Bioreactor for producing tissue engineering products

A technology of bioreactor and production organization, which is applied in the direction of specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, tissue cell/virus culture device, etc. And problems such as too many pipelines and large reactor volume, etc., to achieve the effect of reducing the occupied area of the equipment, wide application range and good scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

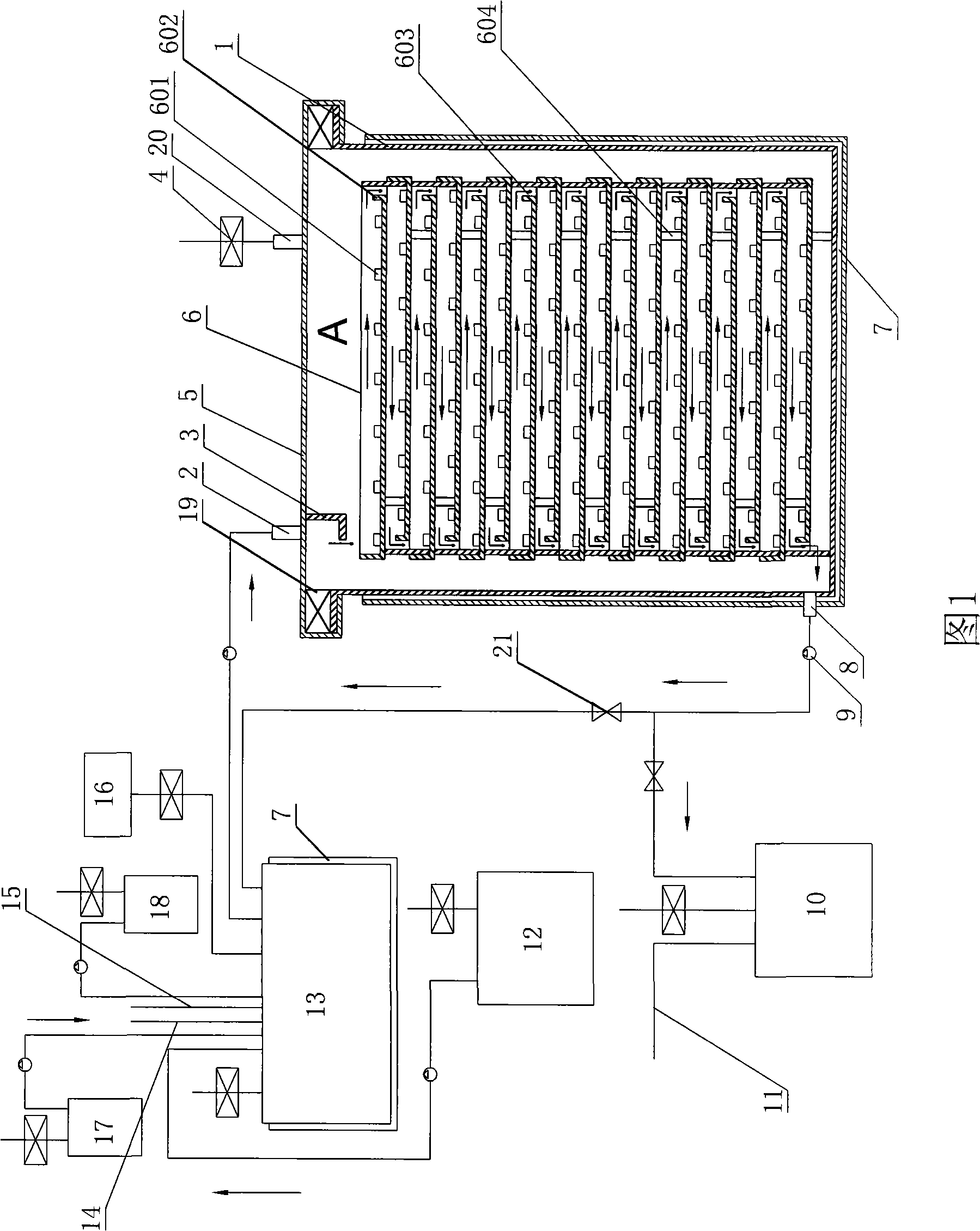

[0018] The specific structure of the bioreactor of the present invention will be further described below in conjunction with the accompanying drawings.

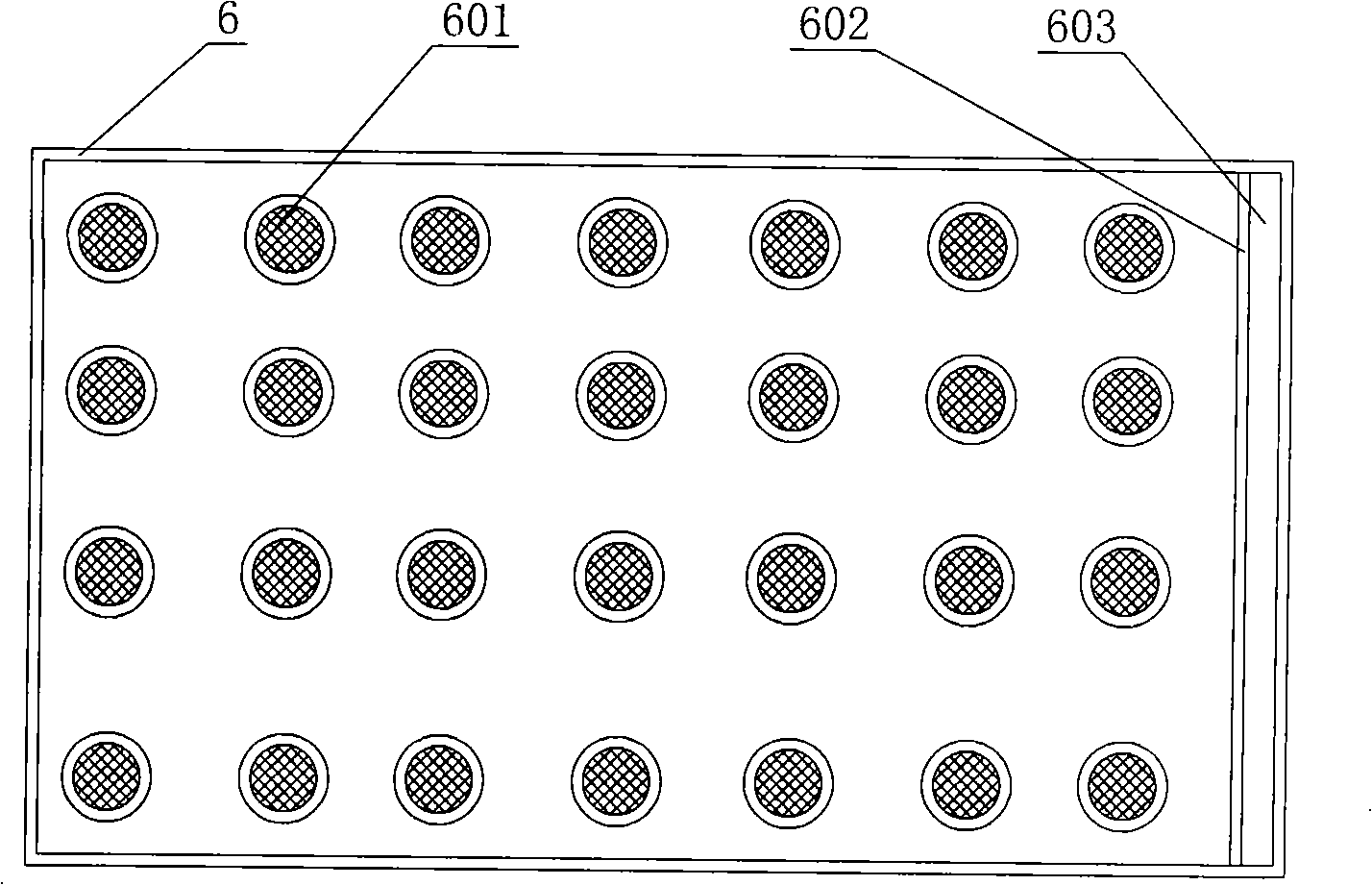

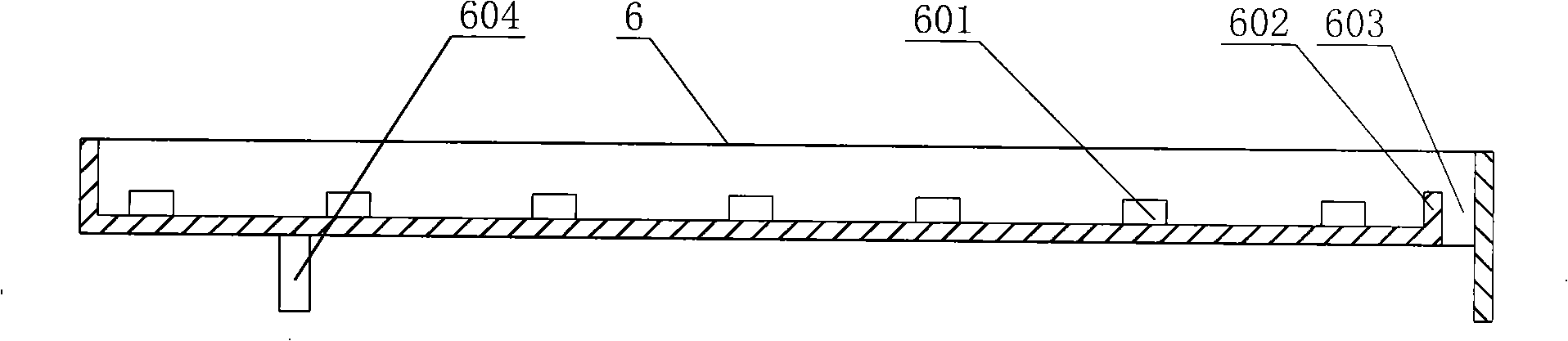

[0019]A bioreactor for producing tissue engineering products, including a waste liquid bottle 10, a liquid replacement bottle 12, a liquid storage bottle 13, a four-gas mixer 16, an acid liquid bottle 17, an alkali liquid bottle 18, and a reaction box Body 1, reaction box cover 5, layer plate 6, thermostatic jacket 7 and sealing gasket 19 assembled biological reaction box A; reaction box cover 5 is provided with liquid inlet 2 and air exchange port 20, near the liquid inlet 2 The bottom surface of the reaction box cover is provided with a liquid baffle 3, the thermostatic jacket 7 is arranged on the periphery of the reaction box body 1, and the lower part of one side of the reaction box body 1 is provided with a liquid outlet 8 passing through the thermostatic jacket, and the sealing gasket 19 is installed on Between the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com