the hinge 12, and cooperate with the support rod 11 to adjust the installation position of the reaction force frame device 1, so that the axis of the frame 10 coincides with the axis of the initial push-in door, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com