Warp knitting machine creel

A warp knitting machine and creel technology, applied in warp knitting, textiles, papermaking, knitting, etc., can solve problems such as poor production continuity, increased production costs, and unstable quality, so as to prevent yarn fluffing and improve production efficiency , The effect of reducing the number of handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific examples. It should be understood that the cited examples are only used to illustrate the present invention, and are not intended to limit the scope of the present invention.

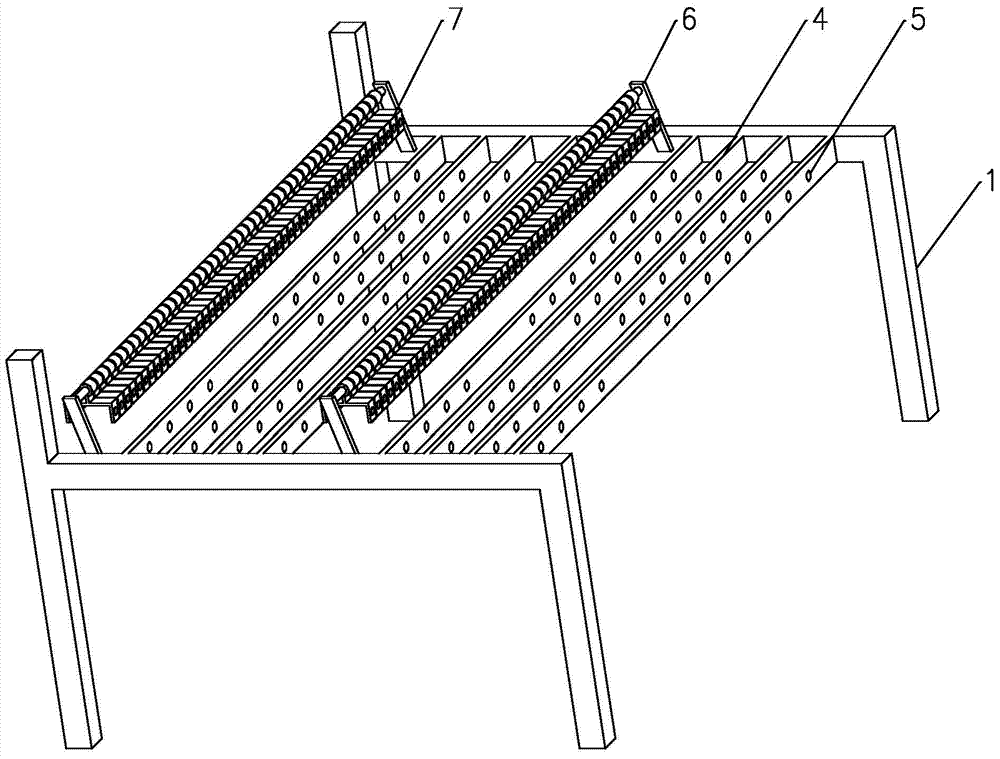

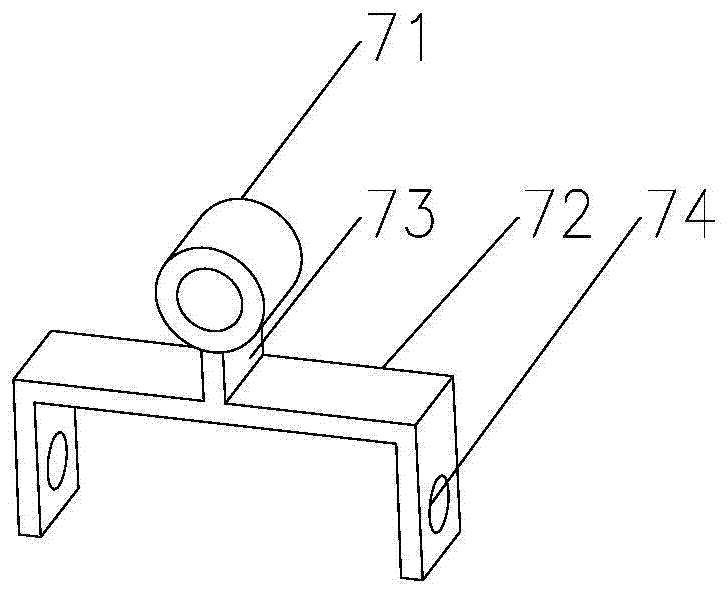

[0020] Such as figure 1 , figure 2 As shown, a creel for a warp knitting machine includes a support frame 1, two groups of yarn guide plates 4 are fixed between the support frames 1, and each group of yarn guide plates 4 includes four yarn guide plates 4, and each of the yarn guide plates 4 Each yarn guide plate 4 is provided with 12 yarn guide holes 5, the yarn guide holes 5 are evenly distributed, the included angle between the axis of the yarn guide hole 5 and the horizontal plane is 0°, and The wear-resistant PEEK resin sleeve that the small yarn rubs against the yarn guide hole 5, a cylindrical tension adjustment beam 6 is arranged above the support frame 1, each group of yarn guide plates 4 corresponds to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com