Patents

Literature

49results about How to "Realize uninterrupted feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

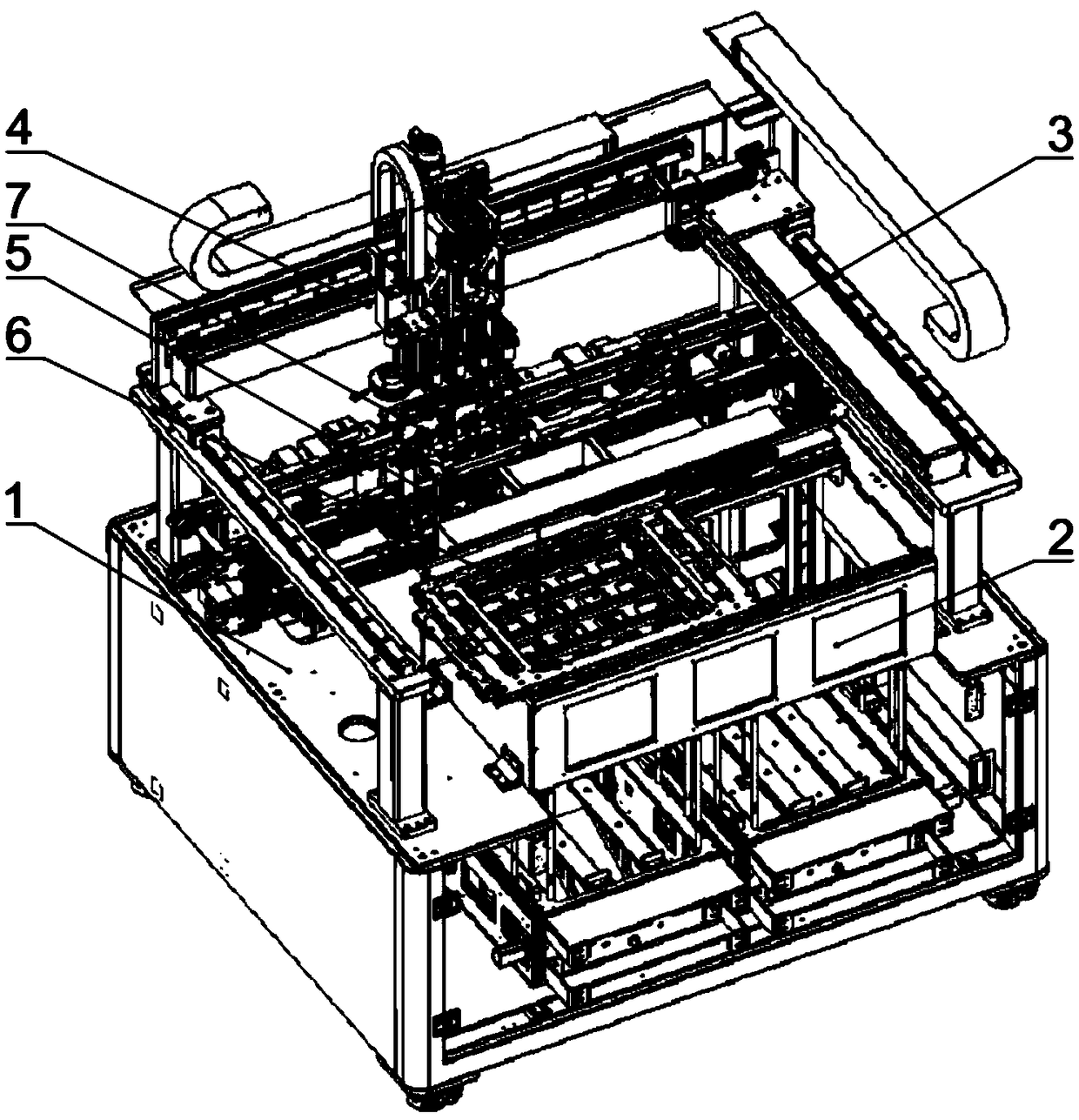

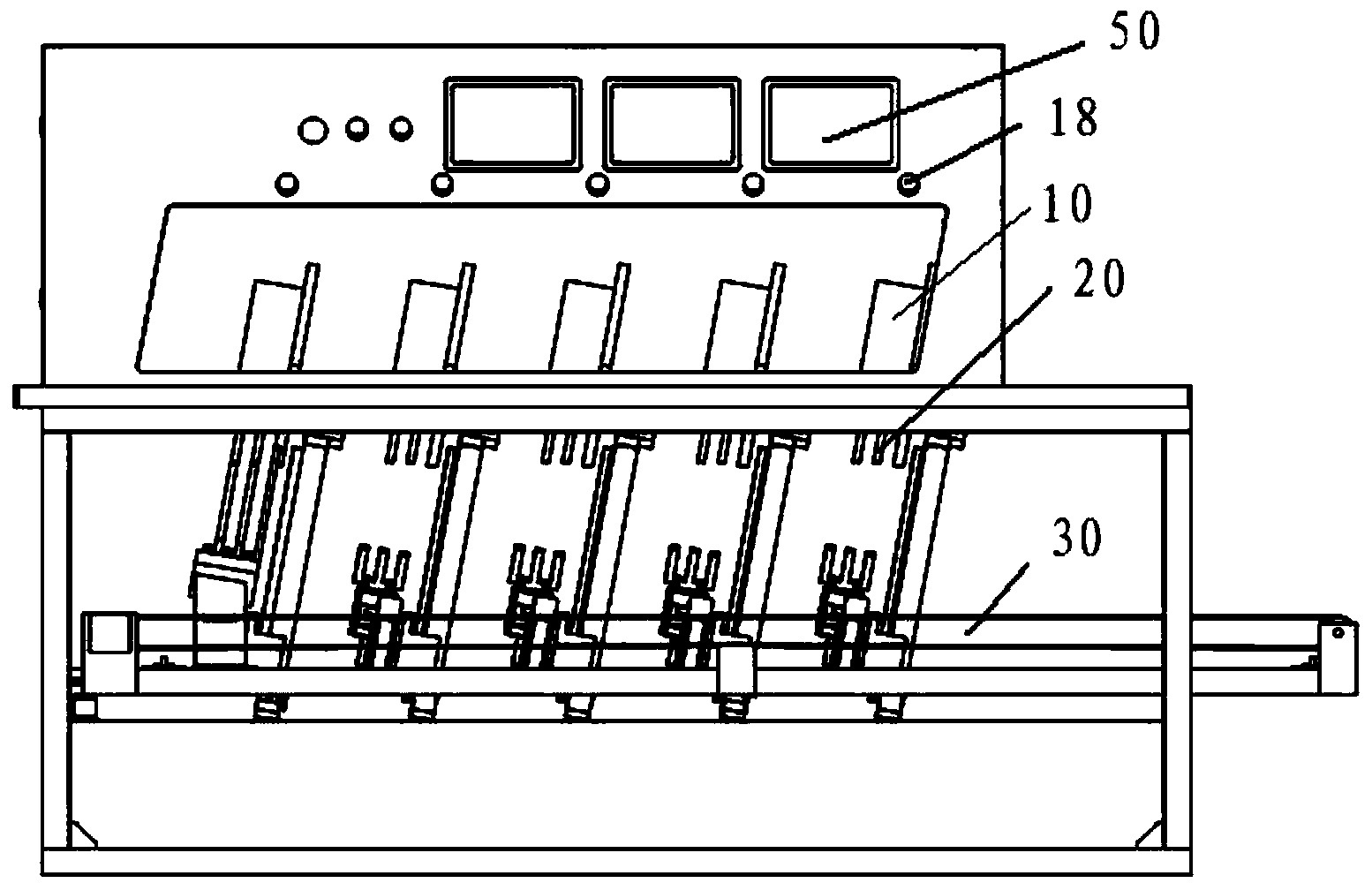

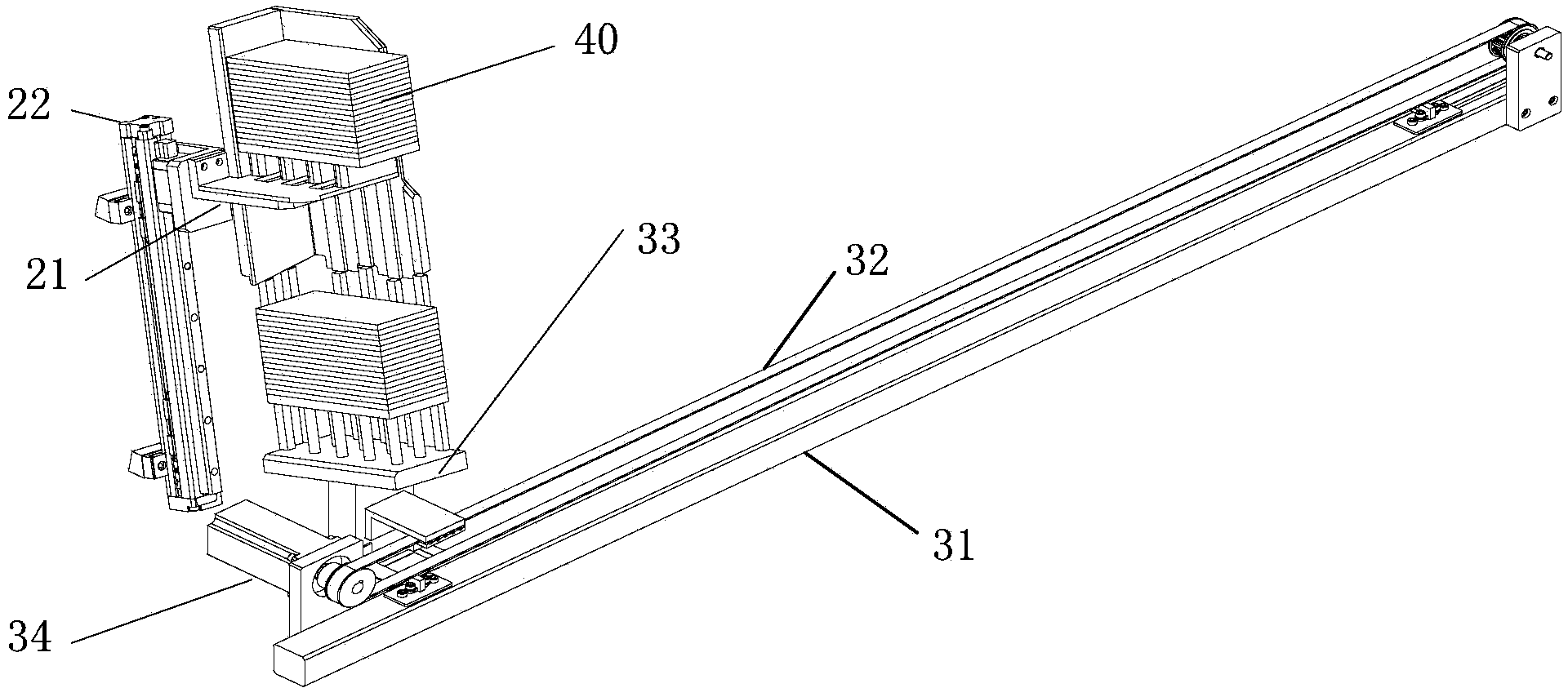

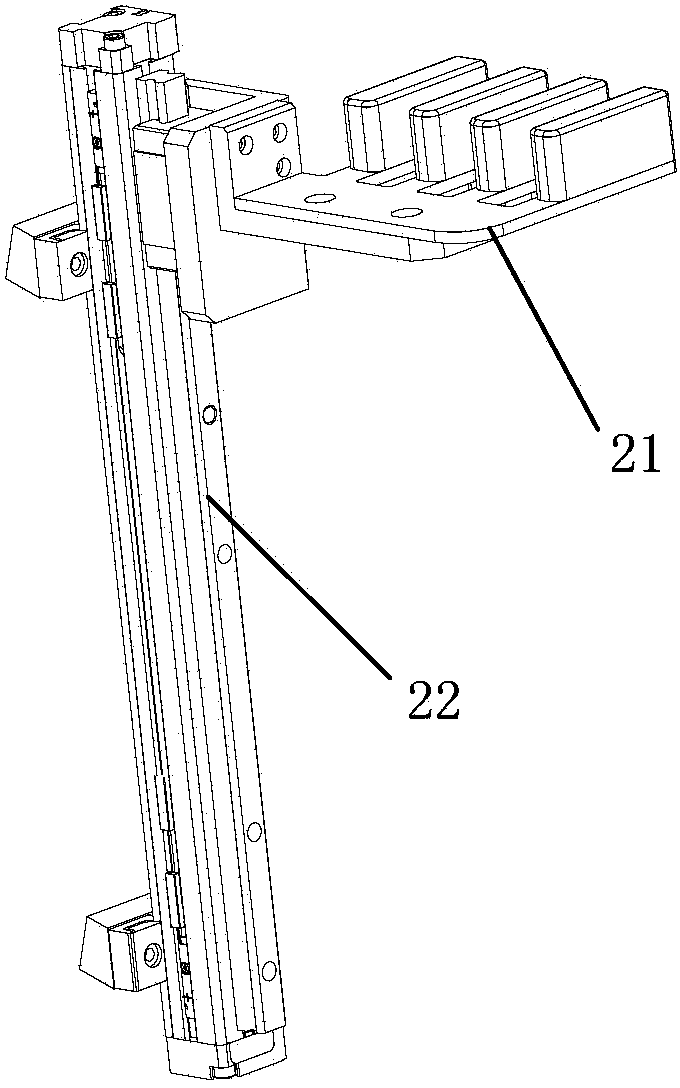

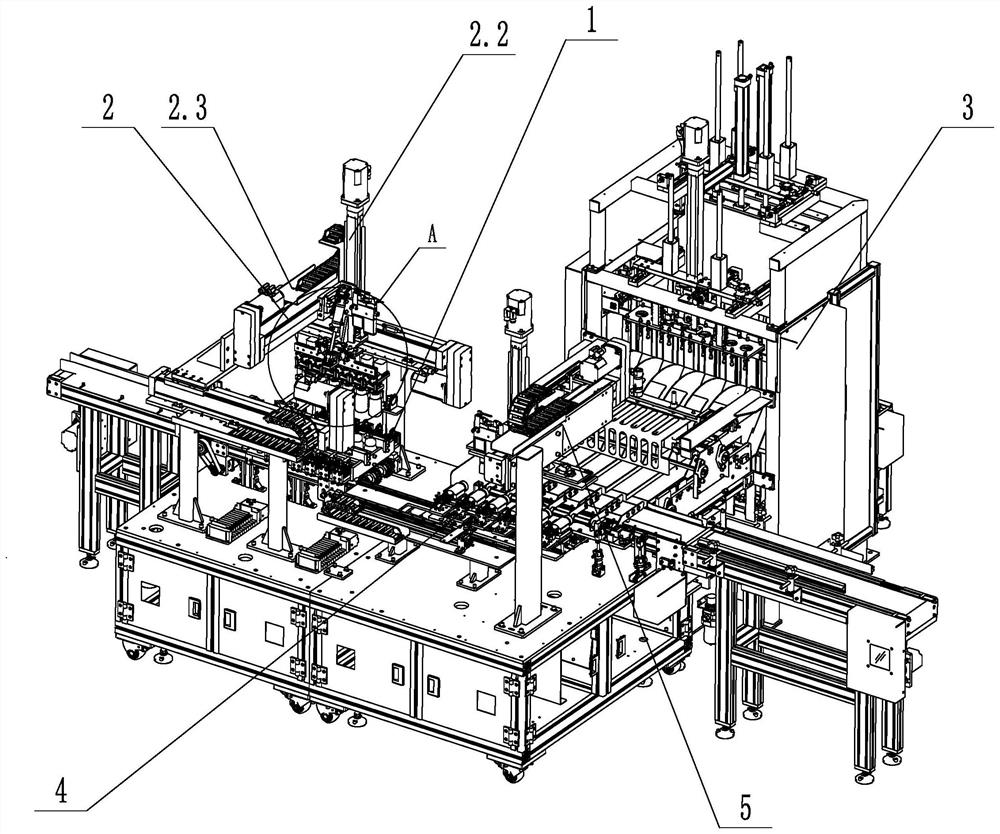

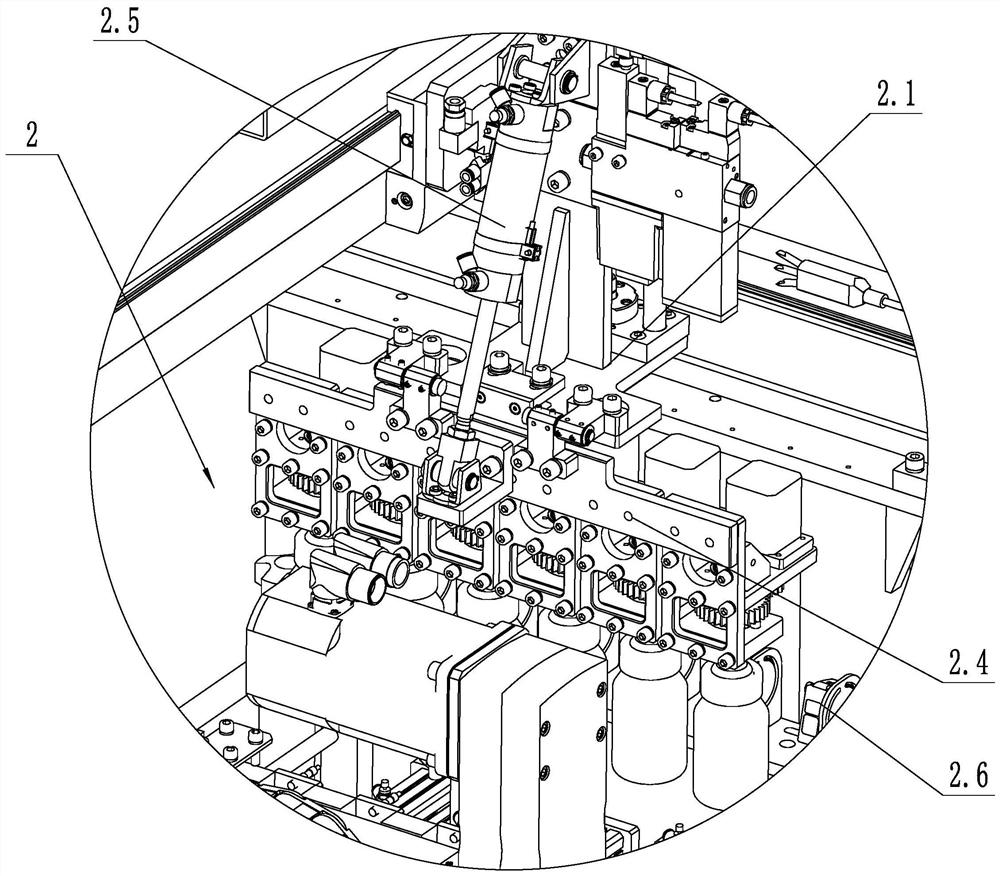

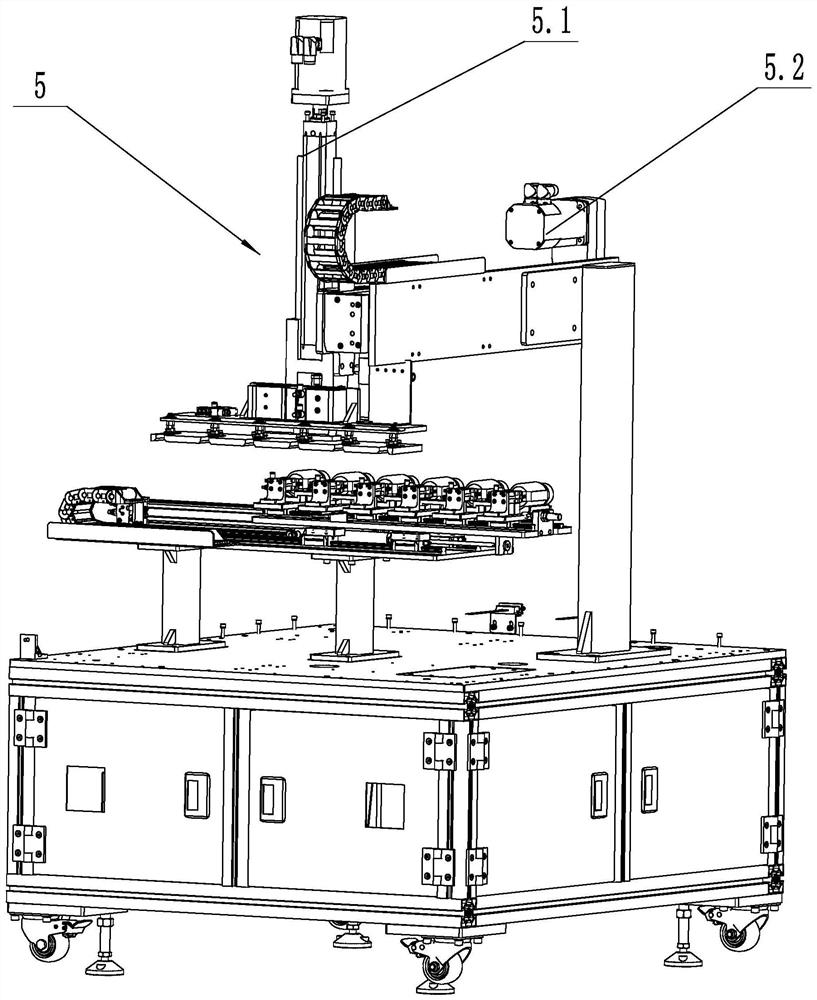

Workpiece feeding device and method

PendingCN109132526AAchieve continuous supplyRealize the loading function of magazine typeConveyorsControl devices for conveyorsEngineeringMechanical engineering

The invention provides a workpiece feeding device. The workpiece feeding device comprises a working platform, a supplying mechanism, a conveying line mechanism, a workpiece carrying mechanism and a screening mechanism, wherein a supplying position is arranged on the supplying mechanism; a mounting position is arranged on the conveying line mechanism. According to the device, the workpiece carryingmechanism is capable of clamping a workpiece from the supplying position; the workpiece subjected to detecting and screening of the screening mechanism moves and then is mounted to a target carrier at the mounting position; the supplying mechanism and the workpiece carrying mechanism realize automatic workpiece supplying and feeding and mounting; the workpiece can be detected through the screening mechanism in the carrying process, so that the qualification rate of the workpiece is ensured; the workpiece is carried through the conveying line mechanism utilizing the carrier, and thus the flow-line type processing work is realized. The invention also provides a workpiece feeding method. With the adoption of the device and the method, the workpiece is automatically fed and detected, and thusthe convenience of production management is ensured.

Owner:SUZHOU RS TECH

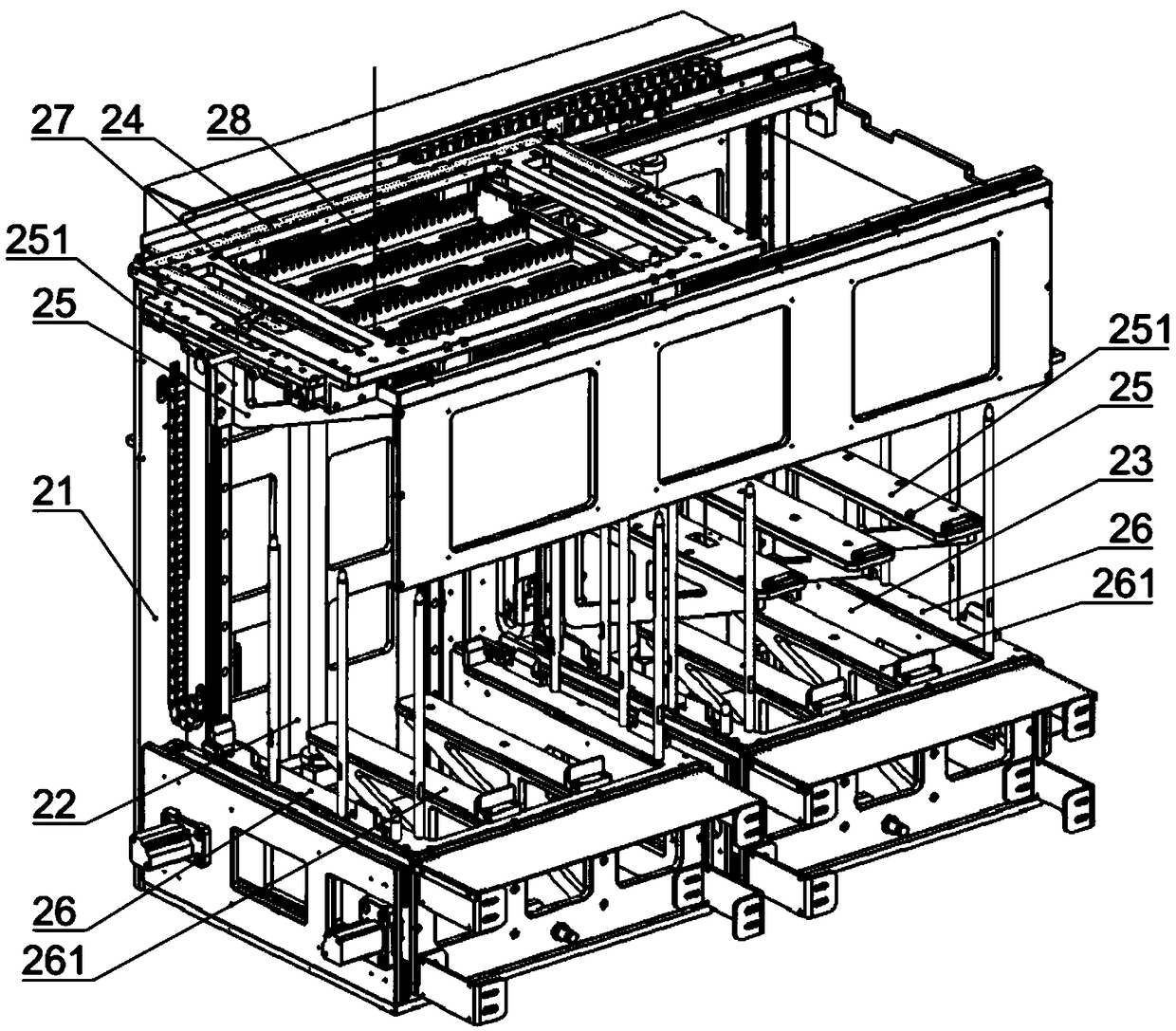

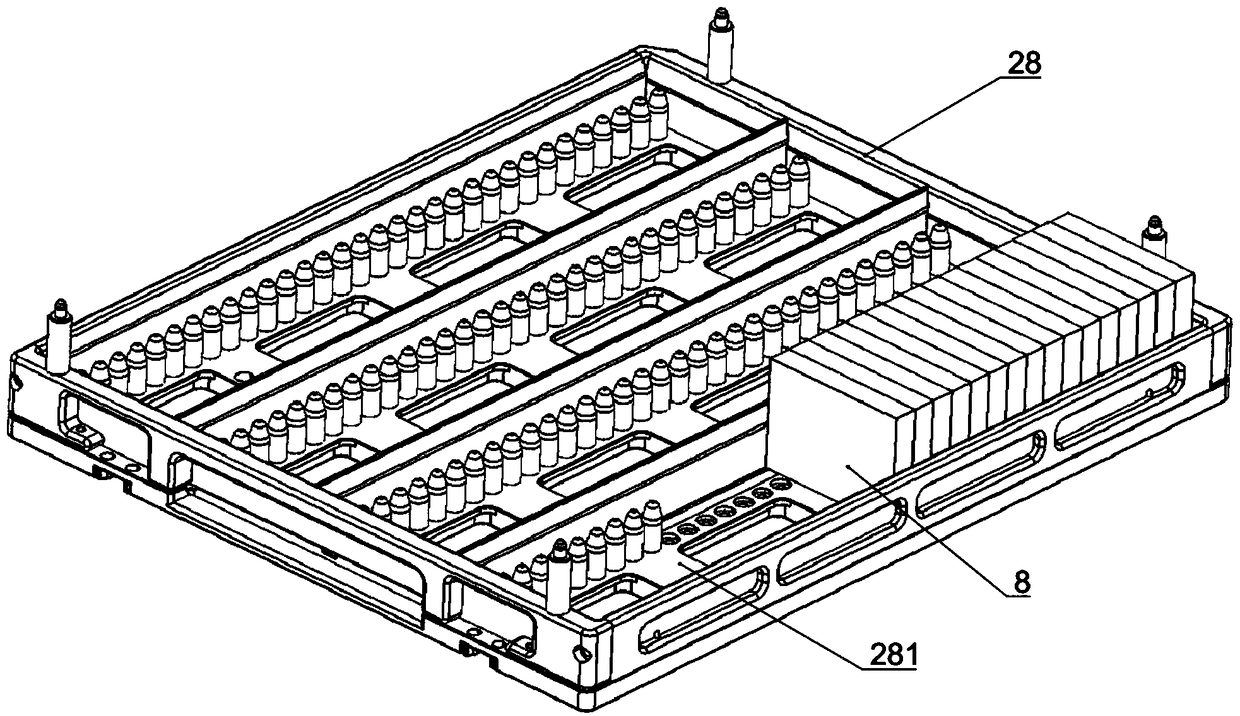

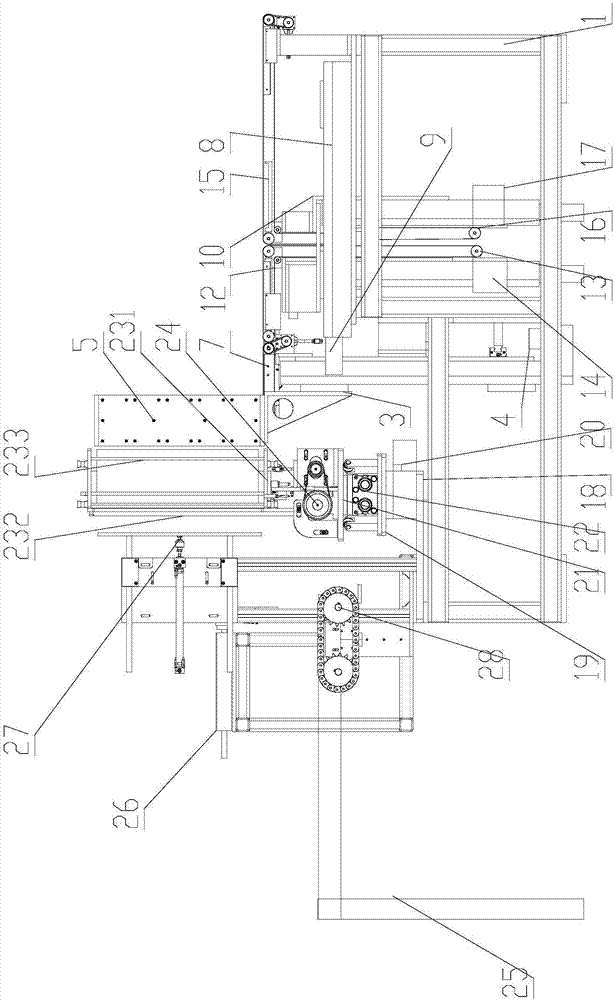

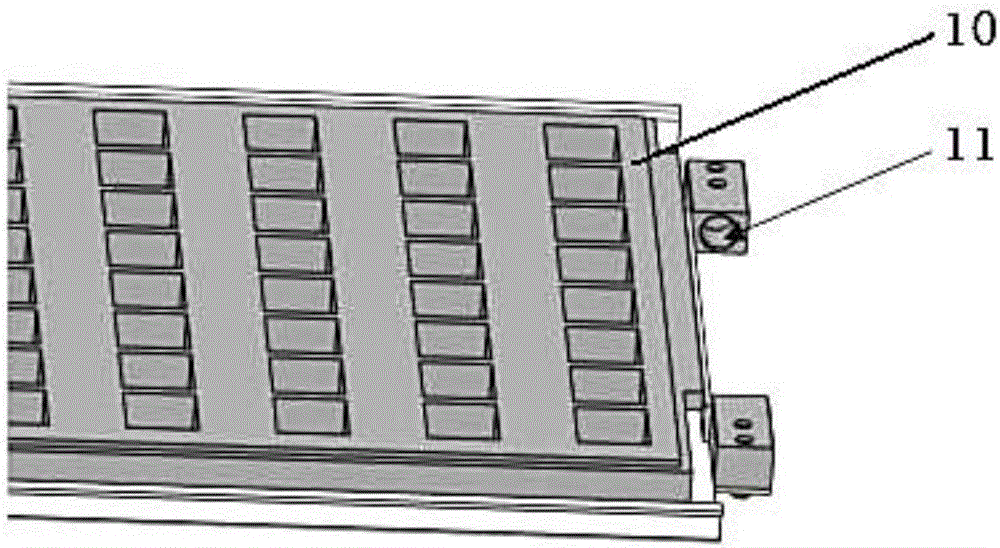

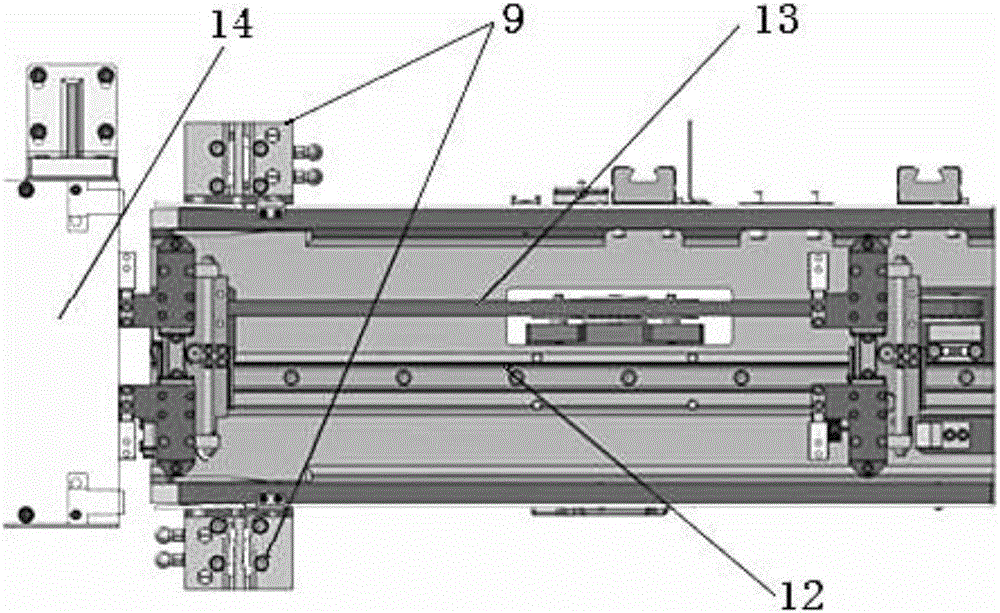

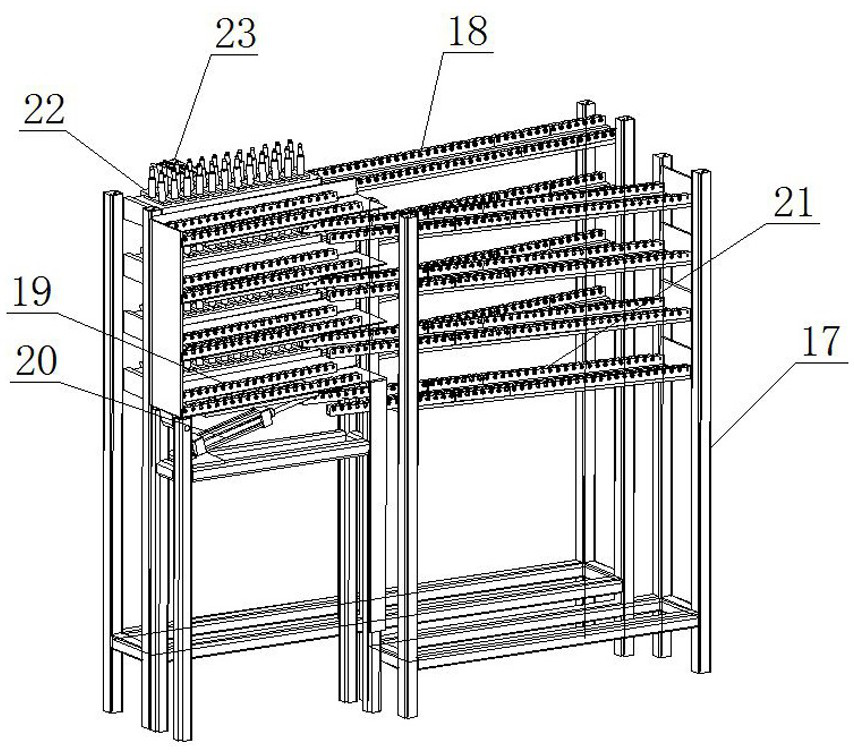

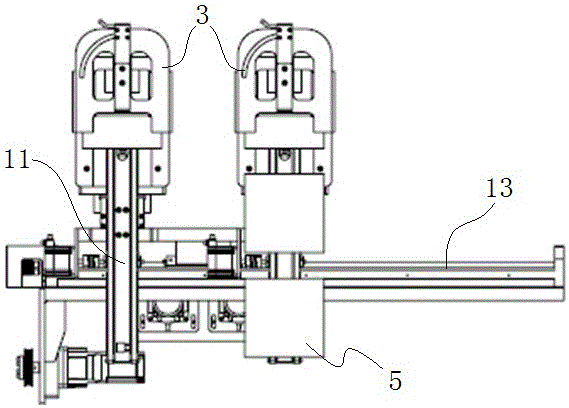

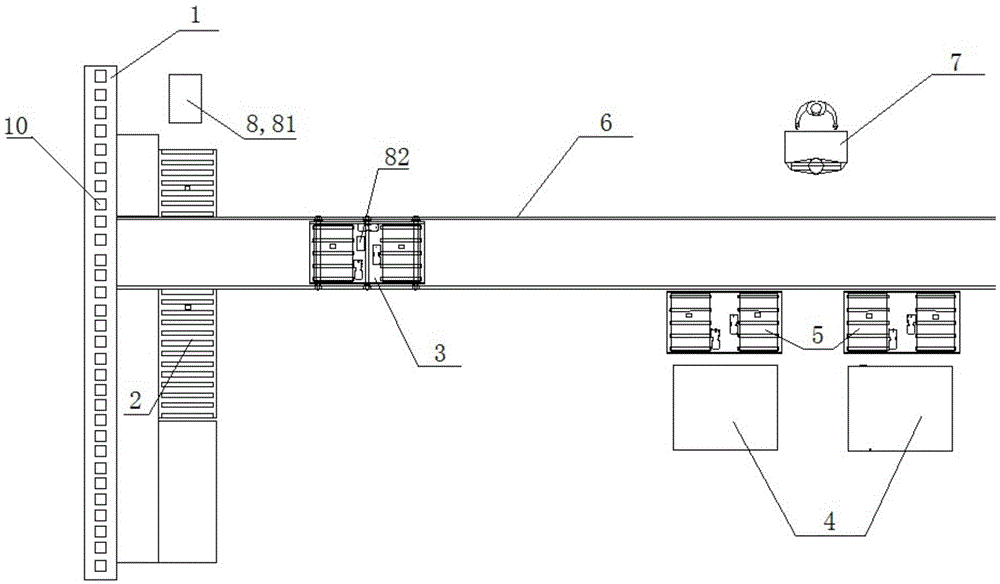

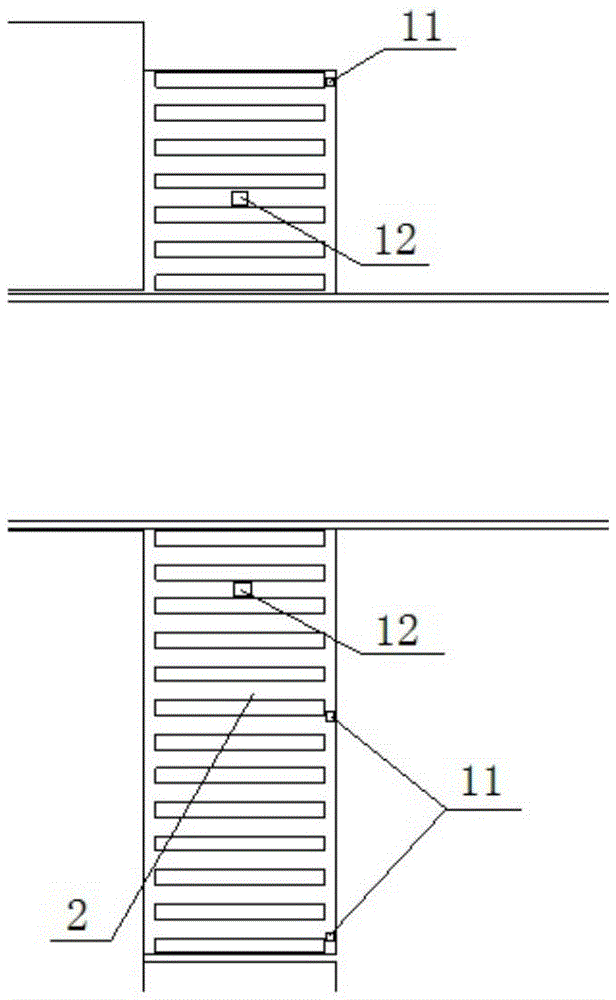

Feeding system and feeding method for silicon chip quality sorting equipment

ActiveCN104307759ARealize uninterrupted feedingIncrease the feeding speedSortingButt jointEngineering

The invention discloses a feeding system for silicon chip quality sorting equipment. The feeding system mainly comprises multiple feeding units with the same structure. Each one of the feeding units comprises a vertical guide rail, the vertical guide rail is provided with a feeding box, a basket case is installed in the feeding box, a side of the vertical guide rail is provided with a horizontal transmission mechanism, the horizontal transmission mechanism is used for transmitting silicon chips in the basket case to a downstream station, an output end of the horizontal transmission mechanism is provided with a horizontal guide rail, and the multiple horizontal transmission mechanisms can horizontally move reciprocatingly so that butt joint of the corresponding horizontal transmission mechanism and the downstream station is switched and thus when the feeding box in the multiple feeding units carries out feeding, the rest of the feeding boxes carry out loading. The multiple feeding units are installed on the horizontal guide rail capable of horizontally moving so that left-to-right switching of the multiple feeding units is realized. When one of the feeding units carries out a feeding process, the rest of the feeding units carry out basket case loading so that uninterrupted feeding is realized.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

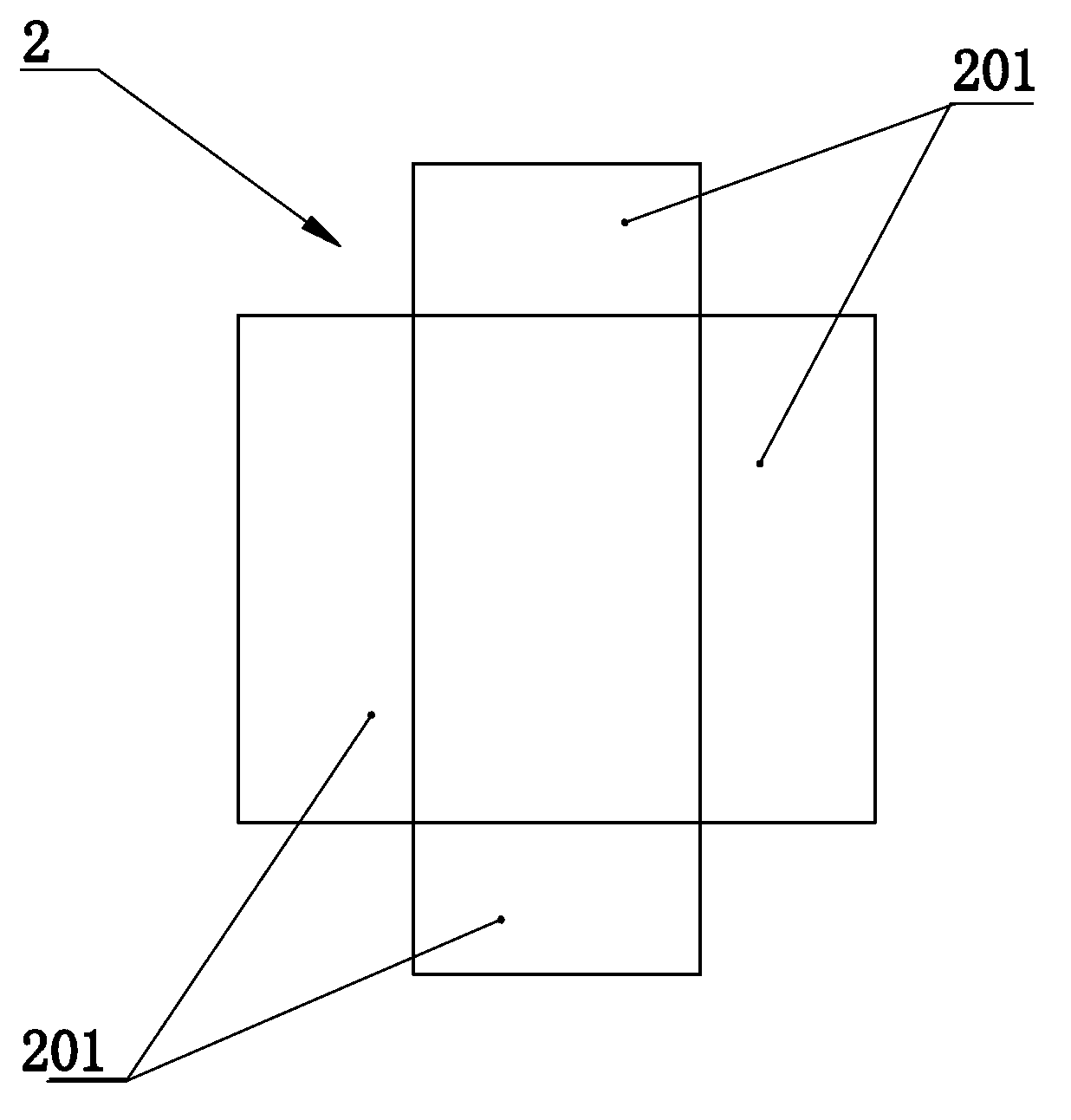

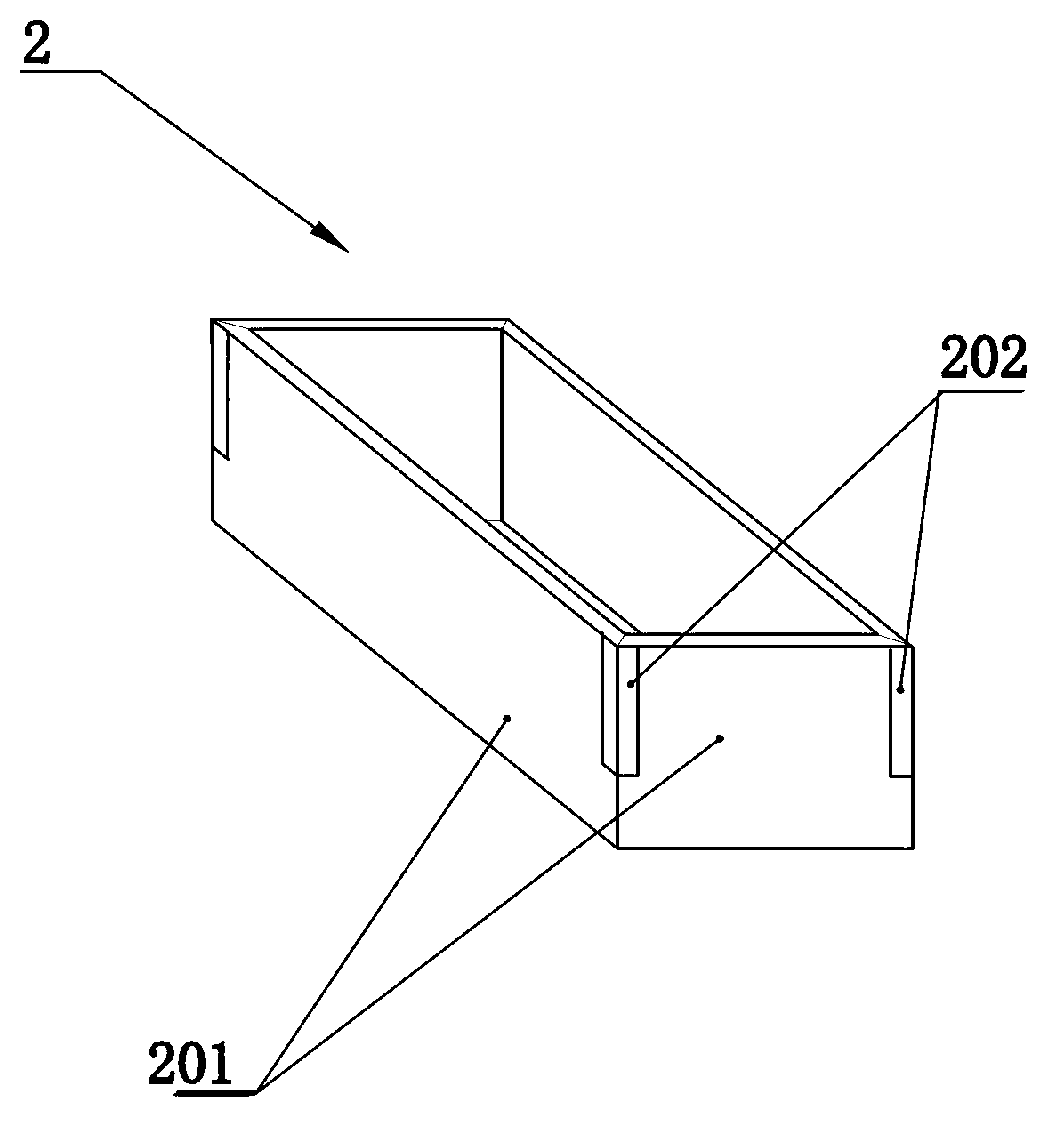

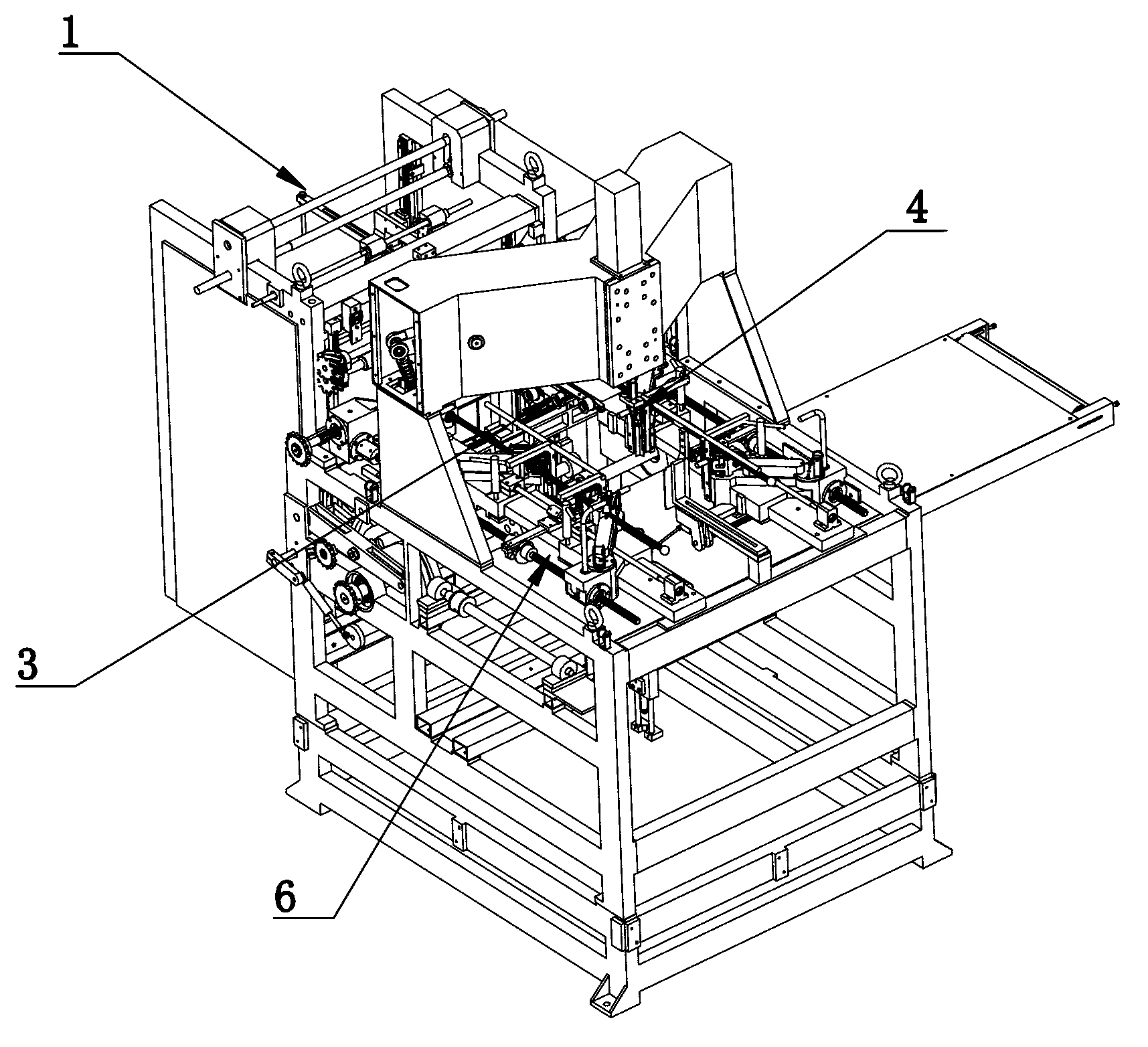

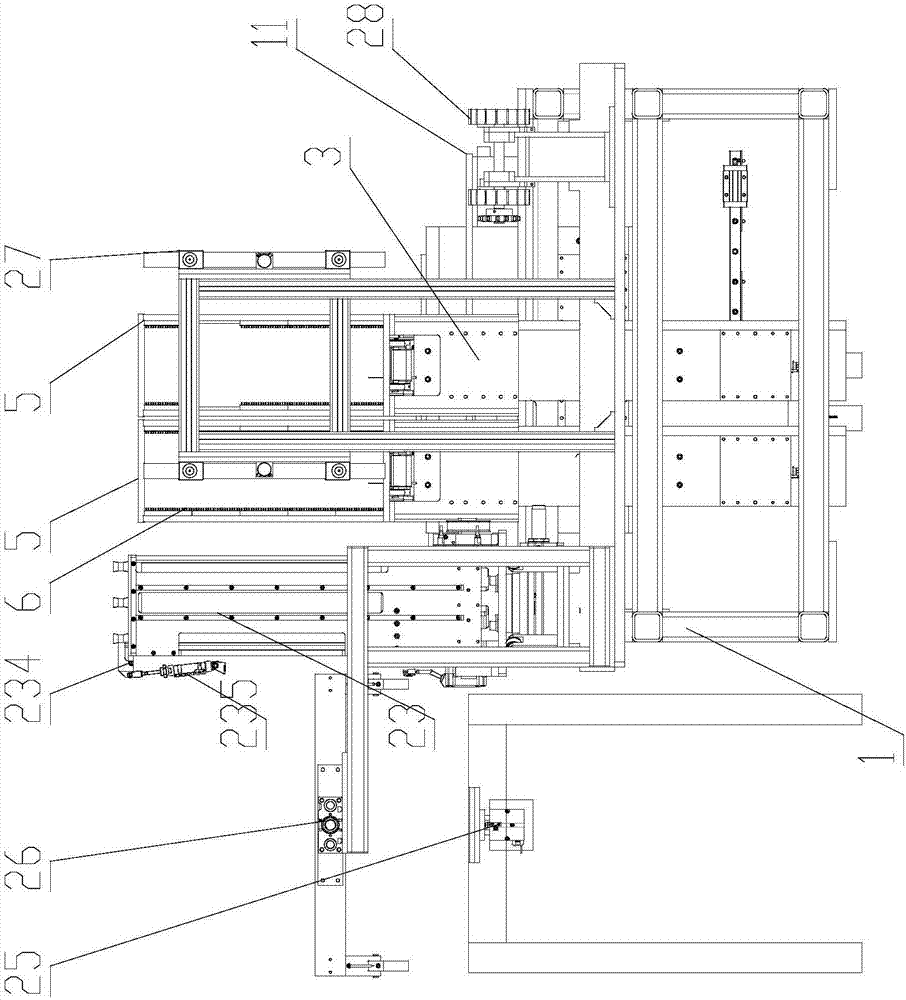

Inner box forming machine

InactiveCN103009673ARealize uninterrupted feedingImprove processing efficiencyBox making operationsPaper-makingMolding machinePaperboard

The invention relates to an inner box forming machine, which comprises a discharging mechanism for discharging inner box paperboards one by one, and a conveying mechanism that is arranged at the back of the discharging mechanism and is used for conveying the inner box paperboards, wherein the other end of the conveying mechanism opposite to the discharging mechanism is provided with a die head capable of moving up and down; forming pieces are arranged at four lug positions of the corresponding inner box paperboards under the die head; and a group of paper sticking mechanisms is respectively arranged at four corners after the corresponding inner box paperboards under the die head form a frame. With adoption of the technical scheme of the inner box forming machine, the mechanical automatic production is realized, the production cost is effectively reduced, and the processing efficiency is improved.

Owner:瑞安市华科包装机械有限公司

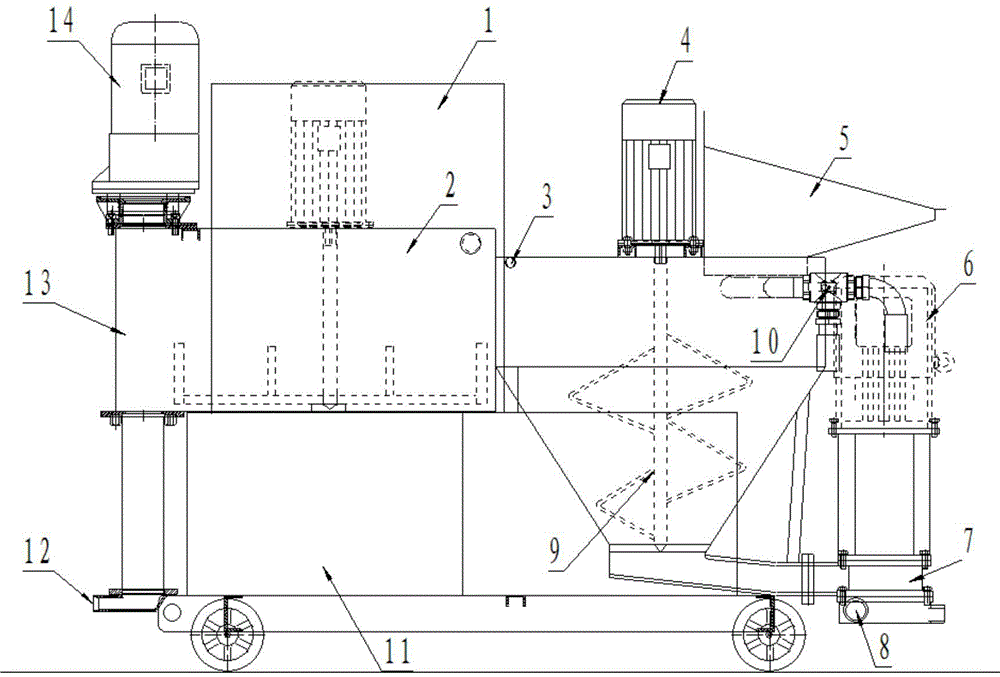

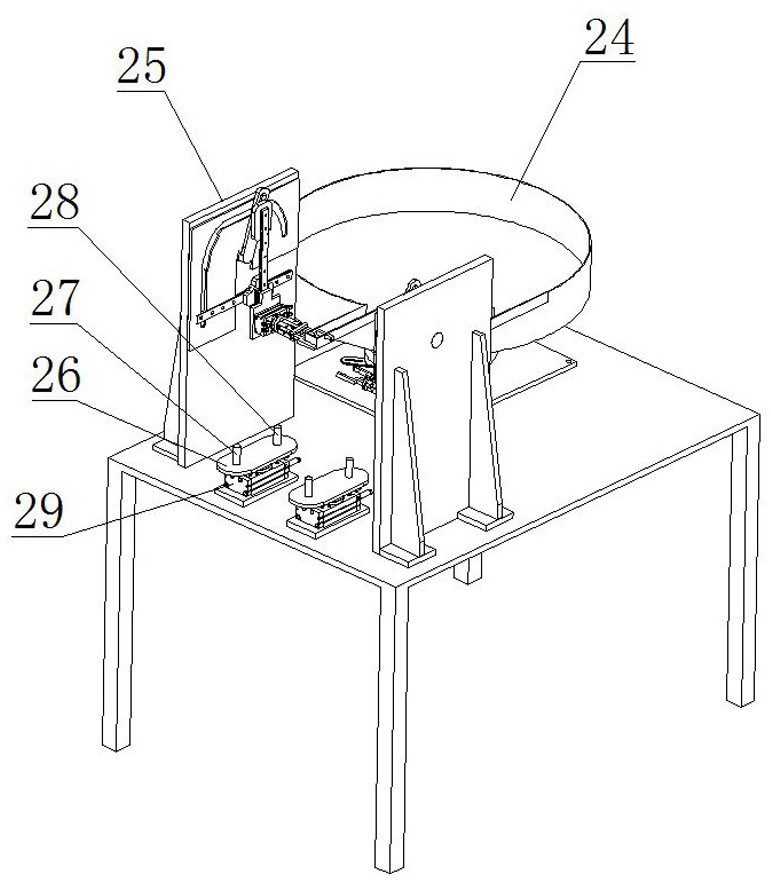

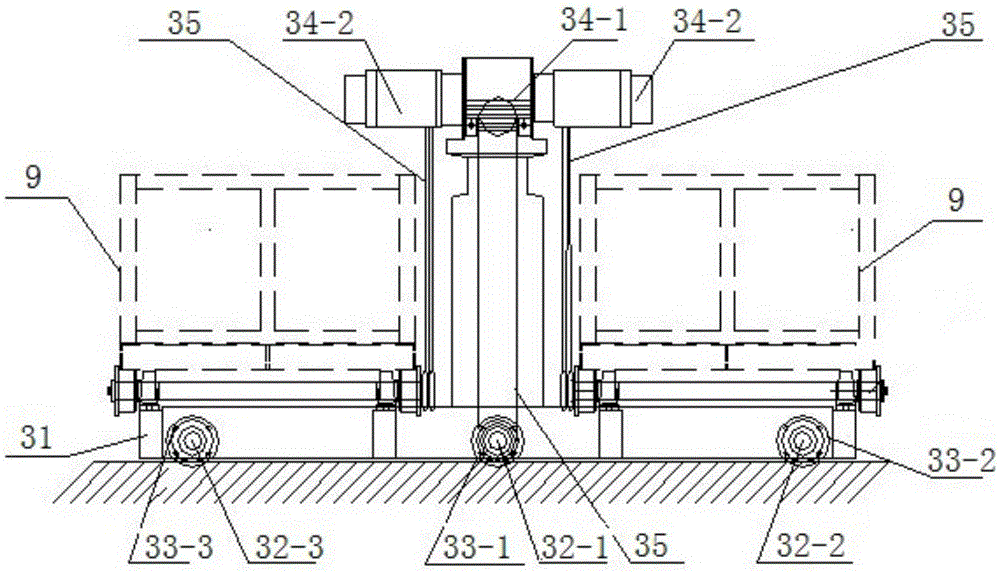

Grouting trolley

InactiveCN104131705AEasy to moveRealize uninterrupted feedingBuilding material handlingCement mixing apparatusManufacturing systemsGrout

The invention relates to a grouting trolley which comprises a machine frame with walking wheels at bottom, a grout manufacturing system arranged on the machine frame, and a grout pumping system arranged on the machine frame and connected with a grout outlet of the grout manufacturing system. Due to the fact that the bottom of the machine frame is provided with the walking wheels, the whole grouting trolley is convenient to move, and accordingly the grouting trolley is suitable for being used in situations when moving operations need to be carried out. Additionally, the machine frame is provided with the grout manufacturing system and the grout pumping system, grout manufacturing and grouting requirements can be met, the grout outlet of the grout manufacturing system is connected with the grout pumping system, and accordingly materials can be constantly supplied to the grouting trolley, the complicated disassembling and assembling processes of the grout manufacturing system and the grout pumping system are eliminated, and production efficiency is effectively improved.

Owner:重庆华式土木建筑技术开发有限公司

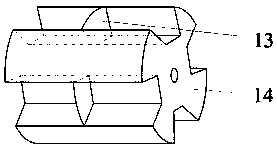

Continuous coating material conveying device for linear metal coating evaporation source

InactiveCN101845617ARealize uninterrupted feedingSimple system structureVacuum evaporation coatingSputtering coatingEvaporationEngineering

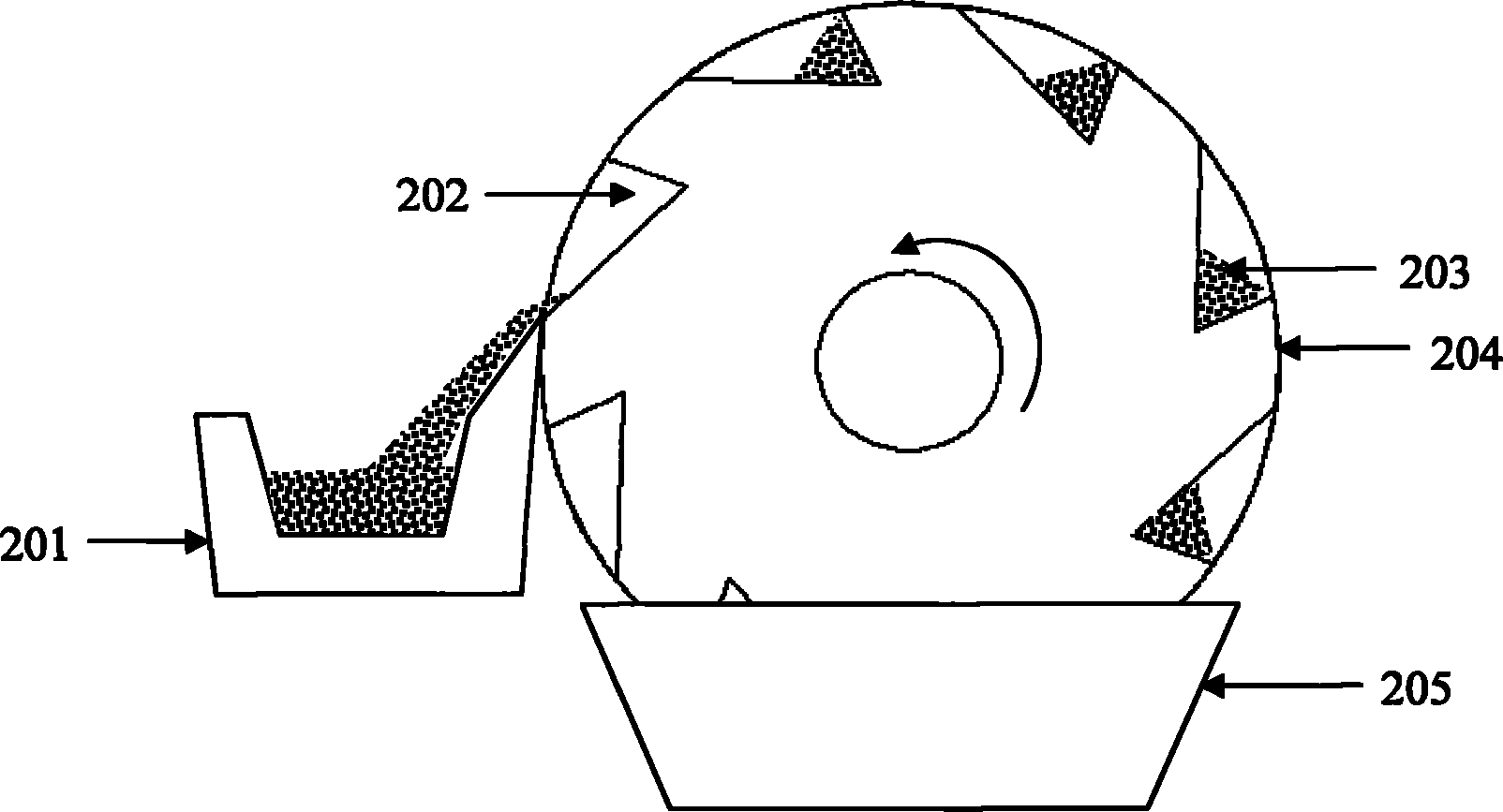

The invention discloses a continuous coating material conveying device for a linear metal coating evaporation source. The device is arranged between the linear evaporation source and a hopper which are arranged in parallel. The continuous coating material conveying device is characterized in that the continuous coating material conveying device is a cylindrical feed roller which rotates around a central shaft, and a plurality of linear grooves are circumferentially distributed on the surface of the feed roller, wherein the toppling heights of the grooves of the feed roller are positioned above the linear heat evaporation source. The device of the invention can realize uninterrupted feed for the linear evaporation source, reduces a heat evaporation coating space, and is favorable for improving the vacuum and cleanness of an evaporation area. Moreover, the device replaces a plurality of evaporation sources in an array by using the single linear evaporation source so as to greatly simplify a system mechanism of the evaporation source at the same time of ensuring continuous and uniform deposition of a large-area base material.

Owner:崔铮

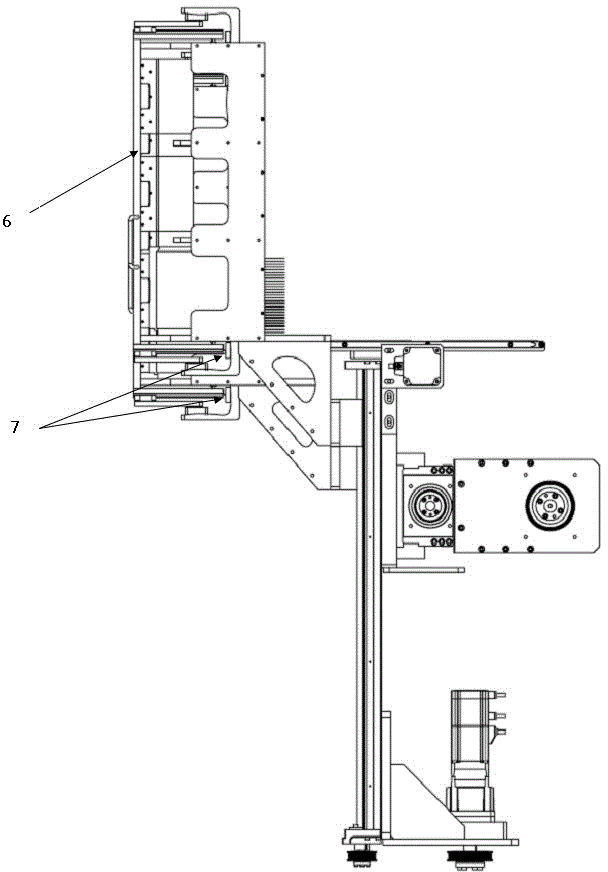

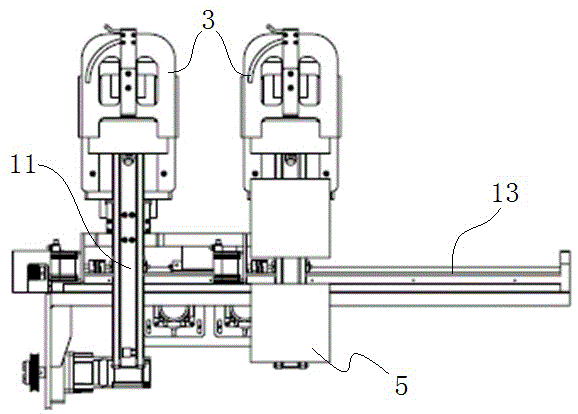

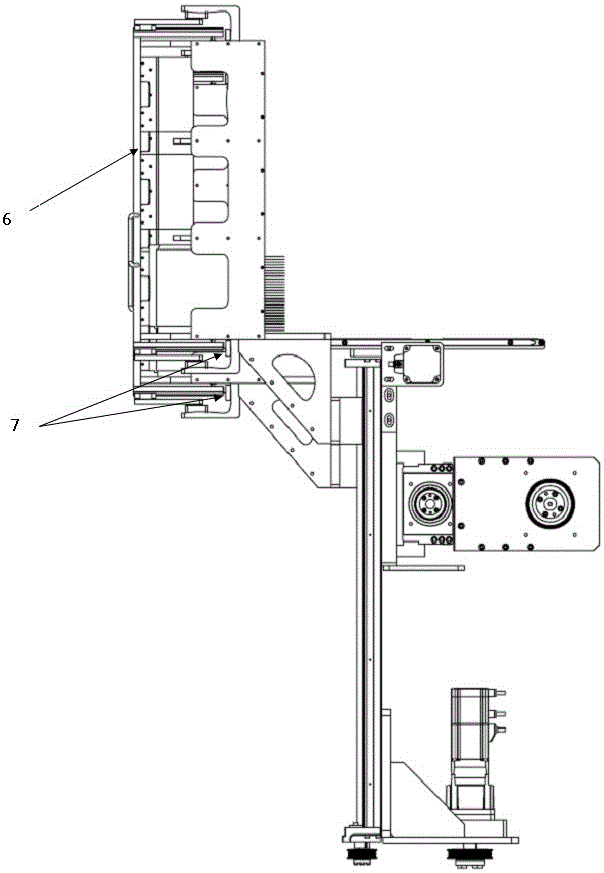

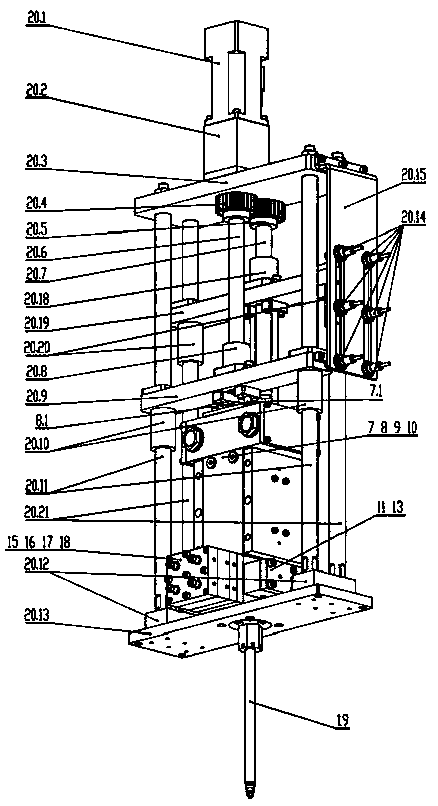

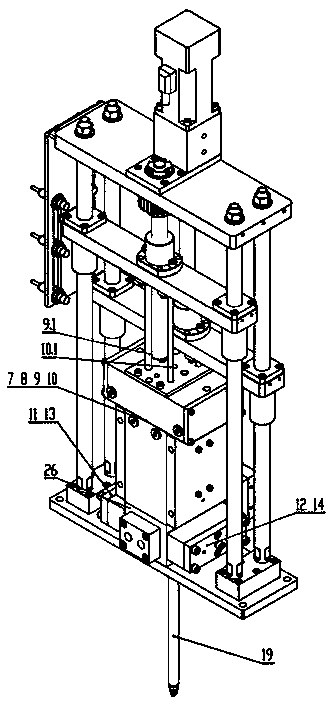

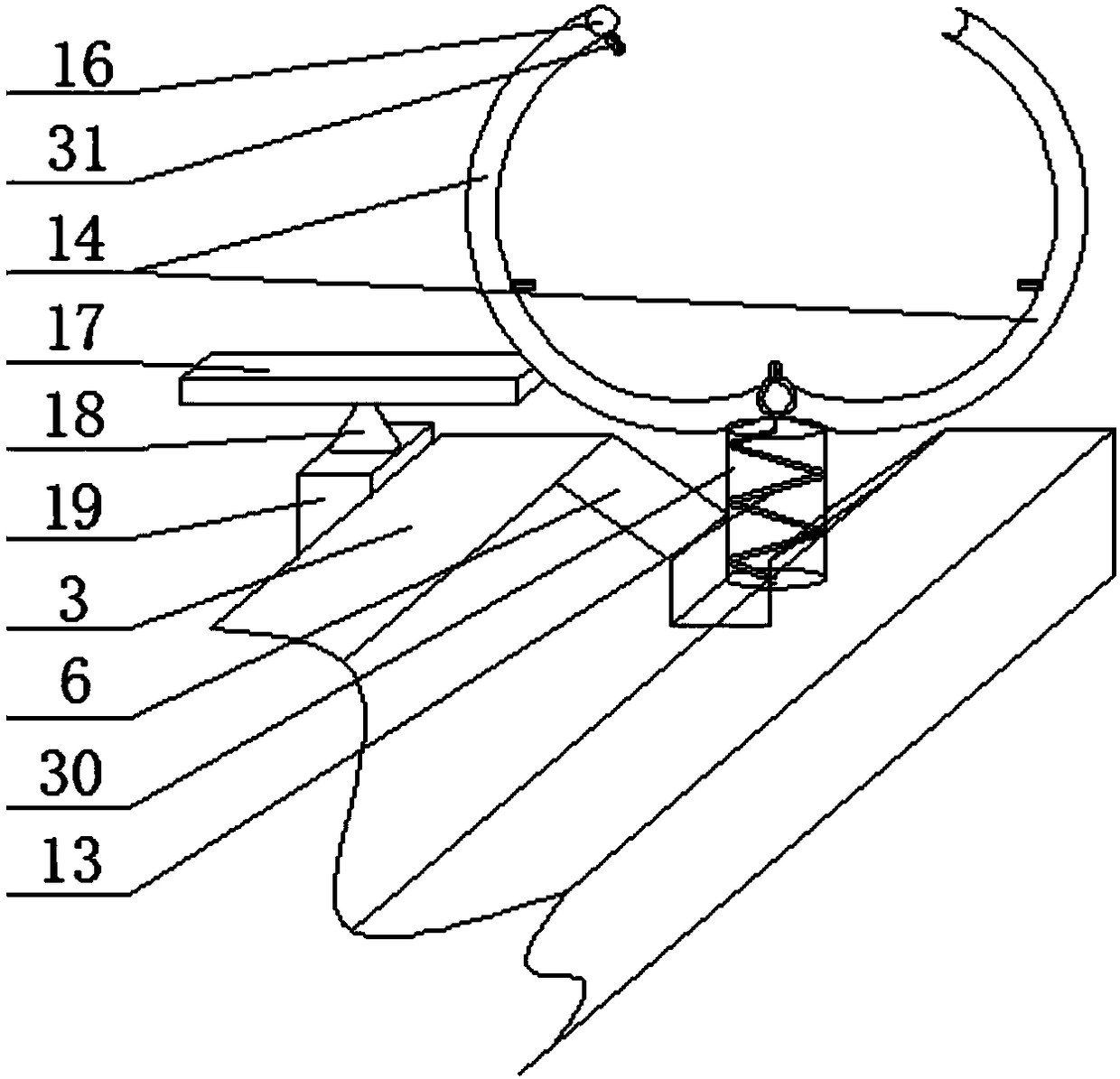

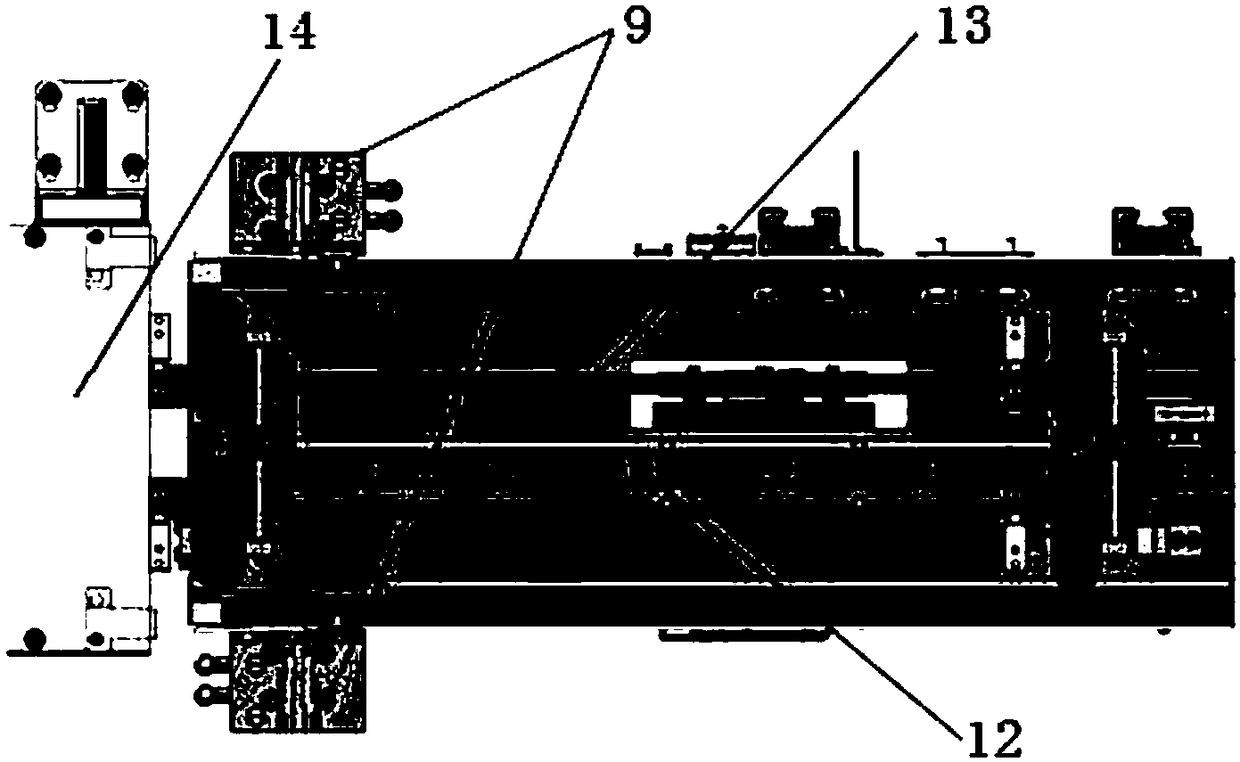

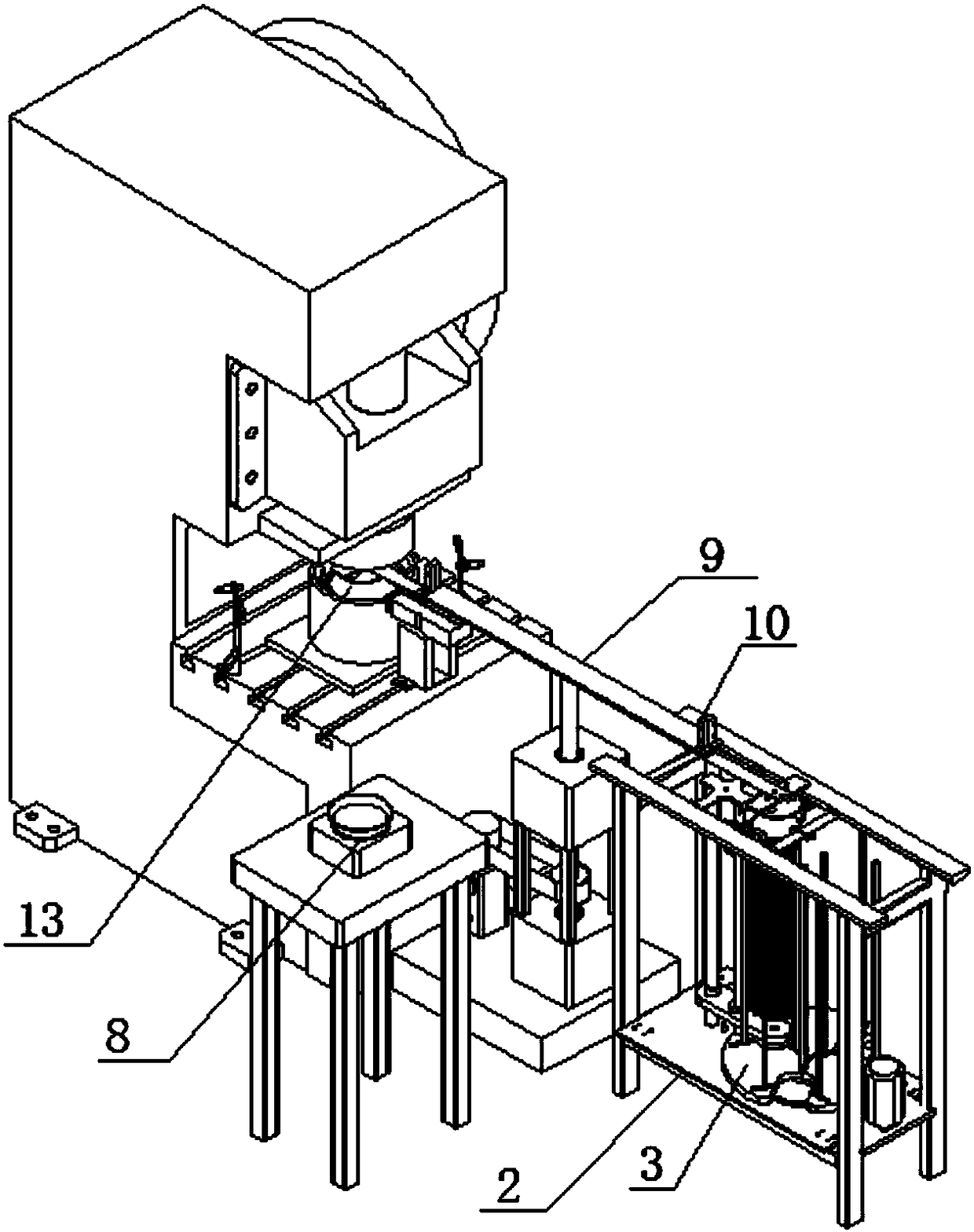

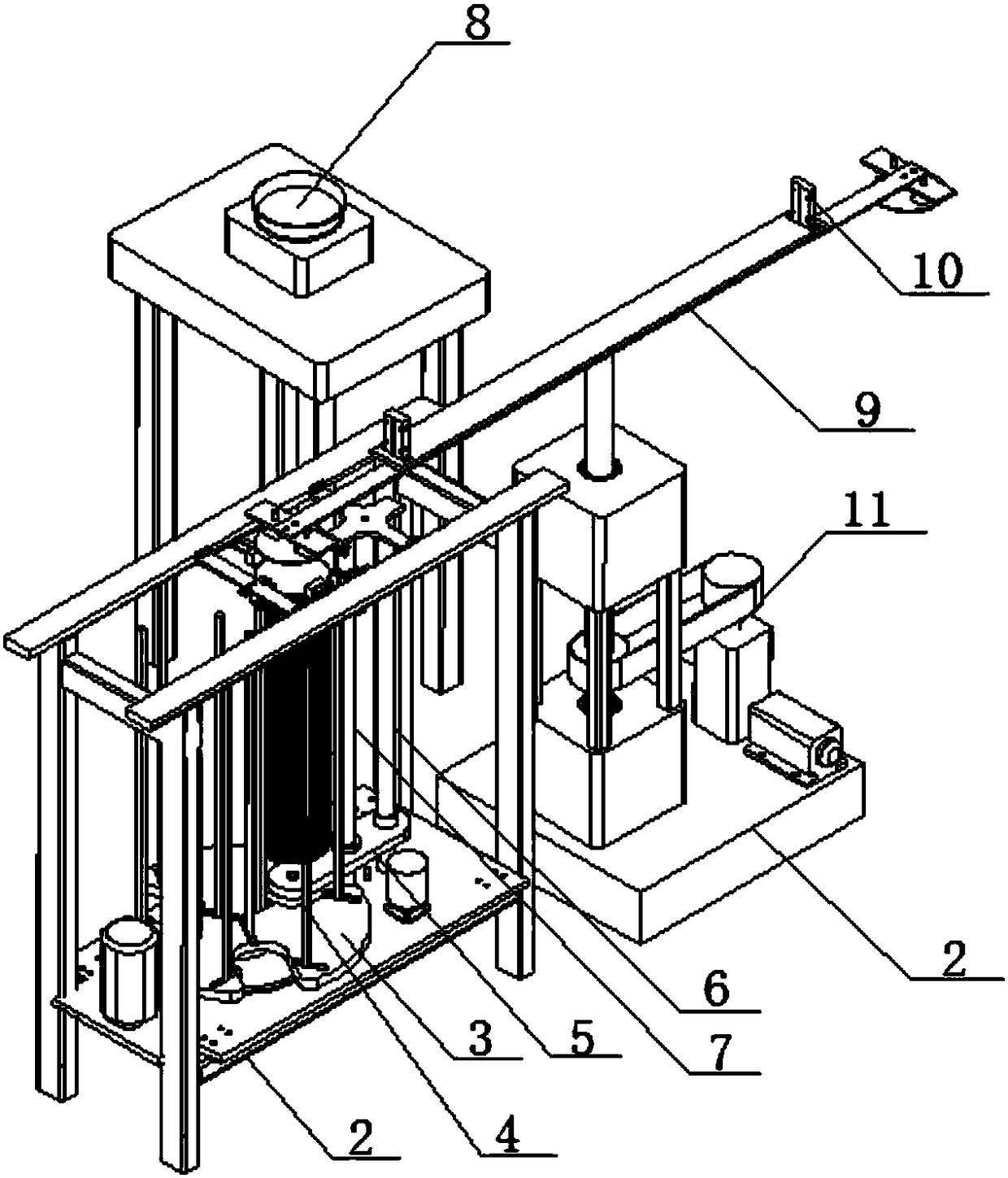

Accurate and continuous feeding device for punching of clutch coil housing

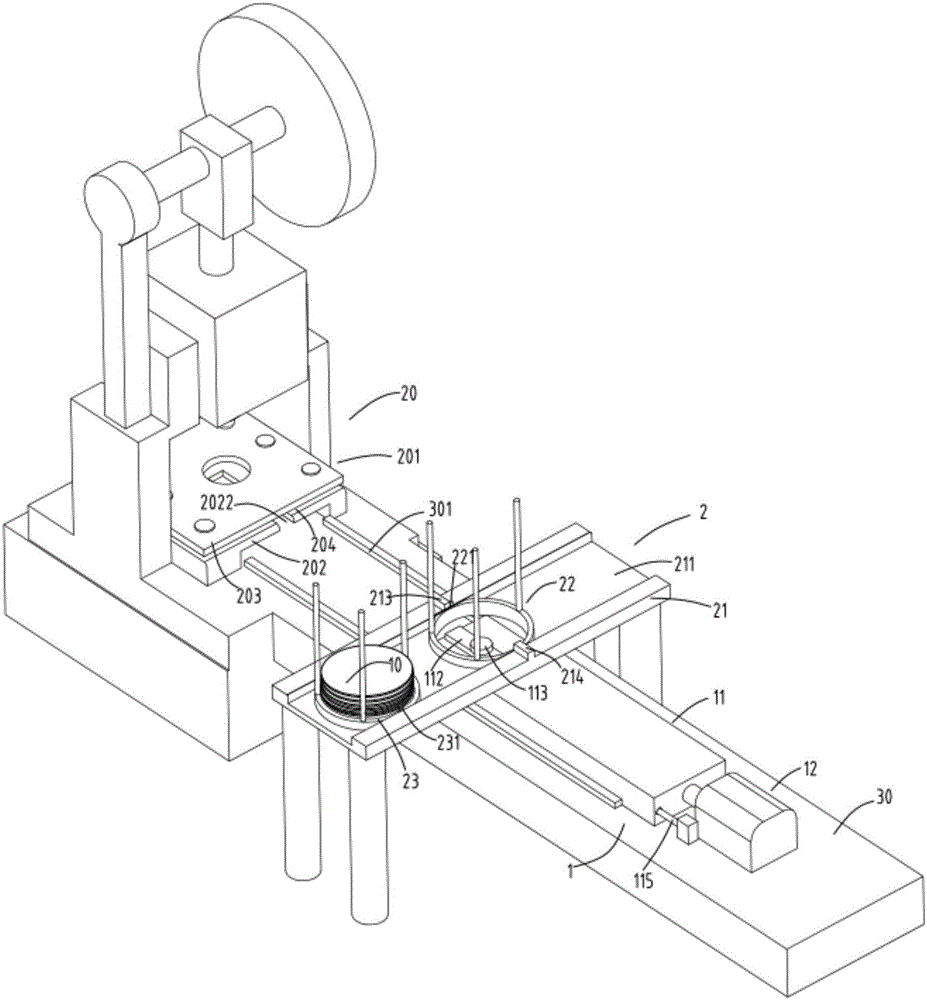

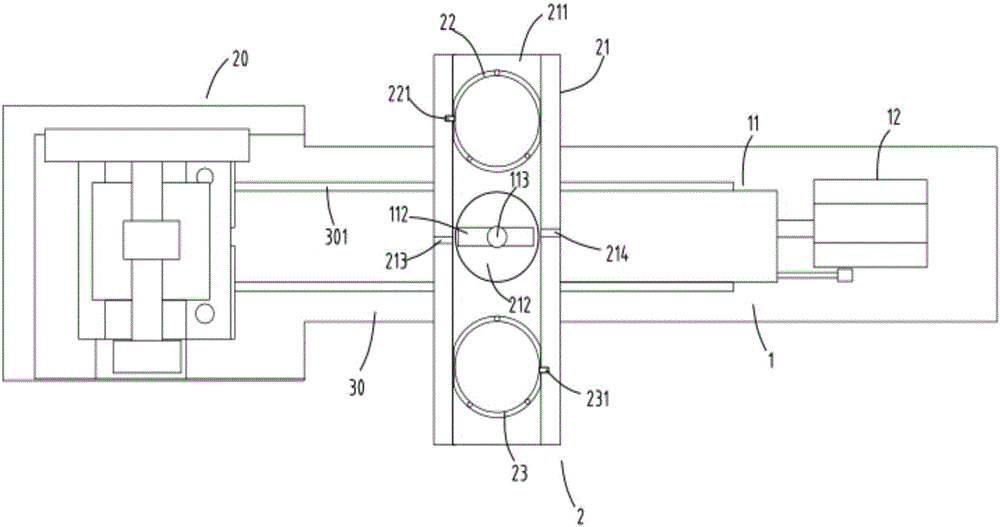

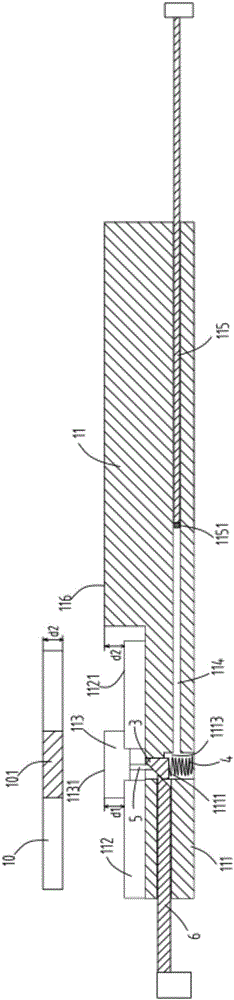

ActiveCN106424408AFully automatedIncrease productivityMetal-working feeding devicesPositioning devicesPunch pressEngineering

The invention relates to an accurate and continuous feeding device for punching of a clutch coil housing. The device comprises a conveying device for conveying a raw steel plate to a stamping station of a punching machine, and a supplying device for supplying materials to the conveying device, wherein the conveying device comprises a bearing body which is arranged on a working platform, and a pushing-pulling device for pushing the bearing body to reciprocate along a guide rail on the working platform; steps are arranged at one end, close to the punching machine, of the bearing body, and a supporting plate is arranged on the steps; a clamping head of which the diameter is in match with the diameter of a central hole of the raw steel plate is arranged on the supporting plate; the supplying device, comprising a supporting plate, a material rack a and a material rack b, is arranged above the clamping head; a chute b in match with the material rack a and the material rack b is formed in the supporting plate; a blanking hole is formed in the supporting plate. With the adoption of the accurate and continuous feeding device for the punching of the clutch coil housing, the problems in the prior art, such as low efficiency of manual charging during punching, waste of manpower, potential risk, and failure of continuous supplying of some automatic conveying devices, can be solved.

Owner:浙江瑞虹机电股份有限公司

Flaky material stacking and conveying device

InactiveCN104376639AImprove feeding efficiency and sorting efficiencyDoes not affect the feeding workCoin/paper handlersMechanical engineeringEngineering

Owner:ZHONG CHAO GREAT WALL FINANCIAL EQUIP HLDGCO +1

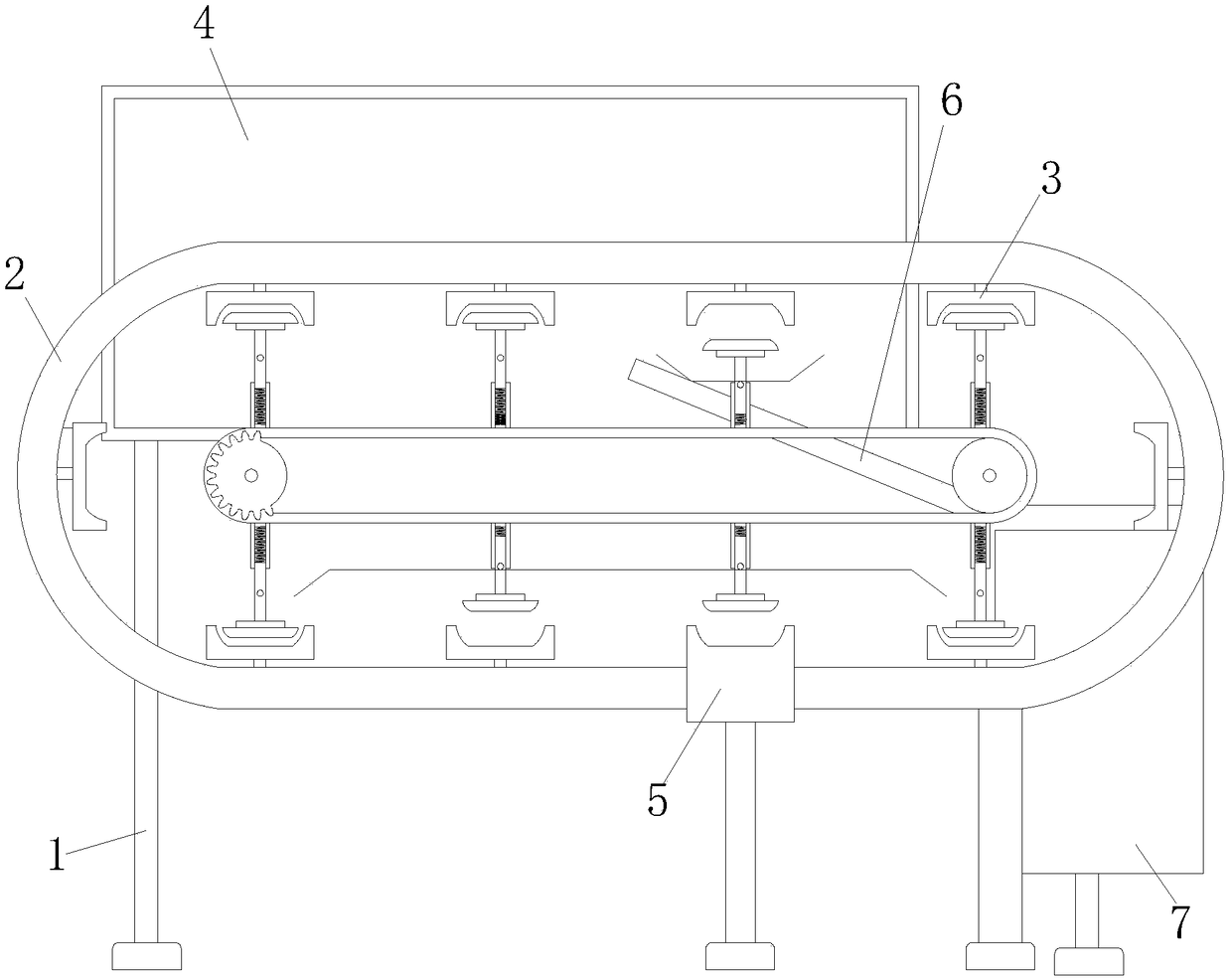

Agricultural rice threshing device with automatic feeding function

The invention discloses an agricultural rice threshing device with an automatic feeding function. The device comprises a rack, an arc outer frame is installed on the rack, rice clamping assemblies isinstalled in the arc outer frame, and a rice threshing assembly is installed at one side of the arc outer frame; a feeding assembly is installed at the side, away from the rice threshing assembly, ofthe arc outer frame, and matched with the rice clamping assemblies to complete uninterrupted feeding of rice, an inclined slide plate is installed between the rice threshing assembly and the arc outerframe, and a rice straw collecting box is connected to the lower portion of the inclined slide plate. According to the device, rice straw is automatically clamped and separated, and the situation that the rice straw is manually held for threshing operation is avoided; through the arrangement of a driving gear and a conveying wheel, the working time difference exists between the feeding assembly and the rice clamping assemblies, uninterrupted feeding of the rice is achieved, uninterrupted running of a driving motor and a conveying motor is achieved at the same time, the situation that the driving motor and the conveying motor are frequently started up and shut down is avoided, and the service life of the driving motor and the conveying motor is prolonged.

Owner:JIXI YUANDAO AGRI IND TECH

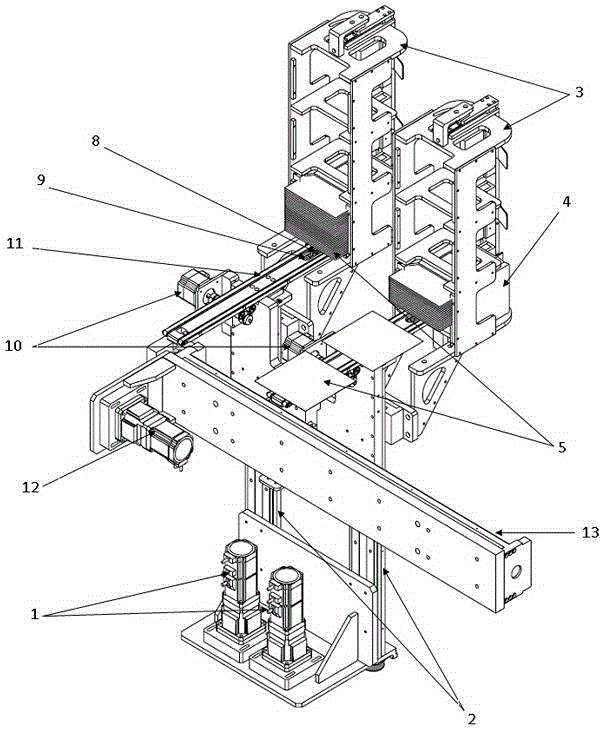

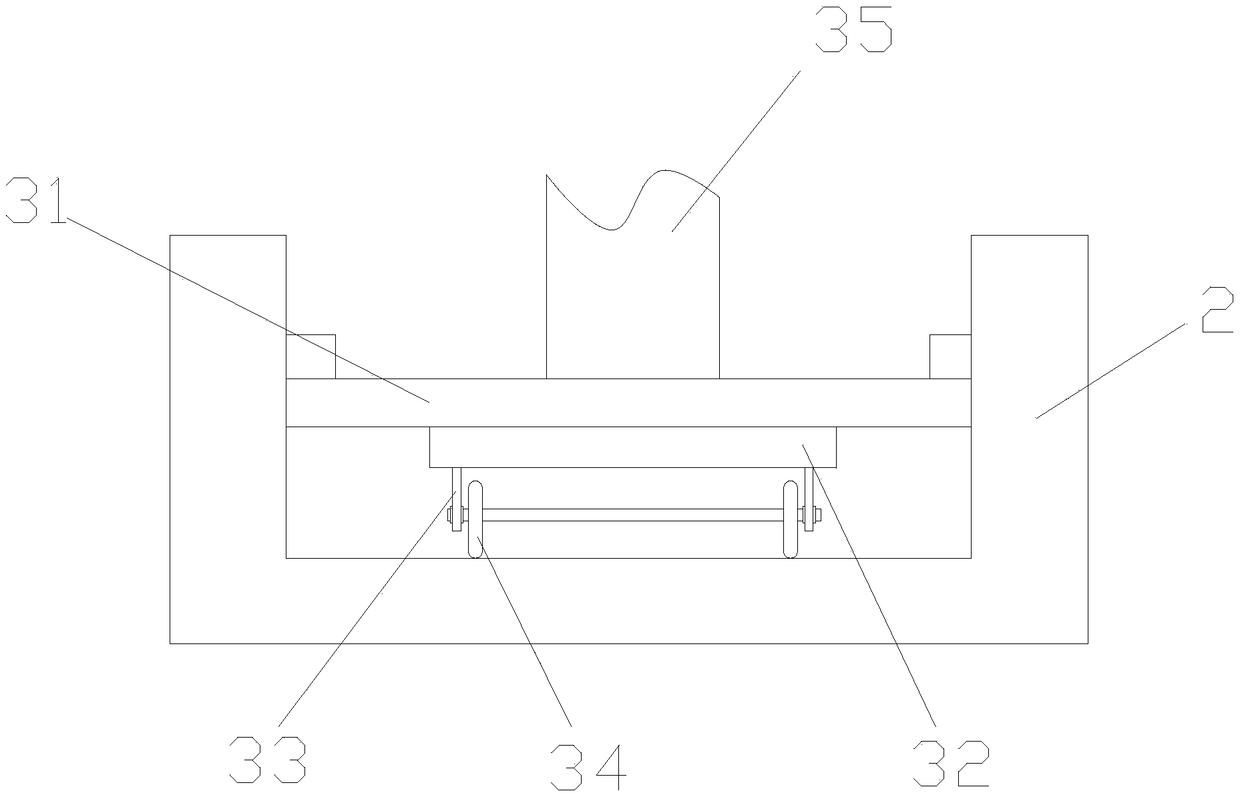

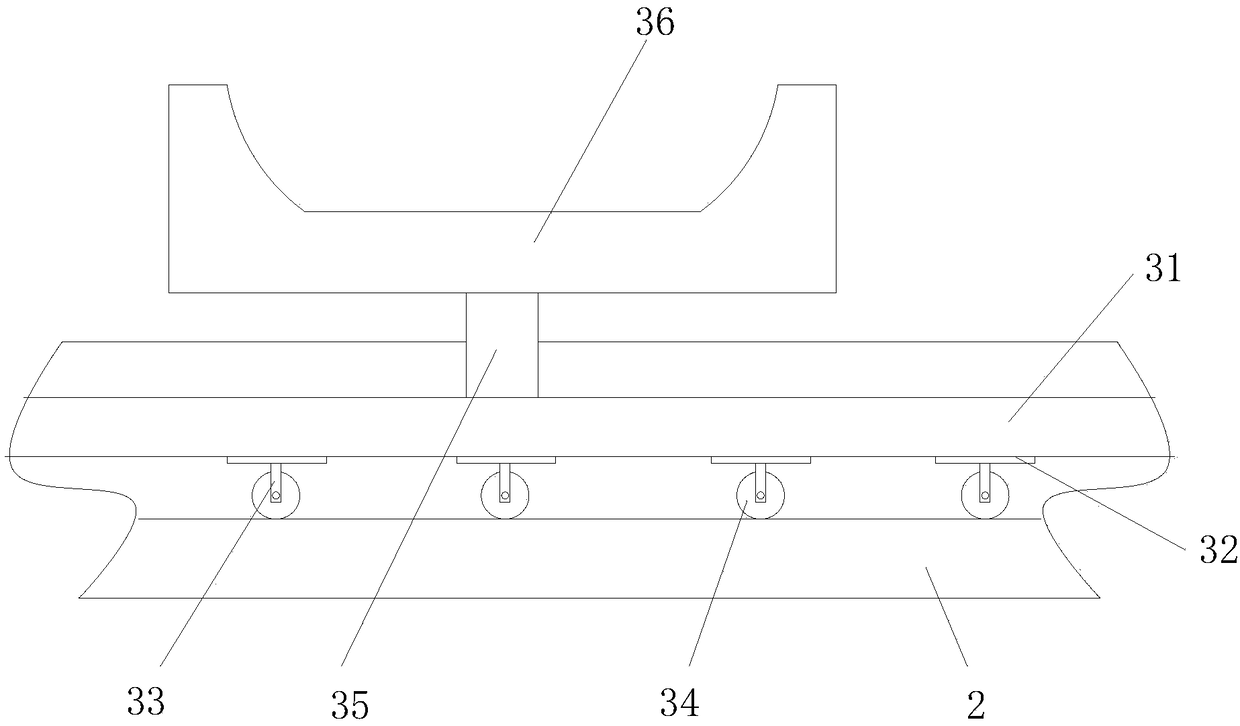

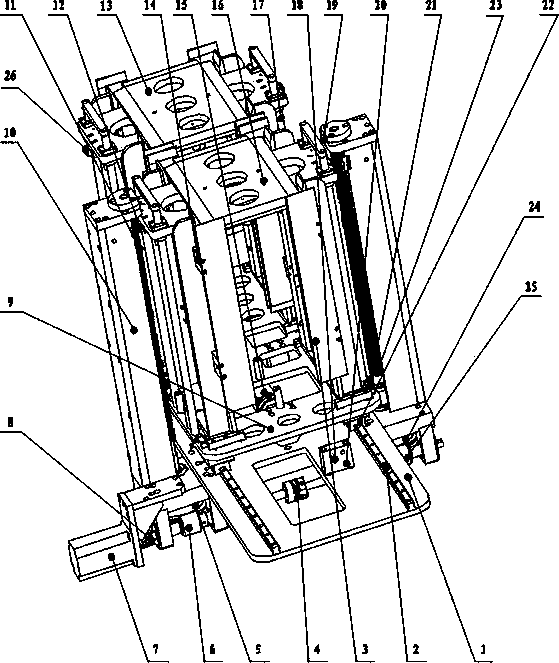

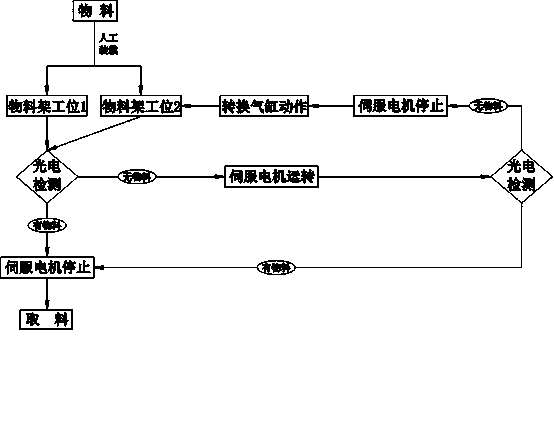

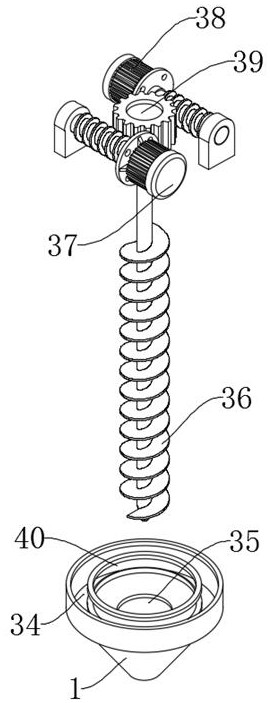

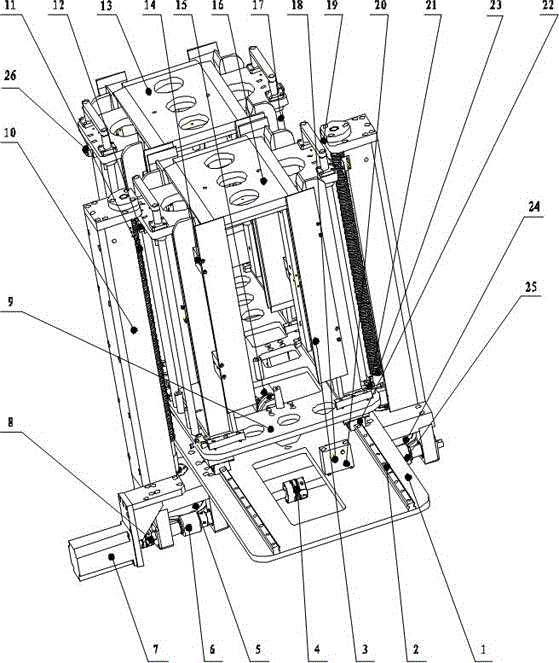

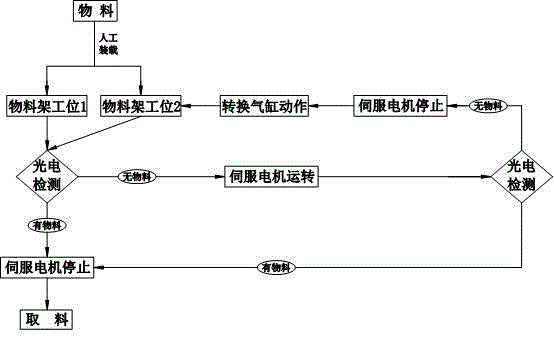

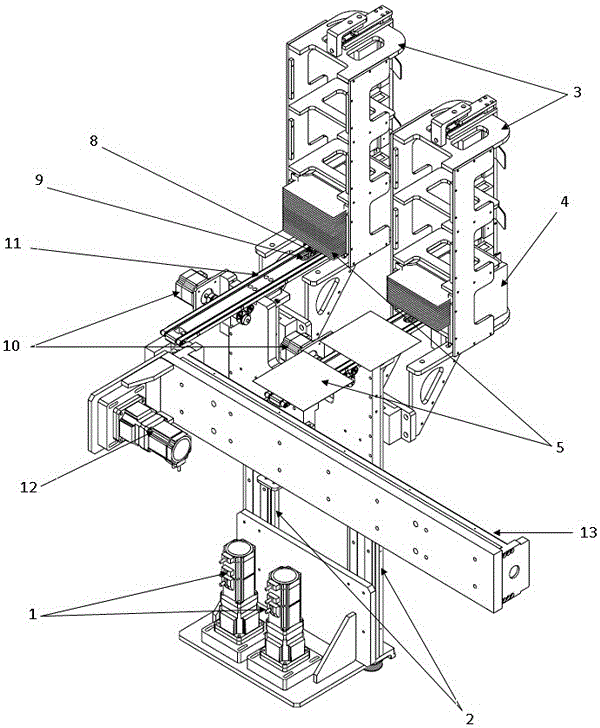

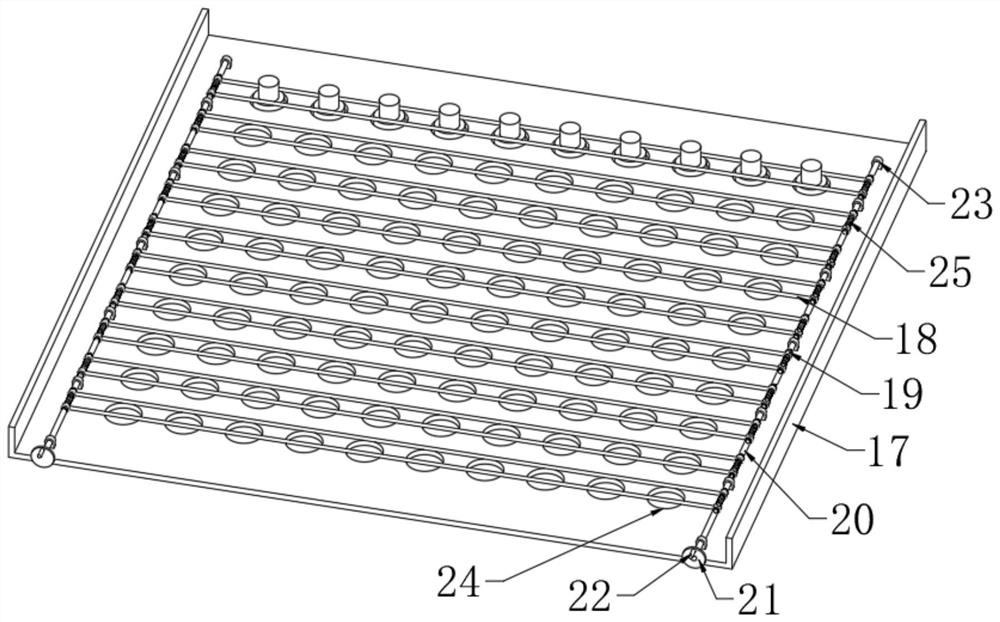

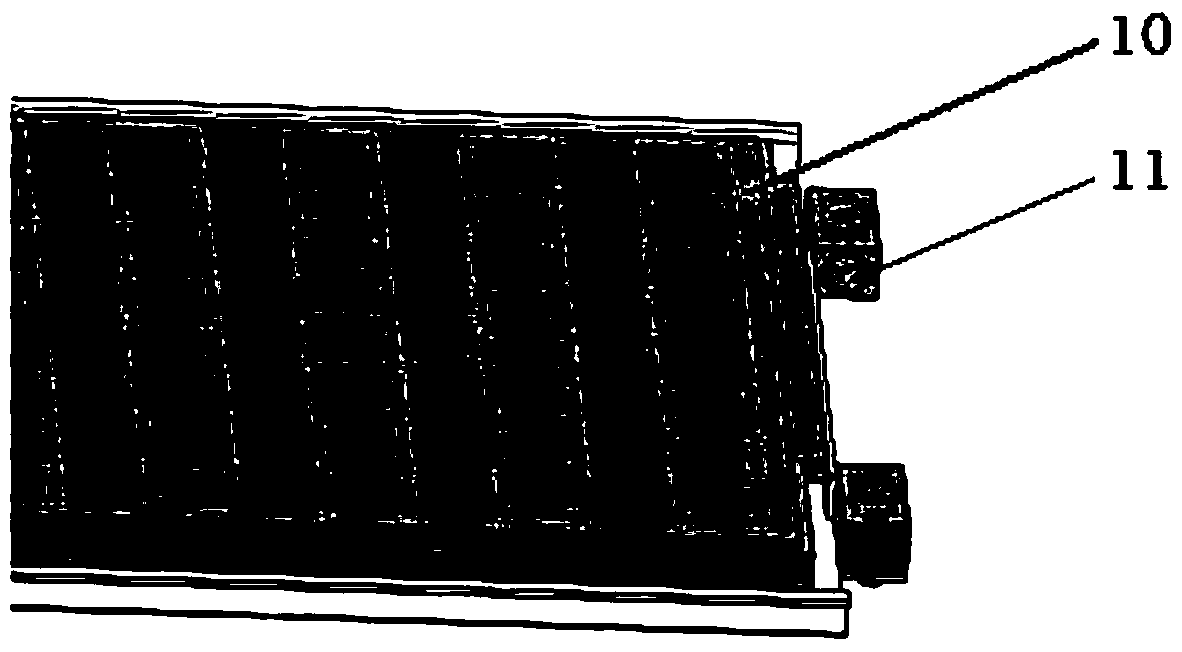

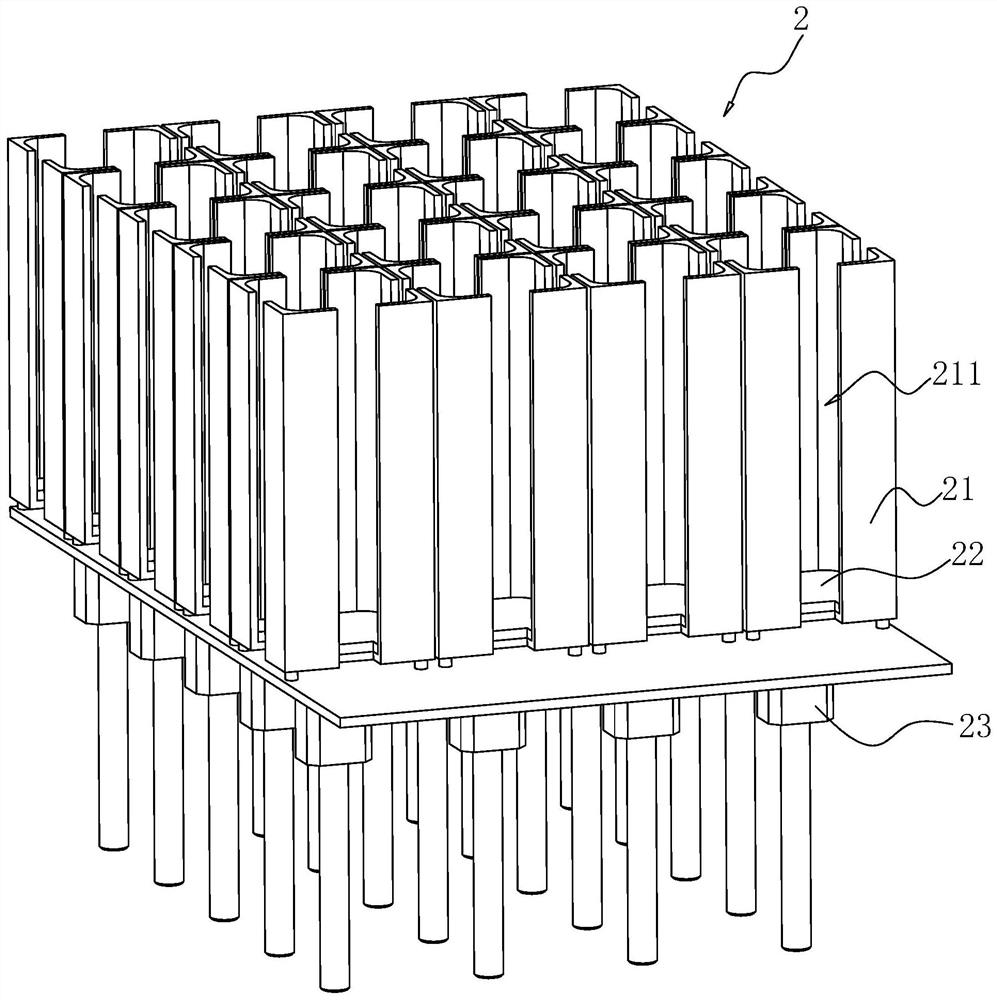

Automatic feeding material frame

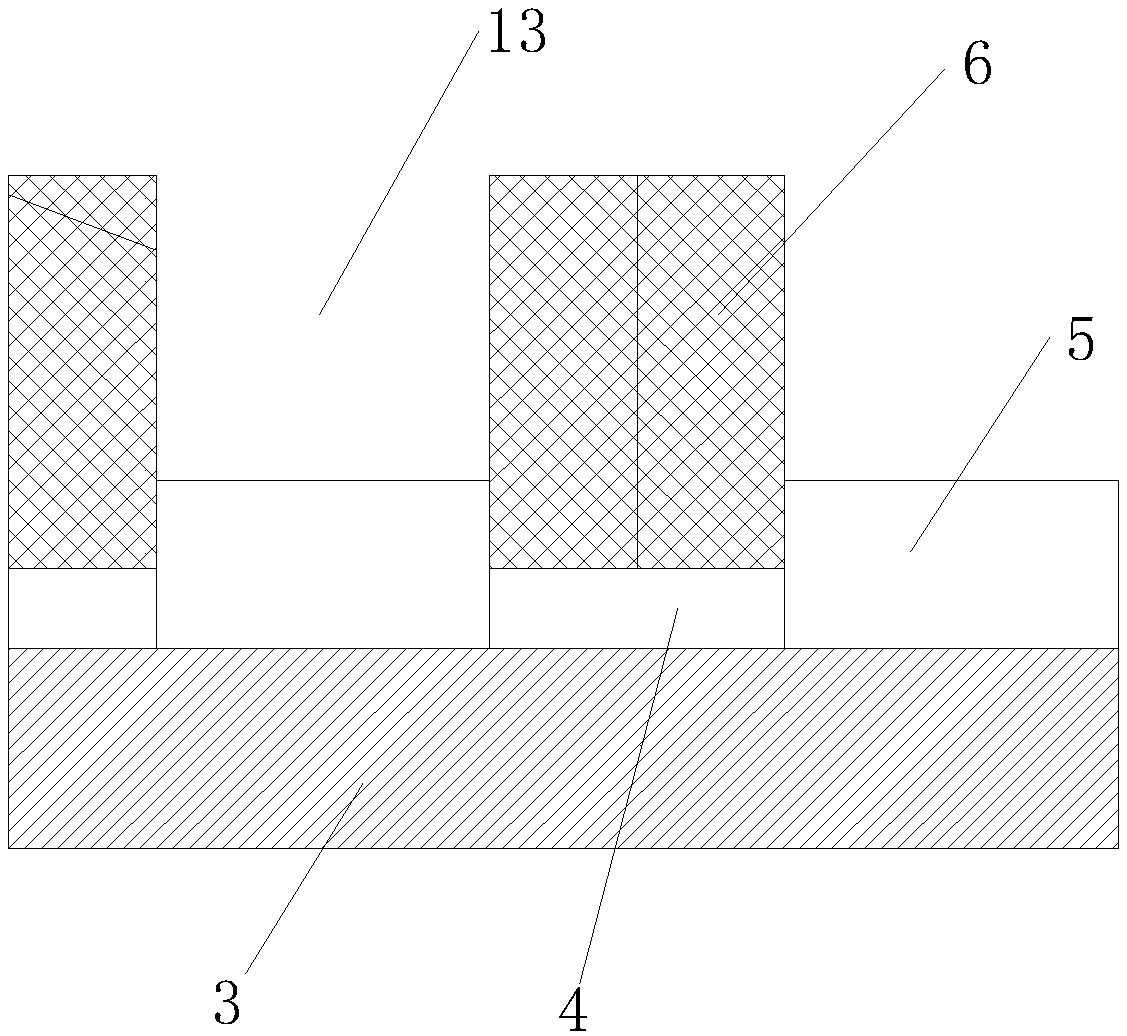

ActiveCN103964228AImprove machine efficiencyMaintain normal operationArticle separationWorm driveServo

The invention provides an automatic feeding material frame which comprises a supporting bottom plate, a screw rod supporting frame, a bearing plate, a material positioning connecting plate, a first material bottom plate, a second material bottom plate, guide columns, a servo motor, worms, worm gears, screw rods and nut pairs. The screw rod supporting frame is used for fixing the screw rods in the axis direction and is perpendicular to the supporting bottom plate, and the screw rods are arranged on the inner sides of two arms of the supporting frame respectively. A station converting cylinder is arranged on the lower portion of the bearing plate, and the guide columns are arranged on the left side and the right side of the first material bottom plate and the left side and the right side of the second material bottom plate and are respectively and fixedly connected with the bearing plate. The first material bottom plate, the second material bottom plate and half nuts are connected to be used as the nut pairs and can move up and down along the guide columns. The shaft heads of the screw rods are connected with the worm gears, and the servo motor is arranged on the lower portion of the supporting bottom plate and is connected with the worms through couplers. According to the automatic feeding material frame, the screw rods are controlled to rotate through transmission of the servo motor, the worm gears and the worms, the corresponding nut pairs gradually ascend or descend along with rotating of the screw rods, automatic and precise feeding can be achieved, two material bottom plates are provided, when materials on one bottom plate are run out, the second bottom plate is used for supplementing materials quickly, continuous material feeding is achieved, and the production efficiency is improved.

Owner:星光印刷(苏州)有限公司

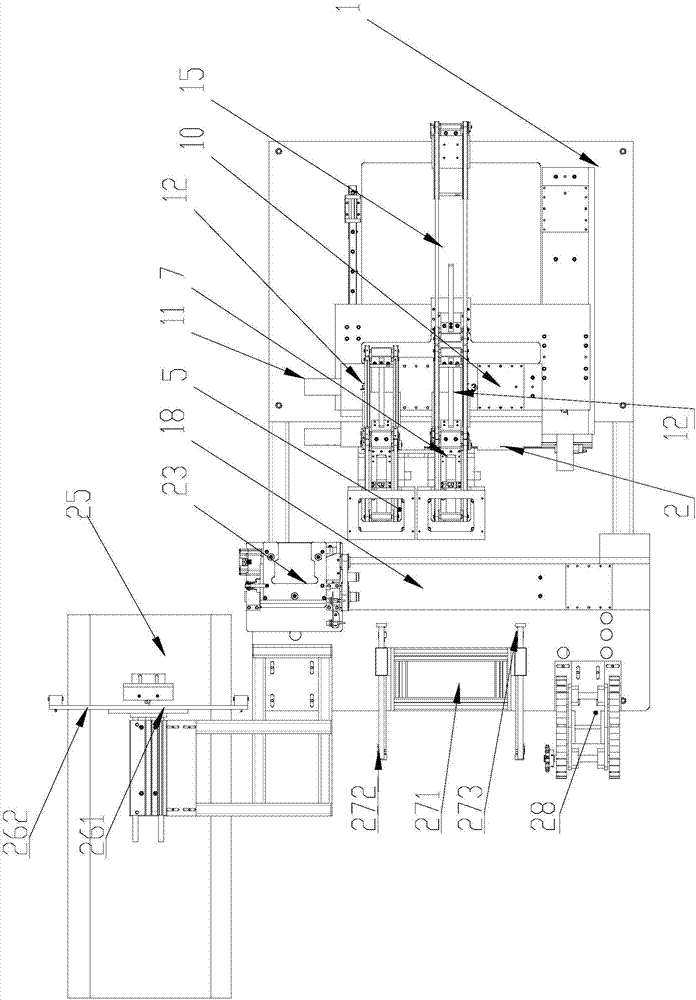

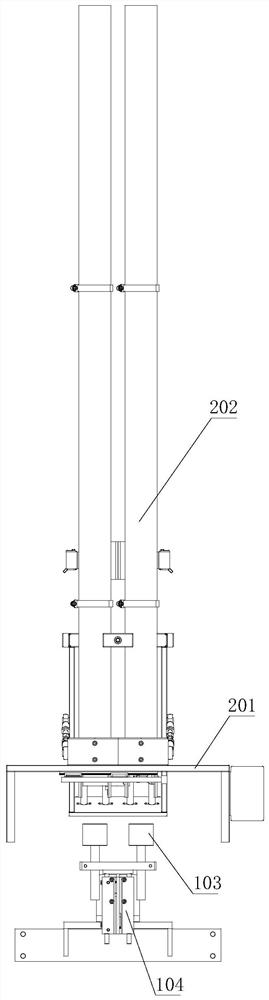

Automatic silicon wafer feeding equipment

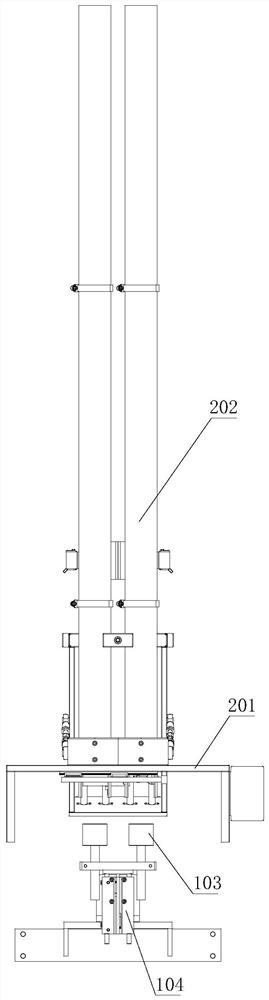

PendingCN106882585AGuaranteed supplyRealize uninterrupted feedingConveyorsConveyor partsStructural engineeringSilicon chip

The invention discloses automatic silicon wafer feeding equipment achieving unintermittent feeding. The automatic silicon wafer feeding equipment comprises a rack. A first sliding base and a first sliding driving device are arranged on the rack. Two lifting tables and two servo lifting driving mechanisms are arranged on the first sliding base. Material storage frames are arranged on the lifting tables. Two material guiding belt mechanisms are arranged on the first sliding base. A transition bottom plate which moves in the direction perpendicular to the sliding direction of the first sliding base and a transition driving device are arranged on the rack. A second sliding base and a second sliding driving device are arranged on the transition bottom plate. Two material conveying belt mechanisms are erected between the second sliding base and the first sliding base. A wafer conveying backstand is arranged on the transition bottom plate. A wafer discharging belt mechanism is erected between the transition bottom plate and the rack. A wafer outlet backstand is arranged on the transition bottom plate. The first sliding base and the second sliding base move synchronously to enable the two material conveying belt mechanisms to be in butt joint with the wafer discharging belt mechanism.

Owner:苏州卓樱自动化设备有限公司

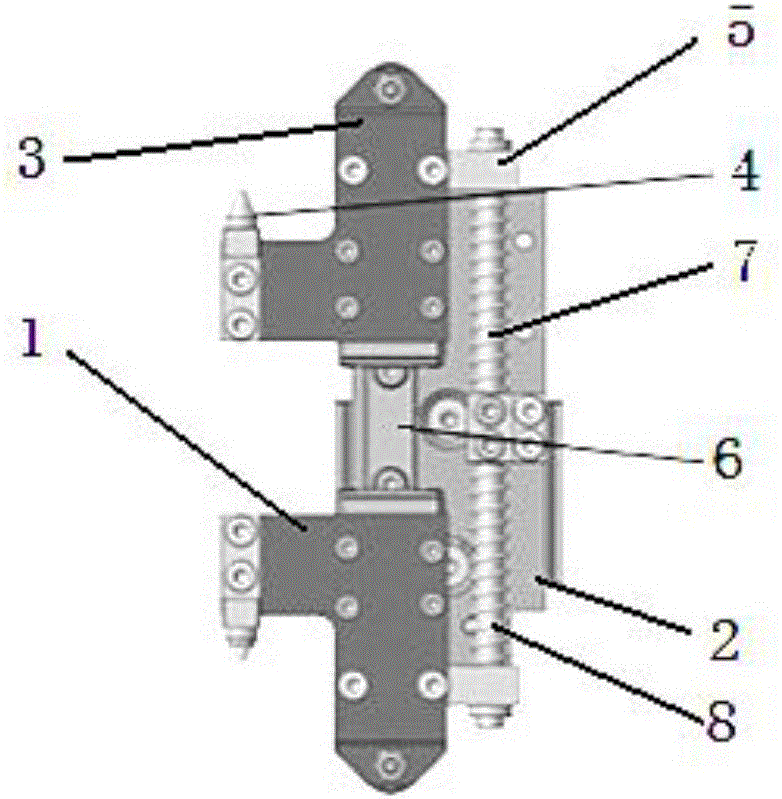

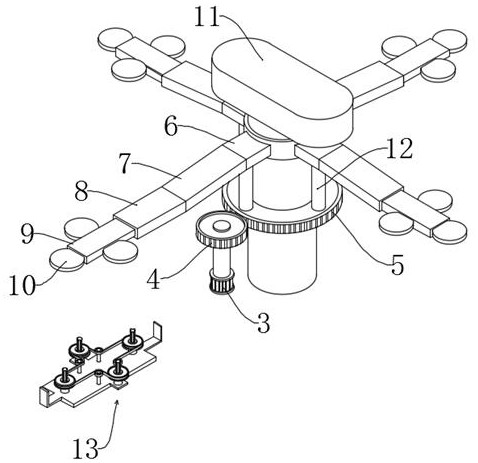

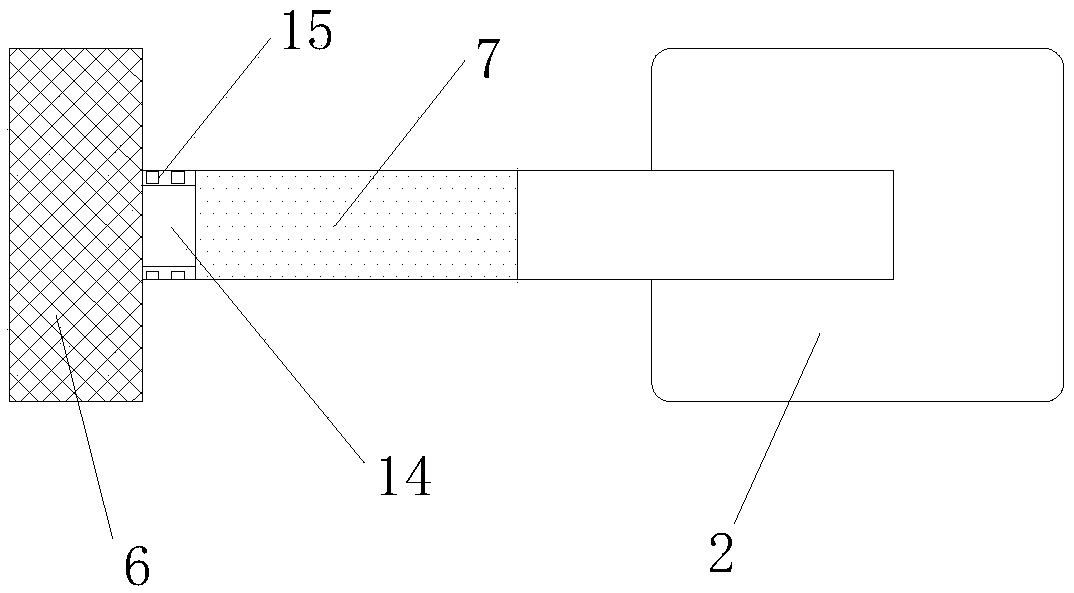

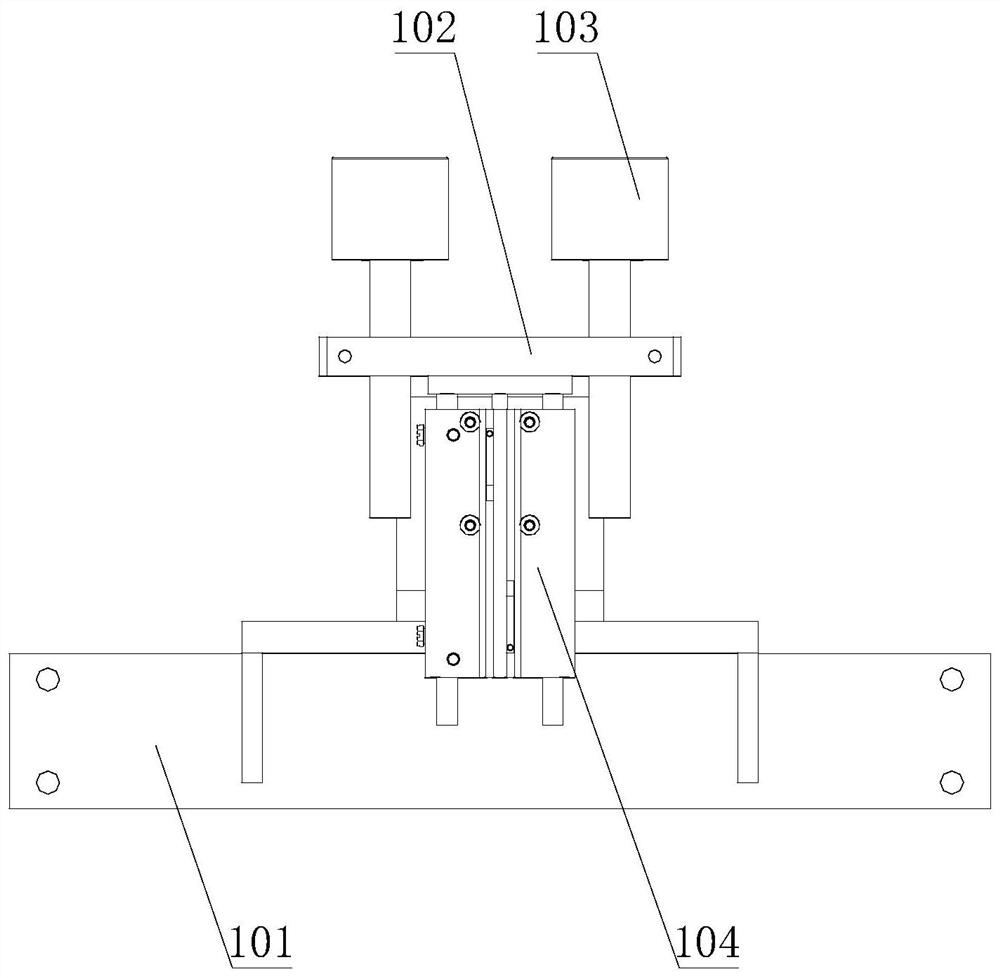

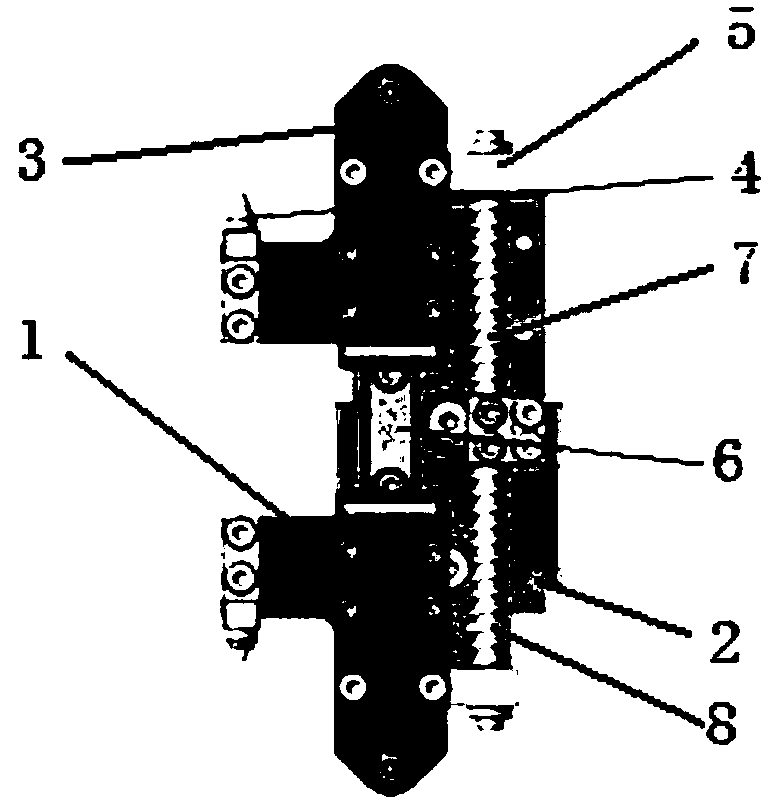

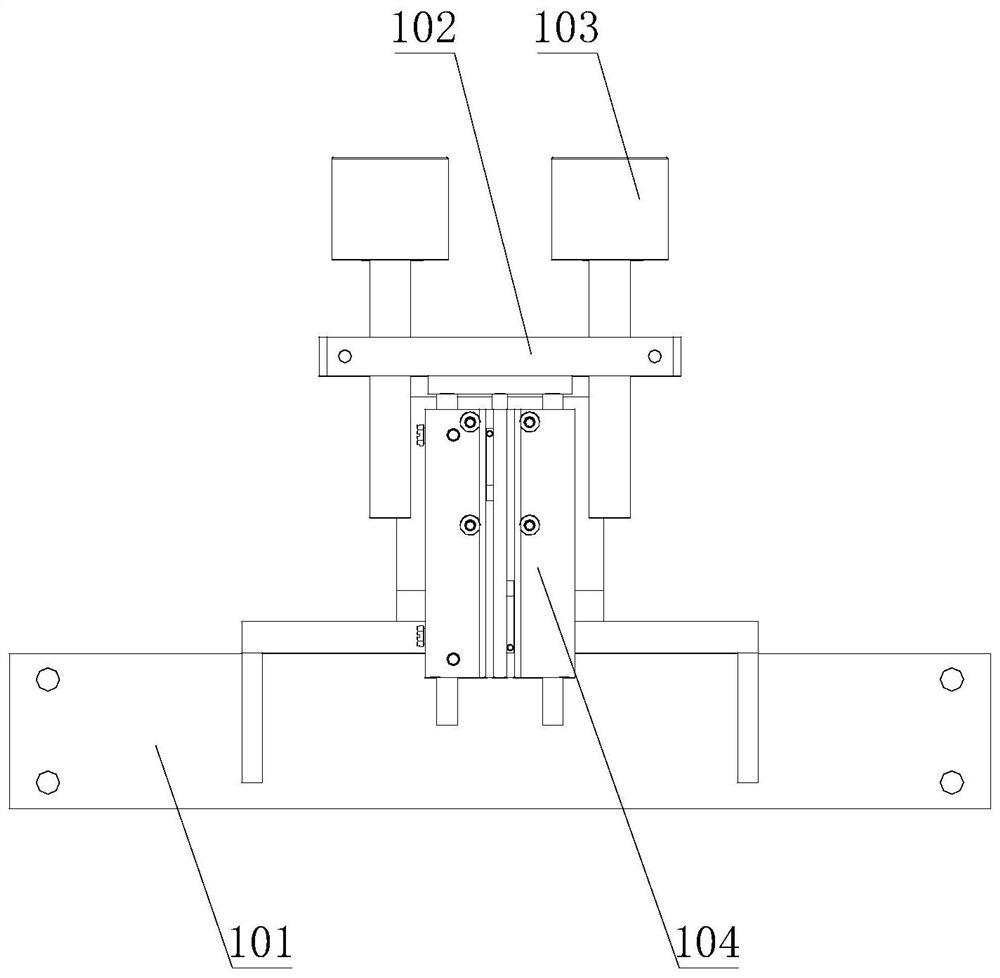

Chip mounter material feeder material disc catching mechanism

The invention relates to the mechanical technical field of chip mounters and provides a chip mounter material feeder material disc catching mechanism comprising a pair of clamping jaws and a pedestal. Each clamping jaw comprises a slide block, a positioning pin, and a slide sleeve, wherein the positioning pin and the slide sleeve are fixed to the slide block. The pedestal is equipped with two clamping jaw guide rails, two guide pillars, and two clamping springs. The two clamping jaw guide rails are arranged end to end. The two guide pillars are arranged end to end. The two clamping springs are arranged end to end. When the pedestal and the pair of clamping jaws are combined, the slide blocks and the clamping jaw guide rails cooperate, the slide sleeves and the guide pillars cooperate, and the clamping springs sleeve the guide pillars and are compacted so that the pair of clamping jaws get close to each other or are separated. The chip mounter material feeder material disc catching mechanism is simple in structure, low in cost and convenient to operate, may achieve accurate positioning and automatic material disc catching, and uninterrupted material feeding.

Owner:JIANGSU TORSUNG M&E

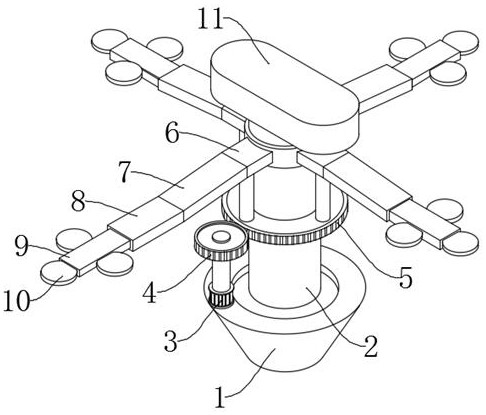

Marine organism bait feeding device

ActiveCN111758643AWide rangeEnsure balanceClimate change adaptationPisciculture and aquariaDrive wheelFishery

The invention discloses a marine organism bait feeding device, and belongs to the technical field of marine organism protection. The marine organism bait feeding device comprises a feeding box and a feeding pipe, the lower end of the feeding pipe penetrates through and is fixedly connected to the center of the upper end of the feeding box, the upper end of the feeding pipe is fixedly connected toa transmission box, the outer wall of the center of the feeding pipe is rotationally connected to a driven wheel disc, the outer side of the driven wheel disc is in engaged connection with a driving wheel, the lower end of the center of the driving wheel is fixedly connected to the upper end of an output shaft of a motor A, and the lower end of the motor A is fixedly connected to the upper wall face of the feeding box; and the upper wall face of the driven wheel disc is fixedly connected to four discharging pipes through connecting columns, four connecting columns and four discharging pipes are provided, and the tail ends of the four discharging pipes are rotationally connected to the side wall of the upper end of the feeding pipe through rotating pieces. The device solves the problem thatin the prior art, bait feeding devices cannot achieve the slow and uniform feeding function.

Owner:台州市拓基科技有限公司

Breeding method of arma chinensis

InactiveCN112385608ABreeding facilities are easily accessibleEasy accessAnimal husbandryBiotechnologyVermin

The invention relates to a breeding method of arma chinensis, and belongs to the technical field of insect breeding and biological pest control. According to the method, a time relation of growth anddevelopment of food-borne plants, prey insects and the arma chinensis is combined, the modern agricultural science and technology are adopted according to biology and ecology habits of the food-borneplants, the prey insects and the arma chinensis, coordinated development of the food-borne plants, the prey insects and the arma chinensis is achieved, manual operation is reduced as much as possible,and rolling feeding of the arma chinensis is achieved. The method has the advantages of being easy to operate, low in cost, high in survival rate, high in intensification degree, capable of facilitating large-scale breeding and easy to popularize.

Owner:云南省烟草公司大理州公司 +1

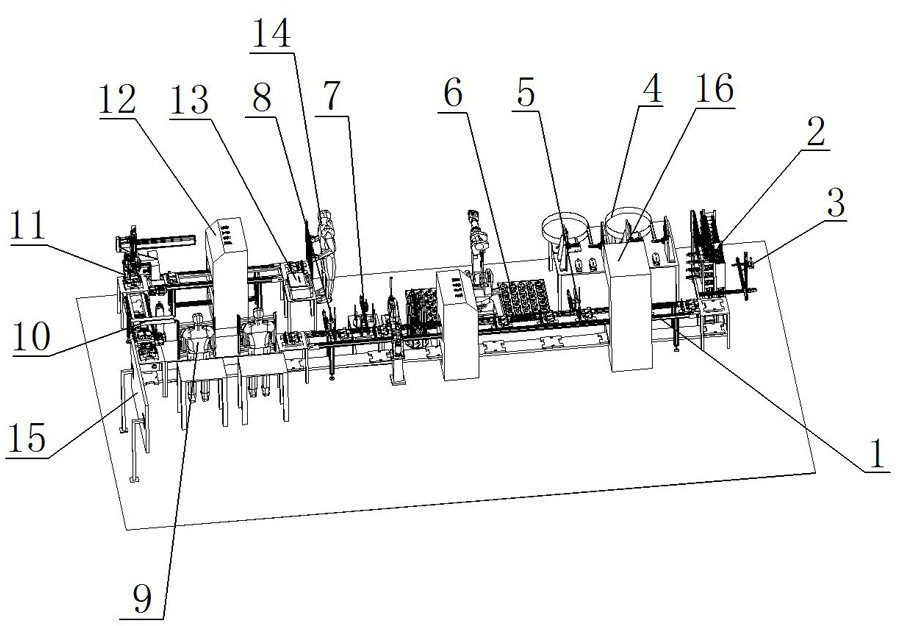

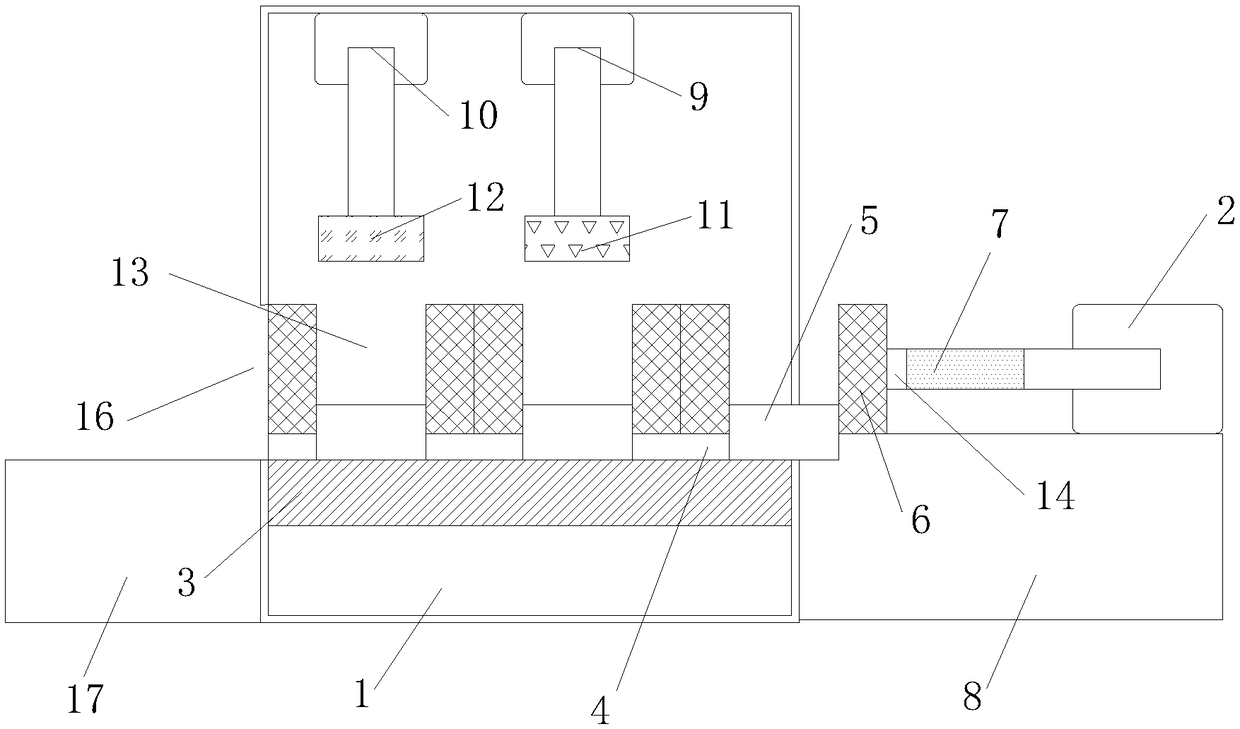

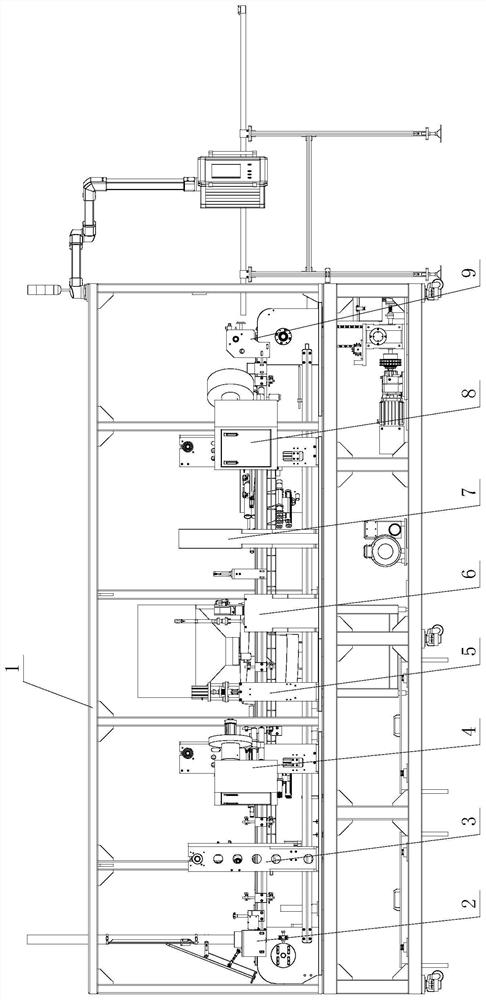

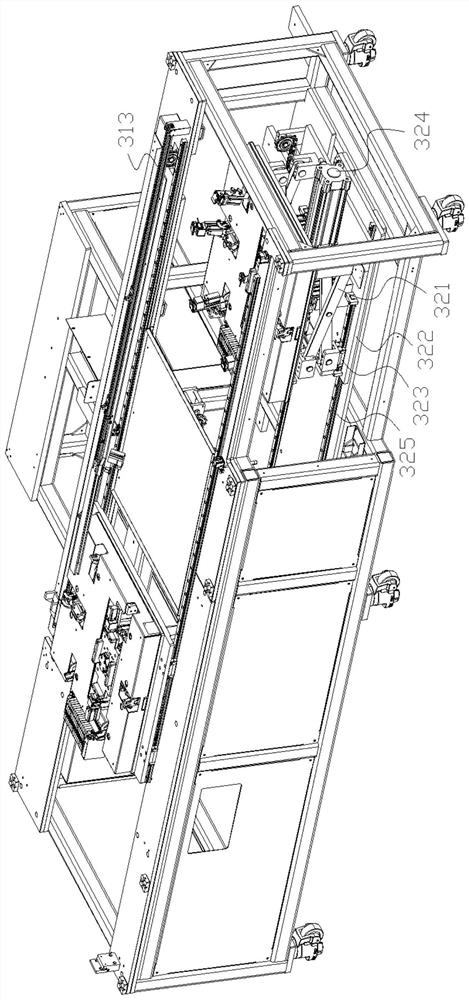

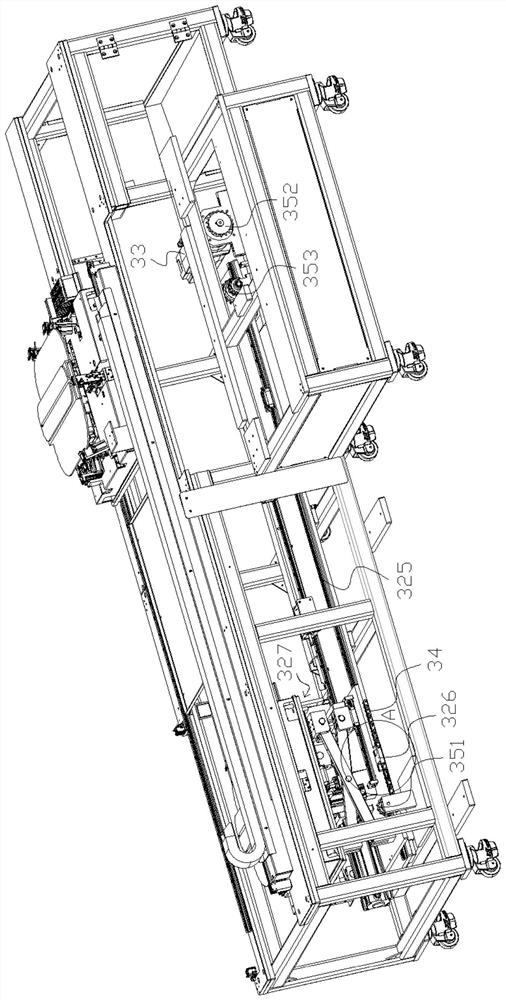

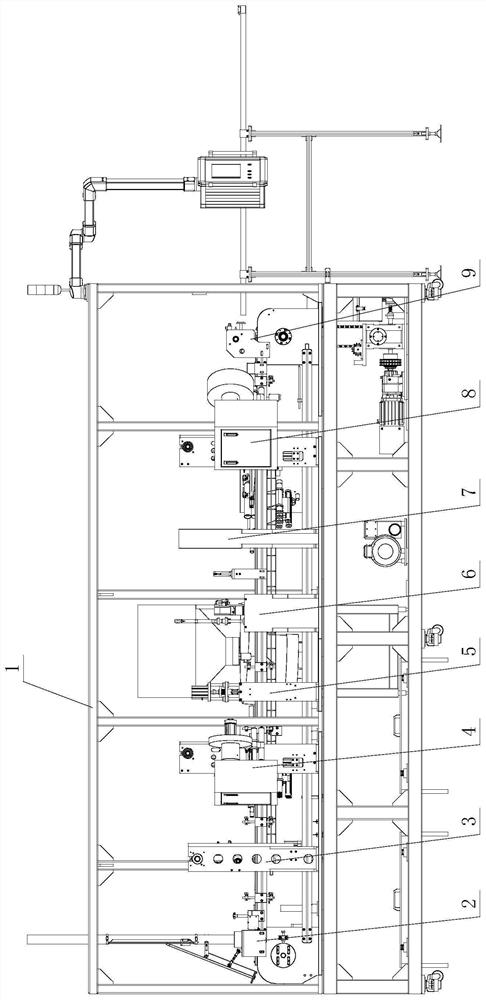

Automatic assembly production line for elevator brake calipers

InactiveCN113732699AGuaranteed installation accuracyLabor savingAssembly machinesMetal working apparatusProduction lineBrake

The invention discloses an automatic assembly production line for elevator brake calipers. The automatic assembly production line comprises a carrying disc conveying device, a brake plate storage mechanism, a brake plate carrying disc feeding mechanism, a disc spring automatic combination mechanism, a first disc spring height measurement mechanism, a shell feeding and shell size automatic measurement mechanism, an adjusting gasket and space ring supply mechanism, a second disc spring height measuring mechanism and a manual final assembly station, wherein the brake plate storage mechanism, the brake plate carrying disc feeding mechanism, the disc spring automatic combination mechanism, the first disc spring height measurement mechanism, the shell feeding and shell size automatic measurement mechanism, the adjusting gasket and space ring supply mechanism, the second disc spring height measuring mechanism and the manual final assembly station are sequentially arranged in the conveying direction of the carrying disc conveying device. According to the automatic assembly production line, the automatic assembly production of the elevator brake calipers is realized, the product circulation process is automatically carried out, manual operation and circulation are not wasted, and the labor force is greatly saved; and the thickness measurement of disc springs, space rings and adjusting gaskets adopts automatic measurement, so that the measurement precision is high, and the installation precision of final products is ensured.

Owner:中天智能装备有限公司 +1

Automatic feeding material rack

ActiveCN103964228BRealize uninterrupted feedingImprove work efficiencyArticle separationCouplingThrough transmission

Owner:星光印刷(苏州)有限公司

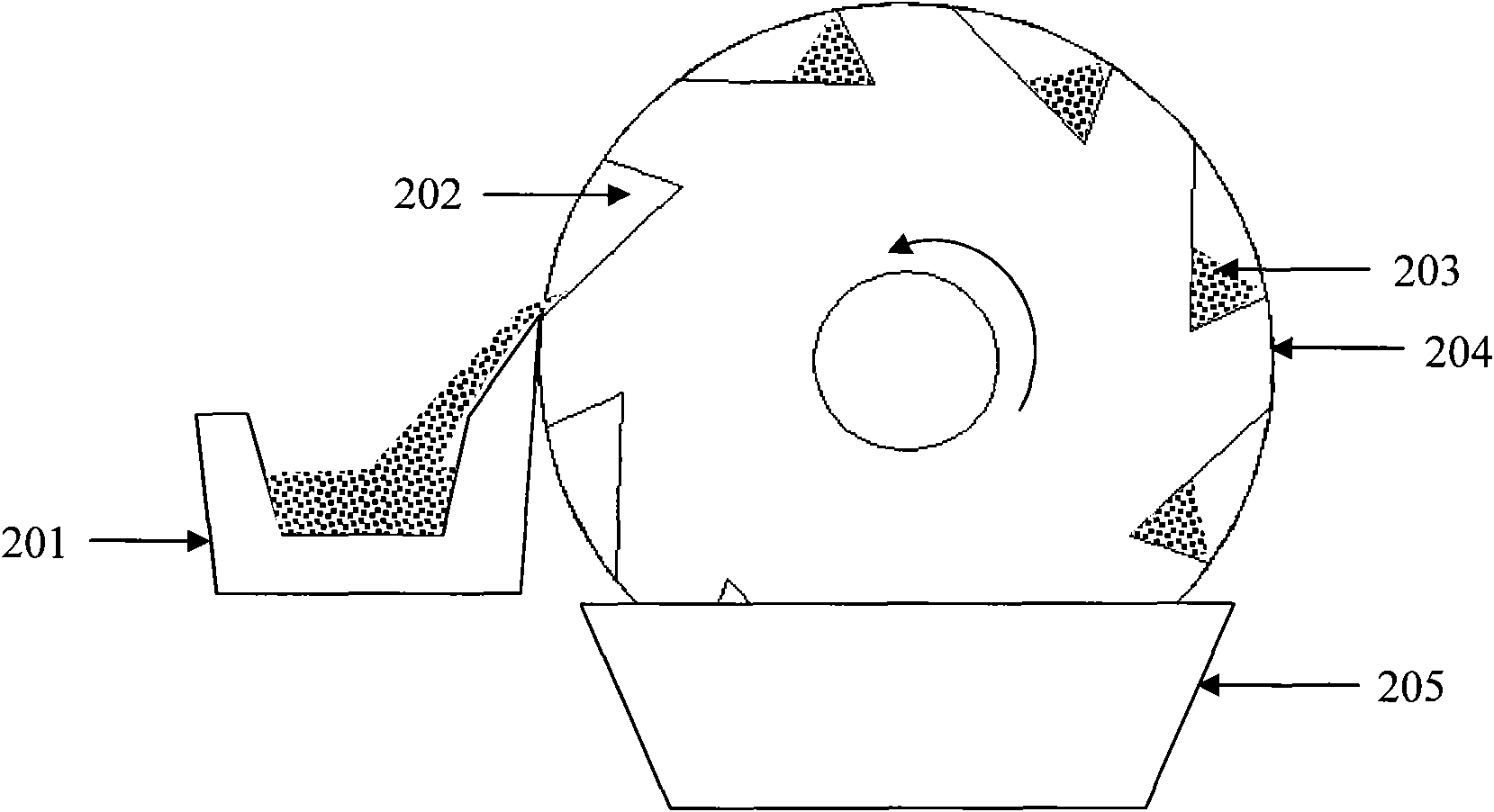

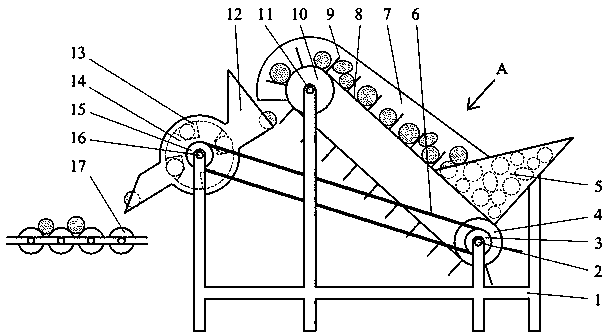

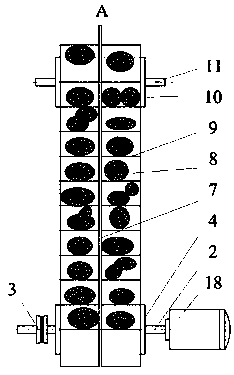

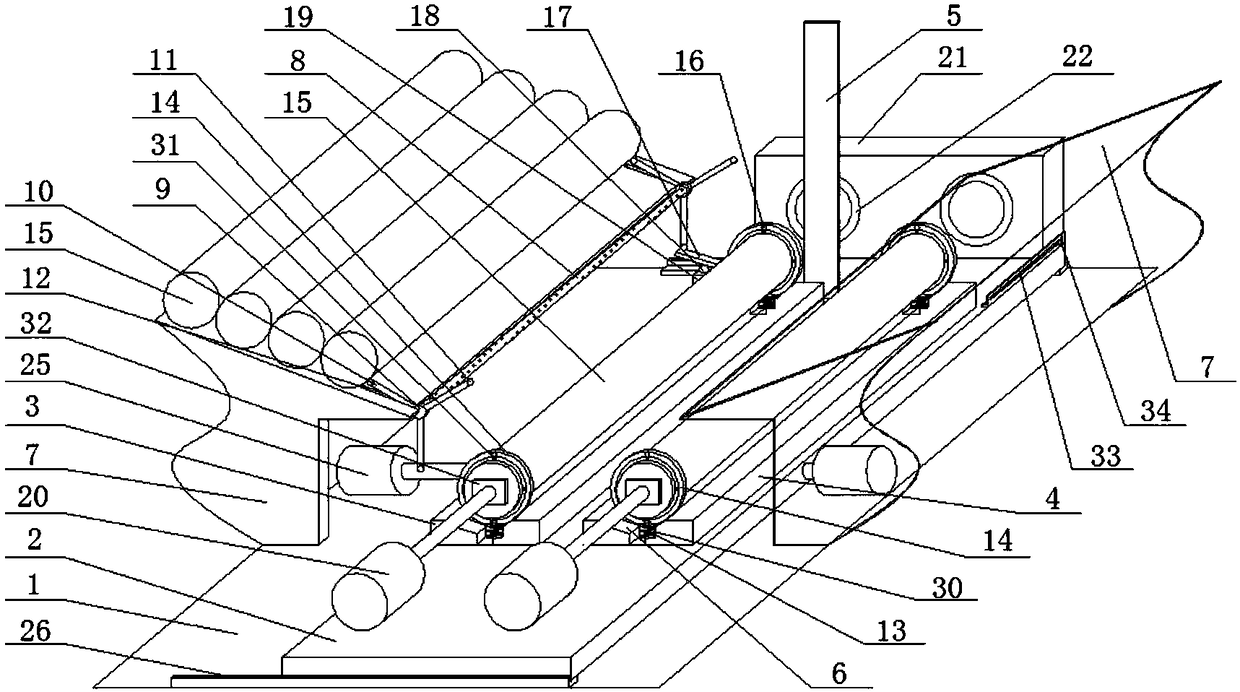

Automatic two-stage red date feeding device

InactiveCN110040434ASolve the phenomenon of congestion jamRealize uninterrupted feedingConveyorsConveyor partsMotor driveDrive shaft

The invention discloses an automatic two-stage red date feeding device. The device comprises a first-stage feeding mechanism, a second-stage feeding mechanism and a synchronous belt transmission mechanism, wherein the first-stage feeding mechanism comprises a driving shaft, a driving conveying belt wheel, a conveying belt partition plate, a conveying belt, a baffle plate, a driven conveying belt wheel and a driven conveying belt wheel shaft; the second-stage feeding mechanism comprises a guide shell, a rotary drum partition plate and a rotary drum; the synchronous belt transmission mechanism comprises a driving synchronous belt wheel, a synchronous belt, a driven synchronous belt wheel and a driven synchronous belt wheel shaft; the first-stage feeding mechanism, the second-stage feeding mechanism and the synchronous belt transmission mechanism are simultaneously supported by a support; and on the one hand, a motor directly drives the first-stage feeding mechanism to operate to continuously convey red dates from a storage box to the second-stage feeding mechanism, and on the other hand, the motor drives the second-stage feeding mechanism to operate through the synchronous belt transmission mechanism to convey the red dates to rollers at equal intervals. According to the device, low-position and equidistant automatic feeding of the red dates are achieved in a two-stage mode, andthe feeding precision is greatly improved.

Owner:NORTHWEST A & F UNIV

A feeding system and feeding method suitable for silicon wafer quality sorting equipment

ActiveCN104307759BRealize uninterrupted feedingIncrease the feeding speedSortingButt jointEngineering

The invention discloses a feeding system for silicon chip quality sorting equipment. The feeding system mainly comprises multiple feeding units with the same structure. Each one of the feeding units comprises a vertical guide rail, the vertical guide rail is provided with a feeding box, a basket case is installed in the feeding box, a side of the vertical guide rail is provided with a horizontal transmission mechanism, the horizontal transmission mechanism is used for transmitting silicon chips in the basket case to a downstream station, an output end of the horizontal transmission mechanism is provided with a horizontal guide rail, and the multiple horizontal transmission mechanisms can horizontally move reciprocatingly so that butt joint of the corresponding horizontal transmission mechanism and the downstream station is switched and thus when the feeding box in the multiple feeding units carries out feeding, the rest of the feeding boxes carry out loading. The multiple feeding units are installed on the horizontal guide rail capable of horizontally moving so that left-to-right switching of the multiple feeding units is realized. When one of the feeding units carries out a feeding process, the rest of the feeding units carry out basket case loading so that uninterrupted feeding is realized.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

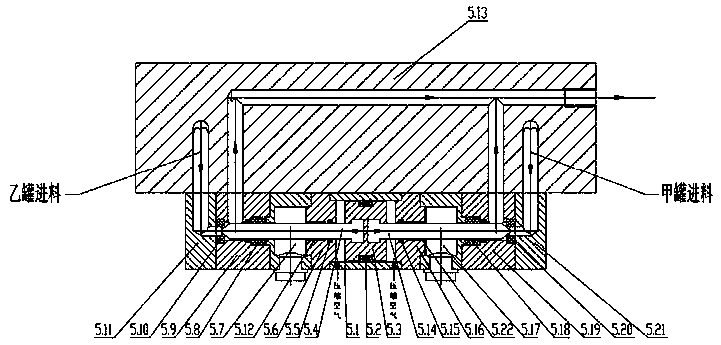

Glue dispenser

PendingCN109985773ARealize uninterrupted feedingIncrease productivityLiquid surface applicatorsCoatingsStorage tankPetroleum engineering

The invention discloses a glue dispenser. The glue dispenser comprises a raw material storage and supply system and a metering and mixing system; the raw material storage and supply system comprises amain agent storage tank including a first main agent storage tank body and a second main agent storage tank body and a curing agent storage tank including a first curing agent storage tank body and asecond curing agent storage tank body; the metering and mixing system comprises a main agent quantitative cylinder including a first main agent quantitative cylinder, a curing agent quantitative cylinder including a first curing agent quantitative cylinder and a mixing pipe, the main agent storage tank and the main agent quantitative cylinder are connected through a main agent supply three-way valve, the curing agent storage tank and the curing agent quantitative cylinder are connected through a curing agent supply three-way valve, and the main agent quantitative cylinder and the curing agentquantitative cylinder are connected with the mixing pipe. The dual-component quantitative cylinder manner is adopted in the glue dispenser, and the equipment manufacturing cost and maintaining cost are reduced while continuous production needs are met.

Owner:XIAMEN INSVAC MACHINERY MFG

Household paper conveying device

InactiveCN108127713ARealize the function of cutting paper rollRealize automatic alternate continuous cuttingMetal working apparatusPaper productionPulp and paper industry

The invention discloses a household paper conveying device and belongs to the field of household paper production equipment. The household paper conveying device comprises a working table, a band sawpaper cutter, paper roll feeding mechanisms, a paper roll clamping mechanism, a paper roll pushing mechanism and a paper roll discharging mechanism, wherein a workbench I is arranged on the working table, a workbench II and a workbench III which are arranged in parallel are fixed on the workbench I, the band saw paper cutter is arranged at the front end of the working table in length direction, aband saw of the band saw paper cutter is longitudinally and vertically arranged on the working table and is arranged in front of the workbench II or the workbench III, the band saw is a double-faced blade band saw, a paper roll placing groove arranged along the length direction is formed in the workbench II and the workbench III respectively, and the paper roll feeding mechanisms are arranged at opposite far sides of the workbench II and the workbench III respectively. The household paper conveying device disclosed by the invention is simple, reasonable and smart in structure, has a bidirectional cutting function, can realize automatic alternate continuous cutting of two paper rolls and realizes automatic line production, so that the working efficiency is improved.

Owner:尹晓晗

Automatic rotary feeding device

InactiveCN113003160ARealize automatic feeding processImprove feeding efficiencyControl devices for conveyorsStructural engineeringControl theory

Owner:SHANGHAI BRANCH FUZHOU GAOYI COMM CO LTD

Capsule bottle product and lining assembly equipment

ActiveCN112357173AIncrease the suction areaPossession is lowPlastic recyclingDe-stacking articlesBottleIndustrial engineering

The invention discloses capsule bottle product and lining assembly equipment. The equipment comprises a continuous capsule bottle distributing and positioning mechanism used for distributing and positioning capsule bottles entering the equipment, a transferring and conveying mechanism used for moving the capsule bottles from the continuous capsule bottle distributing and positioning mechanism to the next station, a product spacing adjusting mechanism used for adjusting the spacing among the plurality of capsule bottles in order to make the product spacing meet the requirement of the next station, an automatic lining plastic support feeding system and turnover mechanism used for sequentially taking out the stacked linings and positioning the linings to a fixed position, and an assembly mechanism used for sucking the capsule bottles on the product distance adjusting mechanism and moving the capsule bottles to the linings prepared by the automatic lining plastic support feeding system andturnover mechanism. According to the capsule bottle product and lining assembly equipment provided by the invention, rapid assembly of the capsule bottle products and the linings can be achieved.

Owner:HANGZHOU WAHAHA PRECISION MACHINERY

Valve diaphragm production equipment

InactiveCN108637122AImprove efficiencyAvoid breakingMetal-working feeding devicesPositioning devicesEngineeringHydraulic pressure

The invention discloses valve diaphragm production equipment. The valve diaphragm production equipment comprises an equipment body, an air cylinder and a supporting table, wherein the supporting tableis mounted inside the equipment body; a guide slot is formed in the upper side of the supporting table; a slide block is arranged inside the guide slot; a baffle plate is arranged on the side part ofthe slide block; the side part of the baffle plate is connected with a telescopic end of the air cylinder through a pushing rod; the air cylinder is mounted on the upper part of the fixed base; the fixed base is mounted on the side part of the equipment body; a first hydraulic cylinder and a second hydraulic cylinder are mounted on the inner wall of the equipment body; the first hydraulic cylinder is adjacent to the second hydraulic cylinder; the telescopic end of the first hydraulic cylinder is equipped with a primary pressure head; and the telescopic end of the second hydraulic cylinder isequipped with a secondary pressure head. The air cylinder pushes the baffle plate and the slide block to move, and the first hydraulic cylinder and the second hydraulic cylinder extend and retract forpressing a metal plate mounted on the upper part of the slide block, so that a continuous feeding process and a two-stage pressing process are simply and conveniently realized.

Owner:安徽特斯艾尔机电设备有限公司

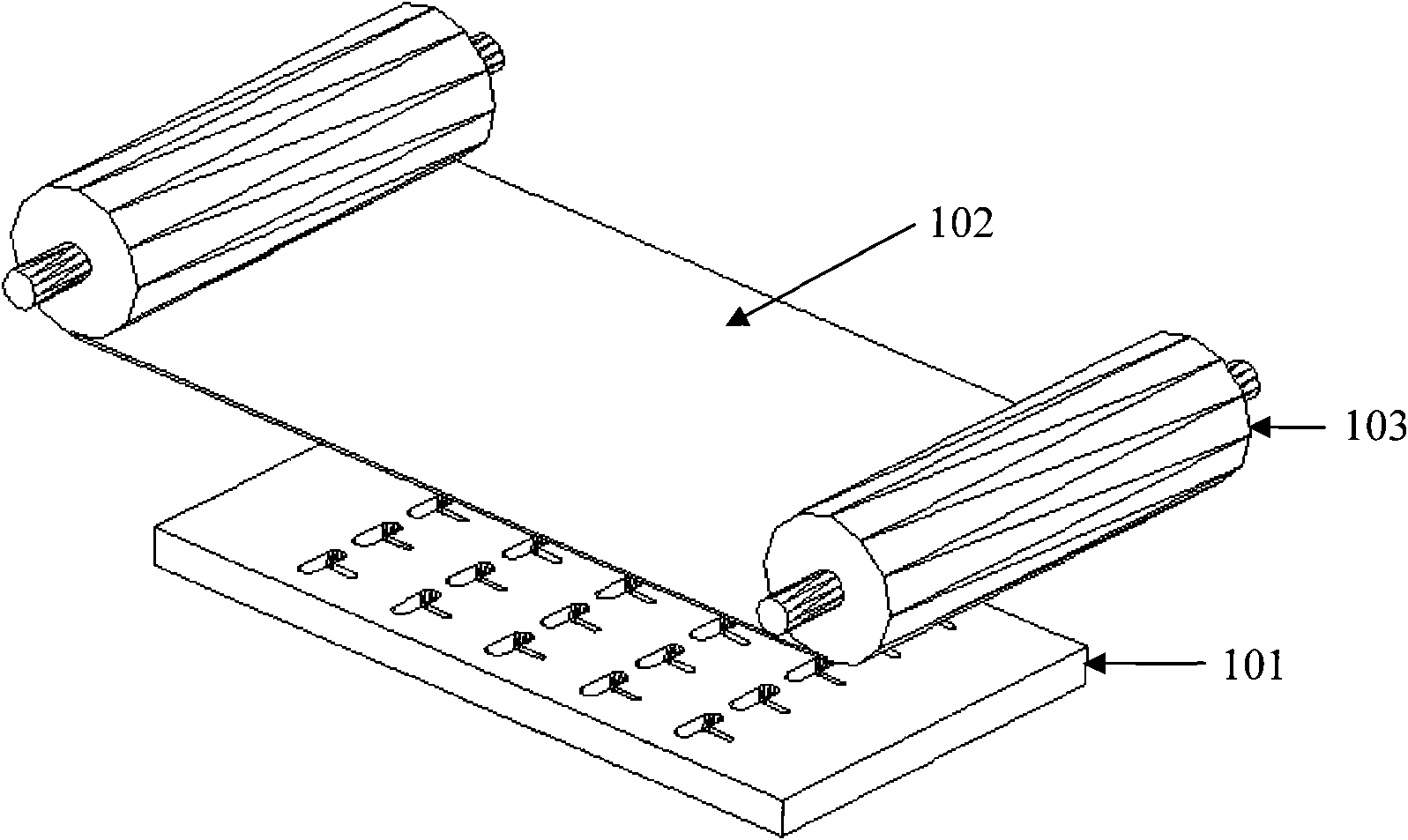

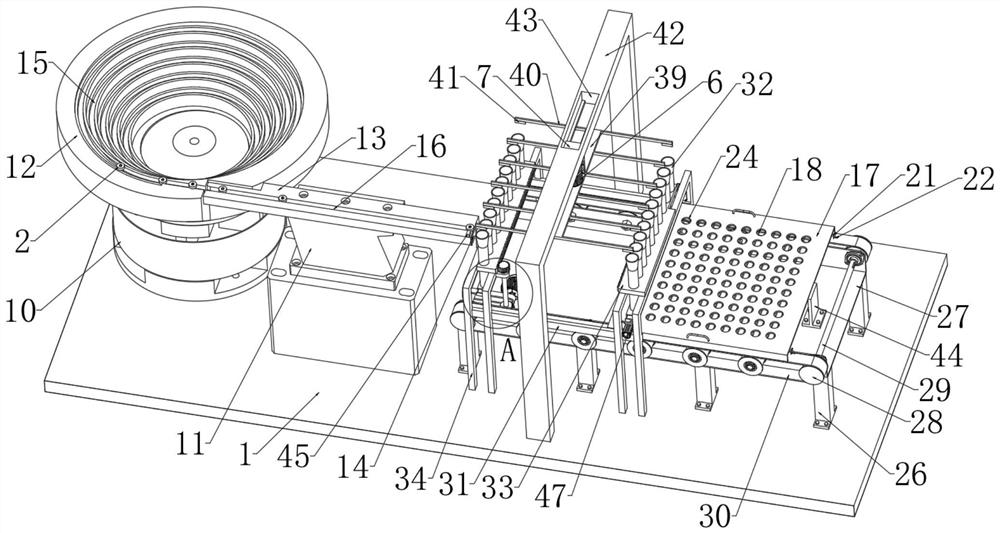

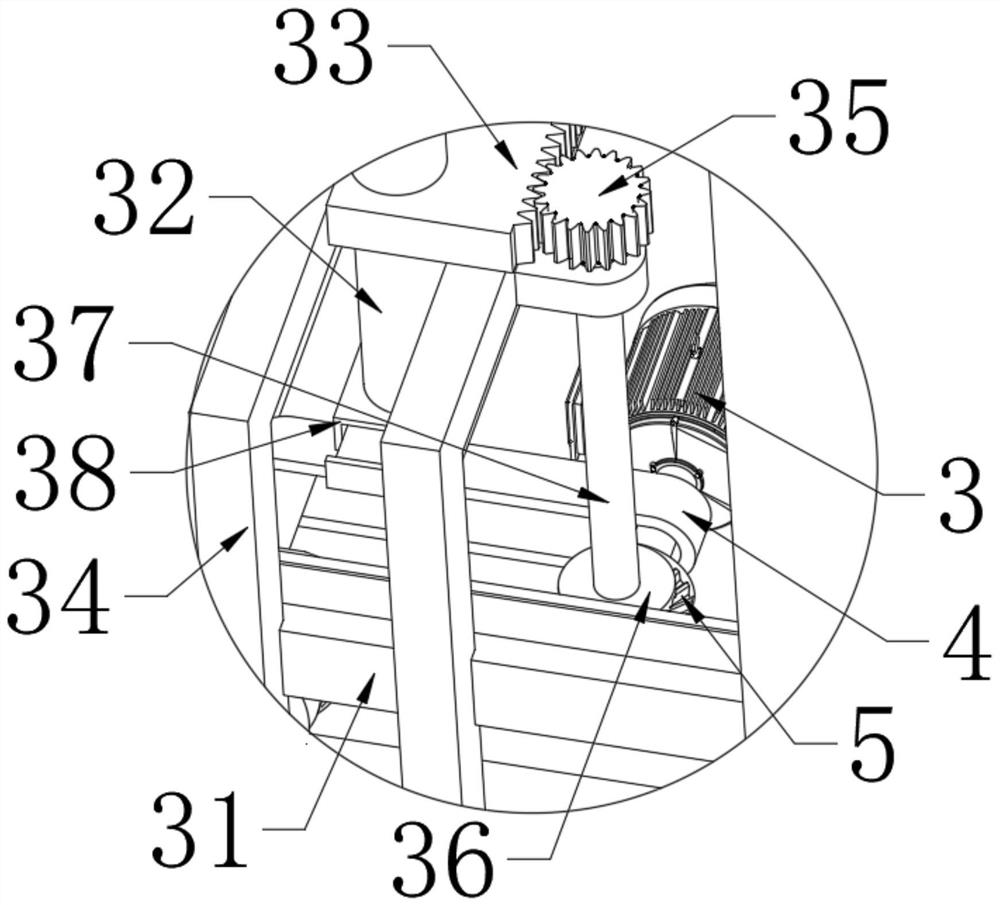

A skeleton feeding device with a nail-shaped skeleton rubber product

ActiveCN112047031BAdjustable spacingImprove reclaiming efficiencyLoading/unloadingJigging conveyorsElectric machineryStructural engineering

A skeleton feeding device with a nail-shaped skeleton rubber product, including a mounting plate, a vibrating feeding unit, an intermediate storage unit, a reciprocating placement unit, and a power unit; the vibrating feeding unit, the intermediate storage unit, and the reciprocating placement unit are all installed on On the mounting plate; the intermediate storage unit includes a rotary grabbing component and a take-by-turn pick-up component; multiple pick-up ports of the take-by-turn pick-up component correspond to the discharge end of the vibrating feeding unit in turn, and the pick-up component by turn takes the skeleton Parts are placed on the reciprocating placement unit; the power unit includes a first motor, a second motor, a first cylinder, and a second cylinder; the first motor provides power for the reciprocating placement unit and the taking-in-turn assembly, and the second motor is a rotary grabbing assembly Provide rotational power, the first cylinder and the second cylinder provide moving power for the rotary grabbing assembly; this application can automatically complete the skeleton loading of products with skeleton rubber material, and the unloading of products with skeleton rubber material after production. efficient.

Owner:CHONGQING JIALONG MFG

Water filter disc feeding mechanism

InactiveCN113059358ARealize uninterrupted feedingAutomatic upgradeOther manufacturing equipments/toolsWater filterEngineering

The invention discloses a water filter disc feeding mechanism. The water filter disc feeding mechanism comprises a stock bin for storing water filter discs, a vibration disc for conveying the water filter discs in order, a feeding track and an indexing placing device; a discharge opening of the stock bin is connected with a feeding port of the vibration disc; an entrance of the feeding track is connected with a discharge hole of the vibration disc; a material entrance of the indexing placing device is connected with an exit of the feeding track; the indexing placing device comprises an indexing frame, a positioning assembly and a transferring assembly, wherein the positioning assembly is arranged on the indexing frame; and the transferring assembly is driven by an air cylinder to move up and down. According to the water filter disc feeding mechanism provided by the invention, the indexing placing device is arranged, and the water filter discs reciprocate and circulate in sequence to implement uninterrupted feeding of the water filter discs, and thus, upgrading of feeding automation of the water filter discs is achieved, and the water filter disc feeding mechanism has the advantages of high efficiency and high safety.

Owner:无锡鼎加弘思饮品科技有限公司

A feeder tray grabbing mechanism for a multifunctional machine

ActiveCN105764321BPrecise positioningRealize uninterrupted feedingElectrical componentsEngineeringMechanical engineering

The invention relates to the mechanical technical field of chip mounters and provides a chip mounter material feeder material disc catching mechanism comprising a pair of clamping jaws and a pedestal. Each clamping jaw comprises a slide block, a positioning pin, and a slide sleeve, wherein the positioning pin and the slide sleeve are fixed to the slide block. The pedestal is equipped with two clamping jaw guide rails, two guide pillars, and two clamping springs. The two clamping jaw guide rails are arranged end to end. The two guide pillars are arranged end to end. The two clamping springs are arranged end to end. When the pedestal and the pair of clamping jaws are combined, the slide blocks and the clamping jaw guide rails cooperate, the slide sleeves and the guide pillars cooperate, and the clamping springs sleeve the guide pillars and are compacted so that the pair of clamping jaws get close to each other or are separated. The chip mounter material feeder material disc catching mechanism is simple in structure, low in cost and convenient to operate, may achieve accurate positioning and automatic material disc catching, and uninterrupted material feeding.

Owner:JIANGSU TORSUNG M&E

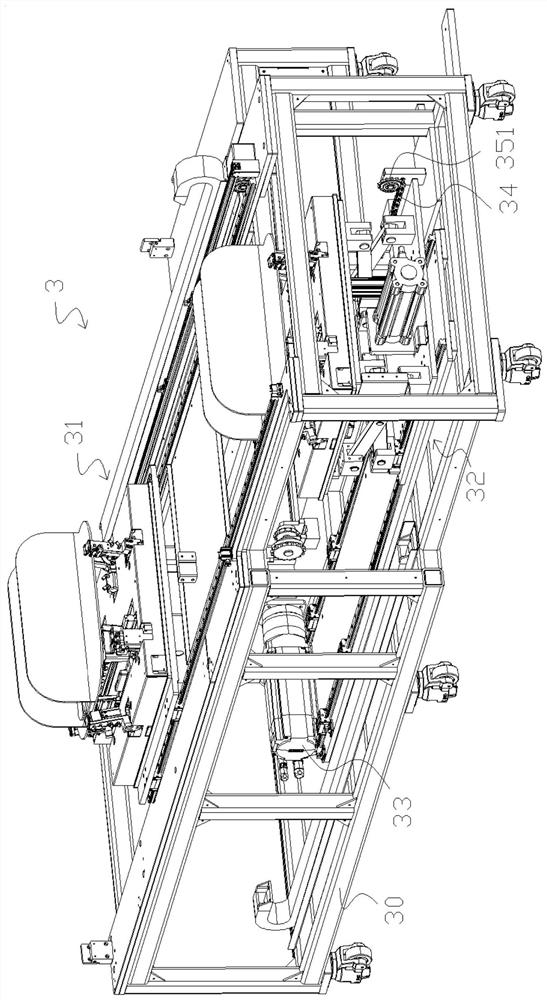

Feeding mechanism and method for vehicle airbag

ActiveCN112722486BRealize uninterrupted feedingImprove feeding efficiencyPackagingAirbagControl theory

The invention provides a feeding mechanism and a feeding method for a vehicle airbag, the mechanism includes a base, a first feeding assembly, a second feeding assembly and a first driving assembly; under the driving force of the first driving assembly When one of the first loading assembly and the second loading assembly moves to the first position on the base, the other of the first loading assembly and the second loading assembly moves to the second position on the base; The mechanism drives the first feeding assembly and the second feeding assembly to move on the same base through the first driving assembly, so as to realize uninterrupted feeding of the airbag and improve the feeding efficiency of the airbag; The first feeding assembly and the second feeding assembly share the same chain, so that the first feeding assembly and the second feeding assembly can move at different positions under the driving force of one driving assembly, reducing the feeding cost while improving Feeding efficiency.

Owner:TZTEK TECH

Cup falling and water filter disc feeding device

ActiveCN113059359ARealize uninterrupted feedingAutomatic upgradeOther manufacturing equipments/toolsWater filterEngineering

The invention discloses a cup falling and water filter disc feeding device. The cup falling and water filter disc feeding device comprises a rack, a cup falling device and a water filter disc feeding mechanism, wherein the rack is provided with a chain plate conveying line; a cup falling station and a water filtering disc placement station are arranged on the chain plate conveying line; the cup falling device is installed on the rack and corresponds to the cup falling station, and is used for separating stacked cup bodies and making the separated single cup bodies to fall into cup hanging through holes; and the water filter disc feeding mechanism is mounted on the rack and corresponds to a water filter disc placement station, and is used for placing the water filter discs at the bottoms of the cup bodies correspondingly. According to the cup falling and water filter disc feeding device, the cup falling link is simplified through a cup distributing assembly, so that cost is reduced; an indexing placing device is arranged, and the water filter discs reciprocate and circulate in sequence to implement uninterrupted feeding of the water filter discs, and thus, upgrading of feeding automation of the water filter discs is achieved, and the cup falling and water filter disc feeding device has the advantages of high efficiency and high safety.

Owner:无锡鼎加弘思饮品科技有限公司

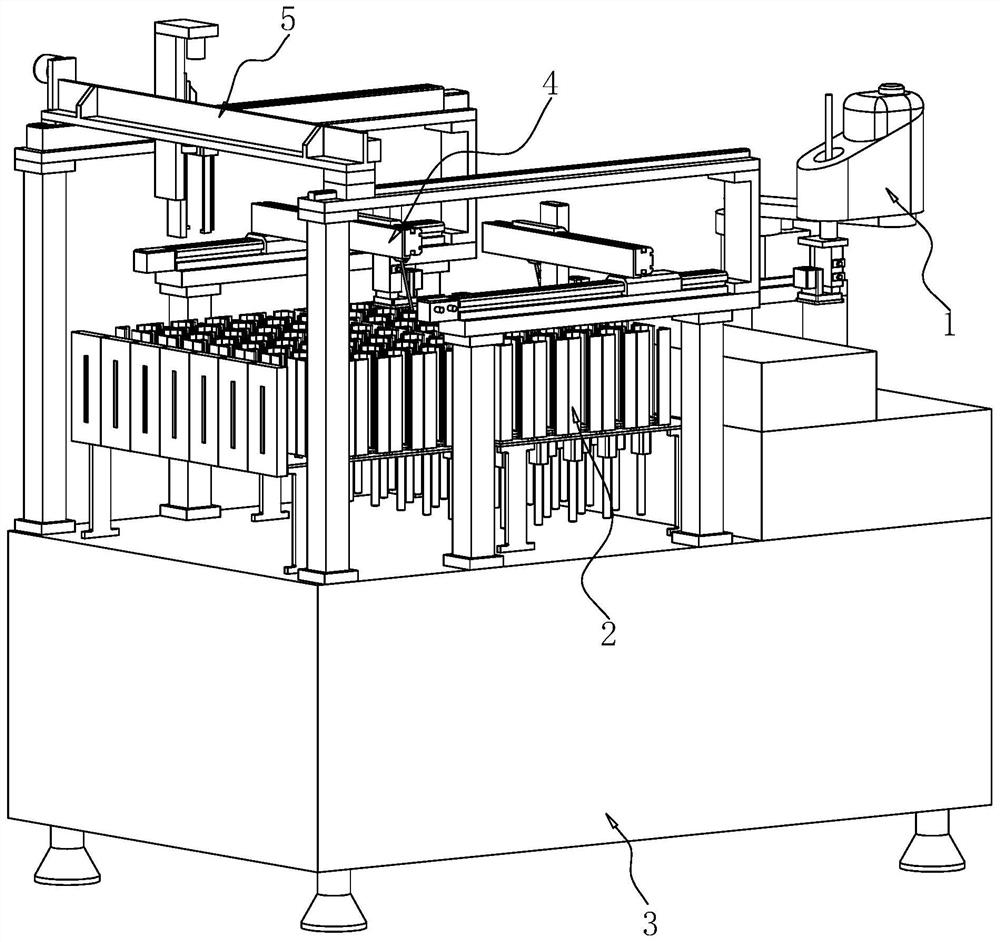

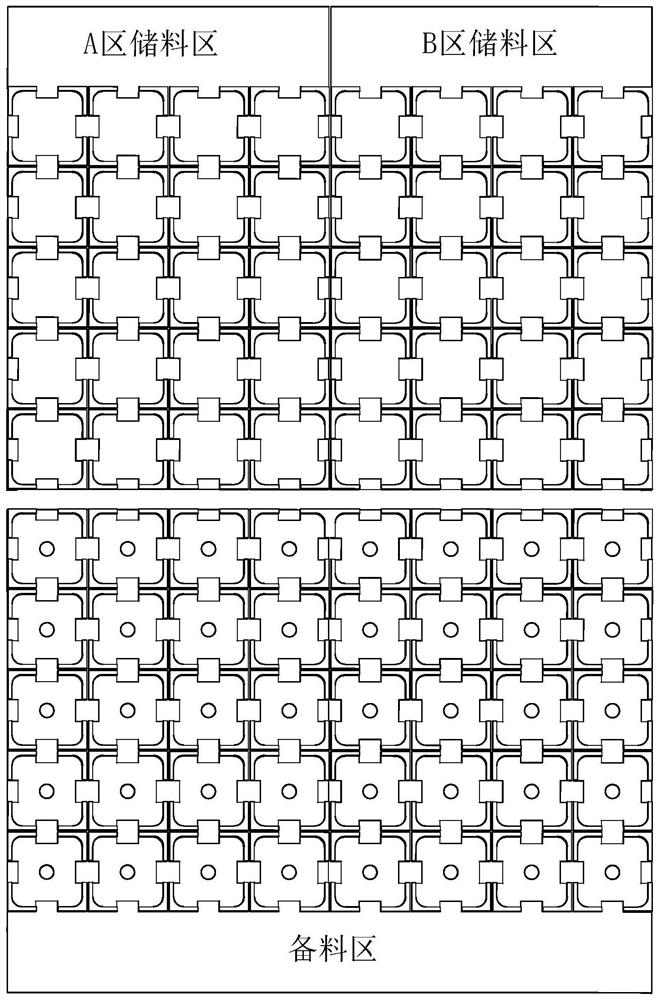

Multi-country specification uninterrupted feeding stock bin mechanism and feeding method

ActiveCN114229142ARealize uninterrupted feedingSmall footprintPackaging machinesMachineMaterial supply

The invention relates to a multi-country specification uninterrupted feeding stock bin mechanism and a feeding method, and the feeding stock bin mechanism comprises a specification taking and placing robot which is used for placing a specification in a packaging box; the multiple storage assemblies are arranged, each storage assembly is used for containing the same type of specification of the country, and the multiple sets of storage assemblies are used for containing different types of specification of the country; the upper surface of the case is divided into a material storage area and a temporary storage area; the material storage area is divided into a material storage area A and a material storage area B; the material storage assembly is installed in the material storage area. The temporary storage area is used for temporarily placing a single instruction book so that the instruction book taking and placing robot can place the instruction book in a packaging box; and the material taking assemblies are installed on the upper surface of the machine box, the A-area material storage area corresponds to the B-area material storage area, and the material taking assemblies are used for recognizing the specifications of different countries in the different material storage assemblies and taking out the specifications in the material storage assemblies to be placed in the temporary storage areas, and the effects that the occupied area of the material supply bin is reduced, and the working efficiency is improved are achieved.

Owner:深圳市昇茂科技有限公司

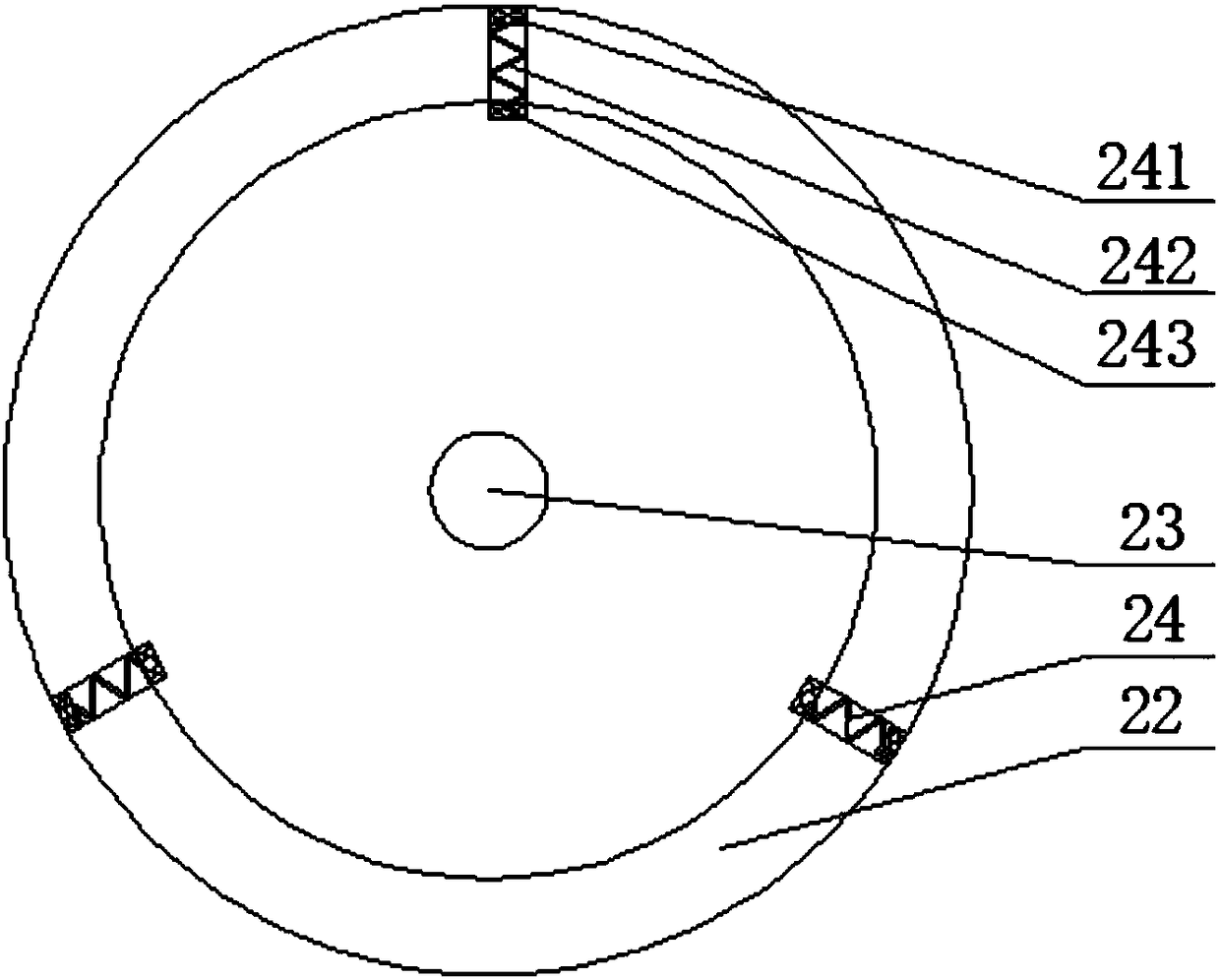

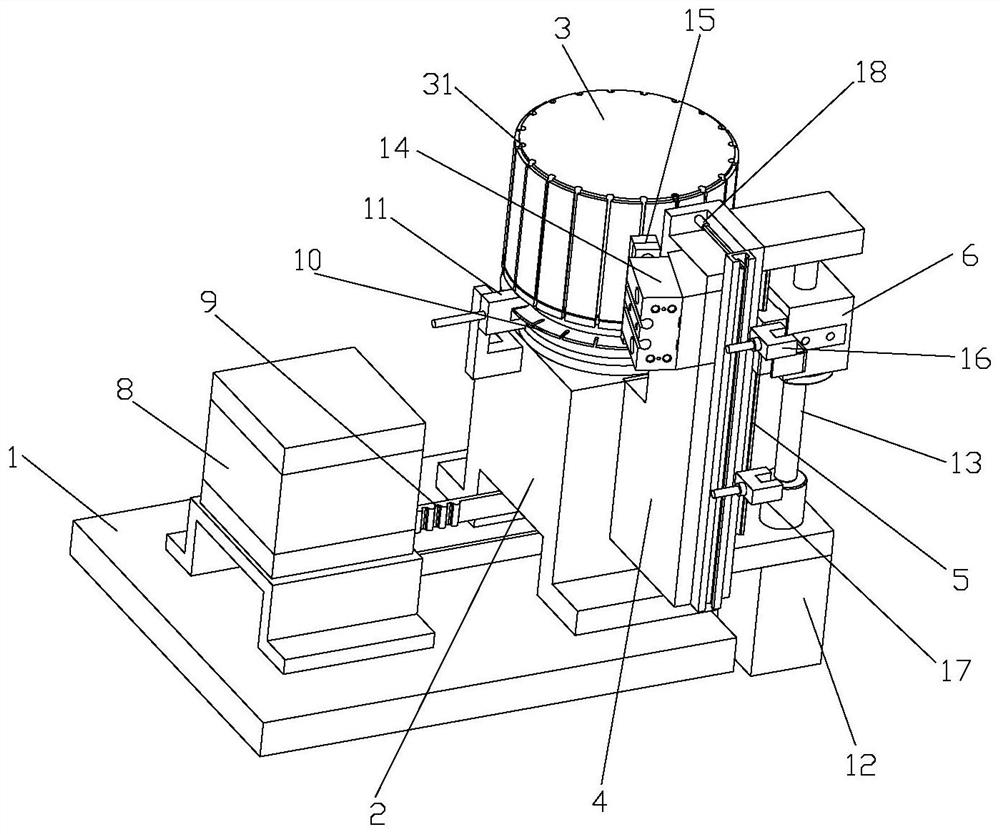

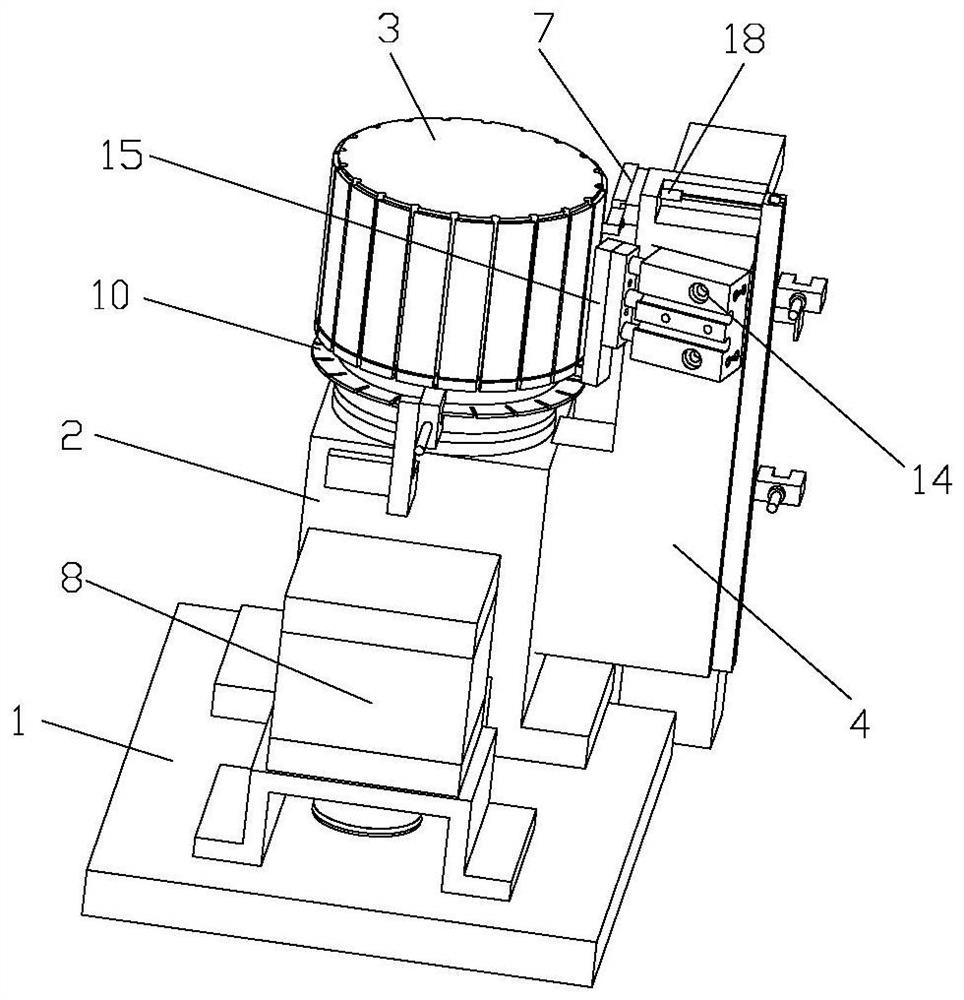

A rotary automatic feeding mechanism for a stamping machine

ActiveCN105710249BRealize uninterrupted feedingEasy to controlMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention discloses a rotary automatic feeding mechanism of a punching machine. The rotary automatic feeding mechanism comprises a rack, a feeding mechanism, a material taking mechanism, a punching machine and a main control machine, wherein the feeding mechanism and the material taking mechanism are both fixed on the rack; the rotary automatic feeding mechanism is characterized by further comprising a detection disk and a blank detecting and positioning mechanism; the detection disk is fixed on the rack; according to the clockwise direction, the feeding mechanism, the detection disk and the punching machine are sequentially fixed at the periphery of the material taking mechanism; the distances from the feeding mechanism, the detection disk and the punching machine to the center of the material taking mechanism are all equal; a gravity sensing device is arranged below the detection disk used for detecting a blank, a sucker is arranged at the internal bottom of the detection disk; and the feeding mechanism, the material taking mechanism and the detection disk are all fixed on the rack.

Owner:浙江杭垫科技有限公司

A casting cleaning line self-transfer system

ActiveCN103896031BSolve the problem of relying on power cables to transmit powerSolve the problem of transmitting powerGrinding machine componentsCasting plantsAutomatic controlTransport system

The invention relates to a casting cleaning line self-transferring system which sequentially comprises a shot blasting casting transferring line, a shot blast machine rear roller bed parallel with the shot blasting casting transferring line, a rail vertical to the shot blasting casting transferring line and the shot blast machine rear roller bed and a polisher located on the outer side of one end, away from the shot blast machine rear roller bed, of the rail. A polisher front roller bed is further disposed between the polisher and the rail. A rail transferring vehicle is disposed on the upper portion of the rail. A master control panel is disposed on the other side of the rail. The casting cleaning line self-transferring system has the advantages that the whole transferring is completed through the system, high automation level is achieved, a large amount of transferring vehicles is not needed, the system is convenient, fast and safe, the problem that the existing rail transferring systems rely on cables for power transmission is solved, and manual and automatic control of the transferring system are achieved; each of shot blasting machine rear roller bed, the rail transferring vehicle and the polisher front roller bed adopts one body two positions, continuous feed of the polisher can be achieved, and production efficiency is increased greatly.

Owner:JIANGSU HENGLI HYDRAULIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com