Liquid crystal display device, manufacturing method of the same and electronic equipment

A liquid crystal display device, liquid crystal layer technology, applied in chemical instruments and methods, devices for capturing or killing insects, transportation and packaging, etc., can solve problems such as light leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

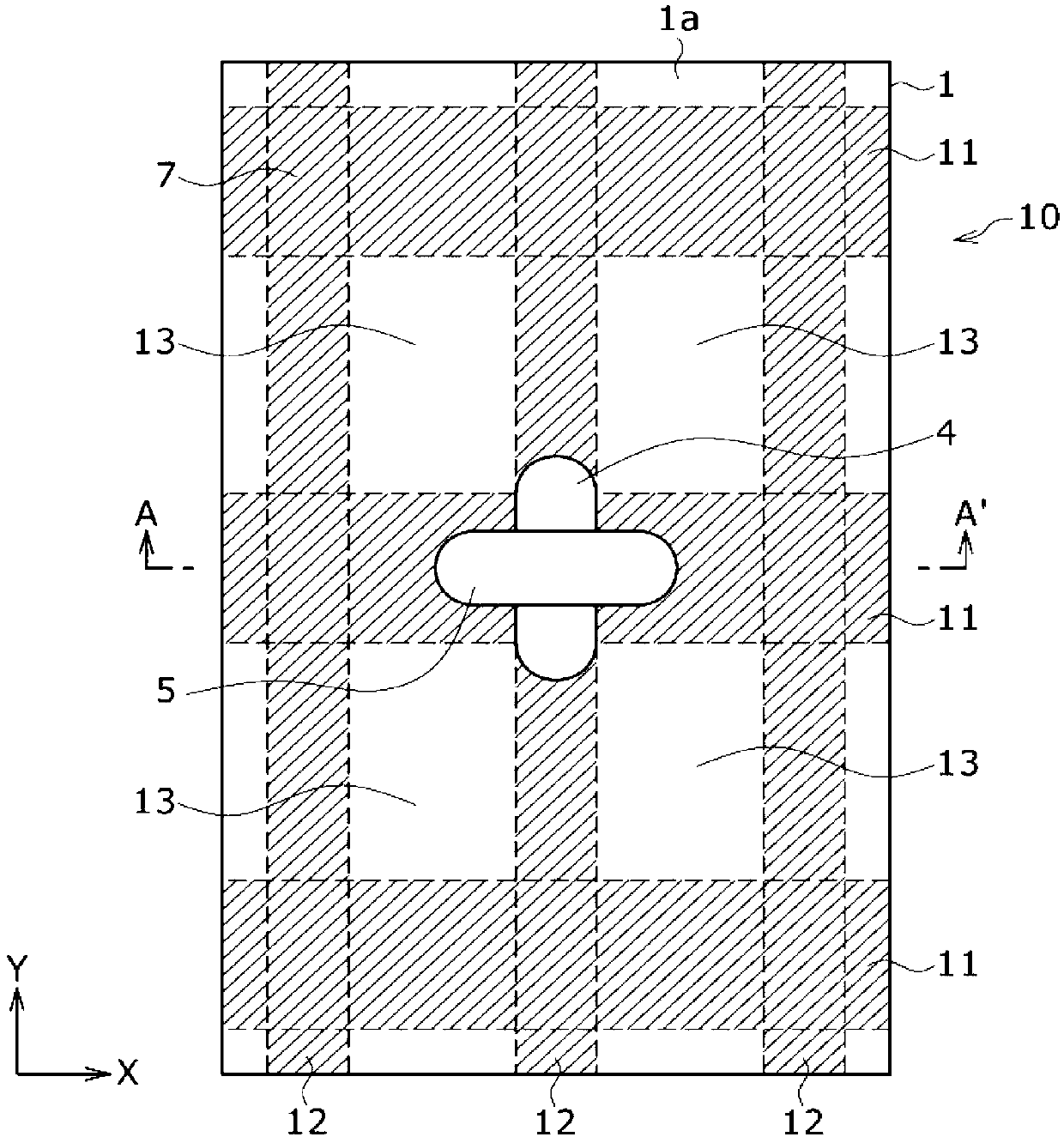

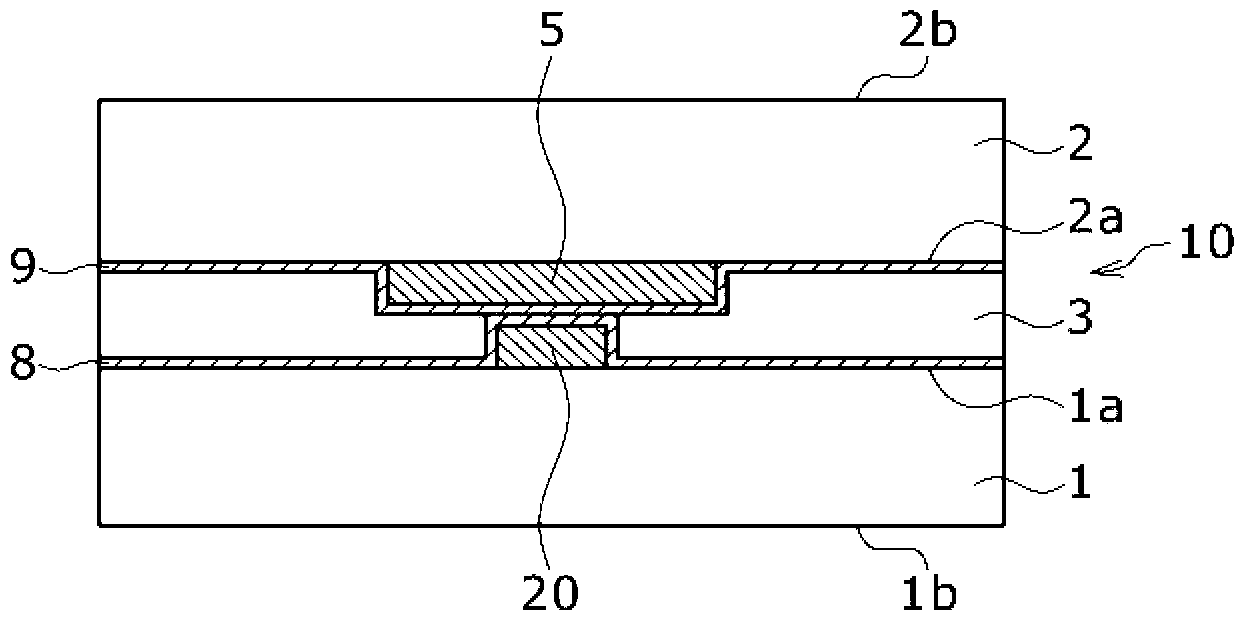

[0036] Figure 1A and 1B is a schematic diagram showing an example of the liquid crystal display device according to the first embodiment. Figure 1A shows a top view of the liquid crystal display device 10, and Figure 1B shows along the Figure 1A A cross-sectional view taken along line A-A'. It should be noted Figure 1A The top view of FIG. 2 does not show the counter substrate 2 and the liquid crystal layer 3 .

[0037] The liquid crystal display device 10 includes an array substrate 1 , a counter substrate 2 , a liquid crystal layer 3 , a spacer portion 4 and a spacer portion 5 , and alignment films 8 and 9 .

[0038] The array substrate 1 has, for example, a plurality of pixel regions arranged in a matrix. A TFT (Thin Film Transistor) and a pixel electrode are formed in each of the pixel regions. For example, a transparent glass substrate is used as the array substrate 1 .

[0039] In addition, the array substrate 1 has a surface 1a and a surface 1b on the opposite ...

no. 2 example

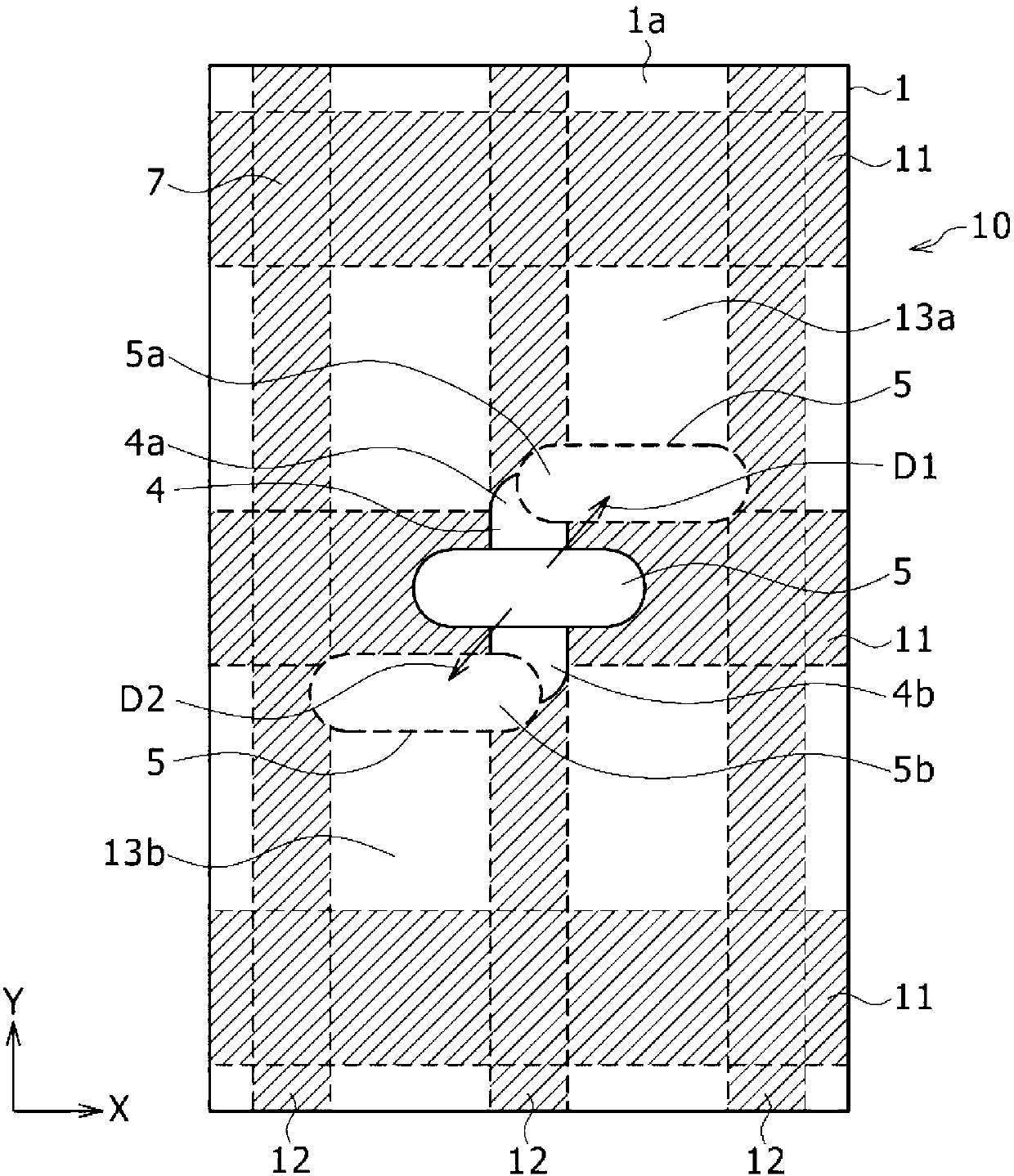

[0056] Next, a second embodiment will be described.

[0057] image 3 is a plan view showing the liquid crystal display device according to the second embodiment. Figure 4 is a partially enlarged view of the spacer part and its surrounding area. Figure 5 is along image 3 A cross-sectional view taken along line B-B' in . It should be noted image 3 Not only components other than the spacer portion 74 of the counter substrate 30 but also the pixel electrode 68 are not shown in .

[0058] The liquid crystal display device 100 includes an array substrate 20 , an opposite substrate 30 and a liquid crystal layer 40 . In the liquid crystal display device 100 , the pixel electrodes 68 are formed on the array substrate 20 , and the common electrodes 73 are formed on the opposite substrate 30 . The liquid crystal display device is a liquid crystal display device of TN (twisted nematic) mode, VA (vertical alignment) mode, and ECB (electrically controlled birefringence) mode.

...

example 1)

[0103] Next, a modified example of the second embodiment is described as Modified Example 1. FIG.

[0104] Figure 8 is a sectional view showing Modified Example 1.

[0105] The liquid crystal display device 110 differs from the liquid crystal display device 100 in that the spacer portion 81 is formed instead of the spacer portion 67 . The liquid crystal display device 110 is the same as the liquid crystal display device 100 in all other respects. The spacer portion 81 is made of, for example, acrylic resin. It should be noted that the spacer portion 81 is the same as the spacer portion 67 in shape and arrangement.

[0106] That is, in the liquid crystal display device 100 , the spacer portion 67 is formed with a part of the organic insulating film 66 . However, in the liquid crystal display device 110 , the spacer portion 81 is formed separately from the organic insulating film 66 . For example, this configuration makes it possible to select a material that is more resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com