Machining technique of anchor chain Kenter shackle

A technology of Kent shackles and processing technology, which is applied in metal processing equipment, manufacturing tools, milling machine equipment details, etc., can solve the problems of difficult product processing quality, long processing auxiliary time, and large cumulative error, etc., and increase the effective processing time , Protection of legitimate rights and interests, the effect of reducing the number of clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing embodiment, the present invention will be further described:

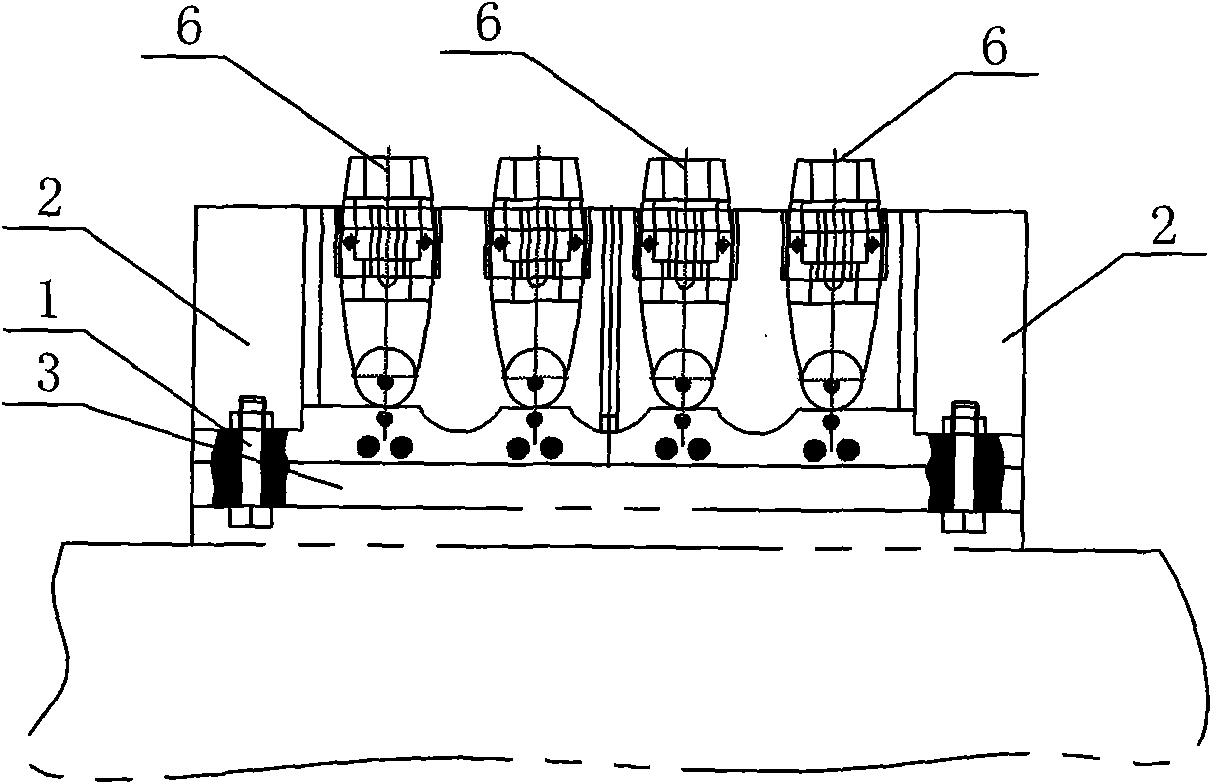

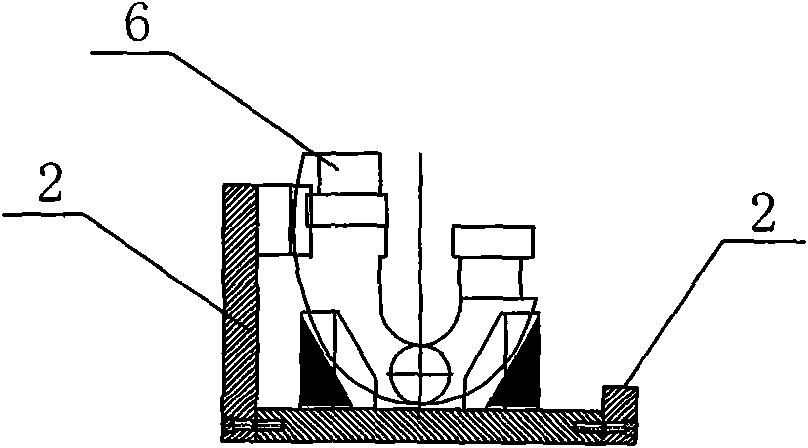

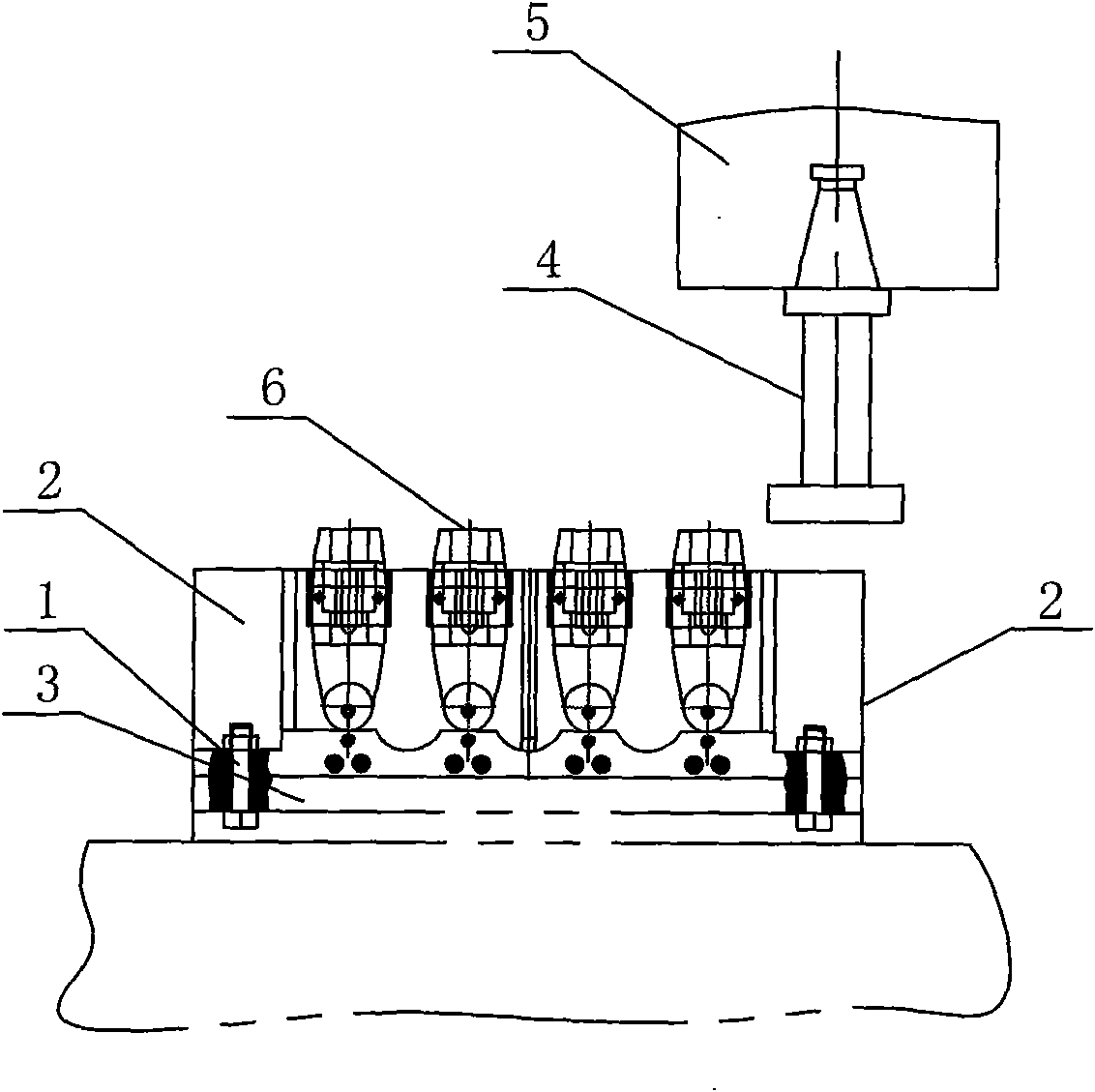

[0024] like Figures 1 to 8 As shown, the processing technology of the anchor chain Kent shackle includes connecting the tooling 2 with the working platform 3 of the CNC milling machine with square bolts 1, connecting the forming tool 4 with the spindle 5 of the CNC milling machine, and the tooling 2 is provided with four The workpiece mounting position, (see figure 1 , 2 . )

[0025] Including the following steps:

[0026] a) Clamp the workpiece 6 on the tooling 2, start the CNC milling machine, make the main shaft 5 rotate, move the working platform 3, and make the forming tool 4 be in the initial position of processing; (see image 3 . )

[0027] b) moving the main shaft 5 down to the workpiece 6, operating the CNC milling machine, so that the working platform 3 moves laterally, and processes the A surface and the B surface of the workpiece 6; (see F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com