Automatic silicon wafer feeding equipment

An automatic feeding and equipment technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of intermittent feeding, high hardware cost, low efficiency, etc., to prevent overturning, save labor costs, and ensure effect of supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

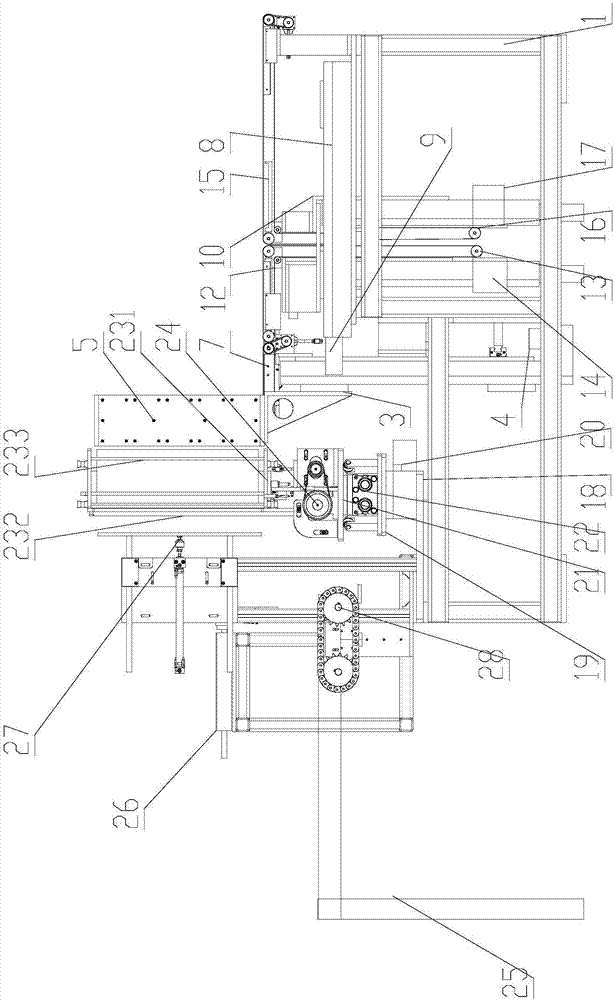

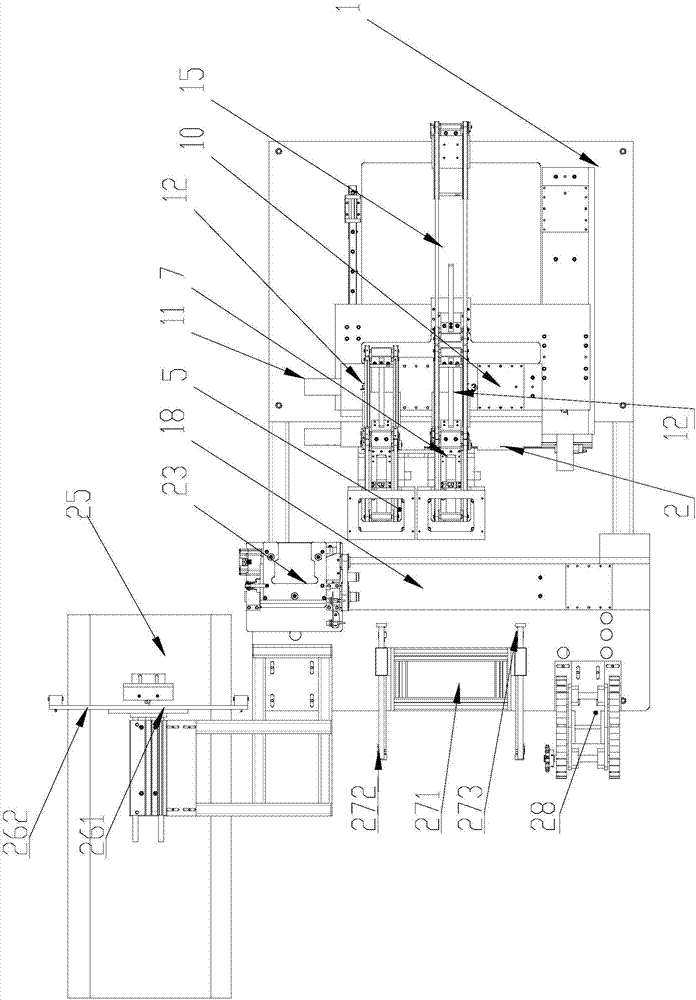

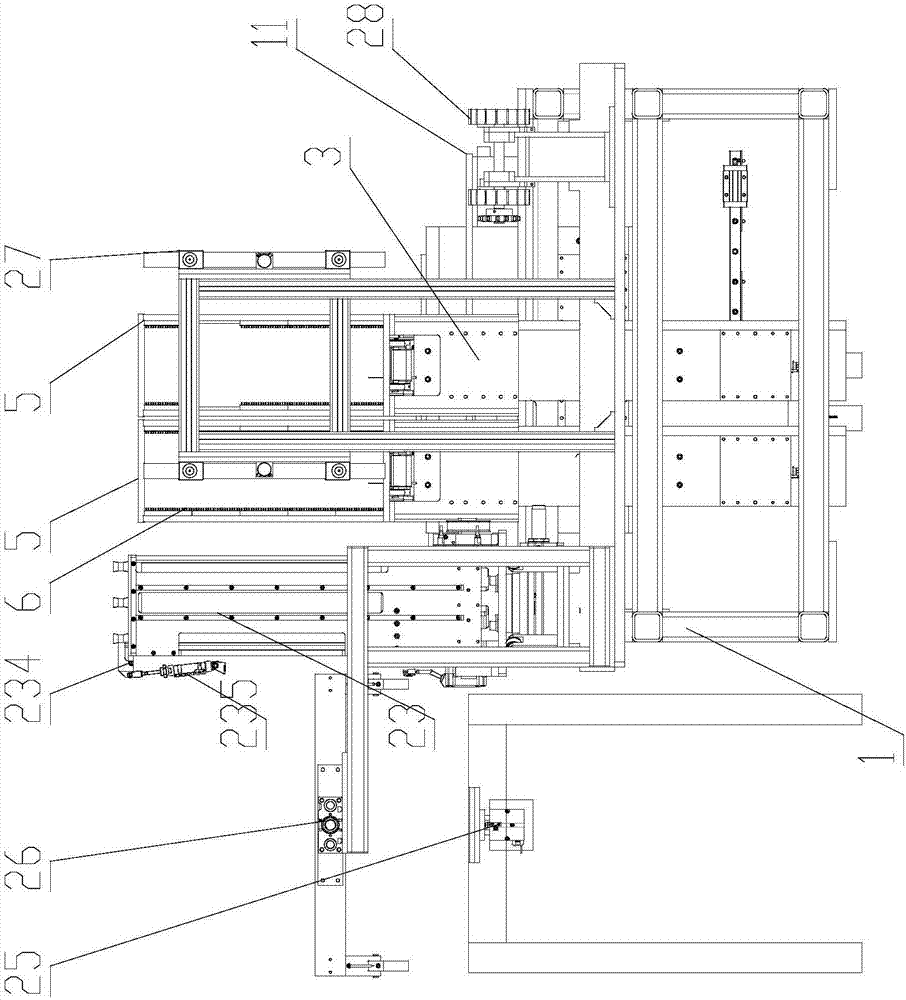

[0022] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] like Figure 1-3 As shown, a kind of silicon wafer automatic feeding equipment comprises frame 1, and frame 1 is provided with the first sliding seat 2 and the first sliding driving device that drives first sliding seat 2 to slide back and forth, on the first sliding seat 2 There are two lifting platforms 3 arranged side by side along the moving direction of the first sliding seat 2 and two servo lifting drive mechanisms 4 that drive the lifting platform 3 to move up and down. The lifting platform 3 is provided with a storage frame 5, and the storage frame 5 There is a material rack 6 that arranges the sheet materials in parallel from top to bottom and has the same distance as the cloth in the material frame;

[0024] The first sliding seat 2 is provided with two material guide belt mechanisms 7 corresponding to the two material storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com